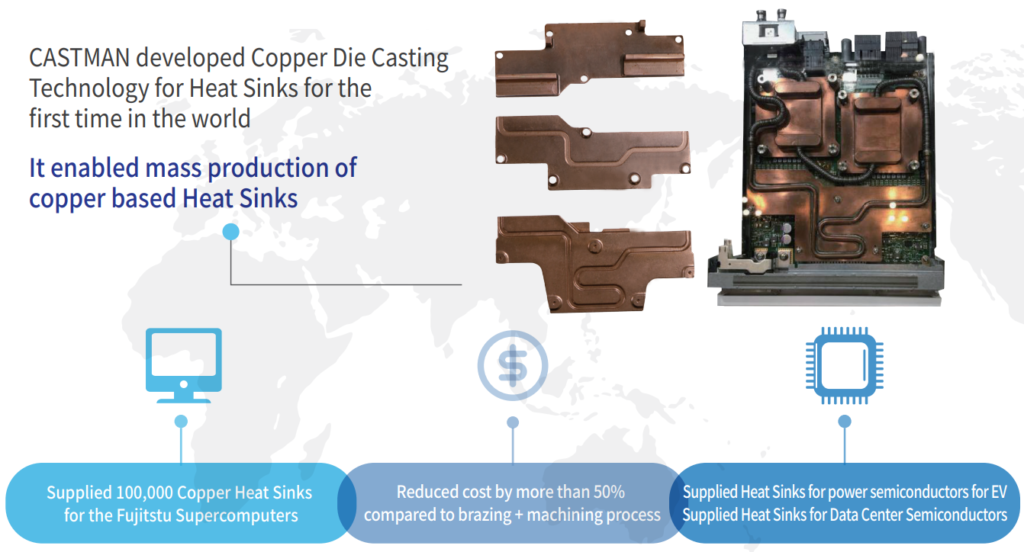

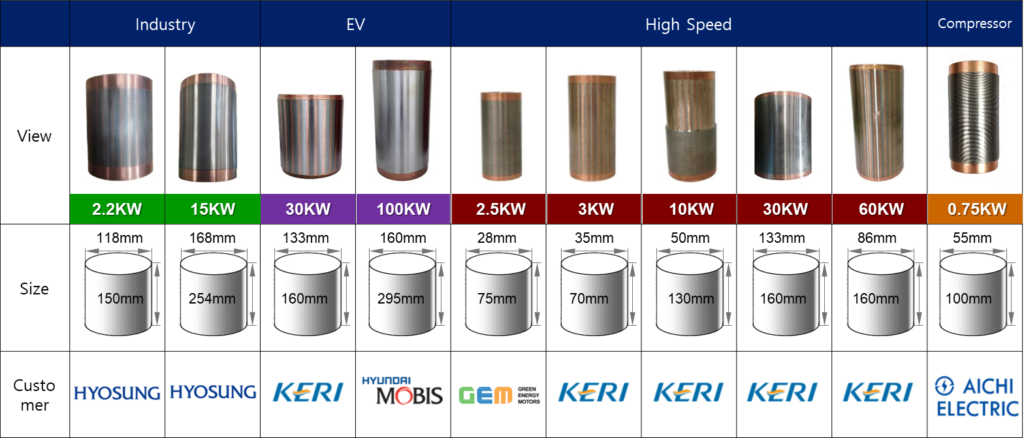

CASTMAN's Products

“High-quality die casting : Copper Roter / Salt Core Diecasting / Copper, Brass, Aluminum Parts.”

キャストマン株式会社は、数年にわたり蓄積されたダイカストエンジニアリングの技術とエンジニアリングの専門知識を有する企業です。 当社は、金型の設計および製造からコンピュータシミュレーション、ダイカスト、後処理まで、ダイカスト全般のプロセスを実施しています。エンジニアリングの専門知識を活かし、キャストマンは銅、アルミニウム、亜鉛合金のダイカストにより多様な製品の開発と量産を行っています。お客様がいらっしゃらなければ、成長はあり得ません。

キャストマン株式会社では、長年にわたるダイカストエンジニアリングのノウハウと技術スキルにより、金型の設計および製造からコンピュータシミュレーション、ダイカスト、後処理までのすべてのプロセスを精密に、専門的に、そして品質高く対応できることをお約束いたします。これにより、銅、アルミニウム、亜鉛合金を使用して幅広い製品を開発および量産することができます。

Thanks.

Salt Core Diecasting / Copper Roter / Copper, Brass, Aluminum Parts

News & Notify, Technical Resource

Development and Testing the Properties of Hybrid Composite Using Aluminium 6061 with TiC and Graphene

Unlocking Superior Hardness in Aluminum Alloys: A Breakthrough in Hybrid AMMC Reinforcement This technical summary is based on the academic ...

