This article introduces the paper "Research Progress on Thermal Conductivity of High-Pressure Die-Cast Aluminum Alloys" presented at the Metals, MDPI

1. Overview:

- Title: Research Progress on Thermal Conductivity of High-Pressure Die-Cast Aluminum Alloys

- Author: Yixian Liu and Shoumei Xiong

- Publication Year: 2024

- Publishing Journal/Academic Society: Metals, MDPI

- Keywords: high-pressure die casting; aluminum alloy; thermal conductivity; alloy development

![Figure 1. Density and thermal conductivity of several pure metals, adapted from [9-11].](https://castman.co.kr/wp-content/uploads/image-195-1024x751.webp)

2. Research Background:

- Social/Academic Context of the Research Topic: High-pressure die casting (HPDC) is widely used for manufacturing aluminum alloy heat dissipation components in vehicles, electronics, and communication industries. The increasing demand for lightweight and environmentally friendly materials, particularly in the automotive industry to reduce CO2 emissions, has broadened the application of aluminum alloys. Aluminum's excellent thermal conductivity compared to other metals makes it crucial for thermal management, especially in heat dissipation components. The rising power density of electronic devices and increasing battery capacity in electric vehicles further intensifies the need for high-thermal-conductivity aluminum alloys in heat dissipation applications.

- Limitations of Existing Research: While extensive research exists on aluminum alloys, a systematic review specifically focusing on the thermal conductivity of HPDC aluminum alloys is absent. Commercial die-cast aluminum alloys exhibit relatively low thermal conductivity due to rapid cooling rates and unique solidification microstructures inherent in the HPDC process. These microstructures often contain higher solute concentrations, smaller grain sizes, and increased porosity compared to gravity castings, impacting thermal conductivity. Furthermore, alloys with high thermal conductivity often demonstrate low yield strength, indicating a property trade-off.

- Necessity of the Research: The development of non-heat-treatable HPDC aluminum alloys with high thermal conductivity is critical to meet the growing demands for efficient heat dissipation in various industries, especially for advanced applications like Giga-Casting in electric vehicles. A comprehensive review is needed to guide the development of new high-thermal-conductivity die-cast aluminum alloys by summarizing the current research status, including the effects of alloy composition, processing parameters, and heat treatment strategies.

3. Research Purpose and Research Questions:

- Research Purpose: This review aims to provide a comprehensive overview of the research progress on the thermal conductivity of high-pressure die-cast aluminum alloys. It intends to guide the development of new high-thermal-conductivity die-cast aluminum alloys by summarizing key findings and research directions.

- Key Research Questions:

- What are the fundamental mechanisms of heat transport in aluminum alloys, and how do they relate to thermal conductivity?

- What are the common die-cast aluminum alloy systems used for heat dissipation components, and how are their compositions optimized for thermal conductivity?

- How do HPDC processing parameters affect the thermal conductivity of die-cast aluminum alloys?

- What heat treatment strategies can enhance the thermal conductivity of die-cast aluminum alloys?

- What theoretical models are used to calculate and predict the thermal conductivity of die-cast aluminum alloys?

- Research Hypotheses: This paper is a review and does not explicitly state research hypotheses. However, implicitly, the review is based on the understanding that:

- Thermal conductivity of HPDC aluminum alloys can be improved by optimizing alloy composition, processing parameters, and heat treatment.

- Theoretical models can aid in understanding and predicting thermal conductivity in these alloys.

4. Research Methodology

- Research Design: This study is a comprehensive literature review.

- Data Collection Method: The authors collected data by reviewing a wide range of published research articles, journals, and patents related to the thermal conductivity of high-pressure die-cast aluminum alloys.

- Analysis Method: The authors performed a qualitative analysis of the collected literature, summarizing and synthesizing the findings into a structured review. They categorized the research progress based on key aspects such as heat transport mechanisms, alloy systems, processing parameters, heat treatment, and theoretical models.

- Research Subjects and Scope: The review focuses on the research progress related to the thermal conductivity of high-pressure die-cast aluminum alloys. The scope includes:

- Heat transport mechanisms in aluminum alloys.

- Common die-cast aluminum alloy systems (Al-Si and silicon-free).

- Effects of HPDC processing parameters on thermal conductivity.

- Heat treatment strategies for enhancing thermal conductivity.

- Theoretical models for calculating thermal conductivity.

5. Main Research Results:

- Key Research Results:

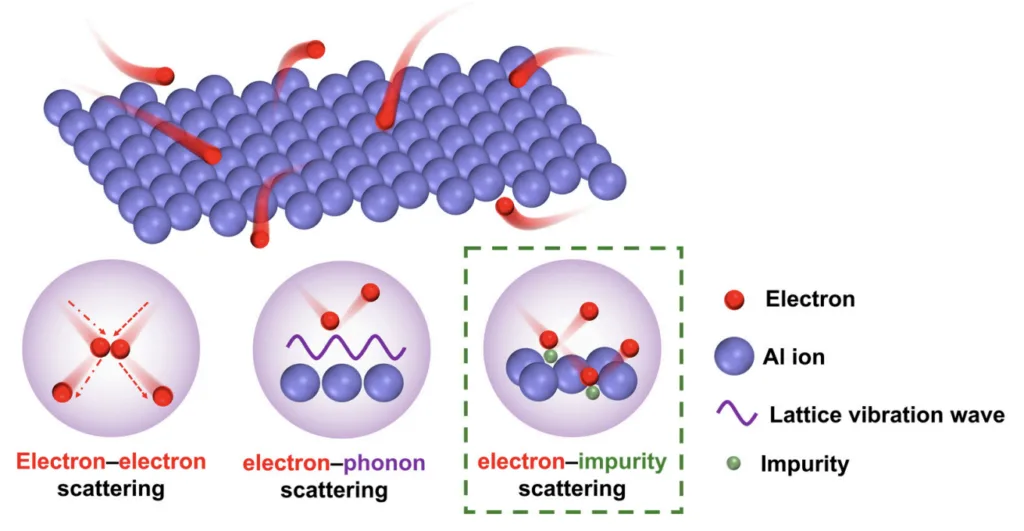

- Heat Transport Mechanism: Heat conduction in aluminum alloys is primarily through electron transport and phonon transport, with electron transport being dominant. Thermal conductivity is influenced by electron scattering mechanisms, including electron-electron, electron-phonon, and electron-impurity scattering. Electron-impurity scattering is particularly significant in alloys.

- Alloy Systems:

- Al-Si Alloys: These are common for heat dissipation components but have limited thermal conductivity due to eutectic silicon and alloying elements. Strategies to improve thermal conductivity include reducing Si content, modifying eutectic particles (e.g., using Sr), and reducing trace elements in solid solutions (e.g., boron treatment).

- Silicon-Free Alloys (Al-Ni, Al-Fe, Al-Fe-Ni): These systems offer higher thermal conductivity potential due to lower eutectic points and reduced detrimental effects of alloying elements compared to Al-Si alloys. Al-Fe and Al-Fe-Ni alloys show promise for achieving very high thermal conductivity.

- Processing Parameters: HPDC processing parameters like shot speed, intensification pressure, and vacuum significantly affect porosity, microstructure, and consequently, thermal conductivity. Increased porosity generally reduces thermal conductivity. Rheological die-casting (ACSR Rheo-HPDC) can improve thermal conductivity by refining microstructure and reducing solute concentration.

