Rethinking Lightweighting: Why Austempered Ductile Iron (ADI) Offers a More Sustainable Alternative to Steel and Aluminum

This technical summary is based on the academic paper "Austempered Ductile Iron (ADI) - A Green Alternative" by John R. Keough, PEng, FASM, published in April 2010.

Keywords

- Primary Keyword: Austempered Ductile Iron (ADI)

- Secondary Keywords: Embodied Energy, Sustainable Design, Lightweighting, Material Selection, Steel Replacement, Aluminum Replacement, Life-Cycle Energy, Ductile Iron Casting

Executive Summary

- The Challenge: Engineers often default to low-density materials like aluminum for weight reduction, overlooking the total life-cycle energy and cost implications of their material choices.

- The Method: The paper analyzes various engineering materials through the lens of "embodied energy"—the total energy required to produce a component—and compares their strength, stiffness, and density.

- The Key Breakthrough: Due to its high strength-to-weight ratio and stiffness, a properly designed Austempered Ductile Iron (ADI) component can replace steel, aluminum, or magnesium parts at a lower life-cycle energy, often at an equal or even reduced mass.

- The Bottom Line: ADI presents a cost-effective, low-waste, and highly sustainable material/process combination that delivers superior performance with a lower environmental footprint compared to traditional lightweighting solutions.

The Challenge: Why This Research Matters for HPDC Professionals

In the pursuit of sustainable or "green" design, weight reduction is a primary goal. This has led many engineers to instinctively choose low-density materials like aluminum and magnesium. However, as the paper highlights, this "lure of low specific gravity" can lock designers into a suboptimal material choice early in the process. The focus on density alone ignores two critical factors: the total energy consumed over the component's life cycle (from raw material to recycling) and the material's inherent strength and stiffness. High-strength steels have advanced significantly, but the design community remains largely unfamiliar with the unique advantages of Austempered Ductile Iron (ADI), a material that challenges the conventional wisdom that lower density always equals a "greener" or lighter part.

The Approach: Unpacking the Methodology

The author evaluates the sustainability of ADI by focusing on the concept of "embodied energy," a term used to define the total energy resident in a manufactured component. This approach provides a quantitative measure for comparing different material/process combinations. The analysis integrates three key material properties to build its case:

Method 1: Embodied Energy Comparison: The study compiles the energy required to produce various materials from raw ore to finished product, expressed in Megajoules per kilogram (MJ/kg). This includes the energy for extraction, processing, and heat treatment, while accounting for average recycling levels. This metric reveals the significant energy cost of primary aluminum production compared to ferrous metals, which can be produced from nearly 100% recycled scrap.

