John G. Cowie

Copper Development Associations Inc.

New York, NY

Dale T. Peters

Consultant to CDA Inc.

Hilton Head Island, SC

Edwin F. Brush, Jr.

Consultant to CDA Inc.

Weston, MA

Stephen P. Midson

Formcast, Inc.

Denver, CO

Articles on materials appearing in materials issues have generally focused on the common aluminum-, zinc- and magnesium-based die casting alloys. This report differs in that it deals with pressure die casting of a relatively high melting metal, pure copper. Short mold life is the limiting factor in achieving a cost effective die casting operation for high melting metals and alloys. This study, where the primary objective was a more efficient induction motor via a coppercontaining rotor, was forced to address the mold or die material issue. Generalizations about the properties of mold materials and modifications to the thermal environment of the die set necessary to achieve cost effective mold life in service were concluded from this study. Properties of the cast copper in the rotor structure and the performance of the cast copper rotor in motor tests are also reported

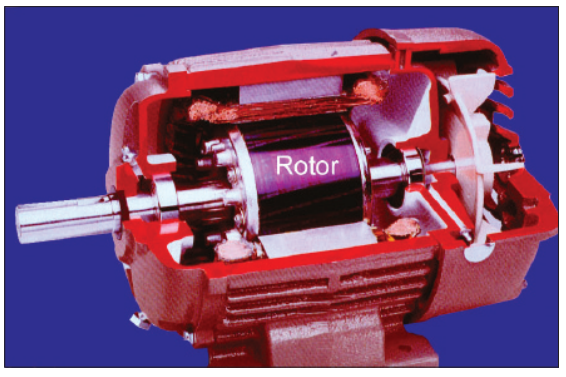

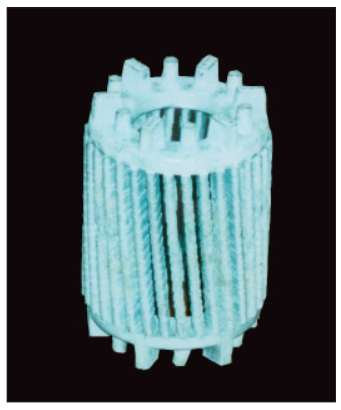

Advantages of the Cast Copper Rotor

An exploded view of a typical motor is shown in figure 1. The rotor structure in the center consists of a stack of punched circular magnetic steel laminations interconnected with a “squirrel cage” structure of conductor bars with shorting rings at each end. Figure 2 is a photograph of an aluminum squirrel cage after dissolution of the iron. This structure has long been aluminum because of aluminum’s high electrical conductivity and the ability to mass produce the rotor by pressure die casting the aluminum into the stack of steel laminations. Die casting, of course, is widely recognized as a low cost manufacturing process for large production volumes.

Motor manufacturers have long realized that replacing the aluminum conductor structure of the rotor with pure copper would very significantly increase the electrical energy efficiency of the motor. Motor modeling had shown that motors with copper-containing rotors would yield overall loss reductions from 15 percent to 20 percent compared to the aluminum counterpart.

For this reason, some special purpose motors and many very large motors (above about 250 Hp) are built with copper rotor structures by a costly and slow fabrication process. The potential total energy savings in applying copper to the rotors of medium horsepower motors are a significant national consideration.

This is because, as reported by the U.S. Department of Energy, motors above 1/6 Hp use about 60 percent of all electricity generated in the United States. Medium horsepower motors in the 1 to 125 Hp range use about 60 percent of the electricity supplied to all motors. Because of the proliferation of electric motors in this horsepower range, a 1 percent increase in motor efficiency would save 20 billion kWhrs per year or 1.4 billion dollars in electricity (at 7 cents per kWhr).

As every die caster knows, tool steel molds used for the aluminum die casting process are entirely inadequate when casting higher melting point metals including copper (copper melts at 1083°C, aluminum at 660°C). Clearly, a durable and cost effective mold material is required for the manufacture of the cast copper rotor.

Mold life measured in thousands of casting cycles must be achieved for the cast copper rotor to be economically feasible. To attack this problem, CDA assembled a consortium of companies including several major motor manufacturers. Funding was largely from the world copper industry through the International Copper Association with participation by the Air Conditioning and Refrigeration Technical Institute.