- Heat Treatment: Heat treatment, particularly T7, can enhance thermal conductivity by spheroidizing eutectic silicon and precipitating solutes from solid solutions. Direct aging treatment is also explored as a potentially efficient method for die castings.

- Theoretical Models: Various theoretical models, including Matthiessen's rule and composite models (Series, Parallel, Maxwell-Eucken, Effective Medium), are used to predict and understand thermal conductivity in aluminum alloys. However, a model specifically tailored for the complex microstructure of die-cast alloys is needed.

- Statistical/Qualitative Analysis Results: The paper primarily presents a qualitative synthesis of research findings. Quantitative data and results are quoted directly from the referenced papers and summarized in the review. For example, Table 1 shows thermal conductivity and yield strength of commercial die-cast aluminum alloys, and Table 2 shows the effect of alloying elements on electrical resistivity.

- Data Interpretation: The review interprets the data from various studies to identify trends and draw conclusions about the factors influencing thermal conductivity in HPDC aluminum alloys. It highlights the trade-offs between strength and thermal conductivity, the benefits and limitations of different alloy systems and processing techniques, and the potential of heat treatment and theoretical modeling.

- Figure Name List:

- Figure 1. Density and thermal conductivity of several pure metals, adapted from [9-11].

- Figure 2. The process of HPDC: (a) pouring the melt; (b) slow-shot filling; (c) melt at the gate; (d) fast-shot filling; (e) pressure intensification; (f) opening the mold (reprinted with permission from ref. [16], Xiaobo Li, Tsinghua Univeristy, 2017).

- Figure 3. Applications of HPDC heat dissipation components.

- Figure 4. The solidification rate of die casting (reprinted with permission from ref. [22], 2022, Elsevier).

- Figure 5. Electron scattering patterns in an aluminum alloy.

- Figure 6. The effect of alloying elements on (a) electrical conductivity (reprinted with permission from ref. [62], 2006, Elsevier) and thermal conductivity using (b) theoretical method (reprinted with permission from ref. [58], 2023, Springer) and (c) experimental method of aluminum alloys (reprinted with permission from ref. [64], 2015, Springer).

- Figure 7. Problems of traditional Al-Si die-cast alloys.

- Figure 8. Microstructure and properties of different Al-Si die-cast alloys with low Si contents: (a) Al-8Si (reprinted with permission from ref. [74], 2018, Elsevier), (b) Al–6Si with Cu and Zn (reprinted with permission from ref. [75], 2016, Springer), (c) Al–(6~8)Si with Cu or Mg (reprinted with permission from ref. [80], 2022, Elsevier).

- Figure 9. The ternary eutectic point of the Al-Si-Ni system (reprinted with permission from ref. [84], 2015, Springer).

- Figure 10. (a) Effect of Mn on thermal conductivity of the die-cast Al-Si alloy (reprinted with permission from ref. [61], 2013, Springer). (b) The purification process of boron treatment (reprinted with permission from ref. [91], 2018, Elsevier) and (c) the effect of boron on the thermal conductivity of ADC12 alloy (reprinted ref. [95]).

- Figure 11. (a,b) Mechanism of improving thermal conductivity by modifying the eutectic Si (reprinted with permission from ref. [24], 2020, Springer).

- Figure 12. (a) Variation in thermal conductivity under different fractions of porosity caused by processing parameters (reprinted with permission from ref. [123], 2017, Elsevier). (b) Thermal conductivity and corresponding (c) porosity distribution under different vacuum levels (reprinted with permission from ref. [124], 2020, Elsevier). (d) Distribution of ESCs and (e) thermal conductivity of die-cast alloys under different shot sleeves (reprinted with permission from ref. [125], 2022, Elsevier).

- Figure 13. The schematic diagrams of the ACSR Rheo-HPDC process (reprinted with permission from ref. [36], 2022, Elsevier).

![Figure 2. The process of HPDC: (a) pouring the melt; (b) slow-shot filling; (c) melt at the gate; (d) fast-shot filling; (e) pressure intensification; (f) opening the mold (reprinted with permission from ref. [16], Xiaobo Li, Tsinghua Univeristy, 2017).](https://castman.co.kr/wp-content/uploads/image-196-1024x632.webp)

![Figure 4. The solidification rate of die casting (reprinted with permission from ref. [22], 2022, Elsevier).](https://castman.co.kr/wp-content/uploads/image-197-1024x590.webp)

![Figure 8. Microstructure and properties of different Al-Si die-cast alloys with low Si contents: (a) Al-8Si (reprinted with permission from ref. [74], 2018, Elsevier), (b) Al–6Si with Cu and Zn (reprinted with permission from ref. [75], 2016, Springer), (c) Al–(6~8)Si with Cu or Mg (reprinted with permission from ref. [80], 2022, Elsevier).](https://castman.co.kr/wp-content/uploads/image-199-1024x362.webp)

![Figure 10. (a) Effect of Mn on thermal conductivity of the die-cast Al-Si alloy (reprinted with permission from ref. [61], 2013, Springer). (b) The purification process of boron treatment (reprinted with permission from ref. [91], 2018, Elsevier) and (c) the effect of boron on the thermal conductivity of ADC12 alloy (reprinted ref. [95]).](https://castman.co.kr/wp-content/uploads/image-200-1024x451.webp)

![Figure 13. The schematic diagrams of the ACSR Rheo-HPDC process (reprinted with permission from ref. [36], 2022, Elsevier).](https://castman.co.kr/wp-content/uploads/image-201-853x1024.webp)

6. Conclusion and Discussion:

- Summary of Main Results: The review concludes that while significant progress has been made in developing high-thermal-conductivity die-cast aluminum alloys, challenges remain. Al-Si alloys are still dominant but require modifications to enhance thermal conductivity. Silicon-free alloys like Al-Ni and Al-Fe show great potential but need further research, especially under die-casting conditions, to optimize microstructure and mechanical properties alongside thermal conductivity. Processing parameters and heat treatments are crucial tools for tailoring alloy properties. Theoretical models are evolving but need to be refined for die-cast alloys' complex microstructures.

- Academic Significance of the Research: This review provides a valuable resource for researchers and engineers in the field of die casting and aluminum alloys. It systematically summarizes the current state of knowledge, identifies research gaps, and highlights promising directions for future research. It emphasizes the need for deeper understanding of phonon thermal conductivity in alloys and the microstructure-thermal conductivity relationship in die-cast conditions.

- Practical Implications: The findings have significant practical implications for the die casting industry. The review guides the development of new aluminum alloys with enhanced thermal conductivity for heat dissipation applications. It underscores the importance of optimizing alloy composition, processing parameters (including vacuum and rheological die-casting), and heat treatment strategies to achieve high-performance die-cast components. The insights into silicon-free alloys offer pathways for developing next-generation high-conductivity materials.

- Limitations of the Research: The review primarily focuses on published literature. The authors acknowledge that the understanding of the effect of processing parameters on microstructure and thermal conductivity is still incomplete. Furthermore, the review notes that research on die-cast alloys is less extensive compared to gravity-cast alloys, indicating a need for more focused studies on die-cast materials. The complexity of microstructure formation during die casting and the lack of a comprehensive theoretical model for die-cast alloys are also limitations.

7. Future Follow-up Research:

- Directions for Follow-up Research:

- Further in-depth studies on the relationship between phonon thermal conductivity and alloy compositions in aluminum alloys.

