This technical summary is based on the academic paper "Numerical and experimental analysis of a high pressure die casting Aluminum suspension cross beam for light commercial vehicles" by S. Cecchel, D. Ferrario, published in La Metallurgia Italiana (2016). It has been analyzed and summarized for technical experts by CASTMAN with the assistance of AI.

Keywords

- Primary Keyword: HPDC Aluminum Suspension Cross Beam

- Secondary Keywords: Lightweighting, High Pressure Die Casting, Automotive Components, Light Commercial Vehicles (LCVs), Aluminum Alloy, Structural Component

Executive Summary

A 30-second overview for busy professionals.

- The Challenge: The dominance of heavy welded steel for safety-critical suspension components in Light Commercial Vehicles (LCVs) limits vehicle lightweighting potential and efficiency gains.

- The Method: Developing and comparing multiple lightweighting solutions, ultimately selecting and optimizing a High Pressure Die Casting (HPDC) design using AlSi9MgMn alloy and a novel hollow-structure manufacturing technique.

- The Key Breakthrough: Achieving a 47% weight reduction and a 40% stiffness improvement over the steel baseline by creating a fully hollow cross beam using full-length sliders in the HPDC process—a new application for this traditional technology.

- The Bottom Line: HPDC can produce large, hollow, safety-critical structural components for LCVs that are significantly lighter and stiffer than traditional steel, offering a viable, cost-effective lightweighting solution.

The Challenge: Why This Research Matters for HPDC Professionals

In the push for greater fuel efficiency and reduced emissions, automotive lightweighting is paramount. However, for Light Commercial Vehicles (LCVs), safety-relevant components like suspension cross beams have remained stubbornly reliant on traditional welded steel and iron. While lighter materials like composites offer theoretical benefits, their use in LCVs is often limited by cost constraints and the need for extremely high stress resistance and stiffness.

This creates a significant technical gap. According to the research, prior to this study, "none suspension cross beam in aluminum has never developed in this range of vehicles." The challenge was to overcome the state of the art by developing a technically reliable, cost-effective, and safety-relevant suspension component in an aluminum alloy that could meet the demanding performance requirements of LCVs while delivering substantial weight savings.

The Approach: Unpacking the Methodology

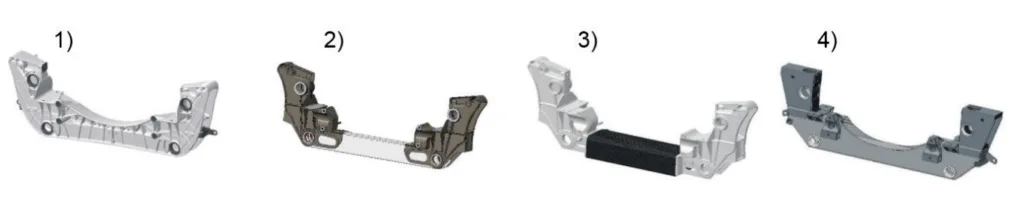

The research team undertook a multi-stage approach to solve this challenge, beginning with a comparative analysis of four distinct lightweighting solutions:

1. High Pressure Die Casting (HPDC) aluminum

2. Low Pressure Die Casting (LPDC) and extruded aluminum

3. LPDC and Carbon Fiber Reinforced Polymer (CFRP)

4. Extruded aluminum

After preliminary finite element analyses (FEA) and business case evaluations, the LPDC/CFRP and all-extruded aluminum concepts were discarded for economic and technical reasons. The HPDC aluminum solution emerged as the one with the "most lightweight and economic potential."

The core innovation was twofold:

- Material Selection: The team selected AlSi9MgMn, a primary aluminum alloy that provides excellent as-cast mechanical properties. This choice cleverly avoids the need for a high-temperature T6 heat treatment, which could cause significant deformation and blistering in such a large, complex part. A lower-temperature T5 treatment was also evaluated to further boost strength for heavy-duty applications.

