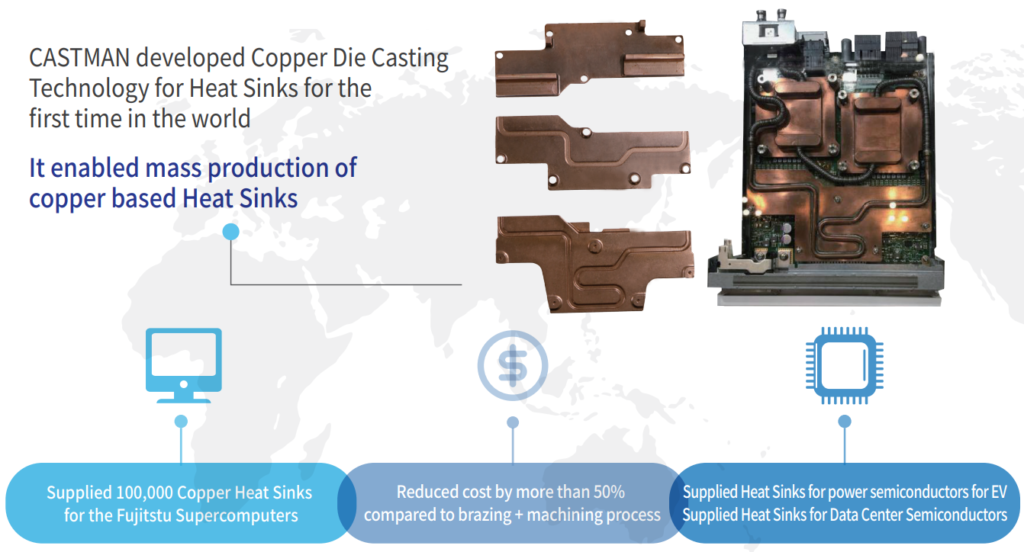

CASTMAN's Products

“High-quality die casting : Copper Roter / Salt Core Diecasting / Copper, Brass, Aluminum Parts.”

キャストマン株式会社は、数年にわたり蓄積されたダイカストエンジニアリングの技術とエンジニアリングの専門知識を有する企業です。 当社は、金型の設計および製造からコンピュータシミュレーション、ダイカスト、後処理まで、ダイカスト全般のプロセスを実施しています。エンジニアリングの専門知識を活かし、キャストマンは銅、アルミニウム、亜鉛合金のダイカストにより多様な製品の開発と量産を行っています。お客様がいらっしゃらなければ、成長はあり得ません。

キャストマン株式会社では、長年にわたるダイカストエンジニアリングのノウハウと技術スキルにより、金型の設計および製造からコンピュータシミュレーション、ダイカスト、後処理までのすべてのプロセスを精密に、専門的に、そして品質高く対応できることをお約束いたします。これにより、銅、アルミニウム、亜鉛合金を使用して幅広い製品を開発および量産することができます。

Thanks.

Salt Core Diecasting / Copper Roter / Copper, Brass, Aluminum Parts

News & Notify, Technical Resource

Development of Platinum-Base Superalloy Components via Powder Metallurgy

This introduction paper is based on the paper "Development of Platinum-Base Superalloy Components via Powder Metallurgy" published by "Euro PM2009 ...

THE STATUS OF THE ALUMINUM INDUSTRY IN JAPAN

This introduction paper is based on the paper "THE STATUS OF THE ALUMINUM INDUSTRY IN JAPAN" published by "Proceedings of ...

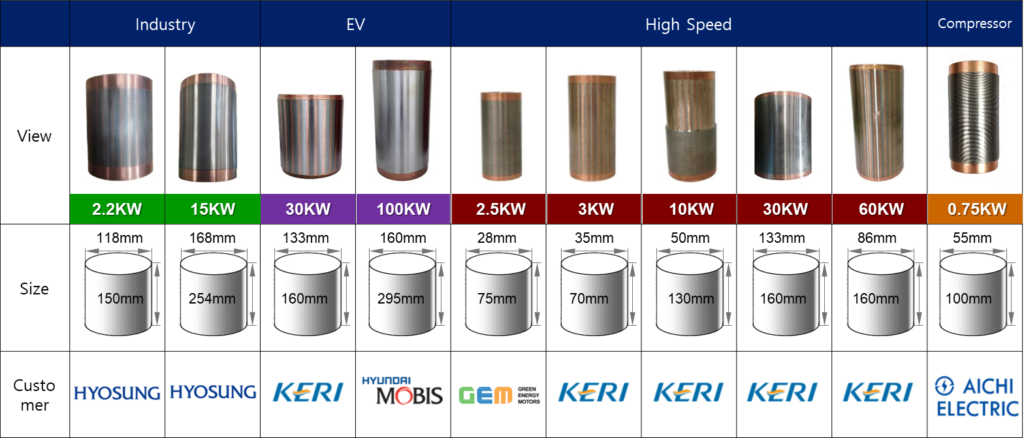

Induction Motors with Copper Rotor: A New Opportunity for Increasing Motor Efficiency

The content of this introductory paper is based on the article "[Title of the paper: Induction motors with copper rotor: ...

