Optimizing the Lost Foam Casting Process: A Deep Dive into Refractory Coatings and Process Parameters for Automotive Parts

This technical summary is based on the academic paper "APPLICATION OF LOST FOAM CASTING PROCESS FOR MANUFACTURING PARTS IN AUTOMOTIVE INDUSTRY" by Marko Pavlović, Tatjana Volkov-Husović, Muhamed Sarvan, Milan Đuričić, Fuad Klisura, and Zagorka Acimović, published in 19th International Research/Expert Conference "Trends in the Development of Machinery and Associated Technology" TMT 2015 (2015).

Keywords

- Primary Keyword: Lost Foam Casting Process

- Secondary Keywords: automotive casting, refractory coating, casting quality, evaporative pattern, aluminum alloys

Executive Summary

- The Challenge: Achieving consistent, high-quality aluminum castings for the automotive industry using the Lost Foam (LF) process is hindered by defects caused by the improper elimination of gases during pattern evaporation.

- The Method: The research systematically evaluated the impact of different refractory coating compositions, evaporative pattern densities, and casting parameters on the final quality of AlSi6Mg3 alloy castings.

- The Key Breakthrough: The study identified a specific set of optimal process parameters—including pattern density (≤ 20 kg/m³), refractory coat thickness (< 1 mm), and casting temperature (760-780°C)—that enables the production of defect-free, high-quality castings.

- The Bottom Line: Precise control over the entire system—polymeric pattern, refractory coating, and sand mold—is essential to balance pattern decomposition and metal solidification, significantly reducing production costs and improving surface quality in the Lost Foam Casting Process.

The Challenge: Why This Research Matters for HPDC Professionals

The Lost Foam (LF) casting process, patented in 1958, offers a flexible and productive method for creating complex parts, particularly for the automotive industry's large series production. Unlike conventional sand casting, the evaporative pattern remains in the mold during metal pouring. However, this advantage presents a significant challenge: as the molten metal vaporizes the pattern, a large volume of gaseous and liquid byproducts is generated.

If these byproducts are not efficiently eliminated from the mold, they lead to characteristic defects that compromise the casting's integrity and quality. Historically, the development of the LF process has been hampered by a lack of suitable materials for both the evaporative patterns and the crucial refractory coatings. For engineers and managers striving for low production expenses and high-quality castings, mastering the control of this decomposition process is the key to unlocking the full potential of LF technology.

The Approach: Unpacking the Methodology

The researchers conducted a series of experiments to optimize the LF process for an AlSi6Mg3 aluminum alloy, a common material in the automotive sector. The methodology focused on controlling the critical variables in the system.

Method 1: Refractory Coating Formulation and Application

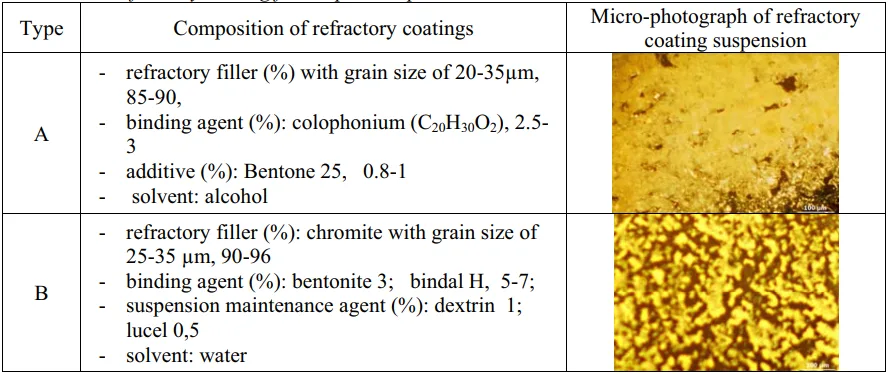

Two primary types of refractory coatings were developed and tested. Both used mineral fillers (like talc, zircon, and chromite) with a grain size of 20-35 μm.

- Coating A (Alcohol-based): Utilized colophonium as a binding agent and alcohol as the solvent.

- Coating B (Water-based): Utilized bentonite and bindal H as binding agents and water as the solvent.

The coatings were applied by immersing the polystyrene patterns, with strict control over suspension density (2 g/cm³), temperature (25°C), and mixing speed to ensure a homogenous, even layer between 0.5-1.5 mm thick.

Method 2: Pattern and Casting Parameter Control

The experiment used evaporable polystyrene patterns with a density of 20-25 kg/m³. These patterns were assembled into "clusters" on a central runner gate. The key casting parameters were:

- Alloy Preparation: The AlSi6Mg3 melt was refined, degassed, and modified with sodium.