Formcast, Inc. in Denver, CO provided the die casting expertise and the Buhler 750 ton horizontal real-time, computer-shot-controlled die casting machine for the trials. The U.S. Department of Energy (DOE), and Office of Industrial Technologies (OIT), provided a NICE³ grant to Trex Enterprises, San Diego, CA, an industrial partner at the inception of the project.

This NICE³ grant, early in the program, was an important catalyst for this successful development. These initial efforts and funding brought together the multi-disciplinary team of motor manufacturers, die casting equipment manufacturers, CDA/ICA technical expertise and Trex high temperature design and materials capabilities.

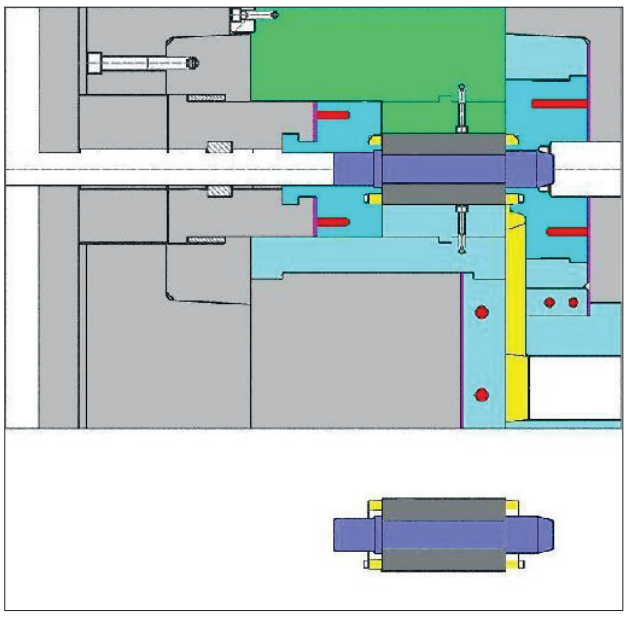

Important equipment, die design and processing/handling variables were jointly developed; these guided the program through testing activities. Important computer analyses of heat transfer to the die casting molds (thermal modeling) was done in this early phase. This work guided the design of test dies and the selection of candidate mold materials, and created the basis for the design of the master die and die inserts utilized for the copper rotor die casting.

Candidate Mold Materials

Mold failures, in attempting to die cast high melting metals, result from thermal shock and thermal fatigue due to the temperature differential between the mold surface and cooler interior. Failures can be very rapid. The high melting temperature, high heat of fusion, substantial latent heat and high thermal conductivity of copper all combine to maximize these failure mechanisms.

The ∆T between the surface and interior could be reduced by preheating the die inserts and by operating the dies at higher temperature. Mold materials that maintain strength on prolonged exposure to elevated temperatures would then be a necessity. A list of high temperature materials having thermal and thermoelastic properties conducive to minimizing thermally induced strain was assembled.

