Xiaorou Ning, Keke Zuo, Yang Li, Wanting Guo, Xiao Peng, Jianguo Su, Lai Song, Weihua Liu, Tongyu Liu & Yuyan Ren

Abstract

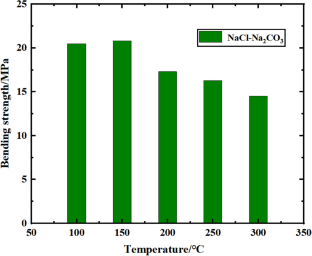

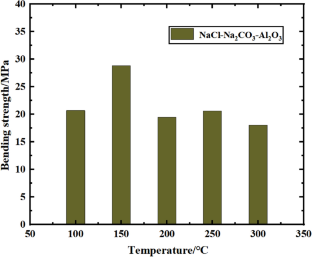

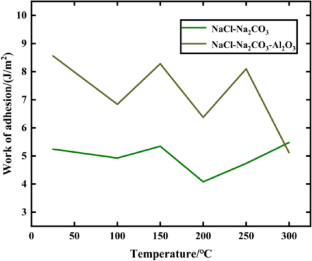

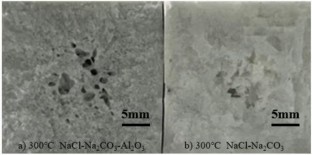

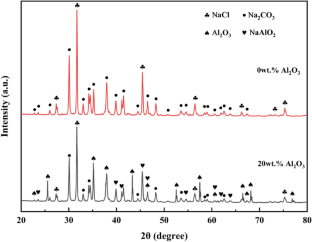

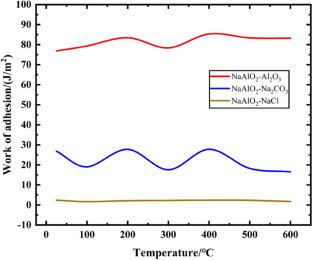

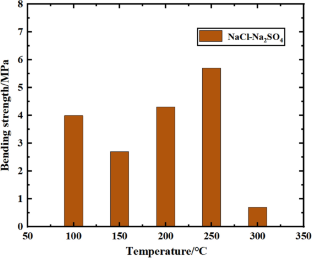

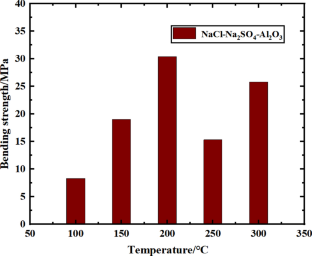

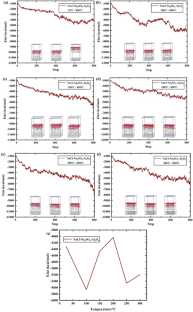

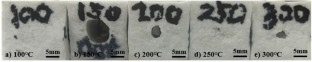

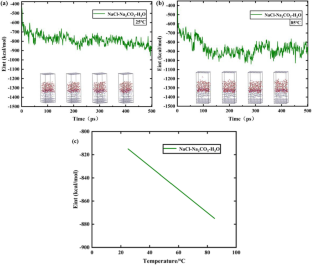

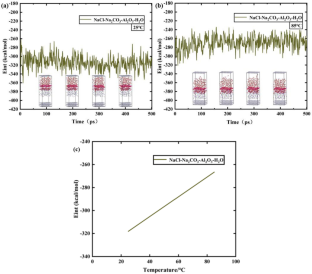

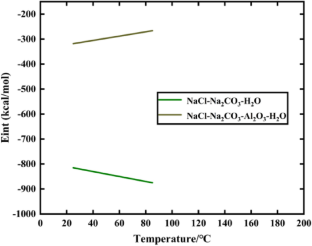

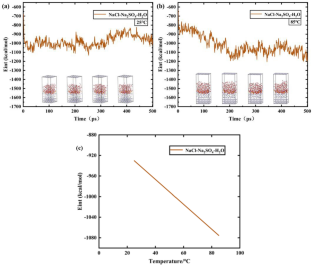

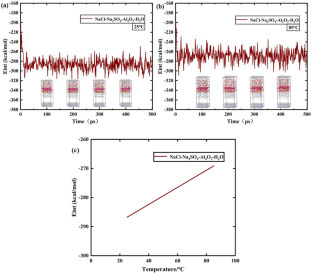

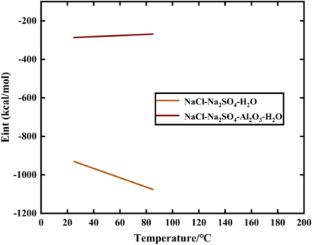

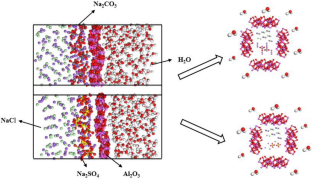

In the process of pouring salt cores, it is crucial to select the appropriate mold temperature, which is essential for the shaping and strength of the salt cores. Additionally, salt cores need to undergo water-soluble cleaning after casting, which has certain requirements for their water solubility. In order to obtain composite water-soluble salt cores with a certain strength suitable for high-pressure die casting processes, sodium chloride, sodium sulfate, and sodium carbonate are used as salt core materials, with ceramic alumina particles as reinforcement materials. The influence of alumina on the performance of NaCl–Na2CO3 and NaCl–Na2SO4 composite salt cores was studied. Through molecular dynamics simulation calculations, the change curve of the adhesion work of salt cores at different mold temperatures was analyzed. Combining XRD detection results and comparative analysis of actual salt core flexural strength, it was found that sodium aluminate generated at high temperatures has a strong interface binding ability with other components in the salt core, which is a key factor affecting the strength of the salt core. Through experimental research combined with simulated calculations of water molecule adsorption at different salt core interfaces, it was found that with increasing water temperature, the water adsorption capacity of NaCl–Na2CO3 and NaCl–Na2SO4 salt cores gradually increases, leading to an accelerated water solubility rate. The addition of Al2O3 reduces the water solubility rate of NaCl–Na2CO3 and NaCl–Na2SO4 salt cores, but significantly improves their strength. The addition of Al2O3 enhances the NaCl–Na2CO3 salt core due to the formation of highly water-soluble sodium aluminate, resulting in a certain improvement in water solubility rate.

