From Theory to Foundry Floor: Using the Niyama Criterion to Eliminate Porosity in Permanent Mold Castings

This technical brief is based on the academic paper "Research on Porosity Defects of Al-Si Alloy Castings Made with Permanent Mold" by MINAMI Rin (July, 2005). It is summarized and analyzed for casting professionals by the experts at STI C&D.

Keywords

- Primary Keyword: Al-Si Alloy Porosity

- Secondary Keywords: Permanent Mold Casting, Porosity Prediction, Niyama Criterion, Solidification Simulation, Gating System Design, Casting Defects

Executive Summary

- The Challenge: Porosity is a chronic and costly defect in Al-Si alloy permanent mold castings, negatively impacting mechanical properties like tensile strength and fatigue life. Traditional trial-and-error methods for mitigation are inefficient.

- The Method: This research leverages a comprehensive literature review and practical solidification simulations to establish a reliable, data-driven methodology for porosity prediction. The study focuses on validating and applying the Niyama criterion (G/R¹/²) as a key predictive tool.

- The Key Breakthrough: The study demonstrates that computer simulation, when correctly applying the Niyama criterion, can accurately diagnose the root cause of real-world porosity defects—such as those at T-junctions or around inserts—and validate effective countermeasures before modifying physical tooling.

- The Bottom Line: A systematic, simulation-aided approach to controlling foundry parameters and optimizing casting design is far superior to guesswork, providing a clear path to reducing porosity, improving quality, and cutting rejection rates.

The Challenge: Why This Research Matters for HPDC Professionals

For decades, foundry engineers have battled the persistent issue of porosity in aluminum alloy castings. This defect, arising from a complex interplay of gas evolution (primarily hydrogen) and solidification shrinkage, compromises the structural integrity and performance of critical components. As outlined in Chapter 1 of the paper, the consequences are severe, leading to reduced tensile strength and fatigue life (Ref. [1], [2]).

While the mechanisms of porosity formation are well-understood (Chapter 2), predicting its precise location and severity in complex castings remains a significant hurdle. The manufacturing of Al-alloy castings has historically relied on a tedious and expensive cycle of trial and error. This research addresses the critical need for a more scientific and predictive approach, aiming to provide foundry professionals with useful, actionable countermeasures to reduce porosity in mass production environments.

The Approach: Unpacking the Methodology

To tackle this challenge, the research undertakes a multi-faceted approach:

- Comprehensive Literature Review: The author first reviews the three primary methods for porosity prediction: the Modulus/Equisolidification Time Method, the Criterion Function Method, and Direct Numerical Simulation (Chapter 3). This review establishes the Niyama criterion (G/R¹/²) as a promising and practical candidate for industrial application.

- Systematic Parameter Analysis: The study meticulously examines the influence of every stage of the foundry process, from metal chemistry (minute elements like Ti, Zr, V) and quality (degassing, refining) to casting process design (gating, runners, pouring temperature, mold cooling) (Chapter 4).

- Simulation and Validation: The core of the research involves using commercial solidification simulation software (AdStefan3D) to rigorously test the Niyama criterion. The author performs detailed preliminary calculations to determine the correct parameters for its use with Al-alloys, such as the moment of calculation (solid fraction, fs) and the type of cooling rate (instantaneous vs. average) (Chapter 5).

- Real-World Case Studies: Finally, the validated simulation methodology is applied to solve actual, daily production problems, including porosity around a non-aluminum insert in a gravity Al piston and porosity at a T-junction ingate area (Chapter 6).

The Breakthrough: Key Findings & Data

This research translates complex solidification theory into practical, data-driven solutions. The key findings provide a clear roadmap for any foundry looking to reduce porosity.

- Finding 1: The Niyama Criterion is a Valid Predictor for Al-Alloys: Despite its origins in steel casting, the research confirms the Niyama criterion is a highly effective tool for predicting porosity locations in Al-Si castings. The study establishes a critical value of 0.5 (deg¹/² s¹/² cm⁻¹) for Al-alloys; areas falling below this value are identified as potential porosity zones (Section 5.2.1, Fig. 5.18).