- More research on silicon-free HPDC aluminum alloys (Al-Ni, Al-Fe, Al-Fe-Ni) under die-casting conditions, focusing on microstructure control and mechanical property optimization.

- Systematical investigations into the definite influence relationships between HPDC processing parameters and thermal conductivity, including solute content, eutectic modification, and porosity.

- Exploration of direct aging treatment for die-cast alloys to improve comprehensive properties efficiently.

- Development of a new thermal conductivity calculation model specifically designed for the complex microstructures of die-cast alloys.

- Areas Requiring Further Exploration:

- Optimizing processing parameters for die-cast alloys with high thermal conductivity using advanced simulation software.

- Improving the mechanical properties (strength, castability) of high-thermal-conductivity die-cast aluminum alloys to meet industrial application requirements.

- Investigating the long-term performance and reliability of new high-thermal-conductivity die-cast aluminum alloys in real-world applications.

8. References:

- Sun, Y. The Use of Aluminum Alloys in Structures: Review and Outlook. Structures 2023, 57, 105290. [CrossRef]

- You, X.; Xing, Z.; Jiang, S.; Zhu, Y.; Lin, Y.; Qiu, H.; Nie, R.; Yang, J.; Hui, D.; Chen, W.; et al. A Review of Research on Aluminum Alloy Materials in Structural Engineering. Dev. Built Environ. 2024, 17, 100319. [CrossRef]

- Mondolfo, L.F. Aluminium Alloys: Structure and Properties, 2nd ed.; Butterworths: London, UK, 1979; ISBN 978-0-408-70932-3.

- Aluminium Applications—Construction. Available online: https://aluminiumleader.com/application/construction/ (accessed on 7 January 2024).

- Yaroshevsky, A.A. Abundances of Chemical Elements in the Earth’s Crust. Geochem. Int. 2006, 44, 48–55. [CrossRef]

- Bhagtani, P.; Bichler, L.; Bardelcik, A.; Elsayed, A. Modeling Thermal Conductivity of Al-Ni, Al-Fe, and Al-Co Spark Plasma Sintered Alloys. J. Mater. Eng. Perform. 2023, 32, 6821–6832. [CrossRef]

- Hirsch, J. Recent Development in Aluminium for Automotive Applications. Trans. Nonferrous Met. Soc. China 2014, 24, 1995–2002. [CrossRef]

- Markaustin Aluminium—The Green Metal. Available online: https://www.hazlemerecommercial.co.uk/blog/aluminium-the-green-metal/2012/04/ (accessed on 7 January 2024).

- Mills, K.C. Recommended Values of Thermophysical Properties for Selected Commercial Alloys; Woodhead: Cambridge, UK, 2002; ISBN 978-1-85573-569-9.

- Klemens, P.G. Thermal Conductivity of Pure Metals and Alloys; Springer: Berlin/Heidelberg, Germany, 1991.

- Haynes, W.M. CRC Handbook of Chemistry and Physics, 96th ed.; CRC Press: Boca Raton, FL, USA, 2015.

- Jiao, X.Y.; Wang, P.Y.; Liu, Y.X.; Wang, J.; Liu, W.N.; Wan, A.X.; Shi, L.J.; Wang, C.G.; Xiong, S.M. Fracture Behavior of a High Pressure Die Casting AlSi10MnMg Alloy with Varied Porosity Levels. J. Mater. Res. Technol. 2023, 25, 1129–1140. [CrossRef]

- Chen, Z.W. Formation and Progression of Die Soldering during High Pressure Die Casting. Mater. Sci. Eng. A 2005, 397, 356–369. [CrossRef]

- Hu, L.; Chen, S.; Miao, Y.; Meng, Q. Die-Casting Effect on Surface Characteristics of Thin-Walled AZ91D Magnesium Components. Appl. Surf. Sci. 2012, 261, 851–856. [CrossRef]

- Kang, C.G.; Lee, S.M.; Kim, B.-M. A Study of Die Design of Semi-Solid Die Casting According to Gate Shape and Solid Fraction. J. Mater. Process. Technol. 2008, 204, 8–21. [CrossRef]

- Li, X. Study on Externally Solidified Crystals and Their Relationship with the Defects and Mechanical Properties of High Pressure Die Cast Magnesium Alloys. Ph.D. Thesis, Tsinghua University, Beijing, China, 2017.

- Liu, W.; Zhang, W.; Wang, P.; Liu, Y.; Jiao, X.; Wan, A.; Wang, C.; Tong, G.; Xiong, S. Effect of Slow Shot Speed on Externally Solidified Crystal, Porosity and Tensile Property in a Newly Developed High-Pressure Die-Cast Al-Si Alloy. China Foundry 2023, 21, 11–19. [CrossRef]

- Jiao, X.Y.; Wang, J.; Liu, C.; Guo, Z.; Wang, J.; Wang, Z.; Gao, J.; Xiong, S.M. Influence of Slow-Shot Speed on PSPs and Porosity of AlSi17Cu2.5 Alloy during High Pressure Die Casting. J. Mater. Process. Technol. 2019, 268, 63–69. [CrossRef]

- Jiao, X.Y.; Liu, C.F.; Guo, Z.P.; Nishat, H.; Tong, G.D.; Ma, S.L.; Bi, Y.; Zhang, Y.F.; Wiesner, S.; Xiong, S.M. On the Characterization of Primary Iron-Rich Phase in a High-Pressure Die-Cast Hypoeutectic Al-Si Alloy. J. Alloys Compd. 2021, 862, 158580. [CrossRef]

- Li, X.-B.; Xiong, S.-M.; Guo, Z.-P. Characterization of the Grain Structures in Vacuum-Assist High-Pressure Die Casting AM60B Alloy. Acta Metall. Sin. Engl. Lett. 2016, 29, 619–628. [CrossRef]

- Guo, Z.-P.; Xiong, S.-M.; Liu, B.-C.; Li, M.; Allison, J. Effect of Process Parameters, Casting Thickness, and Alloys on the Interfacial Heat-Transfer Coefficient in the High-Pressure Die-Casting Process. Metall. Mater. Trans. A 2008, 39, 2896–2905. [CrossRef]

- Luo, A.A.; Sachdev, A.K.; Apelian, D. Alloy Development and Process Innovations for Light Metals Casting. J. Mater. Process. Technol. 2022, 306, 117606. [CrossRef]

- Li, X.; Xiong, S.M.; Guo, Z. Improved Mechanical Properties in Vacuum-Assist High-Pressure Die Casting of AZ91D Alloy. J. Mater. Process. Technol. 2016, 231, 1–7. [CrossRef]

- Gan, J.; Huang, Y.; Wen, C.; Du, J. Effect of Sr Modification on Microstructure and Thermal Conductivity of Hypoeutectic Al–Si Alloys. Trans. Nonferrous Met. Soc. China 2020, 30, 2879–2890. [CrossRef]

- Families of Alloys—RHEINFELDEN ALLOYS. Available online: https://rheinfelden-alloys.eu/en/alloys/ (accessed on 7 January 2024).

