CASTMAN has been introducing outstanding die-casting products through leading activities in the die-casting industry, and continuously contributing to the manufacturing industry. High pressure die casting is often an excellent process for quickly manufacturing many parts and has a high level of engineering skills.

With CASTMAN’s high pressure die casting, you can quickly produce complex shaped parts using highly engineered dies through a strictly controlled process.

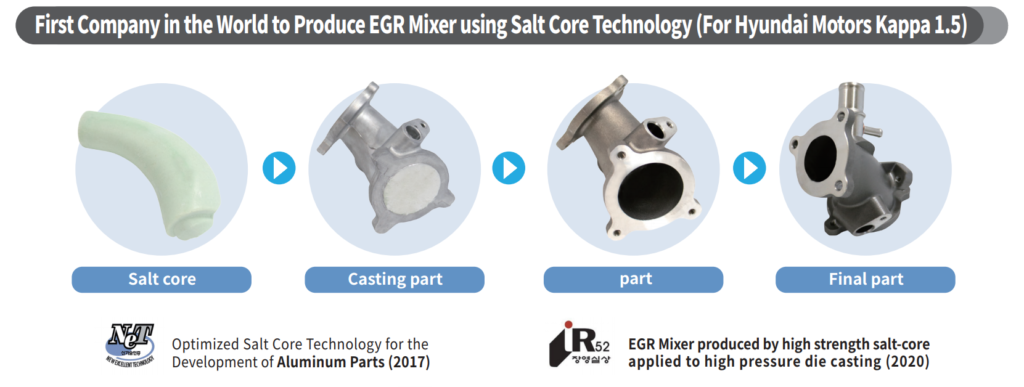

Salt Core Technology

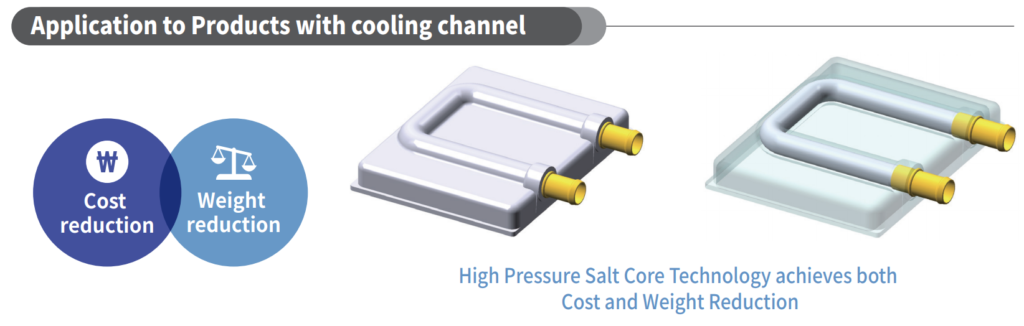

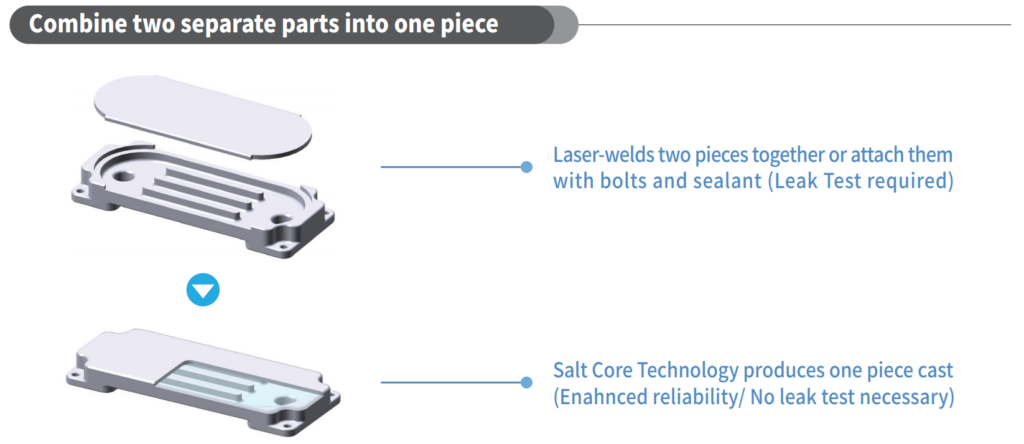

Sand casting and semi-permanent mold casting are generally more complex than die casting, and the design function must be compatible with the opening and closing of the die in the horizontal direction. If you’re using CASTMAN’s salt core, you don’t have to.

The core is made by die casting, these die casting salt cores are placed in different die casting machines, and other die castings include salt cores. The resulting die-casting has the advantage that it is washed in the salt core, so competitors cannot reverse engineer the molds of the used products. The salt core is then used to cast metal parts in high pressure die casting.

Main products applicable to the salt core method

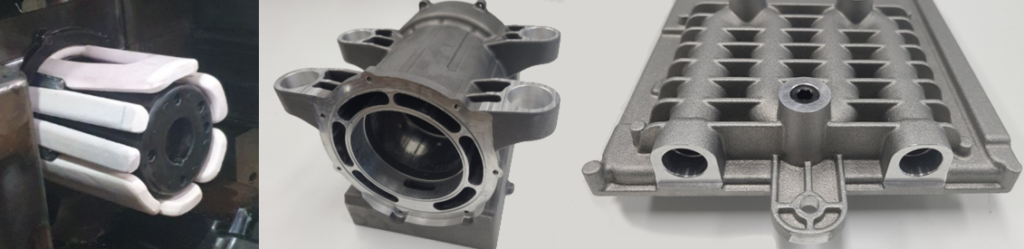

CASTMAN'S Salt Core Products

[robo-gallery id=558]