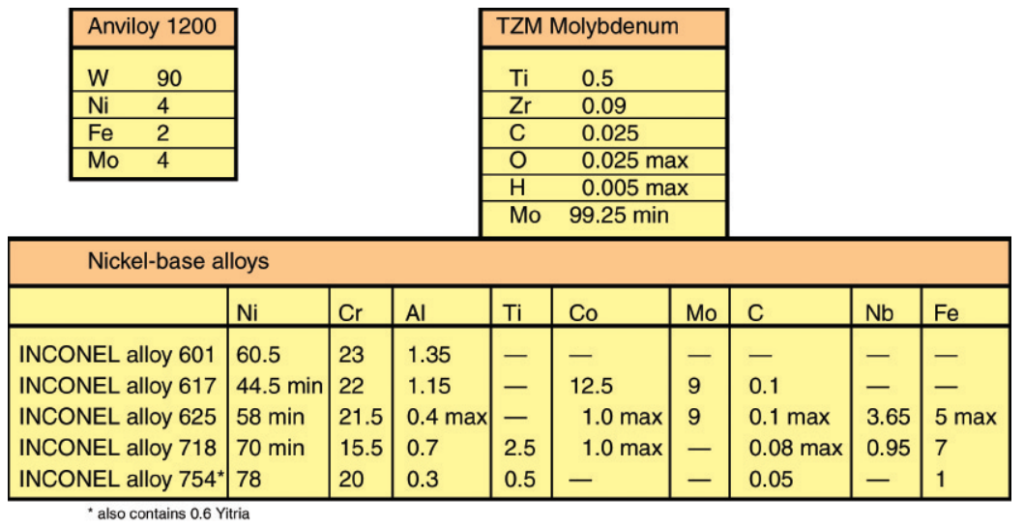

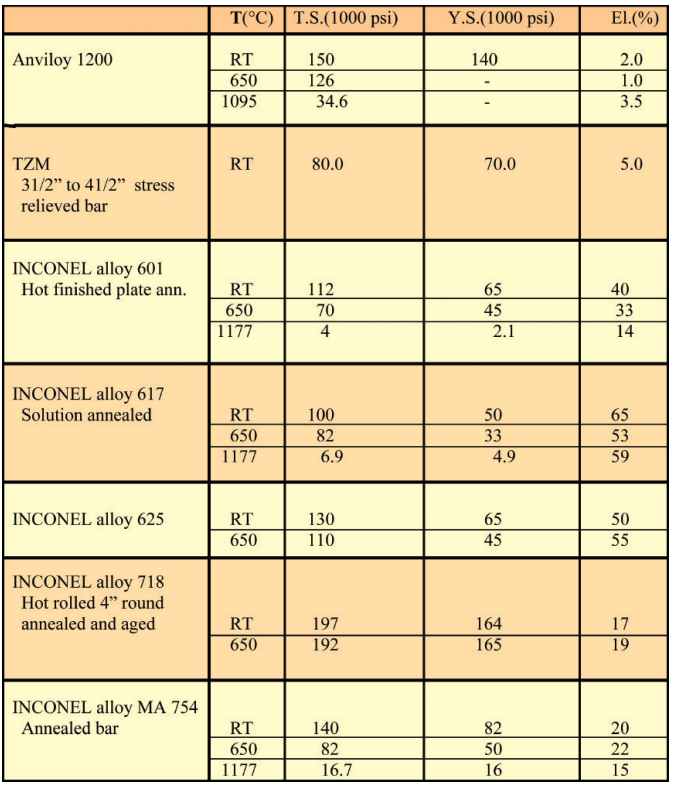

Studies done some years ago by the International Copper Research Association had identified tungsten and molybdenum as good candidates for copper die casting. That work was extended here. Molds machined from the molybdenum-based alloy TZM and the tungsten alloy Anviloy were tested. A variety of nickel-based alloys and superalloys suggest themselves. The nickel-base alloys do not have the low expansion coefficient of tungsten or molybdenum, but they offer high temperature strength and excellent cyclic oxidation resistance.

An alloy with known excellent high temperature strength retention, the dispersion-strengthened INCONEL alloy 754 was selected. Other nickel-base alloys, INCONEL alloys 601,617, 625 and 718, having a range of thermoelastic properties in the anticipated thermal cycling range, were also included in the test program. An H-13 tool steel die set was also fabricated to provide a baseline for comparison with the performance of high temperature mold materials. Compositions of the candidate mold materials are listed in table 1 and selected mechanical properties in table 2.