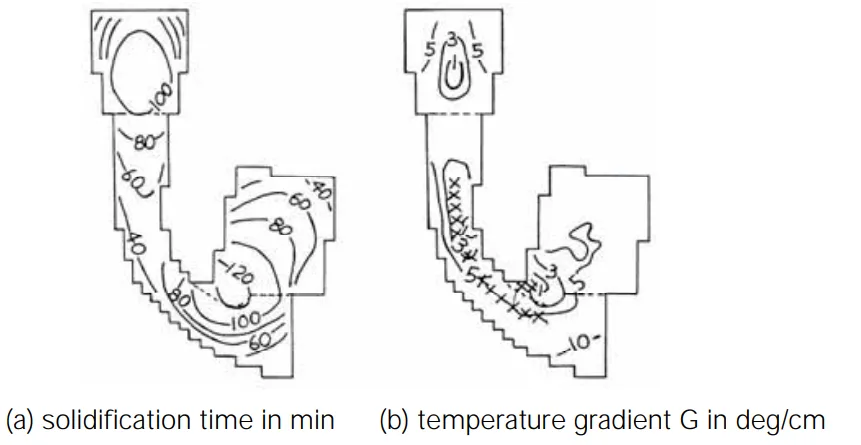

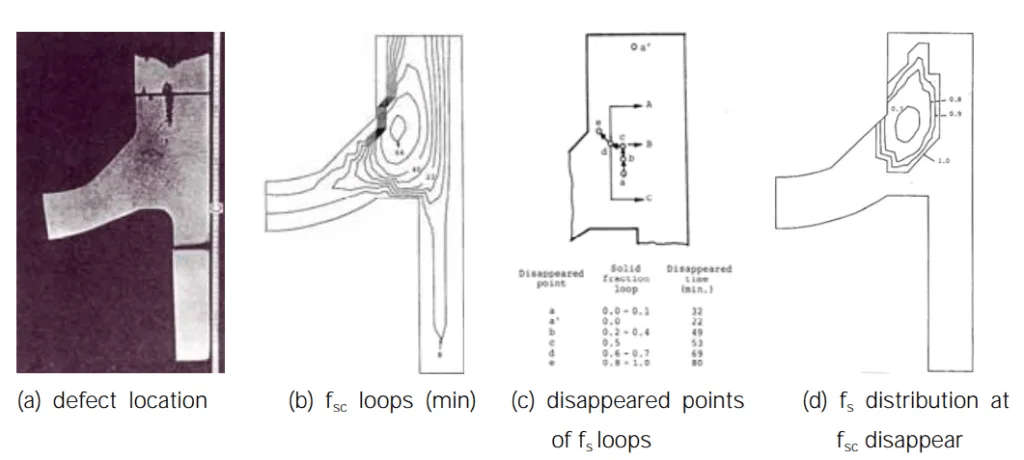

- Finding 2: Calculation Moment is Crucial for Accuracy: The predictive power of the Niyama criterion depends heavily on when it is calculated. The study concludes it must be calculated at the final stage of solidification (fs = 0.80–0.90 for Al-alloys) and must use the instantaneous cooling rate (R_ins). This correctly reflects the acceleration of solidification at the last-to-freeze areas, which are often the most prone to porosity (Section 5.2.3, Fig. 5.8).

