The content of this introduction paper is based on the article "Parametrization of the thermal model of induction motor with outer rotor" published by Przegląd Elektrotechniczny.

1. Overview:

- Title: Parametrization of the thermal model of induction motor with outer rotor

- Author: Szczepan Opach, Tomasz Wolnik

- Year of publication: 2023

- Journal/academic society of publication: Przegląd Elektrotechniczny

- Keywords: CFD simulation, thermal model, induction motor, high power density motor

2. Abstract:

This paper presents a method of parameterization of the thermal model of an electric motor on the example of an external rotor induction motor with high power density. The simulations presented in this paper were carried out on the motor model with a copper rotor cage with a rated power 25 kW and a mass of 16 kg. This construction, due to the demanding operating conditions they are subjected to, require precise thermal analysis at the design stage. In many works, this analysis is usually limited to thermal simulations without taking into account the rotating elements of the motor. This article presents a method of numerical determination of selected parameters of the CFD model, including the value of the heat transfer coefficient through the air gap, taking into account the rotational motion of the rotor, the convection coefficient, describing the intensity of convective heat exchange of the outer surface of the rotor body with the environment, and an alternative method of numerical determination of substitute values stator winding thermal conductivity coefficients. Based on the results obtained in numerical simulations, a three-dimensional CFD model of the motor was developed and solved.

3. Introduction:

The development of high-efficiency electric drives with high Specific Power [kW/kg] is a prominent trend. Accurate thermal modeling and simulations are crucial in the design phase of high power density motors, especially induction motors operating under high current loads [12-15 A/mm²] and high supply voltage frequencies [800-1000 Hz]. These conditions expose motor components to negative thermal effects. Computational Fluid Dynamics (CFD) thermal-flow simulations are employed to ascertain the steady-state thermal behavior under various operating conditions and to optimize cooling system efficiency. Developing accurate CFD models requires detailed CAD models, material characteristics (thermal conductivity λ (W/mK), specific heat Cp (J/kgK), material density ρ (kg/m³), dynamic viscosity η (kg/ms), kinematic viscosity ν (m²/s)), and boundary conditions (ambient temperature Ta (°C), coolant flow F (kg/s), inlet temperature Tin (°C) or fluid pressure Pin (bar), natural convection coefficients an (W/m²K), forced convection coefficients af (W/m²K), heat transfer coefficients k (W/m²K), thermal resistances Rt (m²K/W)). Thermal load is defined by power losses ΔP (W) in components like stator winding ΔPcus (W), stator core ΔPFes (W), rotor winding ΔPcur (W), rotor core ΔPFer (W), and mechanical losses ΔPb.

4. Summary of the study:

Background of the research topic:

High power density electric motors, particularly induction motors, are increasingly important, especially in electromobility. These motors operate under demanding conditions that necessitate precise thermal management to ensure reliability and efficiency. Accurate thermal analysis is crucial during the design phase.

Status of previous research:

Traditional thermal analyses often simplify models by neglecting rotating components and employing constant values for convection coefficients. Meshing the air gap in CFD models also presents challenges due to small dimensions relative to the overall motor size, leading to mesh quality issues (Aspect Ratio).

Purpose of the study:

This study aims to develop a parametrized thermal model for a high power density external rotor induction motor, focusing on numerical determination of key parameters for CFD modeling. This includes:

- Heat transfer coefficient kag (W/m²K) through the air gap considering rotor motion.

- Convection coefficient af (W/m²K) for the outer rotor surface.

- Substitute thermal conductivity coefficients Axy, Az (W/mK) for stator windings.

Core study:

The research focuses on numerically determining parameters for a 3D CFD thermal model of a 25kW, 16kg external rotor induction motor with a copper cage, operating at 8000 rpm. The goal is to accurately predict steady-state temperatures of motor components and analyze coolant heat removal efficiency.

