This introduction paper is based on the paper "Enhancing Side Die Resistance to Thermal Shock in Automotive Casting: A Comparative Study of FCD550 and SKD6 Materials" published by "Eastern-European Journal of Enterprise Technologies".

1. Overview:

- Title: Enhancing side die resistance to thermal shock in automotive casting: a comparative study of FCD550 and SKD6 materials

- Author: Herry Patria, Iwan Susanto, Belyamin, Dianta Mustofa Kamal

- Year of publication: 2024

- Journal/academic society of publication: Eastern-European Journal of Enterprise Technologies

- Keywords: thermal shock, die disc car wheel, manufacturing, automotive parts, casting productivity

2. Abstract:

Enhancement of side die resistance to thermal shock in mold disc car applications was achieved by substituting FCD550 material with SKD6 material. The primary issue addressed is the cracking of side dies due to thermal shock induced by an accelerated production process, leading to production halts and failure to meet large customer orders. The study aims to identify a material that can better withstand thermal shock than FCD550, thereby improving the durability of side dies and the overall productivity of the manufacturing process. The research involved direct production experiments, analyzing the materials FCD550 and SKD6, evaluating die characteristics, and assessing finished product attributes before and after material changes. Laboratory tests and machine-setting trials were conducted, varying production processes and assessing the results. The findings indicate that SKD6 is significantly more resistant to thermal shock than FCD550 in mold disc car applications. The study compared the strength of side die materials using data sheets and adjusted setting parameters under existing cooling conditions. Experimentation involved altering the standard temperature from 520–545 °C to 532–538 °C and reducing the soaking time from a minimum of 270–540 seconds to 332 seconds. This reduced soaking time from 69 seconds to 46 seconds and aging time from 190 seconds to 180 seconds, increasing casting productivity from 194,870 pieces/28 days to 213,311 pieces/28 days across seven machines, thereby fulfilling the customer’s requirement of 200,000 pieces/28 days without side die cracks. Durability testing on five product samples according to TSD5605G standards confirmed the quality as meeting customer specifications.

3. Introduction:

The importance of researching the thermal shock resistance of materials in automotive part manufacturing is crucial, especially as vehicles become more advanced and demand components capable of withstanding rigorous conditions [1]. The disc car wheel is a critical component enduring substantial loads and stresses [2], making its integrity essential for performance and safety. Manufacturing companies face challenges in optimizing production to meet high sales orders while maintaining quality. Accelerated production methods can lead to thermal shock issues, causing side die cracks and compromising product quality [3]. Understanding thermal shock, where rapid temperature fluctuations induce mechanical stress leading to potential structural failure, is paramount [4]. This study investigates enhancing the thermal shock resistance of side dies by comparing traditional FCD550 material with SKD6 alloy, known for heightened thermal shock resistance, to improve manufacturing efficiency and component durability.

4. Summary of the study:

Background of the research topic:

Automotive components like disc car wheels require high durability and resistance to operational stresses. Increased production demands necessitate accelerated manufacturing processes, which can induce thermal shock in die casting molds, particularly in the side die area, leading to cracks and production halts [3]. The object of this study is the thermal shock resistance of side dies used in the production of Car Wheel disc products.

Status of previous research:

Previous studies have identified micro-cracks and related phenomena in die materials [5] and explored aspects like thermal conductivity [6], tempering effects [7], and thermal stress modeling [10]. However, the specific issue of cracking caused directly by thermal shock in accelerated casting processes remained largely unresolved [9, 10]. While SKD6 steel's properties (high heat operation, toughness, erosion resistance) are known [10, 11, 12], its potential to mitigate thermal shock in this specific application compared to FCD550 needed evaluation.

Purpose of the study:

The aim is to enhance the thermal shock resistance of side dies in the production of PSD3K disc car wheel type products, thereby accelerating the manufacturing process while maintaining product integrity and quality. The objectives were:

- To identify and evaluate materials with superior thermal shock resistance, focusing on SKD6 steel as a replacement for FCD550.

- To design a novel side die incorporating an advanced cooling system.

- To modify die casting machine settings (e.g., injection speed, mold temperature, cooling rate) to optimize the process.