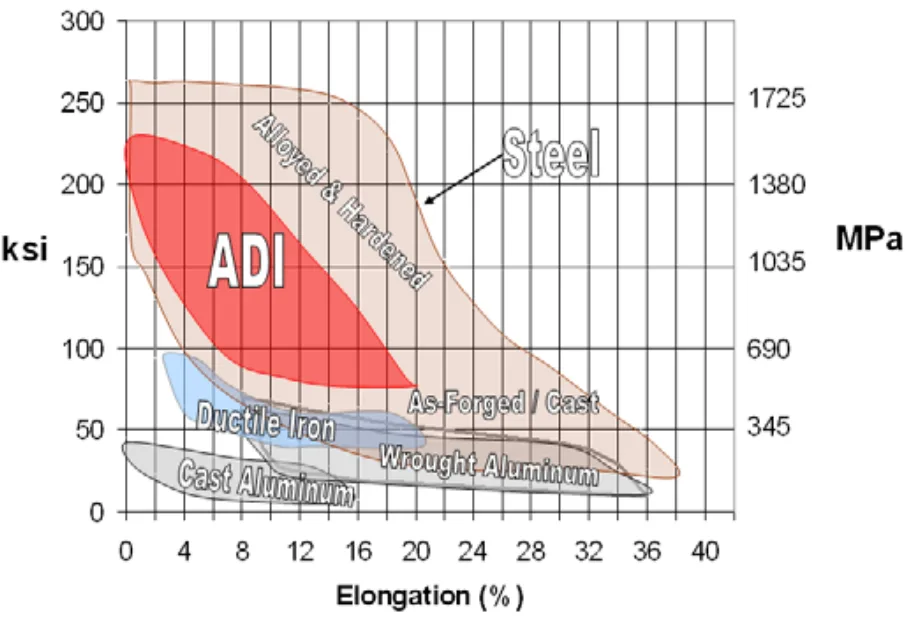

Method 2: Mechanical Property Analysis: The paper compares the yield strength, ductility (elongation %), and stiffness (Young's Modulus) of ADI against materials like steel, cast and forged aluminum, and magnesium. This analysis demonstrates that while ADI is denser than aluminum, its superior strength and stiffness allow for the design of components with thinner walls and less material, offsetting the density difference.

Method 3: Case Study Validation: The research moves from theoretical comparison to practical application by presenting five case studies where ADI components replaced parts made from forged steel, welded steel, and cast aluminum. These real-world examples quantify the savings in mass, embodied energy, and cost.

The Breakthrough: Key Findings & Data

Finding 1: ADI Delivers Equal Performance to Aluminum with Significantly Less Energy

The paper directly challenges the assumption that aluminum is the superior choice for lightweight components. While ADI's density is 2.4 times that of aluminum alloys (7.2 gm/cm³ vs. 3.0 gm/cm³), its stiffness is also 2.4 times greater (168 GPa vs. 70 GPa). Critically, its allowable yield stress is 3-5 times higher than cast aluminum. This means a properly designed ADI part can replace an aluminum one at equal or even lower mass.

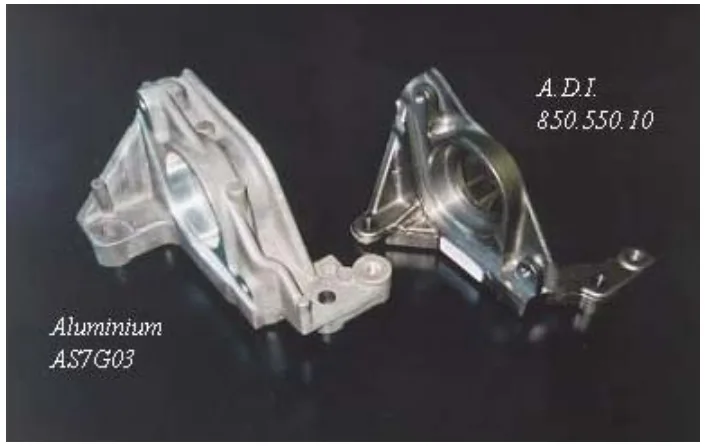

- Case Study: Automotive Bracket: An aluminum bracket weighing 1.0 kg (embodied energy: 58 MJ) was replaced by a thin-walled ADI design weighing 1.1 kg. The ADI component's embodied energy was only 33 MJ, representing an energy saving of over 40% while also solving a noise problem due to ADI's higher damping coefficient.

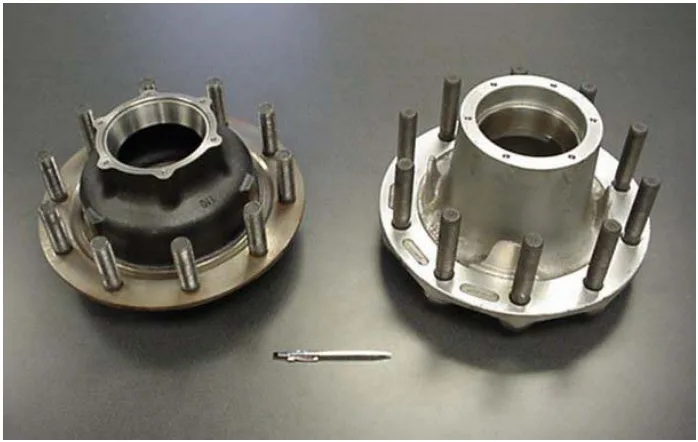

- Case Study: Wheel Hub: An ADI Dura-Light® hub replaced a permanent mold cast aluminum hub, resulting in a 2% weight reduction and a 50% savings in embodied energy (30 MJ/kg for ADI vs. 58 MJ/kg for aluminum).