5. Research Methodology

Research Design:

The study employs numerical simulations using Computational Fluid Dynamics (CFD) software ANSYS 2021 R2 Fluent. Parametrization of the thermal model was achieved through a series of dedicated numerical experiments to determine crucial heat transfer parameters.

Data Collection and Analysis Methods:

- Heat transfer coefficient through the air gap (kag): A 3D air gap model was created and simulated in ANSYS Fluent to numerically determine the equivalent thermal resistance of the air gap Rtag (m²K/W), considering rotor rotation. Temperatures T1 and T2 were assigned to cylindrical surfaces, and heat flux q (W) was calculated to derive kag and Rtag using Formula (2).

- Forced convection coefficient for the outer surface of the rotor body (af): A 2D model of the rotor and surrounding air was simulated. Numerical simulations for varying temperature differences ΔT and rotational speeds were conducted to determine the unit heat flux ġ (W/m²) and subsequently calculate af using Formula (3).

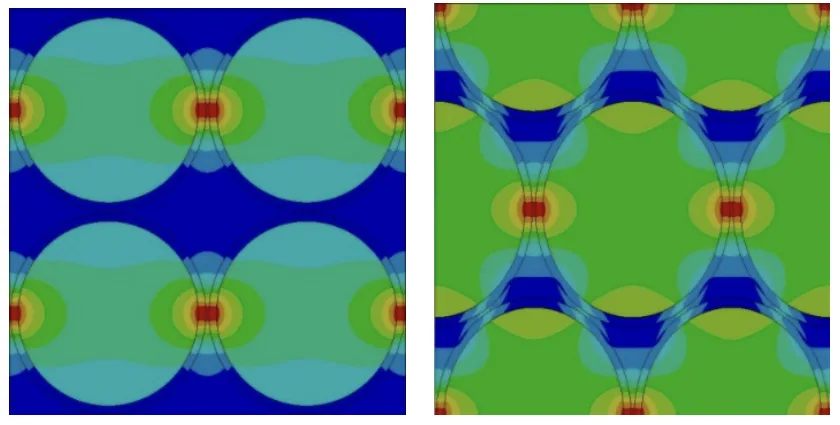

- Equivalent thermal conductivity coefficient of the stator winding in the slot cross-section (Axy): 2D models of stator slots with winding wires arranged in "square" and "triangle" configurations were simulated. Heat flux q (W) for a given temperature difference ΔT was calculated to determine the substitute heat conduction coefficient Axy using Equation (1).

Research Topics and Scope:

The research is focused on an external rotor induction motor with a copper cage designed for high power density applications. The scope includes:

- Numerical determination of air gap heat transfer coefficient considering rotor rotation.

- Numerical determination of forced convection coefficient for the external rotor surface.

- Numerical determination of equivalent thermal conductivity of stator windings.

- Development and solution of a 3D CFD thermal model of the motor.

- Analysis of steady-state temperature distribution and coolant heat removal.

6. Key Results:

Key Results:

- The heat transfer coefficient through the air gap kag was numerically determined, considering rotor motion, and the equivalent thermal resistance of the air gap was found to be Rtag = 0.00773 m²K/W.

- The forced convection coefficient for the outer surface of the rotor body af was numerically determined as 58.43 W/m²K for a rotational speed of 8000 rpm and 32.76 W/m²K for 4000 rpm.

- The equivalent thermal conductivity coefficient of the stator winding in the slot cross-section Axy was determined to be 1.39 W/mK for the "square" configuration with impregnating varnish filling.