Test Molds and Melting Equipment

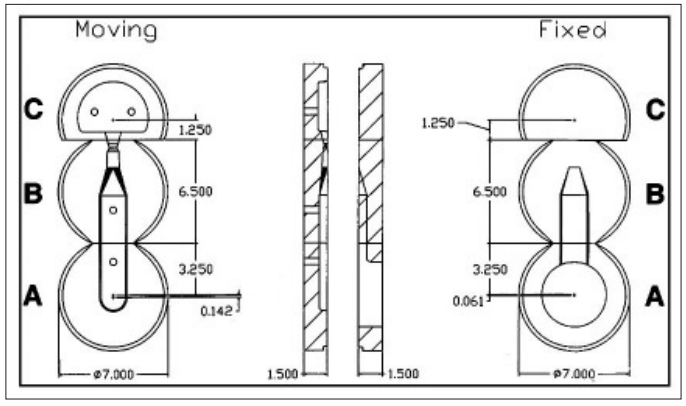

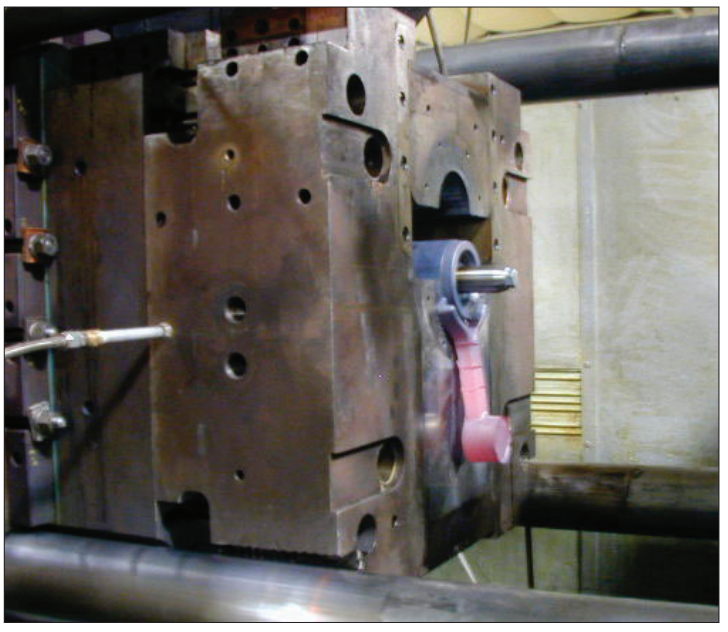

Because of the large amount of copper and the tremendous expense of iron lamination stacks for thousands of test shots, it was not practical to cast motor rotors in the mold material evaluation phase of the project. For this phase of the project, a test mold to simulate the action at one gate of a motor rotor mold was designed. This produced a two- pound flat semi-circular casting and required eight pounds of liquid copper in the shot sleeve. The test casting, gate section, runner and remaining shot sleeve biscuit are shown in figure 3. This test mold consisted of six die inserts set into the steel master mold plates of the machine.

A detailed drawing of the test mold is shown in figure 4. As experience was gained with this design, it was realized that two or three similar materials could be evaluated simultaneously using the several inserts, although admittedly, thermal and flow conditions were not identical at each of the six inserts. But simultaneous testing of materials significantly reduced the machine time required, and the amount of copper required for the mold material evaluation. This test mold design is an aggressive test exceeding the conditions that the rotor die set will experience and proved to be an excellent test for quickly comparing and ranking the various mold materials.

A suitable approach to melting significant quantities of high purity copper and providing a means to safely deliver molten copper to the shot sleeve required consideration. Aluminum is generally melted in a large gas fired furnace and transferred from the holding furnace to the shot sleeve by ladle or mechanized transfer device. This approach was deemed inappropriate for copper because the substantial heat from a large volume of molten copper would present difficult working conditions for the operators and because molten copper picks up oxygen rapidly.

Protecting the melt would be expensive and difficult. The solution was to individually induction melt sufficient copper for each shot with an Inductotherm power supply sized to melt the charge in two minutes: i.e. within the time required for one complete cycle of the machine. (Motor manufacturers die cast aluminum rotors for motors of the size planned for this project in about two minutes).

This required a 60 kW power supply for the eight-pound charge. Use of two furnaces alternately switched to the supply allowed maximum utilization of the power source. Individual charges were conveniently handled and weighed by using chopped copper wire rod. The metal was melted and heated to about 1230°C providing about 150°C of superheat. As noted earlier, operating the mold at higher temperatures minimizes the mold surface strain on each casting cycle and the resulting thermal fatigue or “heat checking.”

This is an absolute necessity to avoid cracking on the first shot of the tungsten and molybdenum alloy mold candidates because of the high ductile-to-brittle transition temperatures of these materials. Thermal modeling of the mold showed that temperatures above about 550°C for the molybdenum and tungsten alloys would result in thermal cycles with resulting maximum stresses below the yield points of these materials. Because of the lower thermal conductivity of the nickelbase alloys, it was estimated that this critical temperature would be about 625°C for these alloys.

These temperatures are well in excess of the capability of the hot oil heaters normally used to increase mold temperatures. A variety of configurations of electric resistance heaters inserted into both the moving and stationary die inserts and into the cavity die holders were tried. To minimize heat loss to the machine and to achieve higher insert temperatures, a NASA-developed high R insulation layer was placed behind the inserts for the last runs. The oil circulation channels in the master mold assembly served to prevent overheating of these components.

Prior to a run, the die inserts in position on the machine were preheated by an oxy-acetylene torch and in later runs by the array of electrical resistance heaters. The rate of heat transfer and resulting thermal shock from contact with molten copper was to some extent controlled also by the use of a dry mold release system sprayed on the die insert surfaces prior to each shot.