Core study:

The study involved a comparative analysis of FCD550 and SKD6 materials for side die application in disc car wheel casting. Material selection was based on comparing standard data sheets (Tables 1-4), focusing on properties relevant to thermal shock resistance (hardness, composition, especially Vanadium content). SKD6 was selected. Side dies were manufactured using SKD6 (Fig. 1, Fig. 2), and their chemical composition was verified (Table 5). A cooling system concept was visualized (Fig. 3). Experimental trials were conducted using a die casting machine, comparing the performance of FCD550 and SKD6 side dies. Initial trials used existing settings, followed by optimization of parameters (temperatures, soaking/aging times) for the SKD6 dies (Table 6, Fig. 8). Performance was evaluated through visual inspection of dies and products, hardness testing (Fig. 6), microstructure analysis (Fig. 5), porosity simulation (Fig. 7), cycle time measurement, and final product quality testing according to TSD5605G standards.

5. Research Methodology

Research Design:

The research employed a comparative experimental design. It involved:

- Material selection based on literature and data sheet comparison (FCD550 vs. SKD6).

- Manufacturing side dies with the selected material (SKD6).

- Designing and implementing a cooling system concept for the side die.

- Conducting direct production experiments on a die casting machine, comparing the performance of FCD550 and SKD6 side dies.

- Optimizing machine setting parameters for the SKD6 material.

- Validating the results through material testing, process monitoring, and product quality assessment.

Data Collection and Analysis Methods:

- Material Properties: Comparison using standard data sheets (JIS G 5502, JIS G4404).

- Manufactured Die Verification: Chemical composition analysis (ARL 3460 OES), Hardness testing (ZHU250CL), Microstructure analysis (GX53 microscope, ESTM 155 standard).

- Process Performance: Recording die casting machine parameters (temperatures, times), cycle time measurement, visual inspection of dies for cracks, production output counting.

- Simulation: Porosity visualization (implied MAGMA software from Fig. 7).

- Product Quality: Dimensional checks (CMM Crystal Apex C7106), Durability testing (Impact test 13° and 90°, Moment life test (CFT), Drum test (RFT)) according to Toyota engineering standard TSD5605G.

Research Topics and Scope:

The study focused specifically on enhancing the thermal shock resistance of side dies used in the high-pressure die casting of automotive disc wheels (PSD3K type). The scope included:

- Comparative evaluation of FCD550 and SKD6 materials.

- Assessment of a modified cooling system design's impact.

- Optimization of die casting machine settings (temperature, soaking time, aging time).

The study was limited to this specific application and the comparison between FCD550 and SKD6. The primary variable investigated was the side die material substitution.

6. Key Results:

Key Results:

- Material Selection: SKD6 was chosen over FCD550 based on data sheet analysis indicating superior potential for thermal shock resistance, attributed to its composition (incl. 0.3-0.5% Vanadium) and mechanical properties (higher hardness potential) (Tables 1-4). The manufactured SKD6 dies met the required chemical composition standards (Table 5).

- Performance Comparison: Experimental trials showed SKD6 dies were significantly more resistant to thermal shock cracking than FCD550 dies. After 1400 production cycles under similar initial conditions, FCD550 dies showed 12% cracking, while SKD6 dies showed only 0.5% hair cracks (Fig. 7). SKD6 dies operated at higher temperatures (up to 450°C vs 362°C for FCD550) but simulations indicated lower microporosity in the product (Fig. 7). Hardness tests confirmed SKD6 achieved 47.50 HRC after hardening (Fig. 6).

- Process Optimization: Machine settings were successfully optimized for SKD6 dies. Key changes included adjusting temperature (RZ1: 520-545°C to 532-538°C) and reducing times (soaking: min 270s to 332s; holding: 69s to 46s; aging: 190s to 180s). This reduced the total cycle time from 517 seconds to 369 seconds (Table 6, Fig. 8).

- Productivity and Quality: The optimized process with SKD6 dies increased casting productivity by 12%, from 194,870 pieces/28 days to 213,311 pieces/28 days across seven machines, meeting the customer requirement of 200,000 pieces/28 days without side die cracking issues. Final product quality was confirmed through testing according to TSD5605G standards, with tested samples showing no cracks.