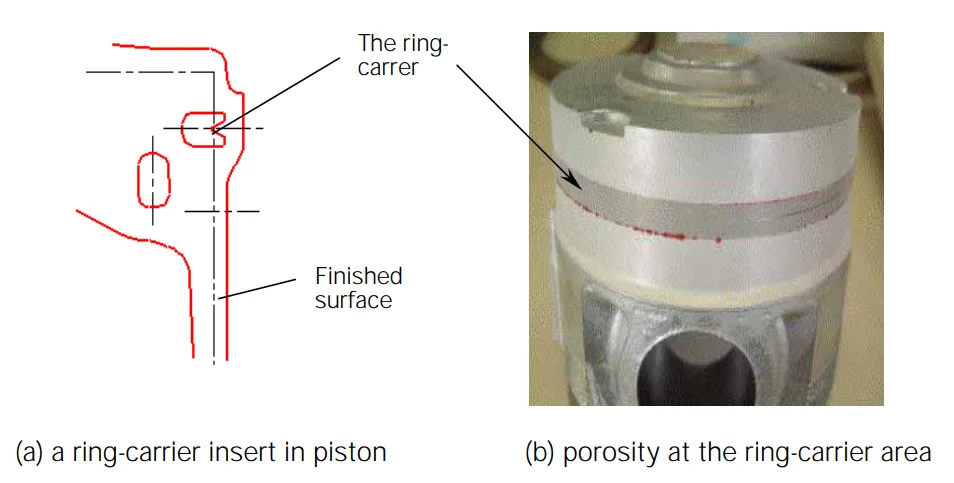

- Finding 3: Diagnosing Porosity Around Inserts: A case study on an Al piston with a Ni-resist iron ring-carrier (Section 6.1) revealed the root cause of porosity. The lower thermal conductivity of the insert creates a low temperature gradient (G) in the adjacent aluminum during solidification. This results in a low Niyama value and subsequent porosity (Fig. 6.5). The simulation correctly predicted that local mold cooling would increase the temperature gradient and solve the problem (Fig. 6.9).

- Finding 4: A Data-Driven Rule for T-Junction Design: The traditional "rule of thumb" for designing T-junctions is often inadequate. Simulation of an ingate T-junction (Section 6.2.1) provided a precise, data-driven design rule: to avoid porosity, the ingate thickness (D₁) should be at least 1.2 times the thickness of the part it feeds (D₀) (Fig. 6.12). This allows the ingate to act as a feeder, preventing a hot spot from being isolated at the junction.

Practical Implications for Your HPDC Operations

The findings from this comprehensive study offer direct, actionable insights for improving real-world casting operations.

- For Process Engineers: The research in Chapter 4 provides a practical guide to process control. The influence of minute elements (Ti, Zr, V) on macrostructure (Section 4.1.1), the critical importance of degassing and metal cleanliness (Section 4.2), and the benefits of higher pouring temperatures combined with intensive mold cooling (Section 4.4.2) are all detailed. This suggests that precise control over melt chemistry and thermal management can significantly reduce porosity.

- For Quality Control: The Niyama criterion, as validated in Chapter 5, offers a powerful predictive quality tool. Instead of relying solely on post-production inspection (dye-check, X-ray), simulations can identify potential porosity hot spots before the first casting is poured. This allows for proactive adjustments, saving time and material. The correlation shown in Figure 6.14 between the predicted low-Niyama area and the actual defect location is a testament to its accuracy.

- For Die Design: This study provides invaluable data for die designers. The detailed analysis of gating systems—including sprue design, runners, and filters (Section 4.4.1)—emphasizes designing for quiescent filling to minimize oxide film entrapment. Furthermore, the T-junction analysis (Section 6.2.1) provides a clear, simulation-backed rule (D₁/D₀ ≥ 1.2) that can be directly implemented to design ingates that prevent, rather than create, porosity.