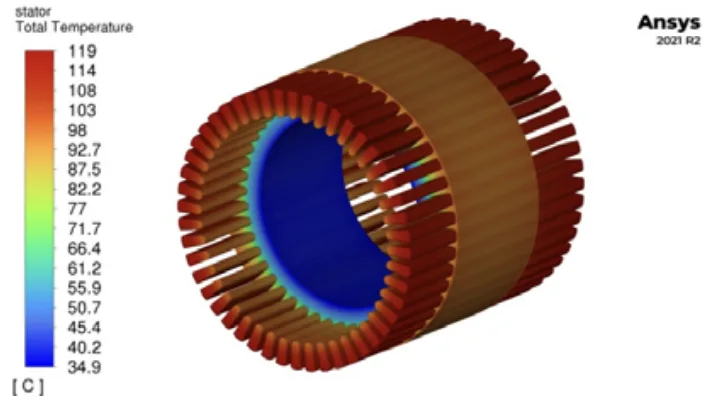

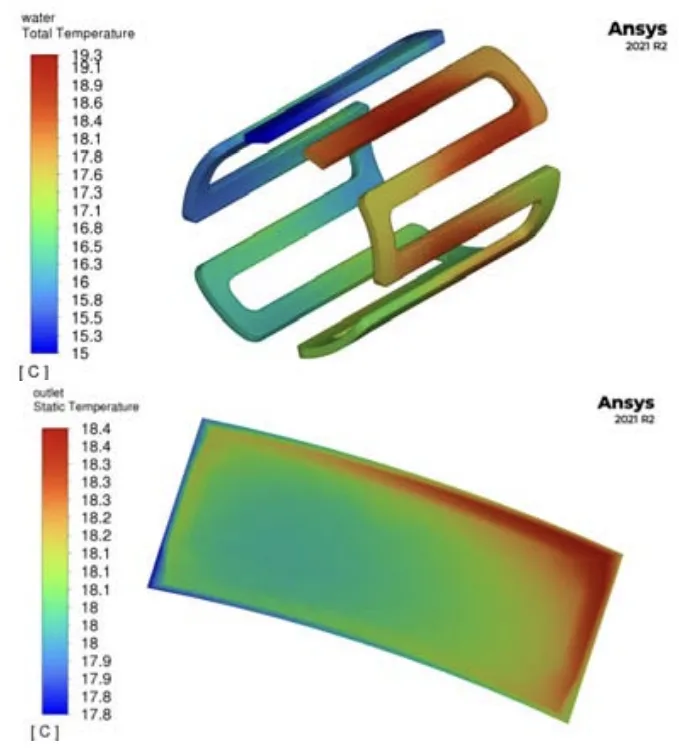

- The 3D CFD model, parametrized with these numerically derived coefficients and thermal resistances (Table 11), was solved to predict the steady-state thermal behavior of the motor (Figures 11-17).

- The temperature increase of the coolant (water) was calculated to be ΔT = 3.1 °C, indicating efficient heat removal by the cooling system.

Figure Name List:

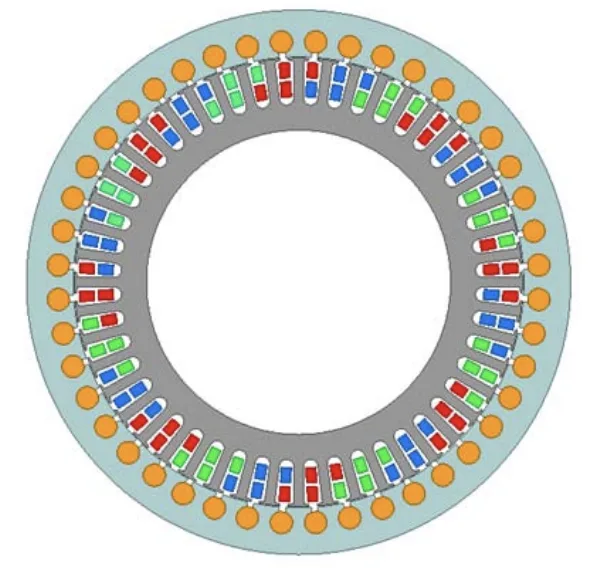

- Fig. 1. Electromagnetic circuit model of an external rotor induction motor.