- Figure 1

View in article

View in article - Figure 2

View in article

View in article - Figure 3

View in article

View in article - Figure 4

View in article

View in article - Figure 5

View in article

View in article - Figure 6

View in article

View in article - Figure 7

View in article

View in article - Figure 8

View in article

View in article - Figure 9

View in article

View in article - Figure10

View in article

View in article - Figure 11

View in article

View in article - Figure 12

View in article

View in article - Figure 13

View in article

View in article - Figure 14

View in article

View in article - Figure 15

View in article

View in article - Figure 16

View in article

View in article - Figure 17

View in article

View in article - Figure 18

View in article

View in article - Figure 19

View in article

View in article - Figure 20

View in article

View in article - Figure 21

View in article

View in article - Figure 22

View in article

View in article - Figure 23

View in article

View in article - Figure 24

View in article

View in article - Figure 25

View in article

View in article - Figure 26

View in article

View in article - Figure 27

View in article

View in article - Figure 28

View in article

View in article

References

- A. Bandivadekar, L. Cheah, C. Evans, T. Groode, J. Heywood, E. Kasseris, M. Kromer, M. Weiss, Reducing the fuel use and greenhouse gas emissions of the US vehicle fleet. Energy Policy 36(7), 2754–2760 (2008)Article Google Scholar

- C. Min, Y. Pan, W. Dai, I. Kawsar, Z. Li, G. Wang, Trajectory optimization of an electric vehicle with minimum energy consumption using inverse dynamics model and servo constraints. Mech. Mach. Theory, 181 (2023).

- W. Zhang, J. Xu, Advanced lightweight materials for automobiles: a review, Mater. Des., 221 (2022).

- S. Siengchin, A review on lightweight materials for defence applications: present and future developments. Defence Technol 24, 1–17 (2023)Article Google Scholar

- M. Agarwal, R. Srivastava, Influence of processing parameters on microstructure and mechanical response of a high-pressure die cast aluminum alloy. Mater. Manuf. Processes 34(4), 462–472 (2018)Article Google Scholar

- X. Dong, H. Yang, X. Zhu, S. Ji, High strength and ductility aluminium alloy processed by high pressure die casting. J. Alloy. Compd. 773, 86–96 (2019)Article CAS Google Scholar

- E. Lordan, J. Lazaro-Nebreda, Y. Zhang, K. Dou, P. Blake, Z. Fan, On the relationship between internal porosity and the tensile ductility of aluminium alloy die-castings. Mater. Sci. Eng. A 778 (2020).