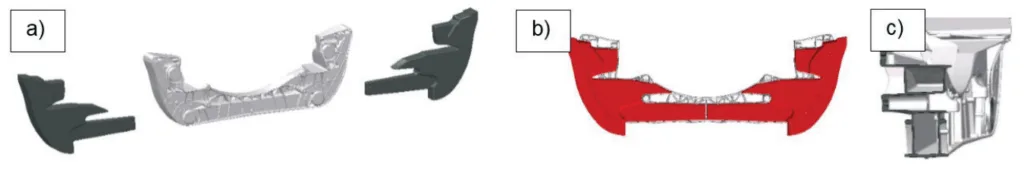

- Hollow Structural Design: The researchers replaced the traditional "U" shape of die-cast parts with a completely hollow structure. This was achieved by implementing sliders along the entire length of the component—a novel application of a well-known technique, typically used only to create localized undercuts.

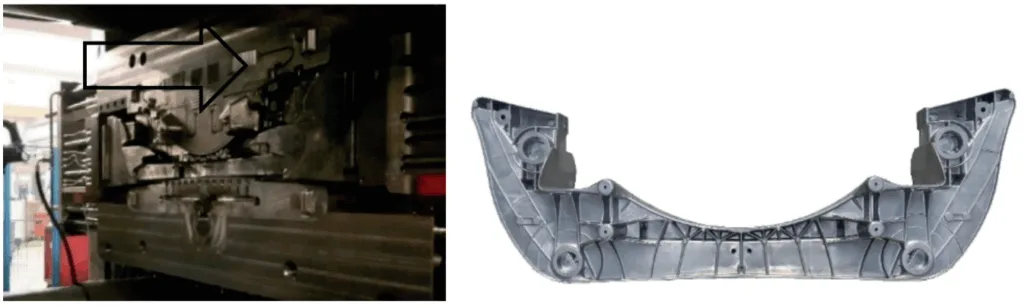

The design was refined through iterative structural FEA (MSC/MarcMentat) and casting process simulations (ESI/PROCAST). Finally, prototypes were manufactured and validated using X-ray inspection and 3D scanning to analyze porosity and dimensional accuracy.

The Breakthrough: Key Findings & Data

The study yielded two transformative results that demonstrate the viability of large, hollow aluminum HPDC components for safety-critical applications.

Finding 1: A Fully Hollow Structure Delivers a 40% Stiffness Improvement

The most significant innovation was the successful production of a completely hollow cross beam. By using full-length sliders, the design moved beyond the limitations of typical planar or "U" shaped castings. This advanced geometry directly translated into superior mechanical performance. Mechanical FEA confirmed that this solution "leads to a component stiffness improvement - in the direction of the main vertical load - of about 40% in comparison with the steel baseline." This proves that a well-designed HPDC aluminum part can not only match but significantly exceed the stiffness of its heavier steel predecessor.

Finding 2: A 47% Weight Reduction Was Achieved Through Iterative Optimization

The combination of the lightweight aluminum alloy and the optimized hollow design resulted in massive weight savings. The project began with an initial target of 35% lightweighting, but through successive iterations of structural and process FEA, the final optimized design achieved an increased lightweighting of 47% compared to the original welded steel structure.