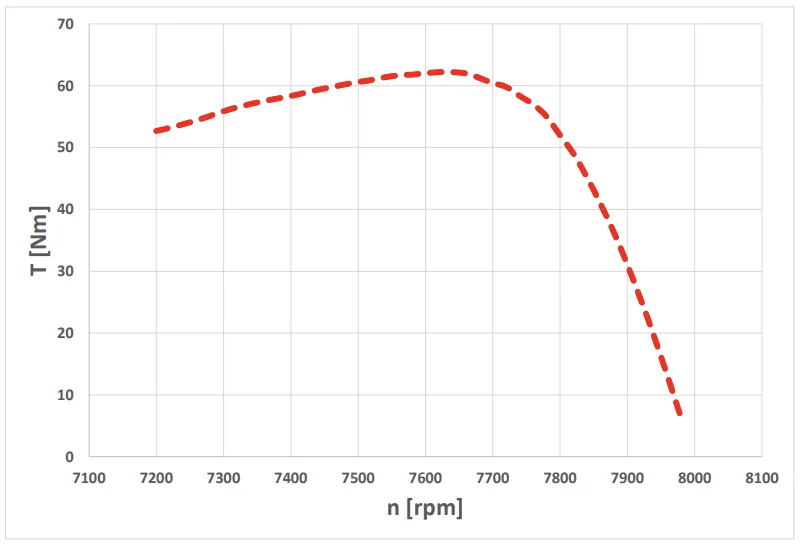

- Fig. 2. Torque vs. rotational speed characteristics.

- Fig. 3. CAD model of an induction motor with an external rotor

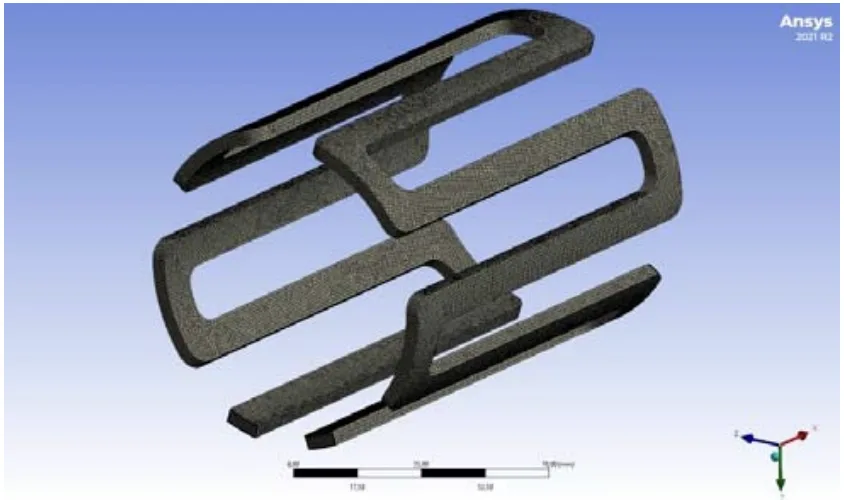

- Fig. 4. Motor model with a finite element mesh in ANSYS software

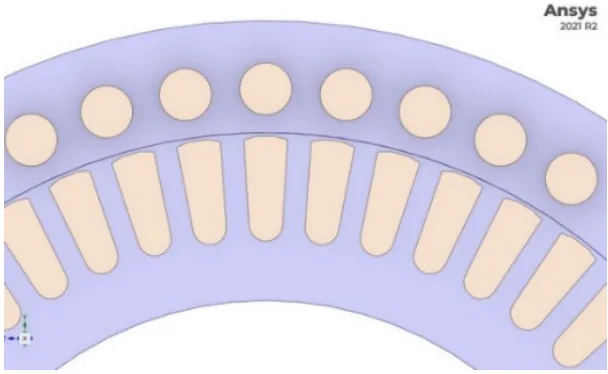

- Fig. 5. Coollant with a finite element mesh in ANSYS software

- Fig. 6. A simplified model of the stator and rotor of the induction motor with the air gap omitted

- Fig. 7. 3D model of an air gap with a finite element mesh in ANSYS

- Fig. 8. Temperature distribution around the rotor for n = 8000 rpm.

