동 다이캐스팅 고속 유도전동기의 불평형 응답 해석

- 홍도관 (한국전기연구원 전동력연구센터) ;

- 정승욱 (동아대학교 대학원 기계공학과) ;

- 우병철 (한국전기연구원 전동력연구센터) ;

- 구대현 (한국전기연구원 전동력연구센터) ;

- 안찬우 (동아대학교 기계공학과)

Abstract

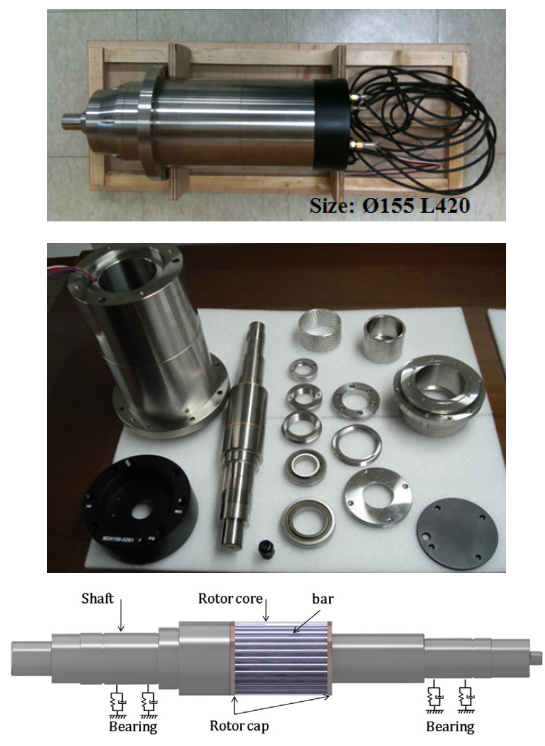

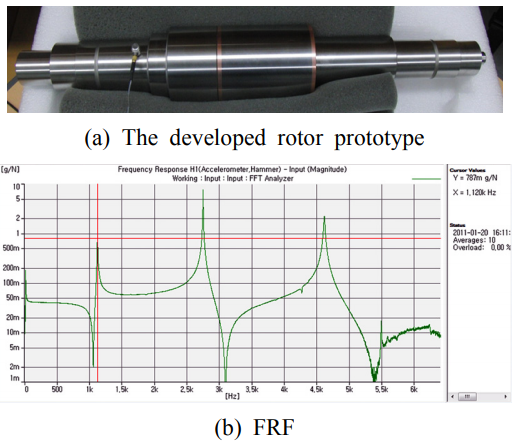

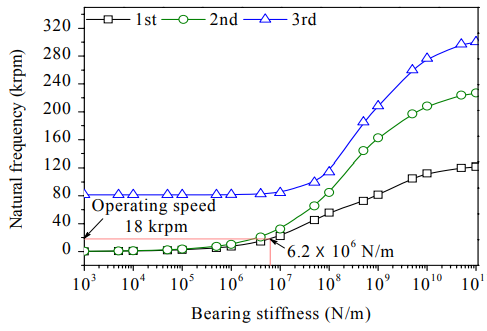

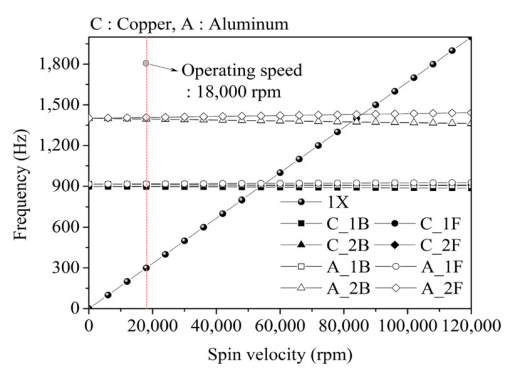

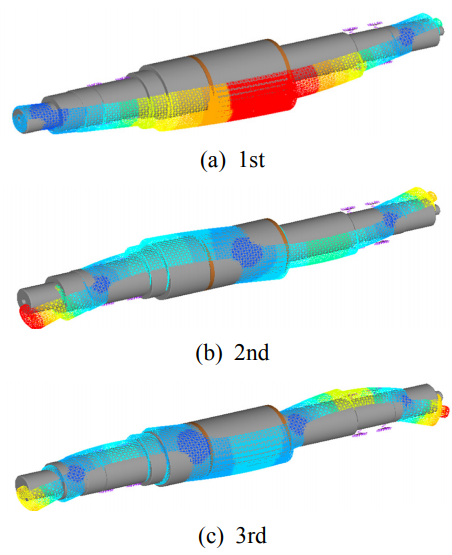

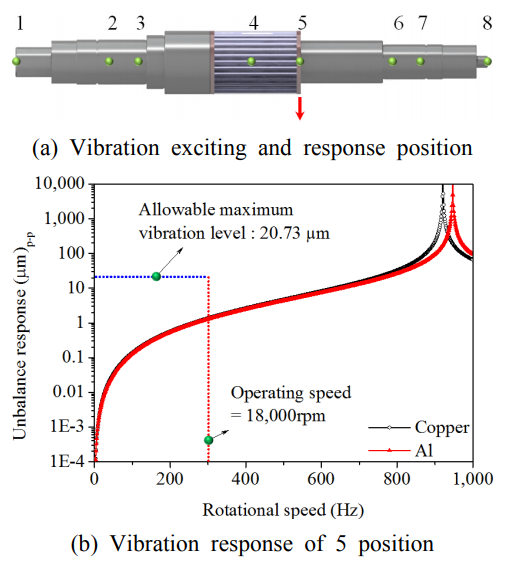

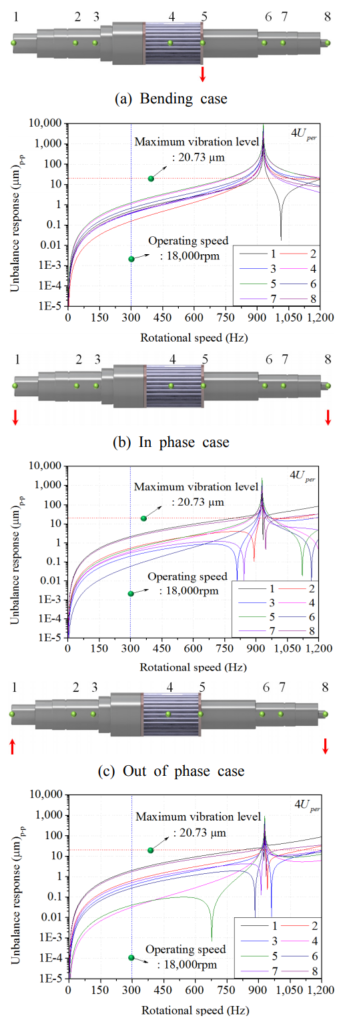

This paper deals with a copper die casting induction motor which has several advantages of motor performance. The developed motor is used as spindle motor in machining center. The dynamic characteristic analysis of rotor is dealt with for precision machining. The critical speed of rotor considering rotation and gyroscopic effect should be above operating speed, 18,000 rpm, and have a 201 % sufficient