Paper Details

Research on Porosity Defects of Al-Si Alloy Castings Made with Permanent Mold

1. Overview:

- Title: Research on Porosity Defects of Al-Si Alloy Castings Made with Permanent Mold

- Author: MINAMI Rin

- Year of publication: 2005

- Journal/academic society of publication: Thesis/Research Paper

- Keywords: Porosity Defects, Al-Si Alloy, Permanent Mold, Niyama Criterion, Solidification Simulation, Casting Process

2. Abstract:

This research clarifies three key aspects regarding porosity defects in Al-Si alloy castings made with permanent molds. First, it establishes that these defects can be reliably predicted. Second, it details how every step of the casting process—from mold design and melting to foundry operations—must be strictly controlled to reduce porosity. Third, it demonstrates that computer simulation integrated with the Niyama criterion (G/R¹/²) is a useful and powerful tool for both predicting and reducing porosity. The paper provides a comprehensive guide based on literature reviews and practical simulation case studies to help foundry professionals mitigate porosity in daily production.

3. Introduction:

Porosity is a chronic defect in aluminum alloy castings that severely degrades mechanical properties such as tensile strength and fatigue life. The formation of porosity is a complex phenomenon involving gas entrapment, solidification shrinkage, and interdendritic feeding failure. The purpose of this research is to move beyond traditional trial-and-error methods by providing a systematic, science-based guide for reducing porosity defects in the mass production of permanent mold castings. This is achieved through a thorough literature survey, a review of thermal-parameter-based prediction criteria, and the application of computer simulation to solve real-world manufacturing problems.

4. Summary of the study:

Background of the research topic:

The fundamental challenge in aluminum casting is the formation of undesirable voids (porosity) during solidification. This is caused by two primary mechanisms: the rejection of dissolved hydrogen gas from the melt and the failure of liquid metal to feed and compensate for volume shrinkage. These factors, often acting together, create porosity that is most frequently found in the last areas to solidify, significantly compromising the casting's quality and performance.

Status of previous research:

The paper categorizes porosity prediction methods into three main approaches (Chapter 3):

- Modulus and Equisolidification Time Method: Based on Chvorinov’s rule, this method identifies the last areas to solidify (hot spots) but does not consider factors like interdendritic feeding or gas evolution, making it suitable for predicting gross shrinkage but not dispersed porosity.

- Criterion Function Method: This approach uses thermal parameters derived from heat transfer simulations to predict porosity. Numerous criteria have been proposed, with the Niyama criterion (G/R¹/², where G is temperature gradient and R is cooling rate) being the most popular and widely implemented for steel castings. Its applicability to Al-alloys is a key focus of this research.

- Direct Numerical Simulation (DNS): This method mathematically models the entire solidification process, including fluid flow and gas evolution. While providing deep insight, its complexity has largely limited its application to the research field.

Purpose of the study:

The primary purpose of this research is to figure out useful, practical countermeasures to reduce porosity defects in the mass production of Al-Si permanent mold castings. It aims to create a useful guidebook for foundry professionals by summarizing the entire foundry process, reviewing existing prediction criteria, and demonstrating how computer simulation can be effectively applied to solve daily manufacturing issues.

Core study:

The core of the study is twofold. First, it conducts a detailed investigation (Chapter 5) to validate the Niyama criterion for Al-Si alloys, determining the precise conditions under which it should be calculated for maximum accuracy (e.g., solid fraction fs = 0.8-0.9, use of instantaneous cooling rate). Second, it applies this validated methodology to solve real-world porosity problems in an industrial setting (Chapter 6), such as porosity around a ring-carrier insert and at an ingate T-junction, demonstrating the practical value of simulation in moving from diagnosis to solution.

5. Research Methodology

Research Design:

The research employs a hybrid design, combining a comprehensive literature review with quantitative computer simulation. The study first establishes a theoretical framework by analyzing existing research on porosity formation and prediction. It then uses this framework to design a series of numerical experiments using a commercial solidification simulation software, AdStefan3D.

Data Collection and Analysis Methods:

Data was generated through 1D and 3D solidification simulations. The primary data points collected were thermal parameters at various points within the casting model, including temperature gradient (G), cooling rate (R), and the resulting Niyama criterion values. These simulated results were then systematically compared against each other under different conditions (e.g., varying solid fraction, cooling rates, mold temperatures) and validated against photographic evidence of actual casting defects from a production environment.