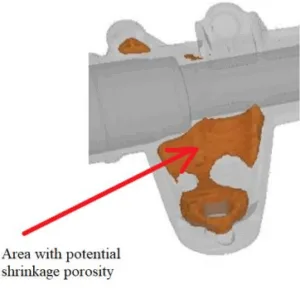

THE EFFECT OF SQUEEZE PIN DIMENSION AND OPERATIONAL PARAMETERS ON MATERIAL HOMOGENITY OF ALUMINIUM HIGH PRESSURE DIE CAST PARTS

Mastering Material Homogeneity: How Squeeze Pin Technology Eliminates Shrinkage Porosity in HPDC This technical summary is based on the academic ...

Trends in the Production of Castings in the World and in Poland in the XXI Century

Global Casting Trends: Analyzing a 15-Year Shift Towards Aluminum & Lightweighting This technical summary is based on the academic paper ...

Influence of Silicon, Superheat and Injection Speed on the Fluidity of HPDC Al-Si Alloys

Mastering HPDC Fluidity: How Silicon, Superheat, and Speed Impact Your Al-Si Alloy Castings This technical summary is based on the ...

Detection and influence of shrinkage pores and non-metallic inclusions on fatigue life of cast aluminum alloys

Beyond Pore Volume: A New Model to Predict Fatigue Life in Cast Aluminum This technical summary is based on the ...

APPLICATION AND ADVANTAGES OF CASTING PROCESS

Unlocking Design Freedom: A Technical Review of Casting Process Advantages for Modern Manufacturing This technical summary is based on the ...

AN ATTEMPT TO USE VARIOUS METALLURGICAL SLAGS IN THE MODIFICATION PROCESSES OF CASTING ALLOYS

From Waste to Worth: How Metallurgical Slags Can Refine High-Performance Casting Alloys This technical summary is based on the academic ...

Impact Strength of AE-type Alloys High Pressure Die Castings

Unlocking Higher Impact Strength in HPDC: The Critical Role of RE/Al Ratio in AE-Type Magnesium Alloys This technical summary is ...

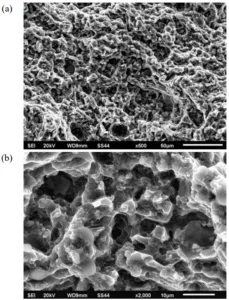

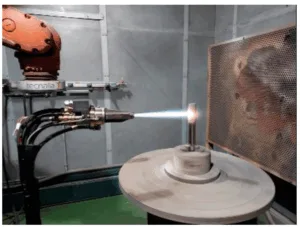

A Breakthrough in Aluminum Performance: New HVOAF Coating Doubles Hardness and Slashes Wear Rates

Study of a New Novel HVOAF Coating Based on a New Multicomponent Al80Mg10Si5Cu5 Alloy This technical summary is based on ...

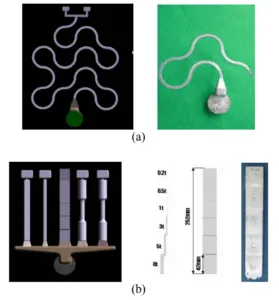

Thermal-Induced Defects and Optimization of Casting Process

Boost Casting Quality: A Simulation-Driven Guide to Casting Process Optimization This technical summary is based on the academic paper "Thermal-Induced ...

Analysis and Evaluation of Effect of Manganese Content on Properties of EN AC 46000 Aluminum Alloy

The Manganese Solution: How a Small Alloy Addition Transforms EN AC 46000 HPDC Properties This technical summary is based on ...

Mechanical Properties of a Structural Component Processed in High-Pressure Die Casting (HPDC) with a Non-Heat-Treated Aluminum Alloy

Ditch the Furnace: Achieving High-Performance HPDC Components with Non-Heat-Treated Aluminum Alloy This technical summary is based on the academic paper ...

EROSION OF MOLD-STEEL SURFACE OXIDATION AND NITRIDING LAYERS DUE TO A DIE-CASTING ALUMINUM ALLOY

Paper Title Boosting Mold Life: Why Oxidation Outperforms Nitriding for H11 Die Steel Surface Treatment This technical summary is based ...

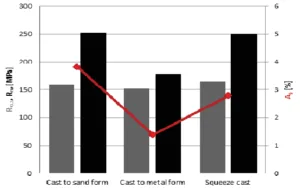

Influence of the conditions of casting and heat treatment on the structure and mechanical properties of the AlMg10 alloy

Unlocking Peak Performance in AlMg10 Alloy: How Casting and Heat Treatment Maximize Mechanical Properties This technical summary is based on ...

Defects, Root Causes in Casting Process and Their Remedies: Review

Mastering Metal Flow: A Technical Guide to Casting Defects and Remedies This technical summary is based on the academic paper ...

![Fig. 1. Shrinkage porosity- microstructural image according to [4]](https://castman.co.kr/wp-content/uploads/image-3225-300x237.webp)