separation margin. Also, the 3-D unbalance vibration response analysis is performed and enabled the prediction of the expected vibration amplitude by unbalance in high speed. The unbalance vibration responses of each position on the rotor are satisfied with allowable vibration displacement of API 611 standard according to balancing G grade(G 0.4, G 2.5, G 6.3). Copper die casting high speed induction motor is successfully developed and verified by experiment.

Korean Abstract

본 논문은 모터 성능의 몇 가지 장점을 가진 구리 다이캐스팅 유도 전동기에 대해 다룬다. 개발된 모터는 머시닝센터의 스핀들 모터로 사용됩니다. 정밀 가공을 위해 로터의 동적 특성 해석을 다룹니다. 회전자와 자이로스코프 효과를 고려한 로터의 임계속도는 운전속도 18,000rpm 이상이어야 하며, 201%의 충분한 이격마진을 가져야 한다. 또한 3차원 불평형 진동 응답 해석을 수행하여 고속에서 불평형에 의한 예상 진동 진폭을 예측할 수 있습니다. 로터의 각 위치의 불평형 진동 응답은 밸런싱 G 등급(G 0.4, G 2.5, G 6.3)에 따른 API 611 규격의 허용 진동 변위를 만족합니다. 구리 다이캐스팅 고속 유도 전동기는 실험을 통해 성공적으로 개발되고 검증되었습니다.