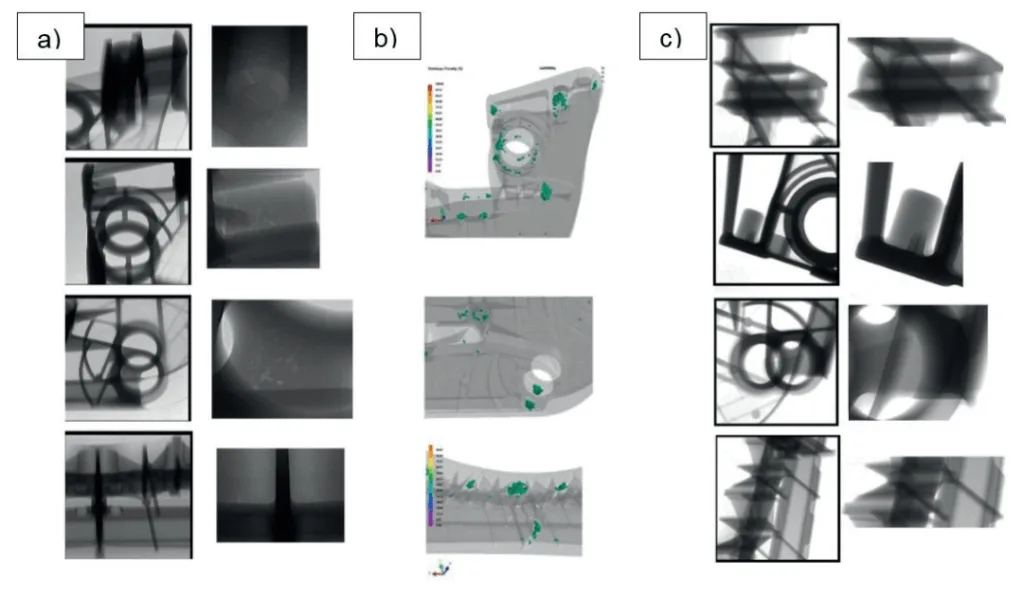

Furthermore, the experimental validation provided crucial insights. Initial X-rays confirmed the presence of porosity in the thickest sections, which had been accurately predicted by the FEM simulations (Figure 4). Based on this data, die modifications and process parameter optimizations were performed, leading to minimized porosity in the final components. Dimensional analysis showed a maximum bending deformation of 1.8 mm, which was less than the 3.8 mm predicted by simulations, highlighting the importance of empirical testing to refine simulation models for highly complex parts.

Practical Implications for R&D and Operations

This paper provides actionable insights for engineering and manufacturing teams working with HPDC.

- For Process Engineers: This study suggests that for large, hollow parts, a careful, iterative selection of process parameters, guided by FEM simulations (like ESI/PROCAST), is crucial for minimizing porosity, especially in thick sections (as shown in Figure 4). The use of full-length sliders on high-tonnage machines (3000t or more) is a viable, though demanding, production method for creating complex, hollow components.

- For Quality Control Teams: The data in Figure 4 of the paper illustrates the direct correlation between FEM porosity predictions and X-ray results. This reinforces the value of simulation-driven quality inspection plans, focusing on predicted high-porosity zones. The dimensional analysis (1.8 mm deformation) provides a valuable benchmark for acceptable warpage in large, structurally critical castings.

- For Design Engineers: The findings prove that a completely hollow structure is feasible in HPDC and offers significant stiffness benefits (~40%). This opens new design possibilities for replacing multi-part welded steel assemblies with monolithic, lightweight aluminum castings. The selection of the AlSi9MgMn alloy to avoid high-temperature T6 treatment is a key consideration for mitigating post-casting deformation risks in large, complex components.

Paper Details

Numerical and experimental analysis of a high pressure die casting Aluminum suspension cross beam for light commercial vehicles

1. Overview:

- Title: Numerical and experimental analysis of a high pressure die casting Aluminum suspension cross beam for light commercial vehicles

- Author: S. Cecchel, D. Ferrario

- Year of publication: 2016

- Journal/academic society of publication: La Metallurgia Italiana - n. 6 2016

- Keywords: ALUMINUM - HIGH PRESSURE DIE CASTING - SUSPENSION - CROSS BEAM - COMMERCIAL VEHICLE - LIGHTWEIGHT - AUTOMOTIVE

2. Abstract:

The purpose of the present paper is to enhance and deepen the lightweight optimization in automotive, in particular for commercial vehicles and buses. In detail, aim of this research is to develop a technically reliable and cost effective safety component for Light Commercial Vehicles (LCVs) in aluminum alloy. At this purpose, different solutions of Aluminium Cross beams for an independent front suspension for LCVs have been analyzed, with a weight saving target in comparison with the traditional welded sheet metal structure of almost 40/50%. Moreover, further environmental advantages have to be considered; for instance improved corrosion resistance, no painting or cataphoresis required, benefits on recyclability and residual value at the end of life. In detail, the goal of this project has been achieved through: technical and economical study of some different lightweighting solution and selection of the best case; improvement of the solution selected with the help of structural FEA and casting process simulations, a Life Cycle Assessment from cradle to grave (not here described), prototypes realization and preliminary experimental correlation.