Figure Name List:

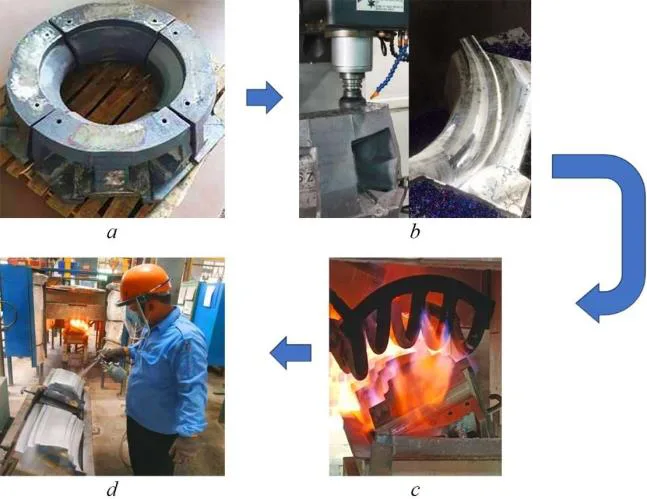

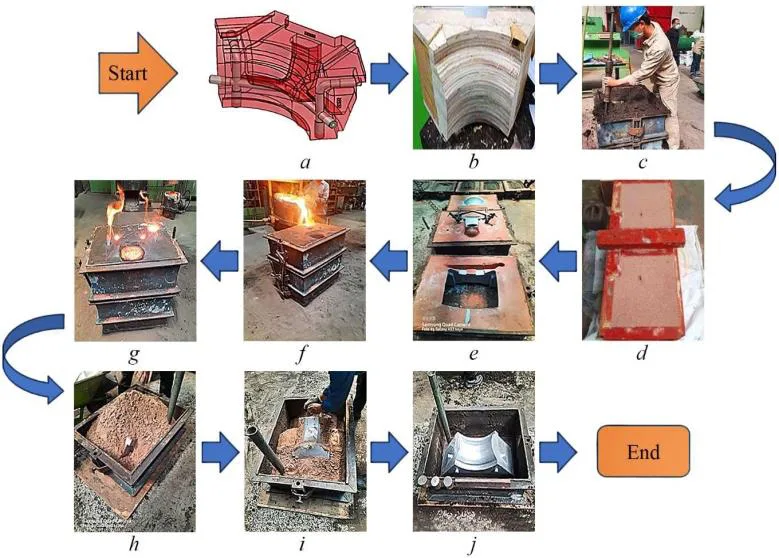

- Fig. 1. Stages of side core mold manufacturing process: a – project design; b - Pola/Patten; c - die manufacture; d - core manufacture; e - furnace preparation; f- casting; g - solidification; h – sand mold disassembly; i – visual check; j – finishing side core

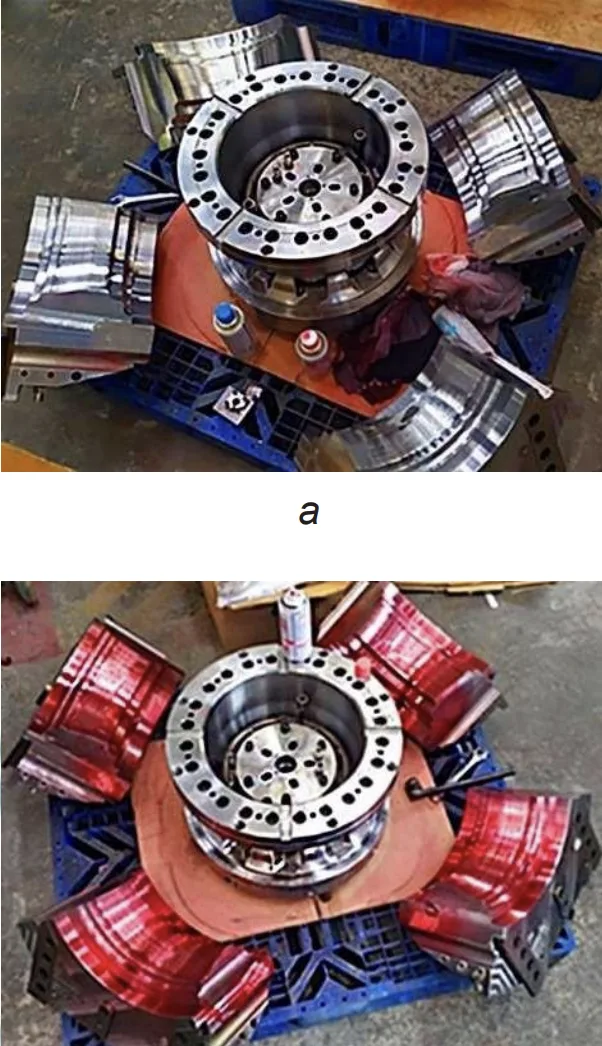

- Fig. 2. Stages of machining and ceramic coating process: a - side core; b - proses machining; c - proses ceramic coating; d - proses spray finishing

