Unlocking Performance: A Microstructural Analysis of Lightweight Automotive Alloys

This technical summary is based on the academic paper "Microstructures of Mg-Al-Zn and Al-Si-Cu cast alloys" by T. Tański, L.A. Dobrzański, and R. Maniara, published in the Journal of Achievements in Materials and Manufacturing Engineering (2010).

Keywords

- Primary Keyword: Light Alloy Microstructure Analysis

- Secondary Keywords: Magnesium alloys, Aluminium alloys, Mg-Al-Zn, Al-Si-Cu, cast alloys, dendritic structure, intermetallic phase, metallography

Executive Summary

- The Challenge: The automotive industry requires lightweight, high-performance materials like magnesium and aluminum alloys, but their final properties are critically dependent on their as-cast microstructure.

- The Method: The study investigated the as-cast microstructures of MCMgAl6Zn1, MCMgAl9Zn1, ACAlSi9Cu, and ACAlSi9Cu4 alloys using light microscopy, scanning electron microscopy, and X-ray microanalysis.

- The Key Breakthrough: The research precisely identified and characterized the key phases (such as γ–Mg17Al12 in magnesium alloys and β-Si in aluminum alloys) and their distribution, which directly govern the mechanical properties of the final cast components.

- The Bottom Line: A detailed understanding of these specific microstructural features is essential for optimizing casting processes and ensuring the reliability and performance of lightweight automotive parts.

The Challenge: Why This Research Matters for HPDC Professionals

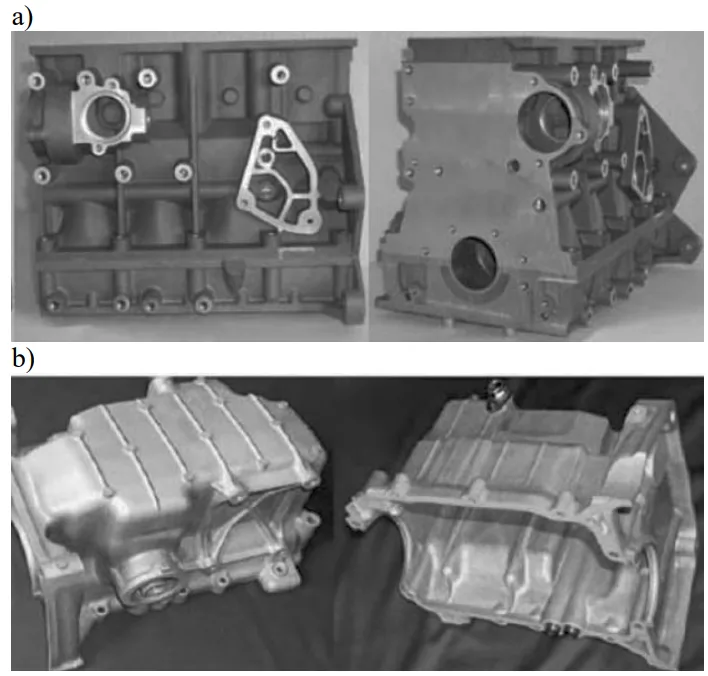

In today's automotive industry, the drive for greater fuel efficiency and performance is relentless. This has led to a massive shift towards lightweight construction, where magnesium and aluminum alloys are star players. These materials offer an excellent strength-to-density ratio, superior vibration damping, and outstanding machinability, making them ideal for components like engine blocks, gearbox housings, and oil pumps.

However, simply specifying an alloy is not enough. The final mechanical properties and in-service reliability of a cast component are dictated by its microstructure—the arrangement, size, and type of microscopic phases that form during solidification. Without a deep understanding of this structure, engineers face challenges in controlling quality, predicting performance, and preventing defects like shrinkage porosity or hot cracking. This research addresses that knowledge gap by providing a detailed microstructural blueprint for four commonly used magnesium and aluminum cast alloys.

The Approach: Unpacking the Methodology

To ensure a rigorous and reliable analysis, the researchers employed a multi-faceted approach to characterize the as-cast structure of the alloys. This methodology provides a clear and verifiable basis for the study's findings.