- Wang, Y.; Kang, H.; Guo, Y.; Chen, H.; Hu, M.; Ji, Z. Design and Preparation of Aluminum Alloy with High Thermal Conductivity Based on CALPHAD and First-Principles Calculation. China Foundry 2022, 19, 225–237. [CrossRef]

- Li, T.; Song, J.; Zhang, A.; You, G.; Yang, Y.; Jiang, B.; Qin, X.; Xu, C.; Pan, F. Progress and Prospects in Mg-Alloy Super-Sized High Pressure Die Casting for Automotive Structural Components. J. Magnes. Alloys 2023, 11, 4166–4180. [CrossRef]

- Li, Y.; Chen, J.; Agrawal, P.; Feng, Z. Microstructure and Mechanical Properties of Ultrasonic Spot Welding of AA7075-T6 and A380 Casting Aluminum Alloy. J. Manuf. Process. 2024, 110, 126–133. [CrossRef]

- Liu, W.; Zhao, C.; Kishita, Y.; Wan, A.; Peng, T.; Umeda, Y. Scenario Analysis on Carbon Peaking Pathways for China’s Aluminum Casting Industry. J. Clean. Prod. 2023, 422, 138571. [CrossRef]

- Technology—Mega-Casting—AMS January-March 2022. Available online: https://automotivemanufacturingsolutions.h5mag.com/ams_january-march_2022/technology_mega-casting (accessed on 9 January 2024).

- Toyota Showcases Its Own Giga Casting in a Bid to Lower EV Costs. Available online: https://insideevs.com/news/671943/toyota-giga-casting/ (accessed on 9 January 2024).

- VW’s Project Trinity to Use Giga-Casting & Automation to Compete with Tesla. Available online: https://insideevs.com/news/577128/volkwagen-compete-tesla-gigapress-robots/ (accessed on 9 January 2024).

- Sharma, A.; Morisada, Y.; Fujii, H. Influence of Aluminium-Rich Intermetallics on Microstructure Evolution and Mechanical Properties of Friction Stir Alloyed Al Fe Alloy System. J. Manuf. Process. 2021, 68, 668–682. [CrossRef]

- Li, Y.; Hu, A.; Fu, Y.; Liu, S.; Shen, W.; Hu, H.; Nie, X. Al Alloys and Casting Processes for Induction Motor Applications in Battery-Powered Electric Vehicles: A Review. Metals 2022, 12, 216. [CrossRef]

- Jiao, X.Y.; Wang, J.; Liu, C.F.; Guo, Z.P.; Tong, G.D.; Ma, S.L.; Bi, Y.; Zhang, Y.F.; Xiong, S.M. Characterization of High-Pressure Die-Cast Hypereutectic Al-Si Alloys Based on Microstructural Distribution and Fracture Morphology. J. Mater. Sci. Technol. 2019, 35, 1099–1107. [CrossRef]

- Qi, M.; Kang, Y.; Xu, Y.; Wulabieke, Z.; Li, J. A Novel Rheological High Pressure Die-Casting Process for Preparing Large Thin-Walled Al-Si-Fe-Mg-Sr Alloy with High Heat Conductivity, High Plasticity and Medium Strength. Mater. Sci. Eng. A 2020, 776, 139040. [CrossRef]

- ADC12 Aluminum A383 | Equivalent Materials & Metal Specifications. Available online: https://redstonemanufacturing.com/adc12-aluminum/ (accessed on 9 January 2024).

- Aluminium Alloy A380 properties | OEFORM. Available online: https://oeform.com/die-cast-aluminium-alloy-a380-properties/ (accessed on 9 January 2024).

- A360 Aluminum Properties | Die Cast Materials. Available online: https://www.dynacast.com/en/knowledge-center/material-information/aluminum-die-casting-metals/a360 (accessed on 9 January 2024).

- 384.0 (384.0-F, SC114A, A03840) Cast Aluminum: MakeItFrom.Com. Available online: https://www.makeitfrom.com/material-properties/384.0-384.0-F-SC114A-A03840-Cast-Aluminum (accessed on 9 January 2024).

- Aluminum Alloy 413 Properties | Aluminum Die Casting. Available online: https://www.dynacast.com/en/knowledge-center/material-information/aluminum-die-casting-metals/413 (accessed on 9 January 2024).

- Etxandi-Santolaya, M.; Canals Casals, L.; Corchero, C. Estimation of Electric Vehicle Battery Capacity Requirements Based on Synthetic Cycles. Transp. Res. Part Transp. Environ. 2023, 114, 103545. [CrossRef]

- Ma, S.; Jiang, M.; Tao, P.; Song, C.; Wu, J.; Wang, J.; Deng, T.; Shang, W. Temperature Effect and Thermal Impact in Lithium-Ion Batteries: A Review. Prog. Nat. Sci. Mater. Int. 2018, 28, 653–666. [CrossRef]

- Hardesty, L. 5G Base Stations Use a Lot More Energy than 4G Base Stations: MTN | Fierce Wireless. Available online: https://www.fiercewireless.com/tech/5g-base-stations-use-a-lot-more-energy-than-4g-base-stations-says-mtn (accessed on 10 January 2024).

- Solkin, M. Electromagnetic Interference Hazards in Flight and the 5G Mobile Phone: Review of Critical Issues in Aviation Security. Transp. Res. Procedia 2021, 59, 310–318. [CrossRef]

- Chou, D. Infrastructure. In Practical Guide to Clinical Computing Systems; Elsevier: Amsterdam, The Netherlands, 2015; pp. 39–70. ISBN 978-0-12-420217-7.

- Yuan, Z.; Guo, Z.; Xiong, S. Microstructure Evolution of Modified Die-Cast AlSi10MnMg Alloy during Solution Treatment and Its Effect on Mechanical Properties. Trans. Nonferrous Met. Soc. China 2019, 29, 919–930. [CrossRef]

- Yuan, Z.; Guo, Z.; Xiong, S.M. Effect of As-Cast Microstructure Heterogeneity on Aging Behavior of a High-Pressure Die-Cast A380 Alloy. Mater. Charact. 2018, 135, 278–286. [CrossRef]

- Li, S.; Yang, X.; Hou, J.; Du, W. A Review on Thermal Conductivity of Magnesium and Its Alloys. J. Magnes. Alloys 2020, 8, 78–90. [CrossRef]

- Tritt, T.M. Thermal Conductivity: Theory, Properties, and Applications; Physics of solids and liquids; Springer: New York, NY, USA, 2004; ISBN 978-0-306-48327-1.

- Wen, C.; Gan, J.; Li, C.; Huang, Y.; Du, J. Comparative Study on Relationship between Modification of Si Phase and Thermal Conductivity of Al-7Si Alloy Modified by Sr/RE/B/Sb Elements. Int. J. Met. 2021, 15, 194–205. [CrossRef]

- Huang, Y.Y.; Hu, Z.L.; Wang, J.J. Research Progress on the Aluminum Alloy with High Thermal Conductivity. Appl. Mech. Mater. 2014, 574, 396–400. [CrossRef]

- Stojanovic, N.; Maithripala, D.H.S.; Berg, J.M.; Holtz, M. Thermal Conductivity in Metallic Nanostructures at High Temperature: Electrons, Phonons, and the Wiedemann-Franz Law. Phys. Rev. B 2010, 82, 075418. [CrossRef]

- Han, S.; Dai, S.; Ma, J.; Ren, Q.; Hu, C.; Gao, Z.; Duc Le, M.; Sheptyakov, D.; Miao, P.; Torii, S.; et al. Strong Phonon Softening and Avoided Crossing in Aliovalence-Doped Heavy-Band Thermoelectrics. Nat. Phys. 2023, 19, 1649–1657. [CrossRef]

- Luckyanova, M.N.; Mendoza, J.; Lu, H.; Song, B.; Huang, S.; Zhou, J.; Li, M.; Dong, Y.; Zhou, H.; Garlow, J.; et al. Phonon Localization in Heat Conduction. Sci. Adv. 2018, 4, eaat9460. [CrossRef] [PubMed]

- Cook, J.G.; Moore, J.P.; Matsumura, T.; Van Der Meer, M.P. The Thermal and Electrical Conductivity of Aluminum. In Thermal Conductivity 14; Klemens, P.G., Chu, T.K., Eds.; Springer: Boston, MA, USA, 1976; pp. 65–71. ISBN 978-1-4899-3753-7.