Finding 2: ADI Castings Offer Massive Waste and Energy Reduction Over Steel Forgings and Weldments

ADI's near-net-shape casting process provides a low-waste, low-energy path to a finished product compared to subtractive manufacturing or multi-part assemblies.

- Case Study: End Connector: A 0.99 kg machined steel part started as a 1.81 kg forging, meaning 45% of the initial material was machined away as waste. The total embodied energy was 92 MJ. The replacement ADI casting started at 1.09 kg to produce a finished 0.93 kg part, consuming only 33 MJ—a 65% reduction in embodied energy.

- Case Study: Suspension Control Arm: A 15 kg stamped and welded steel arm (embodied energy: ~900 MJ) was replaced by a one-piece, 14 kg cast ADI arm. The ADI component required only 420 MJ to produce, an energy saving of over 50%, plus an additional life-cycle fuel saving of 1800 MJ over 300,000 km.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that for components requiring high stiffness and strength, exploring near-net-shape ADI casting can eliminate multiple manufacturing steps (like forging, cutting, and welding), significantly reducing process waste and energy consumption.

- For Quality Control Teams: The data in Figure 1 and Figure 2 of the paper illustrates that ADI offers steel-like strength and stiffness at a lower density. This combination of properties should be considered when evaluating material substitutions for highly loaded structural components.

- For Design Engineers: The findings indicate that focusing solely on specific gravity for material selection is a flawed approach. For components with a minimum wall thickness of around 3mm or more, ADI's high modulus and yield strength allow for designs that are mass-competitive with aluminum but at a much lower cost and environmental impact.

Paper Details

Austempered Ductile Iron (ADI) - A Green Alternative

1. Overview:

- Title: Austempered Ductile Iron (ADI) - A Green Alternative

- Author: John R. Keough, PEng, FASM

- Year of publication: April 2010

- Journal/academic society of publication: Applied Process Inc. Technologies Div.

- Keywords: Austempered Ductile Iron, ADI, Green Design, Sustainable Design, Embodied Energy, Life-Cycle Energy, Lightweighting, Steel, Aluminum, Magnesium

2. Abstract:

In discussions of sustainable or “green” design, the topic of weight reduction is often the first consideration. Immediately, engineers of structural components turn to materials with low density such as aluminum and magnesium. However, when strength and stiffness are taken into consideration, a low density material does not always result in a lower mass component or assembly. Further, in the search to propel devices using less fuel energy, engineers can often lose sight of the total life-cycle energy of the material/process combination they have chosen in their design. High strength steels have made great advances, allowing their designs to compete with "lightweight" metals. The steel manufacturers have done a good job communicating “new steel” to the design community. However, the design community is largely unfamiliar with the light weight and low energy properties of Austempered Ductile Iron (ADI). The lure of low specific gravity can lock design engineers into an improper material/process combination early in the design process to the exclusion of other, more efficient material/process combinations. This paper will familiarize the reader with the concept of embodied energy and some of the environmental advantages of converting from a conventional material/process combination to an ADI casting solution.

3. Introduction:

The sustainability of a product is measured by its energy use and environmental effect throughout its life. The paper introduces the concept of "life-cycle energy," which includes the energy to create, assemble, and operate a component, mitigated by its recyclability. It also defines "embodied energy" as the total energy resident in a manufactured component. For a light vehicle, this embodied energy can be about 20% of its total life-cycle energy. The introduction argues that sustainability is more dependent on waste reduction than just mass reduction and notes that ferrous metals (steel and iron) are highly sustainable due to low cost and high recyclability. The paper's purpose is to discuss the sustainability of ADI castings and demonstrate through case studies how ADI can produce components with less waste and lower life-cycle energy than comparable designs in steel, aluminum, or magnesium.