- Fig. 9. Temperature distribution in the tested sample in the "square" and "triangle" configuration with filling of the slot with the impregnating varnish

- Fig. 10. Temperature distribution in the tested sample in the "square" and "triangle" configuration with filling of the slot with the air

- Fig. 11. Caluclated thermal steady state in winding and stator core

- Fig. 12. Caluclated thermal steady state in cooper cage

- Fig. 13. Caluclated thermal steady state in rotor core

- Fig. 14. Caluclated thermal steady state in the rotor housing

- Fig. 15. Caluclated thermal steady state in the stator housing

- Fig. 16. Calculated thermal steady state in the shaft and bearings

- Fig. 17. Calculated thermal steady state of coolant (water)

7. Conclusion:

This study successfully presented a method for parameterizing a thermal model of a high power density external rotor induction motor. Numerical methods were employed to determine critical parameters like the heat transfer coefficient through the air gap, the convection coefficient of the outer rotor surface, and the equivalent thermal conductivity of stator windings. These parameters were then utilized to develop and solve a 3D CFD model, enabling accurate prediction of the motor's thermal behavior. The results demonstrate the effectiveness of the proposed approach for detailed thermal analysis of high power density motors, leading to optimized designs and efficient cooling systems.

8. References:

- [1] A. Chiba, K. Kiyota, N. Hoshi, M. Takemoto, and S. Ogasawara, 'Development of a Rare-Earth-Free SR Motor With High Torque Density for Hybrid Vehicles', IEEE Trans. Energy Convers., vol. 30, no. 1, pp. 175-182, Mar. 2015, doi: 10.1109/TEC.2014.2343962.

- [2] M. Morimoto, 'Iron loss of non-rare earth traction motor for electric vehicle', in 2010 IEEE Vehicle Power and Propulsion Conference, Lille, France: IEEE, Sep. 2010, pp. 1-4. doi: 10.1109/VPPC.2010.5729030.

- [3] N. G. Ozcelik, U. E. Dogru, M. Imeryuz, and L. T. Ergene, 'Synchronous Reluctance Motor vs. Induction Motor at Low-Power Industrial Applications: Design and Comparison', Energies, vol. 12, no. 11, p. 2190, Jun. 2019, doi: 10.3390/en12112190.

- [4] J. D. Widmer, R. Martin, and M. Kimiabeigi, 'Electric vehicle traction motors without rare earth magnets', Sustainable Materials and Technologies, vol. 3, pp. 7-13, Apr. 2015, doi: 10.1016/j.susmat.2015.02.001.

- [5] T. Wolnik, P. Dukalski, B. Będkowski, T. Jarek 'Selected aspects of designing motor for direct vehicle wheel drive', Przeglad Elektrotechniczny, vol. 1, no. 4, pp. 152-155, Apr. 2020, doi: 10.15199/48.2020.04.31.

- [6] Y. Xia, Y. Han, Y. Xu, and M. Ai, 'Analyzing Temperature Rise and Fluid Flow of High-Power-Density and High-Voltage Induction Motor in the Starting Process', IEEE Access, vol. 7, pp. 35588-35595, 2019, doi: 10.1109/ACCESS.2019.2899346.

- [7] P. Dukalski and R. Krok, 'Selected Aspects of Decreasing Weight of Motor Dedicated to Wheel Hub Assembly by Increasing Number of Magnetic Poles', Energies, vol. 14, no. 4, p. 917, Feb. 2021, doi: 10.3390/en14040917.

- [8] T. Wolnik, V. Styskala, and T. Micak, 'Study on the Selection of the Number of Magnetic Poles and the Slot-Pole Combinations in Fractional Slot PMSM Motor with a High Power Density', Energies, vol. 15, no. 1, p. 215, Dec. 2021, doi: 10.3390/en15010215.

- [9] J. Madej and B. Będkowski, 'Air flow analysis for electrical motor's cooling system with autodesk simulation CDF 2013 program', Acta Mechanica et Automatica, vol. 7, no. 2, pp. 89-92, Jun. 2013, doi: 10.2478/ama-2013-0016.