- Klemens, P.G.; Williams, R.K. Thermal Conductivity of Metals and Alloys. Int. Met. Rev. 1986, 31, 197–215. [CrossRef]

- Zhang, A.; Li, Y. Effect of Alloying Elements on Thermal Conductivity of Aluminum. J. Mater. Res. 2023, 38, 2049–2058. [CrossRef]

- Lumley, R.N. Fundamentals of Aluminium Metallurgy; Woodhead Publishing: Cambridge, UK, 2018; ISBN 978-0-08-102063-0.

- Olafsson, P.; Sandstrom, R.; Karlsson, Å. Comparison of Experimental, Calculated and Observed Values for Electrical and Thermal Conductivity of Aluminium Alloys. J. Mater. Sci. 1997, 32, 4383–4390. [CrossRef]

- Lumley, R.N.; Deeva, N.; Larsen, R.; Gembarovic, J.; Freeman, J. The Role of Alloy Composition and T7 Heat Treatment in Enhancing Thermal Conductivity of Aluminum High Pressure Diecastings. Metall. Mater. Trans. A 2013, 44, 1074–1086. [CrossRef]

- Karabay, S. Modification of AA-6201 Alloy for Manufacturing of High Conductivity and Extra High Conductivity Wires with Property of High Tensile Stress after Artificial Aging Heat Treatment for All-Aluminium Alloy Conductors. Mater. Des. 2006, 27, 821–832. [CrossRef]

- Jing, L.; Cheng, W.; Gan, J. Influencing Mechanisms of Alloying Elements on the Electrical Conductivity of Pure Aluminum. Mater. Rep. 2021, 35, 24101–24106. [CrossRef]

- Chen, J.K.; Hung, H.Y.; Wang, C.F.; Tang, N.K. Thermal and Electrical Conductivity in Al–Si/Cu/Fe/Mg Binary and Ternary Al Alloys. J. Mater. Sci. 2015, 50, 5630–5639. [CrossRef]

- Ashiri, R.; Karimzadeh, F.; Niroumand, B. On Effect of Squeezing Pressure on Microstructural Characteristics, Heat Treatment Response and Electrical Conductivity of an Al-Si-Mg-Ni-Cu Alloy. Mater. Sci. Technol. 2014, 30, 1162–1169. [CrossRef]

- Jiao, X.Y.; Liu, Y.X.; Wang, J.; Liu, W.N.; Wan, A.X.; Wiesner, S.; Xiong, S.M. The Microstructure Characteristics and Fracture Behavior of the Polyhedral Primary Iron-Rich Phase and Plate-Shaped Eutectic Iron-Rich Phase in a High-Pressure Die-Cast AlSi10MnMg Alloy. J. Mater. Sci. Technol. 2023, 140, 201–209. [CrossRef]

- Jiao, X.Y.; Zhang, W.; Liu, Y.X.; Wang, J.; Liu, W.N.; Wan, A.X.; Hu, Y.Y.; Tong, G.D.; Xiong, S.M. The Characterization of Porosity and Its Relationship with Externally Solidified Crystal in a High-Pressure Die-Cast AlSi10MnMg Alloy via a Laboratory CT Technique. Mater. Lett. 2023, 335, 133807. [CrossRef]

- Cingi, C.; Rauta, V.; Suikkanen, E.; Orkas, J. Effect of Heat Treatment on Thermal Conductivity of Aluminum Die Casting Alloys. Adv. Mater. Res. 2012, 538–541, 2047–2052. [CrossRef]

- Jiao, X.Y.; Zhang, Y.F.; Wang, J.; Nishat, H.; Liu, Y.X.; Liu, W.N.; Chen, H.X.; Xiong, S.M. Characterization of Externally Solidified Crystals in a High-Pressure Die-Cast AlSi10MnMg Alloy and Their Effect on Porosities and Mechanical Properties. J. Mater. Process. Technol. 2021, 298, 117299. [CrossRef]

- Lin, S.; Dang, J.; Wang, Z.; Sun, Y.; Xiang, Y. Enhanced Strength and Toughness in Al-Mg-Si Alloys with Addition of Cr, Mn, and Cu Elements. J. Mater. Eng. Perform. 2023, 32, 1039–1050. [CrossRef]

- Cui, X. Research on the Influence Mechanisms of Melt Complex Boron Treatment and Second Phases Morphological Evolution on Electrical Conductively of Aluminum Alloys. Ph.D. Thesis, Shandong University, Jinan, China, 2016.

- Qin, Y.; Yan, Z.; Wu, Q.; Jiang, A.; Li, Y.; Ma, S.; Lü, S.; Li, J. Development of a Novel High Strength Al-Si-Cu-Ni Alloy by Combining Micro-Alloying and Squeeze Casting. J. Alloys Compd. 2023, 967, 171780. [CrossRef]

- Zhai, W.; Sun, H.; Sun, L.; Zhao, Q.; Liu, Y.; Wang, Y.; Pu, B.; Zhang, B.; Wang, S. Influence of Cu Content on Mechanical and Tribological Properties of Al-7Si-Cu Alloy. J. Mater. Res. Technol. 2023, 26, 4848–4859. [CrossRef]

- Qi, M.; Kang, Y.; Qiu, Q.; Tang, W.; Li, J.; Li, B. Microstructures, Mechanical Properties, and Corrosion Behavior of Novel High-Thermal-Conductivity Hypoeutectic Al-Si Alloys Prepared by Rheological High Pressure Die-Casting and High Pressure Die-Casting. J. Alloys Compd. 2018, 749, 487–502. [CrossRef]

- Payandeh, M.; Sjölander, E.; Jarfors, A.E.W.; Wessén, M. Influence of Microstructure and Heat Treatment on Thermal Conductivity of Rheocast and Liquid Die Cast Al-6Si-2Cu-Zn Alloy. Int. J. Cast Met. Res. 2016, 29, 202–213. [CrossRef]

- Jang, J.-C.; Shin, K.S. Effects of Ni and Cu Addition on Tensile Properties and Thermal Conductivity of High Pressure Die-cast Al-6Si Alloys. Korean J. Met. Mater. 2020, 58, 217–226. [CrossRef]

- Samuel, A.M.; Gauthier, J.; Samuel, F.H. Microstructural Aspects of the Dissolution and Melting of Al2Cu Phase in Al-Si Alloys during Solution Heat Treatment. Metall. Mater. Trans. A 1996, 27, 1785–1798. [CrossRef]

- Choi, S.W.; Cho, H.S.; Kumai, S. Effect of the Precipitation of Secondary Phases on the Thermal Diffusivity and Thermal Conductivity of Al-4.5Cu Alloy. J. Alloys Compd. 2016, 688, 897–902. [CrossRef]

- Vandersluis, E.; Ravindran, C. Effects of Solution Heat Treatment Time on the As-Quenched Microstructure, Hardness and Electrical Conductivity of B319 Aluminum Alloy. J. Alloys Compd. 2020, 838, 155577. [CrossRef]