3. Introduction:

Vehicle weight decrease is a remarkable method to moderate the automotive carbon footprint, by reducing fuel consumptions and environmental emissions. Furthermore, the lightweighting improves power to weight ratio and passenger safety and allows an increase of the payload [1]. For these reasons, in the last years the lightweighting design in automotive has exponentially increased. Although, the use of “steel” and “iron” is still predominant for commercial vehicles and buses especially for safety relevant components [2]. Aim of this research is to overcome this state of the art by developing a technically reliable and cost effective safety relevant suspension component for Light Commercial Vehicles (LCVs) in aluminum alloy.

4. Summary of the study:

Background of the research topic:

The need for lightweighting in the automotive sector, particularly for commercial vehicles and buses, to reduce fuel consumption and environmental emissions.

Status of previous research:

The use of steel and iron is still predominant for safety-relevant components in commercial vehicles. While alternative materials like light alloys and composites exist, their application in LCVs is limited by cost and the need for high strength and stiffness. No aluminum suspension cross beam had been previously developed for this vehicle range.

Purpose of the study:

To develop a technically reliable and cost-effective safety component (suspension cross beam) for Light Commercial Vehicles (LCVs) in aluminum alloy, with a weight saving target of 40-50% compared to the traditional welded steel structure.

Core study:

The research involved a technical and economic study of different lightweighting solutions, selecting High Pressure Die Casting (HPDC) as the optimal method. The study focused on improving the selected solution through structural FEA and casting process simulations, leading to a novel hollow design using full-length sliders. The study culminated in prototype realization and experimental correlation to validate the design and manufacturing process.

5. Research Methodology

Research Design:

The research followed a comparative and iterative design process. It began with a benchmark analysis of four different lightweighting solutions (materials and processes). The most promising solution (HPDC) was then selected for further development, which involved multiple iterations of design enhancement using structural and process finite element analyses.

Data Collection and Analysis Methods:

The methodology included numerical simulations and physical experiments. An elastokinematic multibody model was used to determine load conditions. Structural FEA (MSC Marc/Mentat) and casting process FEA (ESI/PROCAST) were conducted. Prototypes were cast, and the resulting components were analyzed using an X-ray machine for macro-defects (porosity) and a 3D scanner for dimensional analysis (deformation).

Research Topics and Scope:

The study is focused on a single safety-relevant component: a suspension cross beam for Light Commercial Vehicles (LCVs). The scope covers the entire development process from concept analysis and material selection to detailed design, simulation, prototyping, and preliminary experimental validation.

6. Key Results:

Key Results:

- The HPDC aluminum solution was identified as having the most lightweight and economic potential compared to LPDC, extruded, and composite solutions.

- A novel, completely hollow structure was achieved using full-length sliders, resulting in a 40% stiffness improvement in the main vertical load direction compared to the steel baseline.

- An overall weight saving of 47% was achieved compared to the traditional welded sheet metal structure.

- Experimental validation confirmed porosity predictions from FEM simulations and demonstrated that process optimization could successfully minimize these defects.

- Dimensional analysis of prototypes showed a maximum bending deformation of 1.8 mm, which was less than the simulated 3.8 mm.

Figure Name List:

- Fig. 1 - Cross beams: -1) HPDC aluminum, 2) LPDC and extruded aluminum, 3) LPDC and CFRP, 4) Extruded aluminum

- Fig. 2 - a) Sliders layout b) Cross beam hollowed longitudinal section c) remarkable hollow sections

- Fig. 3 - Dies and prototypes

- Fig. 4 - Porosity identify by a) X-ray on components from the first experimental activity, b) FEM simulations, c) X-ray on components from the final experimental activity (optimization of process parameters)

7. Conclusion:

The present paper enhances the lightweight optimization for commercial vehicles developing a technically reliable and cost effective safety component for Light Commercial Vehicles (LCVs) in aluminum alloy. In particular, a preliminary benchmark on a complete suspension assembly for LCVs has been performed, outlining the object of the study in a suspension cross beam element, usually made with metal sheet parts or steel tubes welded together in order to fulfil costs and resistance requirements. Subsequently, different lightweight suspension cross beams have been developed and materials, processes, technologies and business case have been analyzed finding the best solution in a high pressure die casting aluminum component. The shape and the technology production of the studied component have been completely devised by optimizing the mechanical properties and by reducing the material used. The design have been enhanced thanks to further iterations of structural and process finite element analyses.