Research Topics and Scope:

The scope is focused specifically on porosity defects in Al-Si alloy castings produced via the permanent mold process. The research covers:

- Mechanisms of porosity formation.

- A review and critical analysis of porosity prediction methods.

- The influence of a wide range of foundry parameters (melt chemistry, process design, etc.).

- Detailed validation of the Niyama criterion for Al-alloys.

- Application of simulation to solve porosity problems in complex geometries like T-junctions and areas with inserts.

6. Key Results:

Key Results:

The research yields several critical conclusions, as summarized in Chapter 7:

- Porosity is Predictable: The porosity defects of Al-Si alloy castings made with permanent mold can be predicted using established methods, particularly the Niyama criterion.

- Process Control is Paramount: Reducing porosity requires strict control over every step of the manufacturing process, from mold design and melting to pouring and cooling.

- Niyama Criterion is a Powerful Tool: The Niyama criterion (G/R¹/²) is a significant and useful tool for predicting porosity. Its importance stems from its relationship to G/Vs, a critical parameter governing solidification.

- Calculation Conditions Matter: For accuracy in Al-alloys, the Niyama criterion should be calculated at a high solid fraction (fs = 0.80–0.90) using the instantaneous temperature gradient and cooling rate, not average values.

- Practical Solutions are Validated: Local intensive cooling is an effective way to reduce porosity, as it increases the Niyama criterion value. Simulation is an effective way to design and verify such solutions.

Figure Name List:

- Fig. 3.1 Shrinkage prediction by Modulus Method

- Fig. 3.2 Porosity prediction of an engine block casting of Al-9.6%Si-3.8%Cu by equisolidification time method

- Fig. 3.3 Comparison of G and equisolidification time method in predicting gross shrinkage and centerline porosity of a steel casting (13Cr-5Ni)

- Fig. 3.4 The relation between the experimentally determined critical temperature gradient G and the calculated solidification time tf

- Fig. 3.5 The relation between the experimentally determined critical Niyama criterion G/R¹/² value and the calculated solidification time tf

- Fig. 3.6 A summery of experimental data showing different criterion functions suitable to predict porosity for various alloys and casting processes

- Fig. 3.7 Shrinkage prediction of a steel sand casting using eq. (3-2)

- Fig. 3.8 Calculated (with eq.3-4) and experimental shrinkage and porosity for a steel casting

- Fig. 3.9 Porosity distribution of a 1.5cm-plate sand casting of Al-4.5% Cu

- Fig. 3.10 Porosity amount versus primary dendrite arm spacing (H₂ - 4×10⁻⁵%)

- Fig. 3.11 Calculated and empirical data of porosity volume versus H₂ content

- Fig. 3.12 The relation between porosity amount and cooling rate, initial H₂ content

- Fig. 4.1 The effect of the three-minute elements on macrostructure

- Fig. 4.2 Microstructure of area A taken from (b) of Fig. 4.1

- Fig. 4.3 The influence of macrostructure on porosity

- Fig. 4.4 Changing of hydrogen content with time

- Fig. 4.5 The influence of P on eutectic composition

- Fig. 4.6 Microstructure of P inclusion (×200)

- Fig. 4.7 Porosity at the land area of a piston

- Fig. 4.8 A gate system with vertical runner and two vertical gates

- Fig. 4.9 Two types of pouring basin

- Fig. 4.10 The shapes of a sprue section

- Fig. 4.11 Inclusion caused by a filter

- Fig. 4.12 Bypass of metal flow when the filter is not well held

- Fig. 4.13 Heat transfer around an iron insert

- Fig. 4.14 Porosity at a metal-insert area

- Fig. 5.1 The influence of calculating instant on the Niyama criterion, G/R¹/² (AC8A)

- Fig. 5.2 The influence of calculating instant on the temperature gradient, G (AC8A)