4. Summary of the study:

Background of the research topic:

The paper establishes the context of "green" engineering, where weight reduction using low-density materials like aluminum and magnesium is a common first step. However, this approach often overlooks the total energy footprint and other critical mechanical properties like strength and stiffness.

Status of previous research:

The paper notes that while high-strength steels are well-marketed, ADI remains a relatively unknown material in the broader design community despite its commercial availability since 1972. It references existing data on the history and market penetration of aluminum and magnesium, and points to standard specifications (ASTM, ISO, SAE) as sources of engineering information for ADI, noting its absence from general handbooks.

Purpose of the study:

The study aims to familiarize designers and engineers with the concept of embodied energy and demonstrate the environmental and performance advantages of converting components from conventional materials (steel, aluminum) to an ADI casting solution. It seeks to prove that ADI is a viable, sustainable, and cost-effective alternative.

Core study:

The core of the study is a comparative analysis of ADI against other engineering materials. It uses quantitative data on density, strength, stiffness, and embodied energy to build a theoretical case for ADI. This case is then substantiated through five real-world industrial case studies where ADI replaced components made of cast aluminum, forged steel, and welded steel, with detailed comparisons of weight, energy consumption, and cost savings.

5. Research Methodology

Research Design:

The research is a comparative study. It contrasts the material properties and life-cycle energy impacts of ADI with those of other common engineering materials. The study uses a combination of established materials science data and industrial case studies to support its thesis.

Data Collection and Analysis Methods:

Data was collected from published academic and industry sources, including standards organizations (ASTM, ISO, SAE), university research departments (Cambridge University), and national laboratories (Argonne National Laboratory). The primary analytical tool is the calculation and comparison of embodied energy (MJ/kg) and the evaluation of material suitability based on specific strength (strength per unit mass) and specific stiffness.

Research Topics and Scope:

The scope is focused on structural components where strength, stiffness, and mass are critical design factors. The materials compared are primarily ADI, various steels (carbon, low alloy), aluminum alloys (cast, wrought), and magnesium alloys. Polymers and other materials are mentioned briefly for context but are not the focus. The analysis is built around strength, stiffness, mass, and the energy used to create and operate the component.

6. Key Results:

Key Results:

- ADI is competitive with steel in strength for a given level of ductility but is 8-10% less dense due to the presence of graphite.

- ADI has 2.4 times the stiffness of aluminum alloys (168 GPa vs. 70 GPa), allowing for mass-neutral or even mass-reductive designs despite its higher density.

- The embodied energy of ADI (average 30 MJ/kg) is significantly lower than that of primary cast aluminum (58 MJ/kg), wrought aluminum (255 MJ/kg), and plain carbon steels (51 MJ/kg).

- Unlike high-performance aluminum alloys that often require virgin materials, ductile iron (the precursor to ADI) can be cast with nearly 100% recycled materials.

- Case studies demonstrated that converting to ADI from other materials resulted in embodied energy savings of 40% to 65%.

- In automotive applications, weight savings from ADI conversions also contribute to life-cycle fuel savings, further enhancing its sustainability. For a suspension control arm, a 2kg vehicle mass reduction led to an estimated 1800 MJ in fuel savings over the vehicle's life.

Figure Name List:

- Figure 1: A comparison of the yield (proof) strength of ADI to that of several engineering materials.

- Figure 2: Young's Modulus (stiffness) of various materials.

- Figure 3: Energy content (embodied energy) vs. cost (£UK) for various metallic and non-metallic materials.

- Figure 4: Energy content (embodied energy) vs. cost (£UK) for various metallic materials.

- Figure 5: Relative mass per unit of yield strength for various materials. (Forged carbon steel centered on unity).

- Figure 6: An ADI prototype bracket with a continuous 3mm wall.

- Figure 7: The ADI bracket (right) replaced the aluminum bracket (left) to solve a specific NVH problem.

- Figure 8: A 0.99kg steel end connector is produced from a 1.81kg forging.

- Figure 9: The finished, 0.93kg ADI end connector was produced from a 1.09kg green sand casting.