- Casting Temperature: Maintained within a tight range of 755-780°C.

- Mold Material: Dry quartz sand with varying grain sizes (0.17, 0.26, 0.35 mm) was used to study the effect of permeability.

The Breakthrough: Key Findings & Data

The study successfully demonstrated that controlling critical process parameters directly correlates with casting quality, yielding precise, shiny, and smooth parts.

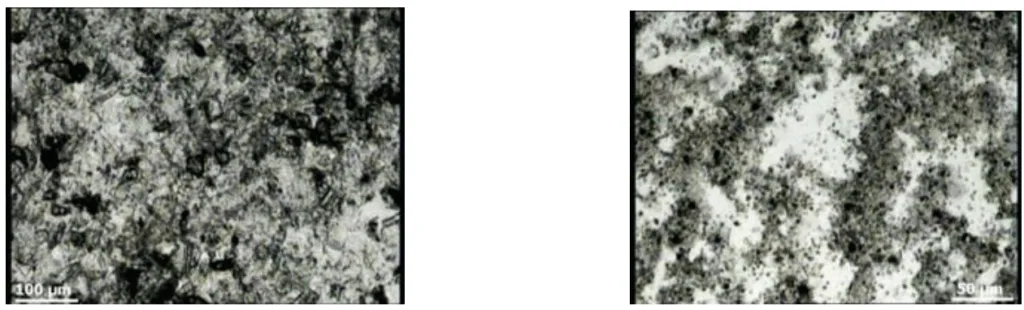

Finding 1: Homogeneity of Refractory Coating is Paramount

Visual inspection revealed a stark difference in casting quality based on the coating's composition and application. A homogenous coating, achieved through constant, slow mixing during application, resulted in smooth, high-quality casting surfaces. In contrast, non-homogenous coatings led to surface defects.

As shown in Figure 1, the difference between a) homogenous composition coats and b) non-homogenous composition coats is visually distinct, directly impacting the final surface finish of the cast parts.

Finding 2: A "Process Window" for Defect-Free Castings

The research established a clear set of parameters that produced castings meeting quality standards. Defects like subsurface porosity, volumetric porosity, and surface roughness were directly linked to exceeding certain thresholds.

- Optimal Results: Achieved with polystyrene patterns with a density up to 20 kg/m³, refractory coat layers below 1 mm, quartz sand grain size above 0.26 mm, and a casting temperature of 760-780°C. This combination ensured complete and even decomposition of the pattern and effective elimination of gaseous products.

- Defect Formation: Castings made with patterns of density above 20 kg/m³ and coat thickness above 1.5 mm consistently exhibited subsurface and volumetric porosity. This indicates that the thicker pattern and coating trapped decomposition byproducts, leading to defects.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that adjusting refractory coating thickness to be below 1.0 mm and ensuring pattern density does not exceed 20 kg/m³ may contribute to significantly reducing porosity defects. The casting temperature window of 760-780°C is a critical control point.

- For Quality Control Teams: The data in Figure 1 of the paper illustrates the effect of coating homogeneity on surface quality. This visual evidence can be used to establish new inspection criteria for the coating process itself, preventing downstream defects before the metal is even poured.

- For Design Engineers: The findings indicate that the selection of polystyrene bead grain size and the resulting pattern density can directly influence defect formation during solidification. This suggests that specifying a lower-density pattern (≤ 20 kg/m³) is a valuable consideration in the early design phase for parts manufactured via the LF process.

Paper Details

APPLICATION OF LOST FOAM CASTING PROCESS FOR MANUFACTURING PARTS IN AUTOMOTIVE INDUSTRY

1. Overview:

- Title: APPLICATION OF LOST FOAM CASTING PROCESS FOR MANUFACTURING PARTS IN AUTOMOTIVE INDUSTRY

- Author: Marko Pavlović, Tatjana Volkov-Husović, Muhamed Sarvan, Milan Đuričić, Fuad Klisura, Zagorka Acimović

- Year of publication: 2015

- Journal/academic society of publication: 19th International Research/Expert Conference "Trends in the Development of Machinery and Associated Technology" TMT 2015, Barcelona, Spain 22-23 July 2015

- Keywords: evaporative pattern, castings quality, refractory coating, auto industry

2. Abstract:

In this paper, some of the results of research are presented, by applying casting technology with evaporative pattern for obtaining castings (Lost foam process). This technology of castings enables obtaining complex parts, intended to, for example, automotive industry. It means that it is characterized by large series, low production expenses and high quality of castings. The investment into equipment and space are not high, the process is flexible and high productivity can be achieved. By research, a satisfactory quality is achieved and necessary, relevant information for industrial production of aluminum alloys casting are obtained.