- Fig. 5.3 The influence of calculating instant on the cooling rate - ①, R (AC8A)

- Fig. 5.4 The influence of calculating instant on the cooling rate - ②, R (AC8A)

- Fig. 5.5 The influence of calculating instant on the Niyama criterion, G/R¹/² (ZDC2)

- Fig. 5.6 The influence of calculating instant on the temperature gradient, G (ZDC2)

- Fig. 5.7 The influence of calculating instant on the cooling rate, R (ZDC2)

- Fig. 5.8 The G/R¹/² values calculated with different cooling rates at fs = 0.8~0.9(AC8A)

- Fig. 5.9 The comparison between the instant and average cooling rate calculated at fs = 0.8~0.9(AC8A)

- Fig. 5.10 The G/R¹/² values calculated with different cooling rates at fs = 0.7~0.85(ZDC2)

- Fig. 5.11 The comparison between the instant and average cooling rate at fs = 0.7~0.85 (ZDC2)

- Fig. 5.12 The influence of element sizes on the Niyama criterion, G/R¹/² (AC8A)

- Fig. 5.13 The influence of heat resistance, Hr on the Niyama criterion, G/R¹/² (AC8A)

- Fig. 5.14 The influence of heat resistance, Hr on the temperature gradient, G (AC8A)

- Fig. 5.15 The influence of heat resistance, Hr on the cooling rate, R (AC8A)

- Fig. 5.16 The influence of heat resistance, Hr and super heat, Sh on the Niyama criterion, G/R¹/² (ZDC2)

- Fig. 5.17 The influence of super heat, Sh on the Niyama criterion, G/R¹/² (AC8A)

- Fig. 5.18 The calculated G, R and G/R¹/² of an infinite plate with one - dimensional heat flow (AC8A)

- Fig. 6.1 Porosity at the ring-carrier area of an Al-alloy piston

- Fig. 6.2 The Niyama criterion value at the land area of a piston

- Fig. 6.3 Porosity at a ring-carrier area (same as Fig. 4.14)

- Fig. 6.4 The mesh model without cooling at the ring-carrier area

- Fig 6.5 Changing of the Niyama criterion G/R¹/² values around a ring-carrier

- Fig. 6.6 The starting and local solidification time of point a1 & b1

- Fig. 6.7 The mesh model with cooling at the ring-carrier area

- Fig. 6.8 The Niyama criterion value at the land area after intensive land cooling

- Fig. 6.9 The influence of local cooling on G, R and G/R¹/² values

- Fig. 6.10 A T-junction

- Fig. 6.11 Simulation 3D model

- Fig. 6.12 The transition of hot spot location with the change of the thickness ratio, D₁/D₀

- Fig. 6.13 The 3D piston model

- Fig. 6.14 Predicted ingate porosity

- Fig. 6.15 The effect of insulating ingate side on ingate porosity

- Fig. 6.16 Ingate porosity optimization aided by computer simulation

- Fig. 6.17 A squeezed cylinder with leakage problem caused by porosity

- Fig. 6.18 Porosity location predicted by simulation (fs = 0.85)

- Fig. 6.19 Porosity location predicted by simulation (fs = 0.25)

- Fig. 6.20 The predicted porosity after reinforcing mold cooling inside the core

- Fig. 6.21 The effect of reinforcing mold-cooling porosity at a hot spot

7. Conclusion:

This research successfully clarifies that porosity defects in Al-Si permanent mold castings can be predicted and reduced through a systematic, scientific approach. Among the available prediction methods, the Niyama criterion is identified as the most practical and popular for its discriminability and ease of verification. The study establishes the critical conditions for its application to Al-alloys, emphasizing the importance of calculating it at the final stage of solidification (fs ≈ 0.8-0.9) using instantaneous thermal parameters.