- G.-H. Cho, J. Li, E.-H. Kim, Y.-G. Jung, Preparation of a ceramic core with high strength using an inorganic precursor and the gel-casting method. Surf. Coat. Technol. 284, 396–399 (2015)Article CAS Google Scholar

- L. Song, W. Liu, F. Xin, Y. Li, Study of adhesion properties and mechanism of sodium silicate binder reinforced with silicate fume. Int. J. Adhesion Adhesives, 106 (2021)

- Z. Cheng, S. Fan, L. Peng et al., Fabrication and characterization of high-strength water-soluble composite salt cores via layered extrusion forming. Inter Metalcast 17, 988–997 (2023). https://doi.org/10.1007/s40962-022-00816-7Article CAS Google Scholar

- Xy. Liu, Wh. Liu, Xt. Wang et al., Composition optimization and strengthening mechanism of high-strength composite water-soluble salt core for foundry. Inter Metalcast 16, 1809–1816 (2022). https://doi.org/10.1007/s40962-021-00725-1Article CAS Google Scholar

- X. Gong, X. Xiao, X. Liu, Z. Fan, Fabrication of high-strength salt cores for manufacturing hollow aluminum alloy die castings. Mater. Manuf. Processes 38(2), 188–196 (2022)Article Google Scholar

- F. Liu, S. Tu, X. Gong, G. Li, W. Jiang, X. Liu, Z. Fan, Comparative study on performance and microstructure of composite water-soluble salt core material for manufacturing hollow zinc alloy castings. Mater. Chem. Phys., 252 (2020)

- J. Yaokawa, D. Miura, K. Anzai, Y. Yamada, H. Yoshii, Strength of salt core composed of alkali carbonate and alkali chloride mixtures made by casting technique. Mater. Trans. 48(5), 1034–1041 (2007)Article CAS Google Scholar

- K. Oikawa, K. Sakakibara, Y. Yamada, K. Anzai, High-temperature mechanical properties of NaCl–Na2CO3 salt-mixture removable cores for aluminum die-casting. Mater. Trans. 60(1), 19–24 (2019)Article CAS Google Scholar

- C. Cantas, B. Baksan, Effects of composition on the physical properties of water-soluble salt cores. Int. J. Metalcast. 15(3), 839–851 (2020)Article Google Scholar

- X.-T. Wang, W.-H. Liu, X.-Y. Liu, L. Song, First-Principles calculation and mechanical properties of NaCl–Na2SO4 composite water-soluble salt core. Int. J. Metalcast. 17(1), 263–271 (2022)Article Google Scholar

- Y. Li, L. Song, G. Chen, W. Liu, J. Zhang, C. Sun, X. Zou, M. Bai, A study of the influence and mechanism of alumina ceramic powder on the high-temperature strength of NaCl–Na2CO3 cores in die-casting production. Int. J. Metalcast. (2024). https://doi.org/10.1007/s40962-024-01400-x

- X. Zhao, J. Zhang, S. Liu, C. Zhao, C. Wang, X. Ren, Q. Yang, Investigation on grain refinement mechanism of Ni-based coating with LaAlO3 by first-principles. Mater. Des. 110, 644–652 (2016)Article CAS Google Scholar

- L. Song, W. Liu, K. Zhao, F. Xin, Y. Li, Effects of water and carbon dioxide pressure on the adhesion of Na2SiO3 and K2SiO3 binders on silica sand surface: Comparison of experimental data and molecular dynamics simulation. Ceram. Int. 47(23), 32648–32656 (2021)Article CAS Google Scholar

- Frey SE, et al. Experimental studies of gas-escape and water-escape structures: mechanisms and morphologies. J. Sedimentary Res., 79(11/12), 808-816 (2009)

- J. Zhang, Y. Li, L. Song, W. Liu, X. Zou, Effect of mold temperature and pouring temperature on the crack behavior of composite water-soluble salt cores. Int. J. Metalcast. (2024). https://doi.org/10.1007/s40962-023-01244-x

- Z. Liu, S.B. Zhang, P.L. Mao et al., Effects of Y on hot tearing formation mechanism of Mg–Zn–Y–Zr alloys. Mater. Sci. Technol. (2014)

- Xujun L, Xingang Q, Libo L et al., Experimental and molecular dynamics simulation study on solubility characteristics of chloride and sulfate salts in supercritical water. J. Supercrit Fluids, 205106150 (2024)