- [10] B. Będkowski and J. Madej, 'The innovative design concept of thermal model for the calculation of the electromagnetic circuit of rotating electrical machines', Eksploatacja i Niezawosność, vol. 17, no. 4, pp. 481-486, Sep. 2015, doi: 10.17531/ein.2015.4.1.

- [11] T. Wolnik, 'LEMOK – silnik o dużej gęstości mocy', Maszyny Elektryczne - Zeszyty Problemowe, no. 1(127), 2022, pp. 107-110.

- [12]T. Wolnik, T. Jarek, J. Golec, R. Topolewski, and D. Jastrzębski, 'High Power Density Motor for Light Electric Aircraft – Design Study and Lab Tests', in 2023 IEEE Workshop on Electrical Machines Design, Control and Diagnosis (WEMDCD), Newcastle upon Tyne, United Kingdom: ΙΕΕΕ, Apr. 2023, pp. 1-6. doi: 10.1109/WEMDCD55819.2023.10110934.

- [13] B. Bedkowski, P. Dukalski, T. Jarek, and T. Wolnik, 'Numerical model for thermal calculation analysis of the wheel hub motor for electric car verified by laboratory tests', IOP Conf. Ser.: Mater. Sci. Eng., vol. 710, no. 1, p. 012018, Dec. 2019, doi: 10.1088/1757-899X/710/1/012018.

- [14]P. Dukalski and B. Będkowski, 'Obliczenia cieplne silnika elektrycznego do zabudowy w piaście koła samochodu' Napędy i Sterowanie, vol. 24, no.7/8, pp. 70-76.

- [15]Ł. Cyganik and B. Będkowski, 'Układ mechaniczny przełączania zazębienia pomiędzy silnikiem elektrycznym, przekładnią planetarną oraz piastę koła w napędzie elektrycznym zabudowanym w kole pojazdu' Maszyny Elektryczne - Zeszyty Problemowe, no. 1(127), 2022, pp. 117-122.

- [16] B. Będkowski, J. Madej, 'Wyznaczenie zastępczej rezystancji cieplnej izolacji żłobkowej badania I symulacje Maszyny Elektryczne - Zeszyty Problemowe, 2(106), 2015, pp. 117-122.

- [17]P. Mynarek, 'Zastosowanie metody homogenizacji do wyznaczania współczynnika przewodnictwa cieplnego w silnikach elektrycznych', Przegląd Elektrotechniczny, vol. 1, no. 1, pp. 183-186, Jan. 2017, doi: 10.15199/48.2017.01.44.

- [18]P. Mynarek and M. Kowol, 'Metoda homogenizacji uzwojeń wsypywanych W maszynach elektrycznych' Maszyny Elektryczne - Zeszyty Problemowe, 1(105), 2015, pp. 149-154.

- [19] G. Kondziołka, 'Kryteria doboru syciw oraz lakierów elektroizolacyjnych' Maszyny Elektryczne - Zeszyty Problemowe, 2(102), 2014, pp. 7-10.

- [20]S. Opach, 'Obliczenia wartości zastępczej rezystancji cieplnej szczeliny powietrznej w wirnikowych maszynach elektrycznych, Maszyny Elektryczne - Zeszyty Problemowe, no. 1(127), 2022, pp. 101-105.

- [21]D. A. Howey, P. R. N. Childs, and A. S. Holmes, 'Air-Gap Convection in Rotating Electrical Machines', IEEE Trans. Ind. Electron., vol. 59, no. 3, pp. 1367-1375, Mar. 2012, doi: 10.1109/ΤΙΕ.2010.2100337.

9. Copyright:

- This material is a paper by "Szczepan Opach, Tomasz Wolnik". Based on "Parametrization of the thermal model of induction motor with outer rotor".

- Source of the paper: doi:10.15199/48.2023.12.45

This material is summarized based on the above paper, and unauthorized use for commercial purposes is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.