3. Introduction:

The Lost Foam (LF) casting process, patented by H.F. Shroyer in 1958, utilizes evaporative patterns and pouring systems that remain in the sand mould until the pouring of metal. Upon contact with liquid metal, the pattern decomposes in a short time, concurrent with the casting's crystallization. This decomposition produces a significant quantity of gaseous and liquid products. If the conditions for their elimination from the mould are not fulfilled, numerous defects characteristic of this process will appear on the castings. The development of this process has been challenged by the lack of appropriate materials for evaporative patterns and refractory pattern coatings.

4. Summary of the study:

Background of the research topic:

The quality of castings produced by the LF process is highly dependent on factors influencing the pattern's decomposition and evaporation. These include the temperature and density of the pattern, the type and thickness of the refractory coating, and the type and grain size of the sand used for the mould. The velocity of liquid metal ingress and its contact with the pattern is regulated by the gating system design.

Status of previous research:

Prior research indicates that to obtain castings of a desired quality, critical process parameters must be determined for each specific polymer pattern and alloy type. This requires optimization of the LF process to achieve specified properties. Understanding the dependency of a casting's structure on the technology is fundamental to controlling process parameters and final casting properties.

Purpose of the study:

This paper presents research results from applying the LF casting technology to obtain castings for the automotive industry. The study aimed to achieve a satisfactory quality and obtain relevant information for the industrial production of aluminum alloy castings by investigating the influence of process parameters, particularly refractory coatings and pattern properties, on the final casting quality.

Core study:

The study involved a series of experiments to prepare and apply mineral fillers within refractory coatings. Two types of coatings were formulated: an alcohol-based coating (Type A) and a water-based coating (Type B). These coatings were applied to evaporable polystyrene patterns, which were then used to cast an AlSi6Mg3 alloy in dry quartz sand moulds. The resulting castings were visually inspected and their properties were tested to evaluate the effects of different process parameters, including pattern density, coating thickness, and casting temperature, on casting quality.

5. Research Methodology

Research Design:

The research was designed as an experimental study to determine the optimal parameters for the LF casting process. The experiment involved the preparation of two series of refractory coatings (A and B) with different compositions and their application to polystyrene patterns. The quality of the resulting castings was then evaluated based on a set of controlled casting parameters.

Data Collection and Analysis Methods:

Data was collected through visual control of the obtained castings. The analysis included assessing surface quality (smoothness, shininess), dimensional accuracy, and the presence of defects such as bubbles, crazing, peeling, roughness, and porosity. The structural and mechanical properties of the castings were also tested and compared against standards for the alloy type.

Research Topics and Scope:

The research focused on the following topics:

- Composition and preparation of refractory coatings for evaporable patterns.

- Application methods and quality control for refractory coatings.

- The influence of evaporable pattern properties (density) on casting quality.

- The effect of casting parameters (temperature, sand grain size) on the final product.

- The correlation between process parameters and the formation of casting defects.

The scope was limited to the LF casting of an AlSi6Mg3 aluminum alloy using evaporable polystyrene patterns.

6. Key Results:

Key Results:

- The homogeneity of the refractory coating is critical for achieving a smooth, high-quality surface on castings. Inhomogeneity in the coating composition leads to surface defects.

- Castings produced with polystyrene patterns of density up to 20 kg/m³, refractory coat thickness below 1 mm, quartz sand grain size above 0.26 mm, and a casting temperature of 760-780°C were within the predicted standards. These parameters enabled even decomposition of the polystyrene and complete elimination of gaseous products.

- Castings from series with pattern densities above 20 kg/m³ and coat thicknesses above 1.5 mm exhibited subsurface and volumetric porosity.

- The resulting castings were dimensionally precise, indicating complete decomposition of the pattern and a satisfactory gating solution.

- Lower parts of the castings exhibited flat, sharp edges and clean, shiny surfaces. Upper surfaces of castings with thicker coatings (above 1.5 mm) were sometimes uneven and folded.