- Kumar, L.; Jang, J.C.; Yu, H.; Shin, K.S. Effect of Secondary Phase on Mechanical and Thermal Conductivity of Al-Si-xFe-Mg-yCu-Mn Die Casting Alloys. Mater. Lett. 2022, 314, 131889. [CrossRef]

- Kumar, L.; Jang, J.C.; Yu, H.; Shin, K.S. Effects of Cr and Ti Addition on Mechanical Properties and Thermal Conductivity of Al-7Si-3Mg Die-Casting Alloys. Met. Mater. Int. 2023, 29, 204–214. [CrossRef]

- Kim, C.W.; Cho, J.I.; Choi, S.W.; Kim, Y.C. The Effect of Alloying Elements on Thermal Conductivity of Aluminum Alloys in High Pressure Die Casting. Adv. Mater. Res. 2013, 813, 175–178. [CrossRef]

- Kim, C.-W.; Kim, Y.-C.; Kim, J.-H.; Cho, J.-I.; Oh, M.-S. Effect of Alloying Elements on the Thermal Conductivity and Casting Characteristics of Aluminum Alloys in High Pressure Die Casting. Korean J. Met. Mater. 2018, 56, 805–812. [CrossRef]

- Cho, Y.H.; Kim, H.W.; Lee, J.M.; Kim, M.S. A New Approach to the Design of a Low Si-Added Al-Si Casting Alloy for Optimising Thermal Conductivity and Fluidity. J. Mater. Sci. 2015, 50, 7271–7281. [CrossRef]

- Becker, H.; Bergh, T.; Vullum, P.E.; Leineweber, A.; Li, Y. β- and δ-Al-Fe-Si Intermetallic Phase, Their Intergrowth and Polytype Formation. J. Alloys Compd. 2019, 780, 917–929. [CrossRef]

- Becker, H.; Bergh, T.; Vullum, P.E.; Leineweber, A.; Li, Y. Effect of Mn and Cooling Rates on α-, β- and δ-Al–Fe–Si Intermetallic Phase Formation in a Secondary Al-Si Alloy. Materialia 2019, 5, 100198. [CrossRef]

- Zhao, J.; Guo, Y.; Xu, B.; Gu, C.; Wang, Y.; Tang, Q. Effect of Microstructure Evolution of Iron-Rich Intermetallic Compounds on Mechanical Property of Al-7Si-0.3Mg Casting Alloy with Low Iron Content. Metall. Mater. Trans. B 2022, 53, 548–560. [CrossRef]

- Wang, M.; Hu, K.; Liu, G.; Liu, X. Synchronous Improvement of Electrical and Mechanical Performance of A356 Alloy Reinforced by Boron Coupling Nano-AlNp. J. Alloys Compd. 2020, 814, 152217. [CrossRef]

- Ye, H.; Cui, X.; Cui, H.; Li, X.; Zhu, Z.; Pan, Y.; Feng, R. Study about Improving Mechanism of Electrical Conductivity of AA1070Al Treated by a Novel Composite Boron Treatment with Trace Ti. J. Alloys Compd. 2021, 870, 159416. [CrossRef]

- Xu, X.; Feng, Y.; Yang, P.; Zhang, B.; Wang, Y.; Wang, Q.; Fan, X.; Ding, H. The Influence of Trace Elements on the Microstructures and Properties of the Aluminum Conductors. Results Phys. 2018, 11, 1058–1063. [CrossRef]

- Cui, X.; Wu, Y.; Cui, H.; Zhang, G.; Zhou, B.; Liu, X. The Improvement of Boron Treatment Efficiency and Electrical Conductivity of AA1070Al Achieved by Trace Ti Assistant. J. Alloys Compd. 2018, 735, 62–67. [CrossRef]

- Khaliq, A.; Rhamdhani, M.A.; Brooks, G.A.; Grandfield, J.F. Removal of Vanadium from Molten Aluminum—Part I. Analysis of VB2 Formation. Metall. Mater. Trans. B 2014, 45, 752–768. [CrossRef]

- Khaliq, A.; Rhamdhani, M.A.; Brooks, G.A.; Grandfield, J.F. Removal of Vanadium from Molten Aluminum—Part II. Kinetic Analysis and Mechanism of VB2 Formation. Metall. Mater. Trans. B 2014, 45, 769–783. [CrossRef]

- Khaliq, A.; Akbar Rhamdhani, M.; Brooks, G.A.; Grandfield, J. Removal of Vanadium from Molten Aluminum—Part III. Analysis of Industrial Boron Treatment Practice. Metall. Mater. Trans. B 2014, 45, 784–794. [CrossRef]

- Yang, Z.; He, X.; Li, B.; Atrens, A.; Yang, X.; Cheng, H. Influence of Si, Cu, B, and Trace Alloying Elements on the Conductivity of the Al-Si-Cu Alloy. Materials 2022, 15, 426. [CrossRef] [PubMed]

- Rauta, V.; Cingi, C.; Orkas, J. Effect of Annealing and Metallurgical Treatments on Thermal Conductivity of Aluminium Alloys. Int. J. Met. 2016, 10, 157–171. [CrossRef]

- Timpel, M.; Wanderka, N.; Schlesiger, R.; Yamamoto, T.; Lazarev, N.; Isheim, D.; Schmitz, G.; Matsumura, S.; Banhart, J. The Role of Strontium in Modifying Aluminium–Silicon Alloys. Acta Mater. 2012, 60, 3920–3928. [CrossRef]

- Moniri, S.; Shahani, A.J. Chemical Modification of Degenerate Eutectics: A Review of Recent Advances and Current Issues. J. Mater. Res. 2019, 34, 20–34. [CrossRef]

- Lu, S.-Z.; Hellawell, A. The Mechanism of Silicon Modification in Aluminum-Silicon Alloys: Impurity Induced Twinning. Metall. Trans. A 1987, 18, 1721–1733. [CrossRef]

- Hamilton, D.R.; Seidensticker, R.G. Propagation Mechanism of Germanium Dendrites. J. Appl. Phys. 1960, 31, 1165–1168. [CrossRef]

- Nagaumi, H.; Wu, Y.F.; Zhu, G.L.; Xu, Y. A Novel High Thermal Conductivity Al-Si Casting Alloy and Application; Canadian Institute of Mining, Metallurgy and Petroleum: Montreal, QC, Canada, 2015.

- Liu, W.; Li, Y.; Song, Z.; Luo, X.; Yang, H.; Bi, G. Effect of Trace Sr+Ce Compound Modification on Microstructure, Thermal Conductivity and Mechanical Properties of AlSi10MnMg Alloy. Chin. J. Nonferrous Met. 2022, 32, 332–342. [CrossRef]

- Liu, W.; Li, Y.; Song, Z.; Bi, G.; Yang, H.; Cao, Y. Effect of Sr+Er Composite Modification on Microstructure, Thermal Conductivity and Mechanical Properties of AlSi10MnMg Alloy. Mater. Rep. 2023, 37, 131–137.

