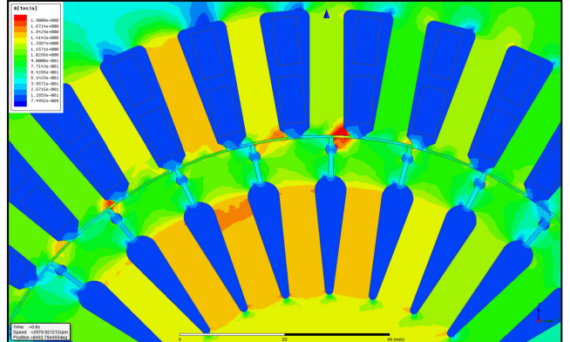

Ashwin D; Ashok S; Manglesh Dixit; Vinila Chavan All Authors Abstract This paper describes the design and simulation of 15 kW, 2 pole, 50 Hz, three phase induction motor to achieve IE4 efficiency level as defined by the International Electrotechnical Commission (IEC). For achieving higher efficiency, the motor is designed, optimized and simulated with copper die-cast rotor and

Read More

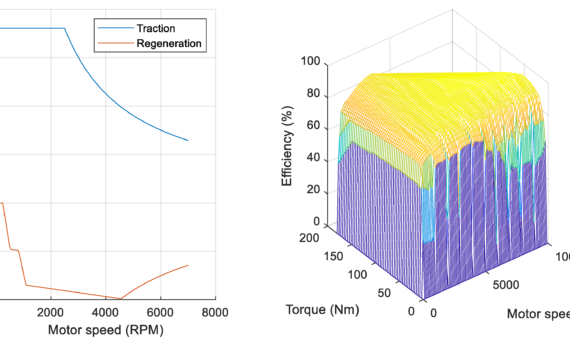

자동차 경량 설계: 전기 자동차의 대량 관련 소비 시뮬레이션 모델링 by Francesco Del Pero *,Lorenzo Berzi,Andrea Antonacci andMassimo DeloguDepartment of Industrial Engineering, University of Florence, Via di S. Marta 3, 50139 Florence, Italy*Author to whom correspondence should be addressed.Machines2020, 8(3), 51; https://doi.org/10.3390/machines8030051Received: 14 August 2020 / Revised: 30 August 2020 / Accepted: 31 August 2020 / Published: 3 September 2020 Abstract 차량 경량화와 관련된 수명 주기

Read More

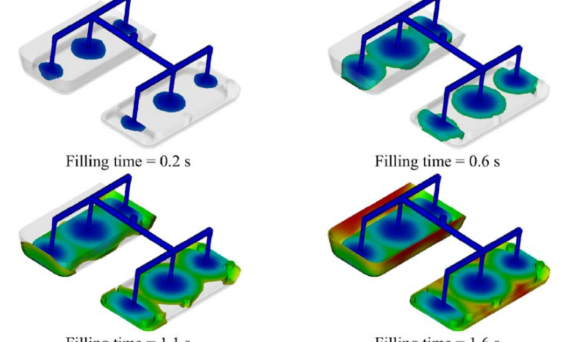

R.SpinaDipartimento di Ingegneria Meccanica e Gestionale, Politecnico di Bari, Bari, Italy Abstract This paper studies the fabrication of a plastic arm of the body interior of a medium-sized car in order to evaluate the beneficial effects of using sequential injection moulding (SIM). The main requirement for the component is optimal surface finishing to maintain an excellent surface

Read More

by Francesco Del Pero *,Lorenzo Berzi,Andrea Antonacci andMassimo DeloguDepartment of Industrial Engineering, University of Florence, Via di S. Marta 3, 50139 Florence, Italy*Author to whom correspondence should be addressed.Machines2020, 8(3), 51; https://doi.org/10.3390/machines8030051Received: 14 August 2020 / Revised: 30 August 2020 / Accepted: 31 August 2020 / Published: 3 September 2020 Abstract A thorough assessment of Life-Cycle effects involved by vehicle lightweighting needs a rigorous evaluation of