Recent Advancement in Conformal cooling channels: A review on Design, simulation, and future trends

Slash Cycle Times and Boost Part Quality: A Deep Dive into Conformal Cooling Channel Technology This technical brief is based ...

Stereometry specification of anodization surface of casting aluminium alloys

This introduction paper is based on the paper "Stereometry specification of anodization surface of casting aluminium alloys" published by "Journal ...

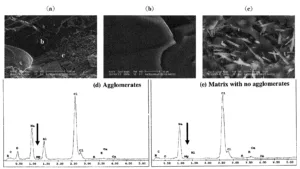

Strength of Aluminum Borate Whisker Reinforced Alkali Halides Salt Core

This introduction paper is based on the paper "Strength of Aluminum Borate Whisker Reinforced Alkali Halides Salt Core" published by ...

Strength of oxide skin on aluminum melts

This introduction paper is based on the paper "Strength of oxide skin on aluminum melts" published by "Not specified in ...

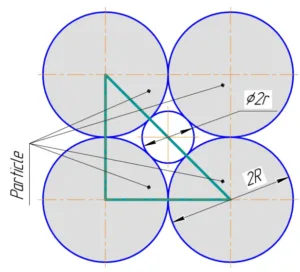

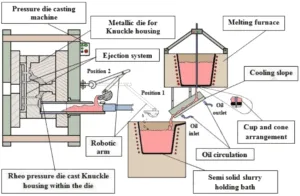

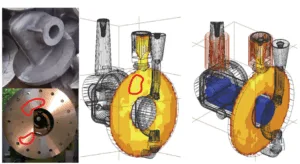

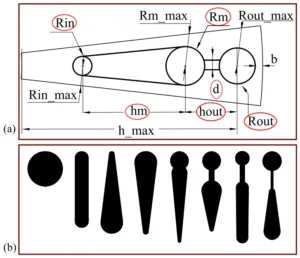

Studies on Die Filling of A356 Al alloy and Development of a Steering Knuckle Component using Rheo Pressure Die Casting System

This introduction paper is based on the paper "Studies on Die Filling of A356 Al alloy and Development of a ...

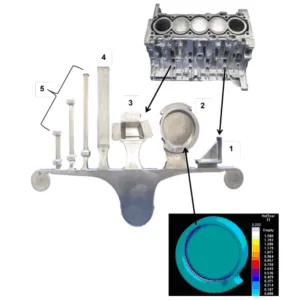

Rapid Casting Development

A Three-Pronged Approach to Slashing Lead Times with Simulation, Rapid Tooling, and Collaboration This technical brief is based on the ...

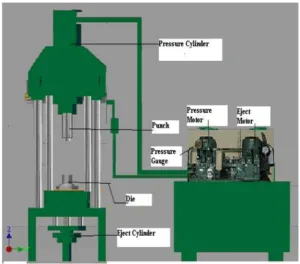

Optimisation of Casting parameters of Squeeze cast LM-24 Al-Si Alloy

This introduction paper is based on the paper "Optimisation of Casting parameters of Squeeze cast LM-24 Al-Si Alloy" published by ...

NOTCH EFFECT ON FATIGUE STRENGTH OF DIE CAST AM60 MAGNESIUM ALLOY

This introduction paper is based on the paper "NOTCH EFFECT ON FATIGUE STRENGTH OF DIE CAST AM60 MAGNESIUM ALLOY" published ...

Design-Based Comparison Between Aluminium and Copper Cages in Squirrel Cage Induction Motors

The content of this introduction paper is based on the article "Squirrel Cage Induction Motor: A Design-Based Comparison Between Aluminium ...

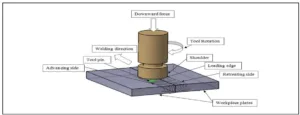

A critical review of friction stir welding process

A Comprehensive Guide to FSW: Understanding the Process, Parameters, and Potential for High-Strength Joints This technical brief is based on ...

New Wear Resistant Hypereutectic AlSi4Cu4FeCrMn Alloys for High Pressure Die Casting

This introduction paper is based on the paper "New Wear Resistant Hypereutectic AlSi4Cu4FeCrMn Alloys for High Pressure Die Casting" published ...

A COMPARATIVE ANALYSIS AMONG THE WELDED Al-6061 PLATES JOINED BY FSW, MIG AND TIG WELDING METHODS

MIG vs. TIG vs. FSW: A Data-Driven Guide to Selecting the Strongest Welding Method for Al-6061 This technical brief is ...

![Fig. 6: Double-logarithmic plot of strain rate vs. applied stress for various Mo-9Si-8B alloys. Data for a single-crystalline Nickelbase superalloy CMSX-4 are shown for comparison [14].](https://castman.co.kr/wp-content/uploads/image-2454-265x300.webp)

![Fig. 2 (a) A typical injection moulding cycle [12], (b) temperature variation in one cycle time [13], (c) factors that have influence in the moulded product quality (surface appearance and dimensional accuracy) [12].](https://castman.co.kr/wp-content/uploads/image-2602-300x173.webp)