모터 성능 향상을 위한 다이캐스트 구리 로터 Authors J.G. CowieCopper Development Association Inc., New York, NY, USAD.T. BrenderCopper Development Association Inc., New York, NY, USA Abstract Aluminum has been the common conductor material for the squirrel cage of the induction motor largely because of ease of manufacturing by pressure die casting. Short die life in

Read More

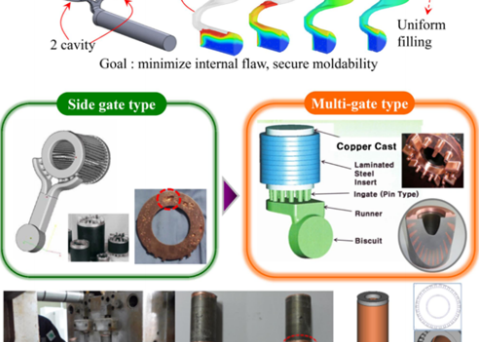

고효율 전동기용 Cu Rotor의 반응고 성형과 공정변수 제어 Jung, W. S. ; Lee, S. Y. ; Shin, P. W. 정우성 (창원대학교 재료공학과) ; 이상용 (안동대학교 신소재공학부) ; 신평우 (창원대학교 재료공학과) Abstract Rotor in small-medium induction motor has been usually manufactured by aluminum diecasting. In order to improve the efficiency of induction motors, newly developed Cu-Ca alloys have been investigated. The

Read More

John G. CowieCopper Development Associations Inc.New York, NY Dale T. PetersConsultant to CDA Inc.Hilton Head Island, SC Edwin F. Brush, Jr.Consultant to CDA Inc.Weston, MA Stephen P. MidsonFormcast, Inc.Denver, CO Articles on materials appearing in materials issues have generally focused on the common aluminum-, zinc- and magnesium-based die casting alloys. This report differs in that

Read More

Soby T. Varghese; K. R. Rajagopal; Bhim Singh Abstract t is well known in the market that the copper rotor motor can give good efficiency at par with the new era motors, and can handle higher temperatures to qualify for electric vehicle application. Being a heavy metal, die-cast copper rotor manufacturing needs absolute care for faithful rotor

Read More

다이캐스트 구리 모터 로터: 구리와 알루미늄 모터 테스트 비교 결과 Edwin F. BrushJr.John G. CowieDale T. PetersDarryl J. Van Son Abstract Motor manufacturers have long realized that because the electrical conductivity of copper is nearly 60% higher than that of aluminum, substituting copper for aluminum in the squirrel cage of the induction motor would markedly increase the electrical energy efficiency of the machine. Most

Read More

구리 다이캐스팅으로 IE4 효율 수준을 달성하기 위한 15kW, 2극 유도 전동기의 설계 최적화 Abstract This paper describes the design and simulation of 15 kW, 2 pole, 50 Hz, three phase induction motor to achieve IE4 efficiency level as defined by the International Electrotechnical Commission (IEC). For achieving higher efficiency, the motor is designed, optimized and

Read More

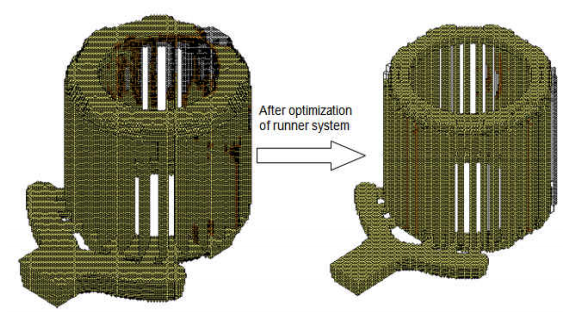

Daniel Liang, Xu Yang, Jiabin Yu, Victor Zhou Abstract This paper introduces the recent technological progress in China on the manufacture of die cast Copper Motor Rotors (CMR) for induction motors. This manufacturing process provides a simple and practical means for large-scale economical production of high-efficiency induction motors. Rotor die casting obstacles/solutions are presented along

Read More

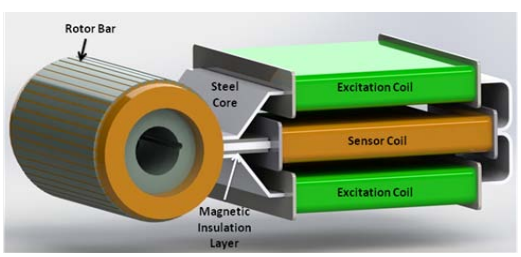

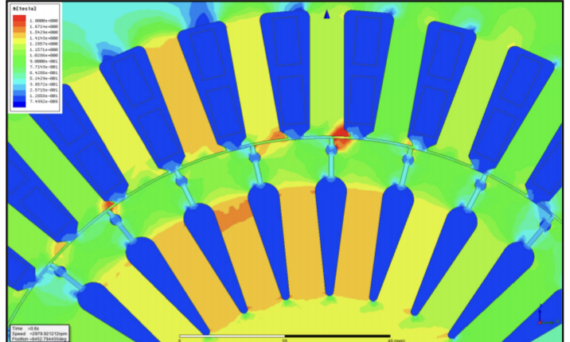

Do-Kwan Hong, Jae-Hak Choi, Pil-Wan Han, Yon-Do Chun, Byung-Chul Woo & Dae-Hyun Koo International Journal of Precision Engineering and Manufacturing volume 13, pages2251–2257 (2012)Cite this article Abstract This paper deals with the analysis techniques of a high speed and high efficiency 10 kW, 30,000 rpm rated induction motor. The induction motor has been analyzed by time-varying magnetic finite element

Read More

동 다이캐스팅 고속 유도전동기의 불평형 응답 해석 Abstract This paper deals with a copper die casting induction motor which has several advantages of motor performance. The developed motor is used as spindle motor in machining center. The dynamic characteristic analysis of rotor is dealt with for precision machining. The critical speed of rotor considering rotation

Read More

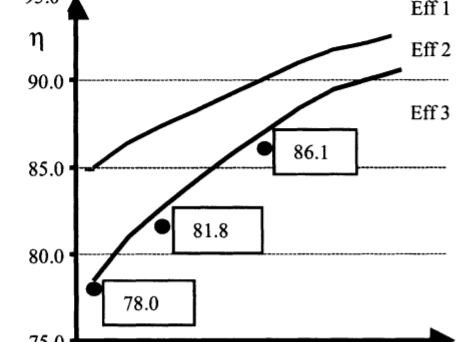

고효율 유도 전동기 설계 다이캐스팅 구리 로터 Francesco Parasiliti, Marco VillaniDepartment ofElectric Engineering, University ofL’Aquila, 67040 L’Aquila, Italy Abstract The paper deals with the use of copper cage in three-phase low voltage induction motors and gives a design guideline to optimize their efficiency, according to the new European classification scheme. An accurate motor design allows

Read More