8. References:

- [1] J. HIRSCH, Materials forum volume 28, (2004), p 15.

- [2] S.DAS, JOM, 8, (2000), p.41-44.

- [3] L. KALLIEN, T. WEIDLER, M. BECKER, International foundry research, 4, (2014), p. 20-27.

- [4] R.MOSCHINI, R.MOLINA, XXXI Congresso tecnico di fonderia ASSOFOND, (2012).

- [5] RHEINFELDEN, Leghe d'alluminio da pressocolata.

Expert Q&A: Your Top Questions Answered

Q1: Why was AlSi9MgMn chosen over other aluminum alloys that might offer higher strength after a T6 heat treatment?

A1: The paper highlights that a high-temperature T6 heat treatment "may cause considerable deformations and blisters" in a large, complex component like this cross beam. AlSi9MgMn was selected because it "guarantees as-cast elevated mechanical properties," avoiding the risks associated with T6. The study also evaluated a lower-temperature T5 treatment as a viable option to "slightly increase the resistance for heavy applications" without introducing significant distortion.

Q2: The paper mentions using full-length sliders is a novel application. What were the main manufacturing challenges associated with this approach?

A2: The primary challenge was the sheer scale of the tooling. The paper states that this component's manufacturing "requests a high tonnage (at least 3000 t) vacuum machine." This is a direct result of the "remarkable dimensions of casting (about 1260x450 mm) and sliders (approximately equal to the piece)." Additionally, to "guarantee their proper alignment and a constant component's thickness," specialized devices had to be developed and integrated into the die.

Q3: The measured deformation (1.8 mm) was significantly lower than the simulated value (3.8 mm). Why was there such a large discrepancy?

A3: The authors attribute this difference to the difficulty of creating an accurate a priori estimation of the numerous process parameters and boundary conditions, "especially for the production of a so complex component." This suggests that while simulation provides an excellent directional guide for deformation behavior, empirical data from initial prototypes is essential for calibrating models and achieving final dimensional accuracy.

Q4: What was the main benefit of creating a hollow structure compared to the traditional "U" shape design?

A4: The primary benefit was a significant increase in structural performance. The paper's mechanical FEA confirmed that the hollow structure "leads to a component stiffness improvement - in the direction of the main vertical load - of about 40% in comparison with the steel baseline." This stiffness gain was crucial for meeting the mechanical property requirements for a safety component while simultaneously enabling substantial weight reduction.

Q5: The initial prototypes showed porosity in the thickest sections. How was this issue addressed?

A5: The presence of porosity was first predicted by the FEM simulations (ESI/PROCAST) and then confirmed by X-ray analysis of the first castings. To resolve this, the paper states that "some die modification have been conducted and further experimental casting activities have been performed with a careful iterative selection of the proper process parameters." This iterative optimization cycle, guided by both simulation and physical testing, successfully minimized the porosities as shown in the final X-ray results (Fig. 4c).

Conclusion: Paving the Way for Higher Quality and Productivity

This research effectively dismantles the long-held assumption that large, safety-critical suspension components for LCVs must be made from heavy welded steel. By innovatively applying HPDC technology, the study demonstrates that a monolithic, hollow HPDC Aluminum Suspension Cross Beam is not only feasible but superior, offering a 47% weight reduction and a 40% stiffness increase. The key breakthroughs—the novel use of full-length sliders and the strategic selection of a non-T6 alloy—provide a clear roadmap for producing lighter, stronger, and more cost-effective structural components.

"At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components."

Copyright Information

- This content is a summary and analysis based on the paper "Numerical and experimental analysis of a high pressure die casting Aluminum suspension cross beam for light commercial vehicles" by "S. Cecchel, D. Ferrario".

- Source: La Metallurgia Italiana - n. 6 2016

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.