Keywords

- Induction Motor;

- Cooper Die Casting;

- ISO 1940-1;

- API Standard;

- Rotor Dynamics;

- Unbalance Response Analysis;

- Critical Speed Map;

- Campbell Diagram

References

- Lie, S. and Pietro, D., 1995, Copper Die-cast Rotor Efficiency Improvement and Economic Consideration, IEEE Transactions of Energy Conversion, Vol. 10, No. 3, pp. 419-424. https://doi.org/10.1109/60.464863

- Malinowski, McCormick, J. and Dunn, K., 2004, Advances in Construction Techniques of AC Induction Motors : Preparation for Super-premium Efficiency Levels, IEEE Transactions of Industry Applications, Vol. 40, No. 6, pp. 1665-1670. https://doi.org/10.1109/TIA.2004.836300

- Jung, S. W., Hong, D. K., Woo, B. C., Koo, D. H. and Ahn, C. W., 2011, Rotordynamics of Induction Motor for Copper Die Casting Control, Proceedings of the KSNVE Annual Autumn Conference, pp. 157-158.

- Hong, D. K., Woo, B. C. and Koo, D. H., 2010, Rotordynamics and Unbalance Response Analysis 200 kW, 15 krpm, 3 Phase Induction Motor, PRZEGLAD ELEKTROTECHNICZNY(Electrical Review), R. 86 NR 5, pp. 129-132.

- ISO 1940-1, Mechanical vibration - Balance Quality Requirements of Rigid Rotors - Part 1 : Determination of Permissible Residual Unbalance.

- API Standard 611, 2008, General-purpose Steam Turbines for Petroleum, Chemical, and Gas Industry Services, Fifth Edition, American Petroleum Institute, Washington, D.C..

- Ganatra, N. and Ratel, R. C., 2011, Witness Testing of API 610 Centrifugal Pumps and API 611 Steam Turbines, Proc. of the 27th International Pump Users Symposium, pp. 71-79.

Reference

(1) Lie, S. and Pietro, D., 1995, Copper Die-cast Rotor Efficiency Improvement and Economic Consideration, IEEE Transactions of Energy Conversion, Vol. 10, No. 3, pp. 419~424.

(2) Malinowski, McCormick, J. and Dunn, K., 2004, Advances in Construction Techniques of AC Induction Motors : Preparation for Super-premium Efficiency Levels, IEEE Transactions of Industry Applications, Vol. 40, No. 6, pp. 1665~1670.

(3) Jung, S. W., Hong, D. K., Woo, B. C., Koo, D. H. and Ahn, C. W., 2011, Rotordynamics of Induction Motor for Copper Die Casting Control, Proceedings of the KSNVE Annual Autumn Conference, pp. 157~158.

(4) Hong, D. K., Woo, B. C. and Koo, D. H., 2010, Rotordynamics and Unbalance Response Analysis 200 kW, 15 krpm, 3 Phase Induction Motor, PRZEGLĄD ELEKTROTECHNICZNY(Electrical Review), R. 86 NR 5, pp. 129~132.

(5) ISO 1940-1, Mechanical vibration - Balance Quality Requirements of Rigid Rotors - Part 1 : Determination of Permissible Residual Unbalance.

(6) API Standard 611, 2008, General-purpose Steam Turbines for Petroleum, Chemical, and Gas Industry Services, Fifth Edition, American Petroleum Institute, Washington, D.C..

(7) Ganatra, N. and Ratel, R. C., 2011, Witness Testing of API 610 Centrifugal Pumps and API 611 Steam Turbines, Proc. of the 27th International Pump Users Symposium, pp. 71~79.