The content of this introductory paper is based on the article “[Title of the paper: Induction motors with copper rotor: a new opportunity for increasing motor efficiency]” published by [Publisher: International Journal of Electrical and Computer Engineering (IJECE)]. 1. Overview: 2. Abstract: The copper rotor induction motor (CURIM) was recently introduced because it has lower

Read More

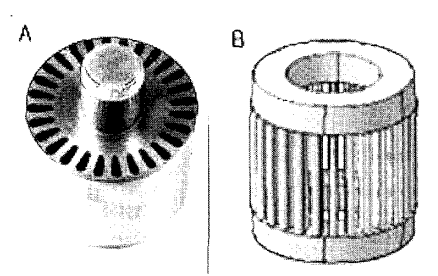

The content of this introduction paper is based on the article “Squirrel Cage Induction Motor: A Design-Based Comparison Between Aluminium and Copper Cages” published by “IEEE Open Journal of Industry Applications”. 1. Overview: 2. Abstract: In many industrial applications the self-starting capability of electric motors is still an important requirement enabling to simplify the drive

Read More

This introduction paper is based on the paper “Novel Method of Improving Squirrel Cage Induction Motor Performance by using Mixed Conductivity Fabricated Rotors (MCFR)” published by “North West University”. 1. Overview: 2. Abstract: The ideal squirrel cage motor should have a varying rotor resistance; large at standstill, and decreasing as the speed rises. Overseas-designed high

Read More

This introductory paper is the research content of the paper “Recent developments in Copper Rotor Motors in China” published by [Publisher is not mentioned in the paper]. 1. Overview: 2. Abstract This paper mainly focuses on the recent progress in the: optimization of the production process, development of high efficiency copper rotor motors as well

Read More

The content of this introduction paper is based on the article [Fabrication and Investigation of Copper Rotor Bar on 0.5HP Induction Motor-A Performance and Economical Study] published by [Australian Journal of Basic and Applied Sciences]. 1. Overview: 2. Abstract: The paper deals with the fabrication of copper rotor bars for a 0.5HP induction motor and

Read More

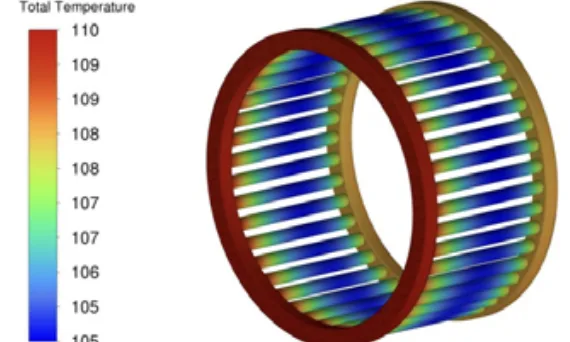

The content of this introduction paper is based on the article “Parametrization of the thermal model of induction motor with outer rotor” published by Przegląd Elektrotechniczny. 1. Overview: 2. Abstract: This paper presents a method of parameterization of the thermal model of an electric motor on the example of an external rotor induction motor with

Read More

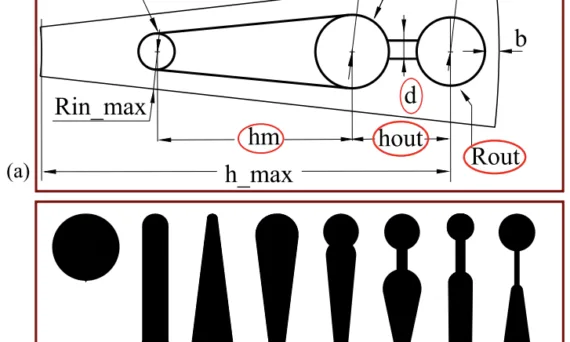

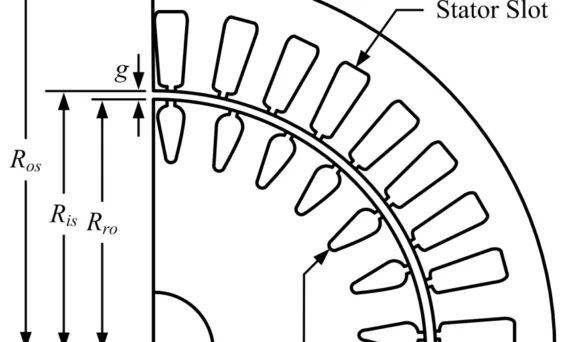

The content of this introduction paper is based on the article “An Analytical Model of Induction Motors for Rotor Slot Parametric Design Performance Evaluation” published by “(IJACSA) International Journal of Advanced Computer Science and Applications”. 1. Overview: 2. Abstract: Induction motors are commonly used in most electricity generation due to their low investment cost. However,

Read More

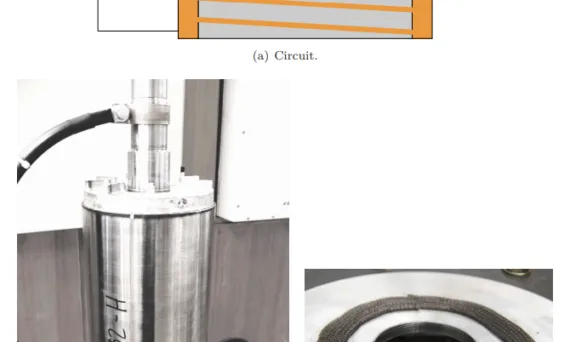

This introduction paper is based on the paper “Process Control and Thixoforming of Cu Rotor for High Efficiency Motors” published by “Transactions of Materials Processing”. 1. Overview: 2. Abstract: Rotor in small-medium induction motor has been usually manufactured by aluminum diecasting. In order to improve the efficiency of induction motors, newly developed Cu-Ca alloys have

Read More

This introduction paper is based on the paper “On Inter-bar Currents in Induction Motors with Cast Aluminium and Cast Copper Rotors” published by “KTH Electrical Engineering”. 1. Overview: 2. Abstract: This thesis presents a study of the effects of inter-bar currents on induction motor starting performance and stray-load losses. The work is focused on the

Read More

This introduction paper is based on the Doctoral Thesis “Analysis and Reduction of Parasitic Effects in Induction Motors With Die-Cast Rotors” published by “KTH Royal Institute of Technology”. 1. Overview: 2. Abstract: This thesis presents a study of inter-bar current effects on induction motors with die-cast aluminium and die-cast copper rotors. The parasitic effects introduced

Read More