Motor Performance with Copper Rotors

Motor companies tested the copper rotors according to IEC 34-2 and IEEE Std. 112 Method B. A standard rotor with die cast aluminum bars and end rings was tested to provide the baseline. All rotors were tested by each company in the same wound stator dynamometer test bench to eliminate other performance variations. Seven of the smaller copper rotors from the first group cast over a range of machine parameters showed very little variation in the numerous electrical parameters measured.

The overall motor losses (sum of five measured losses) were 14 percent lower in the copper rotors compared to the aluminum. Full load losses in the rotor were about 40 percent lower than that of the aluminum. It is important to note that the improvements in motor performance by substituting copper for aluminum in this rotor were made without optimizing the slot design nor the overall design of the motor for the copper.

Laminations for a standard (aluminum) rotor were used in this work. Additional improvements in efficiency by as much as 5 percent to 10 percent reduction in losses are expected through rotor and overall motor design optimization. These motor tests showed that there also was no difference in performance of water quenched vs. air cooled rotors. Although the post-casting cooling method had no effect on the results, water quenching reduced handling time to one minute compared to a 20 minute air cool. This would be important to manufacturing efficiency. Motor tests of the second set of larger rotors cast showed even more dramatic results.

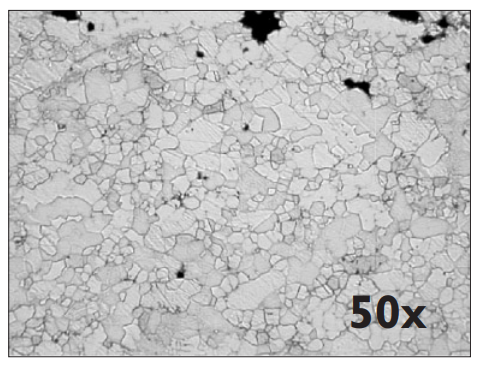

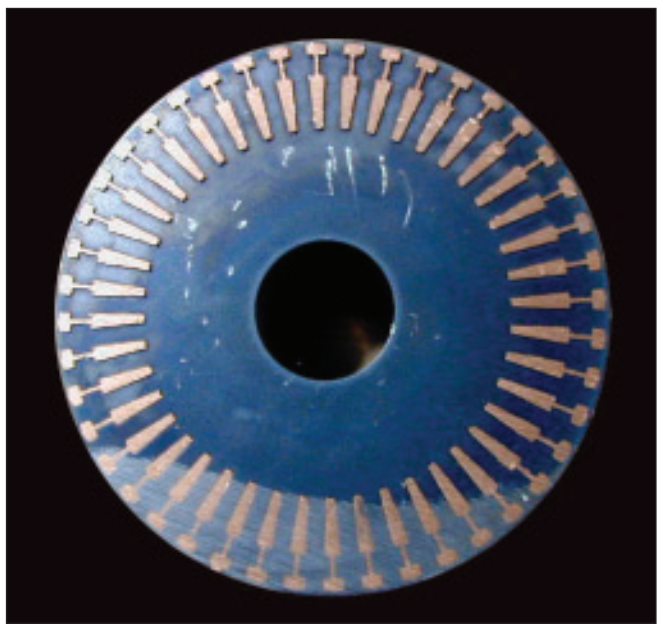

This is, in part, due to the use of a rotor lamination slot design specifically designed for copper. A cross-section of this cast copper rotor is shown in figure 9. The manufacturer provided sufficient laminations for 14 rotors. Again, there was remarkable consistency in the results for the four rotors tested and compared to the same motor with an aluminum rotor. The rotor losses were 40 percent lower in the copper rotors and the overall losses were reduced by 23 percent. Lower losses led to reduced rotor and stator winding temperatures. On completion of testing, the temperature of the stator winding of the motor with the copper rotor was 32°C cooler than the aluminum; the copper rotor was 29°C cooler than the aluminum rotor.

Lower temperatures mean that smaller internal cooling fans can be employed and this had a significant effect in reducing the parasitic component of the friction and windage losses. Motor temperatures translate directly to motor life and maintenance costs. As a general rule, insulation life is doubled for every 10°C decrease in motor operating temperature. Motors with cast copper rotors, with proper maintenance, will last longer and will be more reliable.

Overall motor efficiency was increased by a solid 1.2 and 1.6 percentage point in motors tested with the two sets of copper rotors cast. This is significant because 20 years of motor efficiency improvements have been accomplished by using all of the readily available approaches. Copper rotors represent the only way to reduce losses significantly without turning to expensive amorphous iron or superconductivity.