- Figure 10: A rangeland seeder boot fabricated from cut, formed, punched and welded steel blanks.

- Figure 11: An ADI rangeland seeder boot produced from a green sand ductile iron casting and machined in the as-cast condition.

- Figure 12: The ADI Dura-Light® hub on the left replaced the permanent mold cast aluminum hub on the right with a 50% savings in embodied energy and a 2% weight reduction.

- Figure 13: The ADI control arm (right) exceeded testing requirements and replaced the stamped steel component (left) at a 6% weight savings.

7. Conclusion:

The concept of embodied energy is a useful tool for quantifying the sustainability of a design. Low material density does not automatically lead to a lower weight or more efficient component. ADI's high strength-to-weight ratio and stiffness enable it to replace materials like aluminum or magnesium at equal mass in sections over 3mm. Furthermore, its low embodied energy and high recyclability give it superior sustainability compared to steel, aluminum, or magnesium. Properly designed ADI components can replace these materials at lower life-cycle energy, and the component with the lowest embodied energy is often the lowest cost solution. Designers should consider total life-cycle energy consumption, not just fuel efficiency or light weight.

8. References:

- "On the Road in 2020", by M.A. Weiss, J.B. Heywood, E. M. Drake, A Schafer and F.F. AuYeung, Massachusetts Institute of Technology Energy Laboratory Report No. MIT EL 00-003.

- "Life Cycle Energy Savings Potential from Aluminum-Intensive Vehicles", by F. Stodolsky, A. Vyas, R. Cuenca and L. Gaines, Argonne National Laboratory- Transportation Technology R&D Center, Total Life Cycle Conference & Exposition, Vienna, Austria, October 1995.

- "Life-Cycle Analysis for Heavy Vehicles", by L. Gaines, F. Stodolsky and R. Cuenca. Argonne National Laboratory-Transportation Technology R&D Center and J. Eberhardt, US Dept. of Energy Office of Heavy Vehicle Technologies. Air & Waste Management Association Annual Meeting, San Diego, CA (USA), June 1998.

- "Machinery's Handbook- 28th Edition”, 2008 Edited by Erik Oberg et al, ISBN 9780831128005, Industrial Press New York, NY, USA. www.industrialpress.com.

- ASTM A897/A 897M-06, Standard Specification for Austempered Ductile Iron Castings, ASTM International, West Conshohocken, PA, www.astm.org.

- ISO 17804:2005, Founding Ausferritic Spheroidal Graphite Cast Irons – Classification, ISO, Switzerland, www.iso.org or www.ansi.org.

- SAE J2477:2004, Automotive Austempered Ductile (Nodular) Iron Castings (ADI), SAE International, Warrendale, PA, www.sae.org.

- AGMA 939-A07, Austempered Ductile Iron for Gears, American Gear Manufacturers Association, Alexandria, VA, www.agma.org.

- "Ductile Iron Data for Design Engineers", revised 1998, Rio Tinto Iron & Titanium, Inc., Montreal, Quebec, www.ductile.org.

- "Strain-life Fatigue Properties Database for Cast Iron" (CD), American Foundry Society, Schaumburg, IL (USA), c2003.

- "The Foundry Industry- Review of Process Energy Use, Markets, and Information Resources", Report 155-1, May 1997. The Energy Center of Wisconsin 595 Scenic Drive, Madison, WI 53711.

- "Dematerialisation: not just a matter of weight", by E. van der Voet, L. van Oers and I. Nikolic, Center of Environmental Science (CML) Leiden University, Substances and Products Section, PO Box 9518, 2300 RA Leiden, The Netherlands. www.leidenuniv.nl/cml

- "The role of metals in sustainable development”, by T.E. Norgate and W.J. Rankin, CSIRO Minerals, PO Box 312, Clayton South, Victoria 3169 Australia.

- Cambridge University Materials Engineering Dept., Cambridge, UK, www-materials.eng.cam.ac.uk. (Figures captured from website January 2010).