Furthermore, the paper provides a comprehensive guide to controlling key foundry parameters, including the effects of minute elements, P-inoculation, gating system design, and thermal management. Case studies demonstrate that computer simulation using the validated Niyama criterion is an effective way to diagnose the root cause of porosity and to design and verify countermeasures, such as targeted mold cooling or structural modifications. This data-driven methodology offers a reliable path to avoiding or reducing porosity, moving beyond inefficient trial-and-error practices.

8. References:

- (1) J. A. Eady and D. M. Smith, “The Effect of Porosity on the Tensile Properties of Al-alloy Castings” Mat. Forum, 9(4), 1986, pp217-223.

- (2) M. J. Couper, “Casting Defects and the Fatigue Behavior of an Al-alloy Casting”, Fatigue Fracture Engineering Material Structure, 13 (3), 1990, pp213-227.

- (List continues as per the full paper)

Conclusion & Next Steps

This research provides a valuable roadmap for enhancing quality and reducing defects in Al-Si permanent mold casting. The findings offer a clear, data-driven path toward optimizing casting design and process parameters to mitigate the chronic problem of porosity.

STI C&D is committed to applying cutting-edge industry research to solve our customers’ most challenging technical problems. If the problem discussed in this white paper aligns with your research goals, please contact our engineering team to discuss how we can help you apply these advanced principles to your research.

Expert Q&A:

- Q1: What is the most practical way to predict porosity in Al-Si permanent mold castings according to this research?

- A: The research concludes that the Niyama criterion (G/R¹/²) is the most practical and popular thermal-parameter-based criterion. It is widely integrated into commercial simulation software and is effective for predicting shrinkage and porosity locations. Its significance comes from its direct relationship to G/Vs, a critical parameter that governs the solidification mode. (Supported by findings in Chapter 7, Conclusion 5).

- Q2: The Niyama criterion was developed for steel. Can it really be used for aluminum alloys, and are there any special conditions?

- A: Yes, it can be effectively used for aluminum alloys, but the conditions are critical. The research shows that for Al-alloys, the criterion must be calculated at the moment when an element is in its final stage of solidification (e.g., solid fraction fs = 0.80–0.90). Furthermore, it is crucial to use the instantaneous temperature gradient (Gins) and *instantaneous* cooling rate (Rins) rather than average values covering the whole solidification range. This ensures the calculation accurately reflects the conditions in the last-to-freeze, porosity-prone regions. (Supported by the detailed analysis in Chapter 5 and Conclusion 13).

- Q3: How does a non-aluminum insert, like a ring-carrier in a piston, cause porosity?

- A: The research demonstrates that the insert causes porosity primarily by creating a poor thermal environment. The case study in Section 6.1 shows that the iron ring-carrier has a much lower thermal conductivity than the surrounding aluminum. During solidification, this impedes heat flow, drastically lowering the local temperature gradient (G) in the aluminum adjacent to the insert. This low G value leads to a low Niyama criterion value, indicating a high risk of porosity, even if the area is not the last part of the casting to solidify. (Supported by the data in Figure 6.5 and Figure 6.6).

- Q4: My castings have porosity at the ingate, which is shaped like a T-junction. How can I fix this?

- A: The research provides a specific design rule based on simulation. Porosity at a T-junction ingate occurs when the junction becomes an isolated hot spot. To prevent this, the ingate must be designed to act as a feeder. The simulation results in Section 6.2.1 show that making the ingate thickness (D₁) at least 1.2 times the thickness of the casting section it feeds (D₀) allows the solidification front to progress from the casting into the ingate, eliminating the hot spot at the junction. (Supported by the simulation series in Figure 6.12).

Copyright

- This material is an analysis of the paper "Research on Porosity Defects of Al-Si Alloy Castings Made with Permanent Mold" by MINAMI Rin.

- Source of the paper: Academic Thesis/Paper.

- This material is for informational purposes only. Unauthorized commercial use is prohibited.

- Copyright © 2025 STI C&D. All rights reserved.