Figure Name List:

- Figure 1. Refractory coats

7. Conclusion:

To achieve quality and cost-effective production with the LF casting process, it is necessary to attain a balance in the system comprising the evaporable polymeric pattern, liquid metal, refractory coating, and sand mold. This balance must be maintained during metal inflow, polymeric pattern decomposition and evaporation, and casting formation and solidification. The complexity of the solidification conditions in the LF process necessitates the determination of the correlation between casting parameters, structure, and the properties of the final castings.

8. References:

- [1] R. Monroe: Expandable Pattern Casting, AFS Inc. (1994), SAD

- [2] Z.Aćimović, Lj.Pavlović, Lj.Trumbulović, Lj.Andrić, M. Stamatović: Synthesis and characteriyation of the cordierite ceramics from nonstandard raw materials for application in foundry, Materials Letters, 57 (2003) 2651-2656.

- [3] T. Hübert, S. Svoboda, B. Oertel, “Wear Resistant Alumina Coatings Produced by a sol-gel Process," Surface and Coatings Technology, 201 [1-2] 487-491 (2003).

- [4] U. C Nwaogu, N. S Tiedje "Foundry Coating Technology: A Review, Materials Science and Applications", 2 [8] 1143-1160 (2011).

- [5] Y.Dong, B.Lin, S. Wang, K. Xie, D. Fang, X. Zhang, H. Ding, X. Liu, G. Meng, “Cost-effective tubular cordierite micro-filtration membranes processed by co-sintering" Journal of Alloys and Compounds 477 L35-L40 (2009).

Expert Q&A: Your Top Questions Answered

Q1: Why were two different refractory coatings, one alcohol-based (Type A) and one water-based (Type B), selected for the experiment?

A1: The paper states that two types of coatings were prepared to investigate their application and performance. Type A used an alcohol solvent, while Type B used water. This allowed the researchers to evaluate different binder systems (colophonium vs. bentonite) and solvents to determine their ease of application, drying characteristics, and ultimate effect on casting quality under the controlled experimental conditions.

Q2: What is the specific mechanism that causes defects when pattern density exceeds 20 kg/m³ and coating thickness is above 1.5 mm?

A2: The paper indicates that these conditions lead to subsurface and volumetric porosity. The reason is that a higher density pattern and a thicker, less permeable refractory coating hinder the complete and rapid elimination of the gaseous and liquid products generated during pattern decomposition. This trapped material results in porosity within the casting as the metal solidifies around it.

Q3: The paper mentions that the homogeneity of the refractory coating is critical. What specific steps were taken during the process to ensure homogeneity?

A3: To achieve a homogenous coating, the paper specifies that it is necessary to "slowly constantly mix the coat during its applying on patterns." Furthermore, maintaining a defined suspension density (2 g/cm³) and temperature (25°C) was critical. These control measures prevent the mineral fillers from settling, ensuring the coating applied to the pattern has a uniform composition and thickness.

Q4: How does the grain size of the quartz sand affect the quality of the Lost Foam casting?

A4: The paper identifies that a sand grain size "above 0.26 mm" contributed to optimal results. A larger grain size increases the permeability of the sand mold. This higher permeability is crucial for allowing the gaseous products from the evaporated polystyrene pattern to escape from the mold cavity efficiently, preventing them from being trapped by the incoming liquid metal and causing gas-related defects.

Q5: What makes the Lost Foam Casting Process particularly suitable for the automotive industry, according to this research?

A5: The paper highlights several characteristics of the LF process that are advantageous for automotive applications. It enables the production of complex parts, is well-suited for large series production, and is associated with low production expenses. The research confirms that when parameters are optimized, high-quality castings can be achieved with high productivity and flexibility, which are key requirements for the automotive sector.

Conclusion: Paving the Way for Higher Quality and Productivity

The challenge of producing defect-free, complex aluminum parts for the automotive industry requires a deep understanding of the material interactions within the Lost Foam Casting Process. This research effectively demonstrates that by establishing a precise balance between the evaporative pattern, the refractory coating, and the casting parameters, it is possible to overcome common defects like porosity and poor surface finish. The key breakthrough is the identification of a clear operational window—pattern density below 20 kg/m³, coating thickness under 1 mm, and a casting temperature of 760-780°C—that leads to high-quality, cost-effective components.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components.

Copyright Information

This content is a summary and analysis based on the paper "APPLICATION OF LOST FOAM CASTING PROCESS FOR MANUFACTURING PARTS IN AUTOMOTIVE INDUSTRY" by "Marko Pavlović, et al.".

Source: The paper was presented at the 19th International Research/Expert Conference "Trends in the Development of Machinery and Associated Technology" TMT 2015, Barcelona, Spain 22-23 July 2015.

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.