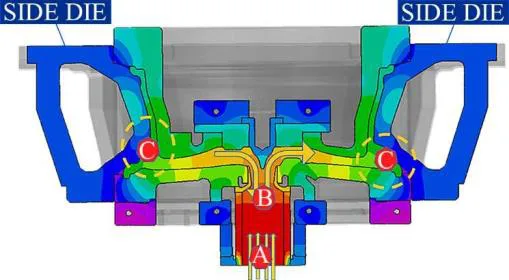

- Fig. 3. Visualization of main die and side die pieces

- Fig. 4. Results of material disposition: a - side die before coating; b - side die after coating

- Fig. 5. Structure micro: a - FCD550; b – SKD6

- Fig. 6. Hardness test results on SKD6 148 hours cooling on FCD550 material after cooling with water temperature 40 °C obtained test value 47.50 HRC

- Fig. 7. Micro photo visualization of: a - porosity temperature conditions FCD550; b – porosity temperature conditions SKD6; c - micro photo of porosity of FCD550; d - micro photo of porosity of SKD6

- Fig. 8. Graph of trial result evaluation data change setting parameters

7. Conclusion:

- The study successfully identified SKD6 steel as a highly suitable material for diecasting molds used in car and motorcycle disc wheels. Compared to FCD550, SKD6 exhibited superior thermal shock resistance, reducing crack formation by 12 % and increasing durability by 0.5 %. This material’s advanced properties enhanced heat resistance, toughness, and erosion resistance address the critical issue of thermal shock-induced cracking, ensuring higher precision and durability in mold manufacturing. This underscores the importance of high engineering standards in producing reliable and high-quality automotive components.

- An advanced cooling system was effectively designed, ensuring uniform temperature distribution within the molds and mitigating thermal stress. This design resulted in a 23 % reduction in thermal gradients and a 100 % improvement in product dimensional accuracy. The research demonstrated that meticulous planning and calculations in cooling system design can preemptively address mold cracking issues, ensuring that products are formed accurately and maintain their integrity according to design specifications.

- The study achieved optimized diecasting machine parameters, including injection speed, mold temperature, and cooling rate, which accelerated production by 15 % while reducing defect rates by 100 %. These optimizations, based on rigorous experimental data, ensured that production enhancements did not compromise product quality. This strategic approach aligns machine settings with product standards and customer expectations, ultimately enhancing both the quality and quantity of the output.

8. References:

- [1] Wankhede, V. A., Vinodh, S. (2022). State of the art review on Industry 4.0 in manufacturing with the focus on automotive sector. International Journal of Lean Six Sigma, 13 (3), 692–732. Available at: https://www.x-mol.net/paper/article/1451642237902290944

- [2] Zhao, X., Gao, P., Zhang, Z., Wang, Q., Yan, F. (2020). Fatigue characteristics of the extruded AZ80 automotive wheel. International Journal of Fatigue, 132, 105393. https://doi.org/10.1016/j.ijfatigue.2019.105393

- [3] Klobčar, D., Kosec, L., Kosec, B., Tušek, J. (2012). Thermo fatigue cracking of die casting dies. Engineering Failure Analysis, 20, 43–53. https://doi.org/10.1016/j.engfailanal.2011.10.005

- [4] Schwam, D., Wallace, J., Birceanu, S. (2002). Die Materials for Critical Applications and Increased Production Rates. Office of Scientific and Technical Information (OSTI). https://doi.org/10.2172/806823

- [5] Su, Y., Fu, G., Liu, C., Liu, C., Long, X. (2021). Fatigue crack evolution and effect analysis of Ag sintering die-attachment in SiC power devices under power cycling based on phase-field simulation. Microelectronics Reliability, 126, 114244. https://doi.org/10.1016/j.microrel.2021.114244

- [6] Cai, H., Wang, Z., Liu, L., Li, Y., Xing, F., Guo, F. (2022). Crack source and propagation of AZ91-0.9Gd alloy. Journal of Materials Research and Technology, 16, 1571–1577. https://doi.org/10.1016/j.jmrt.2021.12.065

- [7] Schumacher, O., Marvel, C. J., Kelly, M. N., Cantwell, P. R., Vinci, R. P., Rickman, J. M. et al. (2016). Complexion time-temperature-transformation (TTT) diagrams: Opportunities and challenges. Current Opinion in Solid State and Materials Science, 20 (5), 316–323. https://doi.org/10.1016/j.cossms.2016.05.004