- Zhang, Y.; Wei, F.; Mao, J.; Niu, G. The Difference of La and Ce as Additives of Electrical Conductivity Aluminum Alloys. Mater. Charact. 2019, 158, 109963. [CrossRef]

- Choi, S.W.; Kim, Y.M.; Lee, K.M.; Cho, H.S.; Hong, S.K.; Kim, Y.C.; Kang, C.S.; Kumai, S. The Effects of Cooling Rate and Heat Treatment on Mechanical and Thermal Characteristics of Al-Si-Cu-Mg Foundry Alloys. J. Alloys Compd. 2014, 617, 654–659. [CrossRef]

- Ravi, K.R.; Pillai, R.M.; Amaranathan, K.R.; Pai, B.C.; Chakraborty, M. Fluidity of Aluminum Alloys and Composites: A Review. J. Alloys Compd. 2008, 456, 201–210. [CrossRef]

- Rohatgi, P.K.; Prabhakar, K.V. Wrought Aluminum-Nickel Alloys for High Strength-High Conductivity Applications. Metall. Trans. A 1974, 6, 1003–1008. [CrossRef]

- Sankanit, P.; Uthaisangsuk, V.; Pandee, P. Tensile Properties of Hypoeutectic Al-Ni Alloys: Experiments and FE Simulations. J. Alloys Compd. 2021, 889, 161664. [CrossRef]

- Palanivel, S.; Kuehmann, C.; Stucki, J.R.; Filip, E.; Edwards, P. Aluminum Alloys for Die. Casting. Patent WO2020028730A1, 11 October 2019.

- Wang, K.; Hu, S.; Zhong, Y.; Jin, S.; Zhou, Z.; Wang, Z.; Chen, J.; Wan, B.; Li, W. Effects of Trace Ytterbium Addition on Microstructure, Mechanical and Thermal Properties of Hypoeutectic Al–5Ni Alloy. J. Rare Earths 2022, 40, 1305–1315. [CrossRef]

- Developed Alloys | Products and Services | Nikkei MC Aluminium Co., Ltd. Available online: https://www.nmca.jp/en/product/development-alloy.html (accessed on 7 January 2024).

- Liu, C.; Jiao, X.; Nishat, H.; Akhtar, S.; Wiesner, S.; Guo, Z.; Xiong, S. Characteristics of Fe-Rich Intermetallics Compounds and Their Influence on the Cracking Behavior of a Newly Developed High-Pressure Die Cast Al-4Mg-2Fe Alloy. J. Alloys Compd. 2021, 854, 157121. [CrossRef]

- Okamoto, H.; Schlesinger, M.E.; Mueller, E.M. ASM Handbook Volume 3 Alloy Phase Diagrams, 10th ed.; ASM International: Materials Park, OH, USA, 1990; ISBN 978-0-87170-377-4.

- Kim, K.T.; Lim, Y.S.; Shin, J.S.; Ko, S.H.; Kim, J.M. Effects of Zn and Mg Amounts on the Properties of High Thermal Conductivity Al-Zn-Mg-Fe Alloys for Die Casting. J. Korea Foundry Soc. 2013, 33, 113–121. [CrossRef]

- Jiang, H.; Li, S.; Zheng, Q.; Zhang, L.; He, J.; Song, Y.; Deng, C.; Zhao, J. Effect of Minor Lanthanum on the Microstructures, Tensile and Electrical Properties of Al-Fe Alloys. Mater. Des. 2020, 195, 108991. [CrossRef]

- Luo, G.; Zhou, X.; Li, C.; Du, J.; Huang, Z. Design and Preparation of Al-Fe-Ce Ternary Aluminum Alloys with High Thermal Conductivity. Trans. Nonferrous Met. Soc. China 2022, 32, 1781–1794. [CrossRef]

- Luo, G.; Huang, Y.; Li, C.; Huang, Z.; Du, J. Microstructures and Mechanical Properties of Al-2Fe-xCo Ternary Alloys with High Thermal Conductivity. Materials 2020, 13, 3728. [CrossRef]

- Bian, Z.; Liu, Y.; Dai, S.; Chen, Z.; Wang, M.; Chen, D.; Wang, H. Regulating Microstructures and Mechanical Properties of Al-Fe-Ni Alloys. Prog. Nat. Sci. Mater. Int. 2020, 30, 54–62. [CrossRef]

- Bian, Z.; Xiao, Y.; Hu, L.; Liu, Y.; Chen, Z.; Wang, M.; Chen, D.; Wang, H. Stimulated Heterogeneous Distribution of Sc Element and Its Correlated Local Hardening Effect in Al-Fe-Ni-Sc Alloy. Mater. Sci. Eng. A 2020, 771, 138650. [CrossRef]

- Koutsoukis, T.; Makhlouf, M.M. Alternatives to the Al–Si Eutectic System in Aluminum Casting Alloys. Int. J. Met. 2016, 10, 342–347. [CrossRef]

- Jiang, M.; Mo, L.; Zhou, X.; Liu, X.; Zhan, M.; Du, J. Microstructure Evolution and Thermophysical Properties of Hypereutectic Al-Fe-Ni Alloys. Int. J. Met. 2023, 17, 2780–2793. [CrossRef]

- Luo, G. Study on Microstructure Regulation and Performance of Al-Fe Based Alloys with High Thermal Conductivity. Master’s Thesis, South China University of Technology, Guangzhou, China, 2021.

- Chen, J.K.; Hung, H.Y.; Wang, C.F.; Tang, N.K. Effects of Casting and Heat Treatment Processes on the Thermal Conductivity of an Al-Si-Cu-Fe-Zn Alloy. Int. J. Heat Mass Transf. 2017, 105, 189–195. [CrossRef]

- Hu, C.; Zhao, H.; Wang, X.; Fu, J. Microstructure and Properties of AlSi12Fe Alloy High Pressure Die-Castings under Different Vacuum Levels. Vacuum 2020, 180, 109561. [CrossRef]

- Liu, Y.; Zhang, Y.; Liu, W.; Jiao, X.; Nishat, H.; Ajavavarakula, D.; Chen, H.; Xiong, S. Enhanced Mechanical Properties and Thermal Conductivity of High-Pressure Die-Cast AlMg6Si2MnZr Alloy by Controlling the Externally Solidified Crystals. J. Mater. Process. Technol. 2022, 306, 117645. [CrossRef]

- Hitchcock, M.; Wang, Y.; Fan, Z. Secondary Solidification Behaviour of the Al-Si-Mg Alloy Prepared by the Rheo-Diecasting Process. Acta Mater. 2007, 55, 1589–1598. [CrossRef]

- Fan, Z. Semisolid Metal Processing. Int. Mater. Rev. 2002, 47, 49–85. [CrossRef]

- Kirkwood, D.H. Semisolid Metal Processing. Int. Mater. Rev. 1994, 39, 173–189. [CrossRef]

- Qi, M.; Kang, Y.; Zhu, G. Microstructure and Properties of Rheo-HPDC Al-8Si Alloy Prepared by Air-Cooled Stirring Rod Process. Trans. Nonferrous Met. Soc. China 2017, 27, 1939–1946. [CrossRef]

- Lordan, E.; Zhang, Y.; Dou, K.; Jacot, A.; Tzileroglou, C.; Wang, S.; Wang, Y.; Patel, J.; Lazaro-Nebreda, J.; Zhou, X.; et al. High-Pressure Die Casting: A Review of Progress from the EPSRC Future LiME Hub. Metals 2022, 12, 1575. [CrossRef]

- Arunkumar, K.; Bakshi, S.; Phanikumar, G.; Rao, T.V.L.N. Study of Flow and Heat Transfer in High Pressure Die Casting Cooling Channel. Metall. Mater. Trans. B 2023, 54, 1665–1674. [CrossRef]