Method 1: Materials and Preparation

The investigation focused on four commercially relevant alloys in their as-cast state:

* Magnesium Alloys: MCMgAl9Zn1 and MCMgAl6Zn1

* Aluminum Alloys: ACAlSi9Cu and ACAlSi9Cu4

Test samples were mounted in thermohardening resins. To clearly reveal the grain boundaries and different phases, the samples were etched using a solution of 5% molybdenic acid and 1% HBF4 acid for 5-10 seconds.

Method 2: Microscopic Examination and Analysis

A comprehensive suite of analytical equipment was used to examine the prepared samples:

* Light Microscopy: A LEICA MEF4A microscope was used for initial metallographic observations.

* Scanning Electron Microscopy (SEM): Opton DSM-940 and ZEISS SUPRA 25 scanning electron microscopes provided high-resolution images of the microstructures using secondary electron detection.

* X-ray Microanalysis: The SEMs were equipped with an Oxford EDS LINK ISIS energy-dispersive spectrometer to perform qualitative and quantitative chemical analysis, identifying the elemental composition of specific phases and mapping their distribution across the microstructure.

The Breakthrough: Key Findings & Data

The investigation yielded detailed characterizations of the microstructures for both the magnesium and aluminum alloy families.

Finding 1: Microstructure of Mg-Al-Zn Alloys (MCMgAl6Zn1 & MCMgAl9Zn1)

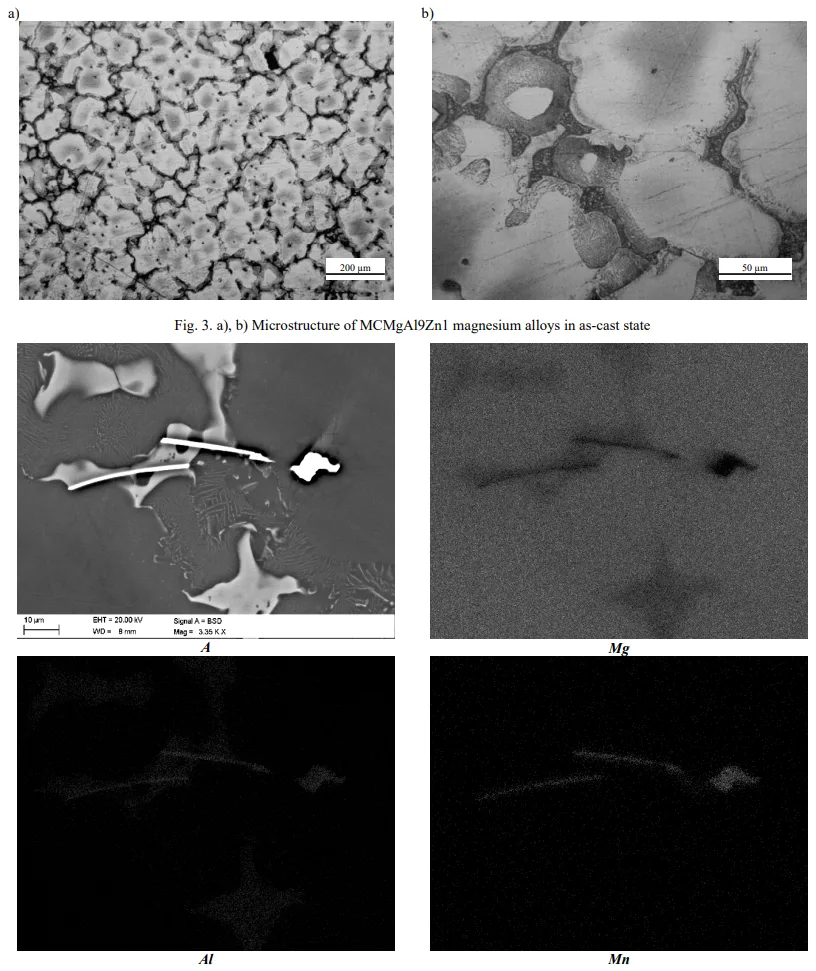

The magnesium alloys exhibited a complex structure consisting of a primary solid solution (α-Mg) that forms the matrix of the alloy. The key findings include:

* Intermetallic Phase: A discontinuous intermetallic phase, identified as γ–Mg17Al12, was observed primarily in the form of plates located at the grain boundaries (Figure 2).

