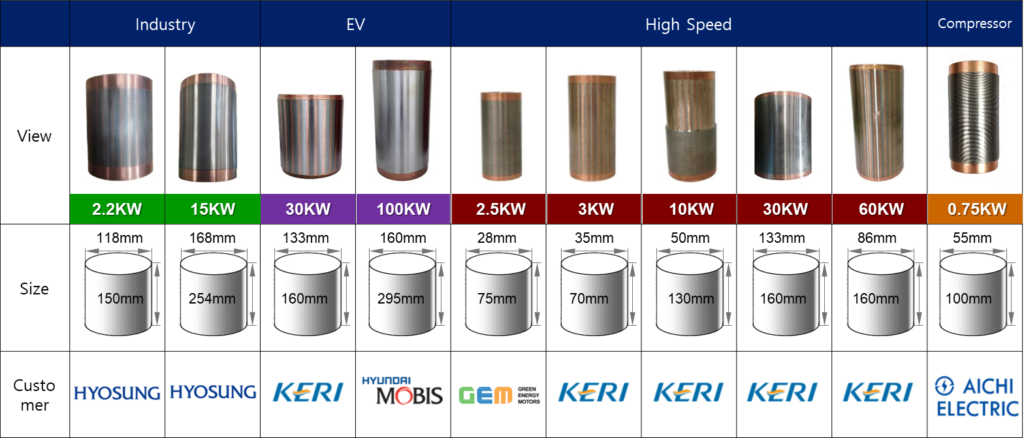

Started mass production of Hyosung Heavy Industries' COPPER ROTOR

Started mass production of Hyosung Heavy Industries' COPPER ROTOR (Copper rotor) From May 2019, the company started producing copper rotors and supplying them to Hyosung Heavy Industries. It is a rotor used for premium class (IE3) motors, and CASTMAN is the only company in Korea to have production technology and production results.

![Figure 1: Mechanisms of morphology change in the solid phase during isothermal holding of semi-solid alloy. [6] a) Coarsening mechanisms (b) Coalescence mechanisms](https://castman.co.kr/wp-content/uploads/image-2374-300x157.webp)