Read More

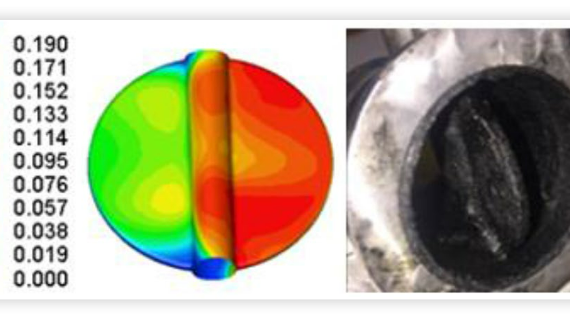

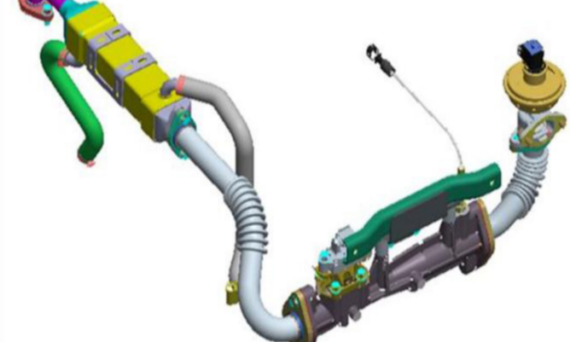

CFD 시뮬레이션을 사용하여 플라스틱 덕트의 열 핫스팟 및 스로틀 밸브의 그을음 침착을 최소화하기 위한 EGR 믹서 최적화 In recent time, with inception of BS VI emission regulation with more focus on fuel economy and emission, many engine parts which were conventionally made from metal are getting replaced with plastic components for reducing weight to attain

Read More

Hardik Lakhlani, Jyotirmoy Barman, Karan Rajput, and Angshuman GoswamiVE Commercial Vehicles Ltd ABSTRACT Future emissions regulations like BSIV and above in India, Diesel engine manufacturers are forced to find complex ways to reduce exhaust gas pollutant emissions, in particular NOx and particulate matter (PM). Exhaust gas recirculation (EGR) into the engine intake is an established

Read More

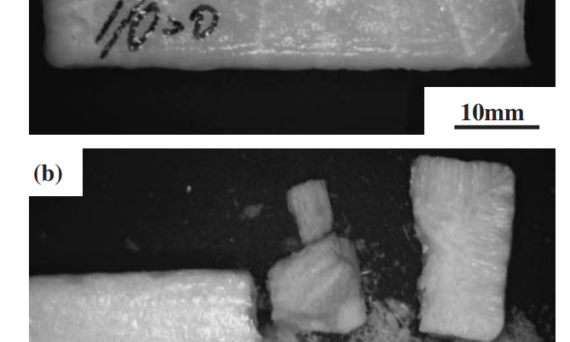

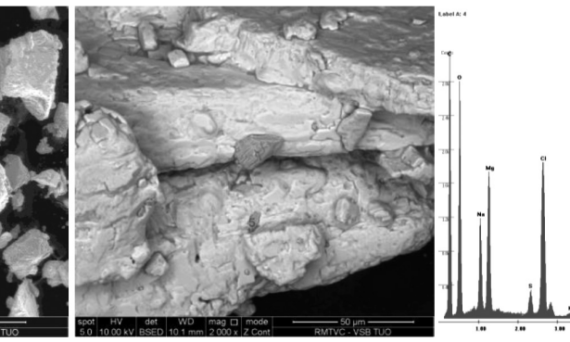

Jun Yaokawa, Daisuke Miura, Koichi Anzai, Youji Yamada, Hiroshi Yoshii Abstract The strength of four binary systems NaCl–Na2CO3, KCl–K2CO3, KCl–NaCl and K2CO3–Na2CO3 was investigated in order to develop expendable salt core for high pressure die casting processes. Four point bending test was conducted to determine the strength of specimens made from molten salts by using the permanent mold casting technique.

Read More

B. Fuchs and C. KörnerPublished Online:February 10, 2014pp 24-30 Abstract High pressure die casting is limited in its geometry since a lost core technology as with sand or low pressure casting is not state-of-the art. Using lost cores made from sodium chloride may be a solution for high pressure die casting. Due to the high dynamical forces

Read More

Renhe Huang &aamp; Baoping Zhang International Journal of Metalcasting volume 11, pages440–447 (2017)Cite this article Metricsdetails Abstract Soluble salt cores have been successfully used for the die casting of aluminum and magnesium alloys. However, it has not been reported that the soluble salt cores were used for zinc alloy die casting. In this paper, a soluble salt core system

Read More

Authors: Eliska Adamkova, Petr Jelinek, Jaroslav Beňo SAND TEAM spol.r.o., Frantisek Mikgovsky Abstract Application of pure inorganic salt-based cores has been known since the end of the 20th century, especially in the field of gravity and low-pressure die casting. The contemporary trend in technology leads to the use of the cores in the field of

Read More