- Koru, M.; Serçe, O. Experimental and Theoretical Investigation of Heat Transfer in Vacuum Assisted High Pressure Die Casting (HPDC) Process. Int. J. Met. 2023. [CrossRef]

- Gautam, S.K.; Roy, H.; Lohar, A.K.; Samanta, S.K. Studies on Mold Filling Behavior of Al–10.5Si–1.7Cu Al Alloy During Rheo Pressure Die Casting System. Int. J. Met. 2023, 17, 2868–2877. [CrossRef]

- Trometer, N.; Godlewski, L.A.; Prabhu, E.; Schopen, M.; Luo, A.A. Effect of Vacuum on Die Filling in High Pressure Die Casting: Water Analog, Process Simulation and Casting Validation. Int. J. Met. 2024, 18, 69–85. [CrossRef]

- Dou, K.; Lordan, E.; Zhang, Y.; Jacot, A.; Fan, Z. A Novel Approach to Optimize Mechanical Properties for Aluminium Alloy in High Pressure Die Casting (HPDC) Process Combining Experiment and Modelling. J. Mater. Process. Technol. 2021, 296, 117193. [CrossRef]

- Niu, Z.; Liu, G.; Li, T.; Ji, S. Effect of High Pressure Die Casting on the Castability, Defects and Mechanical Properties of Aluminium Alloys in Extra-Large Thin-Wall Castings. J. Mater. Process. Technol. 2022, 303, 117525. [CrossRef]

- Cai, Q.; Mendis, C.L.; Wang, S.; Chang, I.T.H.; Fan, Z. Effect of Heat Treatment on Microstructure and Tensile Properties of Die-Cast Al-Cu-Si-Mg Alloys. J. Alloys Compd. 2021, 881, 160559. [CrossRef]

- Tao, C.; Cheng, X.-N.; Li, Z.-Q.; Liu, G.-L.; Xu, F.-H.; Xie, S.-K.; Kuang, Z.-H.; Guo, Y.; Liu, H.-X. Mechanism of Cryogenic, Solid Solution and Aging Compound Heat Treatment of Die-Cast Al Alloys Considering Microstructure Variation. Rare Met. 2023, 42, 3130–3138. [CrossRef]

- Zhang, J.; Cinkilic, E.; Huang, X.; Wang, G.G.; Liu, Y.; Weiler, J.P.; Luo, A.A. Optimization of T5 Heat Treatment in High Pressure Die Casting of Al-Si-Mg-Mn Alloys by Using an Improved Kampmann-Wagner Numerical (KWN) Model. Mater. Sci. Eng. A 2023, 865, 144604. [CrossRef]

- Zhang, A.; Li, Y. Thermal Conductivity of Aluminum Alloys—A Review. Materials 2023, 16, 2972. [CrossRef]

- Yuan, Z. Effect of Heat Treatment on Microstructure, Defects and Mechanical Properties of High Pressure Die Castings of Aluminum Alloys. Ph.D. Thesis, Tsinghua University, Beijing, China, 2019.

- Han, Y.; Shao, D.; Chen, B.A.; Peng, Z.; Zhu, Z.X.; Zhang, Q.; Chen, X.; Liu, G.; Li, X.M. Effect of Mg/Si Ratio on the Microstructure and Hardness-Conductivity Relationship of Ultrafine-Grained Al-Mg-Si Alloys. J. Mater. Sci. 2017, 52, 4445–4459. [CrossRef]

- Li, K.; Zhang, J.; Chen, X.; Yin, Y.; He, Y.; Zhou, Z.; Guan, R. Microstructure Evolution of Eutectic Si in Al-7Si Binary Alloy by Heat Treatment and Its Effect on Enhancing Thermal Conductivity. J. Mater. Res. Technol. 2020, 9, 8780–8786. [CrossRef]

- Kim, Y.-M.; Choi, S.-W.; Kim, Y.-C.; Kang, C.-S. Influences of Heat Treatment on the Thermal Diffusivity and Corrosion Characterization of Al-Mg-Si alloy. Korean J. Met. Mater. 2021, 59, 582–588. [CrossRef]

- Zhong, L.; Wang, Y.; Gong, M.; Zheng, X.; Peng, J. Effects of Precipitates and Its Interface on Thermal Conductivity of Mg-12Gd Alloy during Aging Treatment. Mater. Charact. 2018, 138, 284–288. [CrossRef]

- Lumley, R.N.; Polmear, I.J.; Groot, H.; Ferrier, J. Thermal Characteristics of Heat-Treated Aluminum High-Pressure Die-Castings. Scr. Mater. 2008, 58, 1006–1009. [CrossRef]

- Pauzon, C.; Buttard, M.; Després, A.; Charlot, F.; Fivel, M.; Chehab, B.; Blandin, J.-J.; Martin, G. Direct Ageing of LPBF Al-1Fe-1Zr for High Conductivity and Mechanical Performance. Acta Mater. 2023, 258, 119199. [CrossRef]

- Algendy, A.Y.; Javidani, M.; Khangholi, S.N.; Pan, L.; Chen, X.-G. Enhanced Mechanical Strength and Electrical Conductivity of Al-Ni-Based Conductor Cast Alloys Containing Mg and Si. Adv. Eng. Mater. 2024, 26, 2301241. [CrossRef]

- Wang, J.; Carson, J.K.; North, M.F.; Cleland, D.J. A New Approach to Modelling the Effective Thermal Conductivity of Heterogeneous Materials. Int. J. Heat Mass Transf. 2006, 49, 3075–3083. [CrossRef]

- Helsing, J.; Grimvall, G. Thermal Conductivity of Cast Iron: Models and Analysis of Experiments. J. Appl. Phys. 1991, 70, 1198–1206. [CrossRef]

- Su, C. Thermal Mechanism of Magnesium Alloys Based on Solute Atom and Second Phase. Ph.D. Thesis, Shanghai Jiao Tong University, Shanghai, China, 2019.

- Hamilton, R.L.; Crosser, O.K. Thermal Conductivity of Heterogeneous Two-Component Systems. Ind. Eng. Chem. Fundam. 1962, 1, 187–191. [CrossRef]

- Vaney, J.-B.; Piarristeguy, A.; Ohorodniichuck, V.; Ferry, O.; Pradel, A.; Alleno, E.; Monnier, J.; Lopes, E.B.; Gonçalves, A.P.; Delaizir, G.; et al. Effective Medium Theory Based Modeling of the Thermoelectric Properties of Composites: Comparison between Predictions and Experiments in the Glass-Crystal Composite System Si10As15Te75-Bi0.4Sb1.6 Te3. J. Mater. Chem. C 2015, 3, 11090–11098. [CrossRef]

- Jiao, X.Y.; Wang, P.Y.; Liu, Y.X.; Jiang, J.J.; Liu, W.N.; Wan, A.X.; Shi, L.J.; Wang, C.G.; Xiong, S.M. Effect of Shot Speeds on the Microstructural Framework and Abnormal Eutectic Bands in a High Pressure Die Casting Hypoeutectic AlSi10MnMg Alloy. J. Mater. Process. Technol. 2024, 326, 118312. [CrossRef]

9. Copyright:

This material is Yixian Liu and Shoumei Xiong's paper: Based on Research Progress on Thermal Conductivity of High-Pressure Die-Cast Aluminum Alloys.

Paper Source: https://doi.org/10.3390/met14040370

This material was summarized based on the above paper, and unauthorized use for commercial purposes is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.