- "Thin Wall Ductile and Austempered Iron Castings as Substitutes for Aluminum Alloy Castings" by E. Fras and M. Gorny, AGH University of Science and Technology, Cracow, Poland and H.F. Lopez, University of Wisconsin- Milwaukee, WI (USA). International Foundry Research / Giessereiforschung 61 (2009) No. 3.

- "Low Life-Cycle Energy Consumption in Car and Truck Radiators: Another Plus for Copper and Brass”. www.copper.org. Copper Development Association (US).

Expert Q&A: Your Top Questions Answered

Q1: The paper claims ADI can replace aluminum at equal mass, despite being 2.4 times denser. How is this physically possible?

A1: This is possible because mass is a function of both density and volume. While ADI is denser, its mechanical properties—specifically its stiffness (Young's Modulus) and yield strength—are significantly higher than aluminum's. As shown in Figure 1 and Figure 2, ADI is 2.4 times stiffer and has 3-5 times the yield strength of cast aluminum. This allows engineers to design ADI components with much thinner sections and less overall volume to achieve the same or better performance, thereby offsetting the higher density and resulting in a part of comparable mass.

Q2: What is "embodied energy," and why is it a better metric for sustainability than just component weight?

A2: Embodied energy is the total energy consumed to produce a component, from raw material extraction through processing and manufacturing. It provides a holistic view of a material's environmental impact. Focusing only on weight for fuel efficiency ignores the massive "up-front" energy cost of producing materials like primary aluminum, which the paper quantifies as 255 MJ/kg for wrought forms. ADI, which can be made from 100% recycled scrap, has an embodied energy of only 30 MJ/kg, making it a far more sustainable choice from a total energy perspective.

Q3: The paper mentions a 3mm minimum wall thickness for ADI to be competitive with aluminum. Is this a hard limitation of the casting process?

A3: The paper states that ADI can replace aluminum at equal mass in sections over 3mm, and Figure 6 shows a prototype ADI bracket with a continuous 3mm wall. This suggests 3mm is a practical thickness achievable with leading-edge casting techniques. While not explicitly stated as a hard limit, it implies that for very thin-walled applications (under 3mm), the mass advantage may shift back to lower-density materials. However, for a vast range of structural components, 3mm is a perfectly acceptable and achievable design parameter.

Q4: How does the near-net-shape nature of ADI casting contribute to its sustainability?

A4: Near-net-shape casting is inherently a low-waste process. As demonstrated in the steel end connector case study (Figure 8), a forged steel part started at 1.81 kg to create a 0.99 kg finished product, generating 0.82 kg of machined chips (45% waste). The ADI replacement (Figure 9) started at 1.09 kg to create a 0.93 kg part, generating only 0.16 kg of waste (15%). This drastic reduction in material waste directly translates to lower embodied energy, as less material needs to be melted, formed, and machined.

Q5: The paper focuses on energy and weight. What about cost?

A5: The paper strongly links embodied energy to cost. Figure 3 and Figure 4 from Cambridge University show a roughly proportional relationship between a material's embodied energy and its cost. The case studies confirm this: the ADI seeder boot was 65% less expensive than the weldment it replaced, and the paper states ADI components are typically priced 25-50% less than the aluminum components they replace. The conclusion reinforces this by stating, "the component with the lowest embodied energy... may likely be the lowest cost solution."

Conclusion: Paving the Way for Higher Quality and Productivity

This research compellingly argues that a holistic, life-cycle approach to material selection is essential for true sustainable design. By looking beyond simple density metrics, engineers can unlock the significant potential of Austempered Ductile Iron (ADI). The core breakthrough is that ADI's superior combination of strength, stiffness, and low embodied energy allows it to replace steel and aluminum components with less waste, lower cost, and a dramatically smaller environmental footprint, often at a comparable weight.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components.

Copyright Information

This content is a summary and analysis based on the paper "Austempered Ductile Iron (ADI) - A Green Alternative" by "John R. Keough, PEng, FASM".

Source: The paper was presented in April 2010. A direct link is not provided in the document, but it is attributed to Applied Process Inc. Technologies Div.

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.