- [8] Lordan, E., Zhang, Y., Dou, K., Jacot, A., Tzileroglou, C., Wang, S. et al. (2022). High-Pressure Die Casting: A Review of Progress from the EPSRC Future LIME Hub. Metals, 12 (10), 1575. https://doi.org/10.3390/met12101575

- [9] Luthfiyah, S., Faridh, A., Soegijono, B. (2019). The Effect of Vacuum Quenching on Corrosion and Hardness of the Surface of SKD61 Steel. IOP Conference Series: Materials Science and Engineering, 694 (1), 012033. https://doi.org/10.1088/1757-899x/694/1/012033

- [10] Sudjadi, U., Sinaga, R. V. (2020). Study of the hardness and microstructure profiles of SKD61 steel plunger tip (local material) after plasma nitriding. IOP Conference Series: Materials Science and Engineering, 839 (1), 012019. https://doi.org/10.1088/1757-899x/839/1/012019

- [11] Yi, W., Liu, G., Gao, J., Zhang, L. (2021). Boosting for concept design of casting aluminum alloys driven by combining computational thermodynamics and machine learning techniques. Journal of Materials Informatics. https://doi.org/10.20517/jmi.2021.10

- [12] Walsh, E., Maclean, N., Turner, A., Alsuleman, M., Prasad, E., Halbert, G. et al. (2022). Manufacture of tablets with structurally-controlled drug release using rapid tooling injection moulding. International Journal of Pharmaceutics, 624, 121956. https://doi.org/10.1016/j.ijpharm.2022.121956

- [13] Yang, Q., Wu, X., Qiu, X. (2023). Microstructural Characteristics of High-Pressure Die Casting with High Strength–Ductility Synergy Properties: A Review. Materials, 16 (5), 1954. https://doi.org/10.3390/ma16051954

- [14] Zhou, Y., Tian, N., Liu, W., Zeng, Y., Wang, G., Han, S. et al. (2022). Mechanism of heterogeneous distribution of Cr-containing dispersoids in DC casting 7475 aluminum alloy. Transactions of Nonferrous Metals Society of China, 32 (5), 1416–1427. https://doi.org/10.1016/s1003-6326(22)65883-7

- [15] Wei, C., Ou, J., Farhang Mehr, F., Maijer, D., Cockcroft, S., Wang, X. et al. (2021). A thermal-stress modelling methodology in ABAQUS for fundamentally describing the die/casting interface behaviour in a cyclic permanent die casting process. Journal of Materials Research and Technology, 15, 5252–5264. https://doi.org/10.1016/j.jmrt.2021.10.120

- [16] Campos Neto, N. D., Korenyi-Both, A. L., Vian, C., Midson, S. P., Kaufman, M. J. (2023). The development of coating selection criteria to minimize die failure by soldering and erosion during aluminum high pressure die casting. Journal of Materials Processing Technology, 316, 117954. https://doi.org/10.1016/j.jmatprotec.2023.117954

- [17] Ahmadein, M., Elsheikh, A. H., Alsaleh, N. A. (2022). Modeling of cooling and heat conduction in permanent mold casting process. Alexandria Engineering Journal, 61 (2), 1757–1768. https://doi.org/10.1016/j.aej.2021.06.048

- [18] Niu, Z., Liu, G., Li, T., Ji, S. (2022). Effect of high pressure die casting on the castability, defects and mechanical properties of aluminium alloys in extra-large thin-wall castings. Journal of Materials Processing Technology, 303, 117525. https://doi.org/10.1016/j.jmatprotec.2022.117525

- [19] Li, Z., Li, D., Zhou, W., Hu, B., Zhao, X., Wang, J. et al. (2022). Characterization on the formation of porosity and tensile properties prediction in die casting Mg alloys. Journal of Magnesium and Alloys, 10 (7), 1857–1867. https://doi.org/10.1016/j.jma.2020.12.006

- [20] Dudek, P., Białoń, J., Piwowońska, J., Walczak, W., Wrzała, K. (2023). The impact on the cost of making high pressure die castings with multi-cavity die and vacuum assistance. Vacuum, 210, 111859. https://doi.org/10.1016/j.vacuum.2023.111859

9. Copyright:

- This material is a paper by "Herry Patria, Iwan Susanto, Belyamin, Dianta Mustofa Kamal". Based on "Enhancing side die resistance to thermal shock in automotive casting: a comparative study of FCD550 and SKD6 materials".

- Source of the paper: https://doi.org/10.15587/1729-4061.2024.306615

This material is summarized based on the above paper, and unauthorized use for commercial purposes is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.