* Eutectic Structure: In the vicinity of the γ–Mg17Al12 plates, a needle-like eutectic structure composed of (α + γ) was revealed.

* Hardening Compounds: The analysis also identified angular, grey-green phases confirmed to be Mg2Si compounds (Figure 2b). The paper notes that the precipitation of this compound increases the hardness of the castings.

Finding 2: Microstructure of Al-Si-Cu Alloys (ACAlSi9Cu & ACAlSi9Cu4)

The aluminum alloys were characterized by a dendritic structure, with the morphology of key phases depending on the silicon and copper concentration.

* Matrix and Eutectic: The structure consists of a dendritic α solid solution (the alloy matrix) and a discontinuous β-Si phase, which together form α+β eutectic grains (Figure 5). The β-Si phase appears as big, irregular plates with sharp corners.

* Complex Phases: The presence of additional, more complex eutectics was confirmed, including α+Al₂Cu+β and α+Al₂Cu+AlCuMgSi+β. Needle-shaped precipitations of the Al5FeSi phase were also observed, typically near these eutectic regions (Figure 6).

* Copper-Rich Phase: The Al₂Cu phase was found both as part of a triple eutectic and as a separate, irregular, brown-colored precipitate (Figure 7).

Practical Implications for R&D and Operations

- For Process Engineers: The study's detailed characterization of phases like γ–Mg17Al12 and β-Si, which form during solidification, suggests that controlling cooling rates during the casting process is critical for managing the morphology and distribution of these phases, thereby influencing final mechanical properties like ductility and strength.

- For Quality Control Teams: The distinct morphologies of phases shown in Figures 2, 5, and 6 provide a clear visual baseline for metallographic inspection. Deviations from these typical as-cast structures could serve as an early indicator of issues in the casting process or alloy composition.

- For Design Engineers: The findings highlight that brittle intermetallic phases like the plate-like γ–Mg17Al12 tend to precipitate at grain boundaries. This is a crucial consideration during component design, as these areas can act as stress concentrators, potentially impacting the fatigue life and structural integrity of the part.

Paper Details

Microstructures of Mg-Al-Zn and Al-Si-Cu cast alloys

1. Overview:

- Title: Microstructures of Mg-Al-Zn and Al-Si-Cu cast alloys

- Author: T. Tański, L.A. Dobrzański, R. Maniara

- Year of publication: 2010

- Journal/academic society of publication: Journal of Achievements in Materials and Manufacturing Engineering (VOLUME 38, ISSUE 1)

- Keywords: Metallography; Magnesium alloys; Aluminium alloys, Structure

2. Abstract:

Purpose: The aim of this paper was to investigate the structure of the MCMgAl6Zn1 magnesium and ACAlSi9Cu aluminium cast alloy in as-cast state.

Design/methodology/approach: The following results concern the microstructure of the cast magnesium and aluminium alloys using ZEISS SUPRA 25, Opton DSM-940 scanning and LEICA MEF4A light microscopy, X-ray qualitative microanalysis as well as X-ray analysis.

Findings: The analysis of the structure magnesium alloy consists of the solid solution α – Mg (matrix) of the secondary phase γ – Mg17Al12 evenly located in the structure. The structure creates agglomerates in the form of needle precipitations, partially coherent with the matrix placed mostly at the grain boundaries. The AC AlSi9Cu and AC AlSi9Cu4 cast aluminium alloys are characterised by a dendritic structure of the α solid solution – as the alloy matrix, as well are characterised by a discontinuous β-Si phase forming the α+β eutectic grains, with a morphology depending on the silicon and copper mass concentration.

Research limitations/implications: Taking into account the fact that some of the properties are of great importance only for the surface of the material, the future investigation will concern modelling of the alloy surface using surface layers deposition methods like physical vapour deposition methods.

Practical implications: A desire to create as light vehicle constructions as possible and connected low fuel consumption have made it possible to make use of magnesium and aluminium alloys as constructional material in automotive industry.

Originality/value: Contemporary materials should possess high mechanical properties, physical and chemical, as well as technological ones, to ensure long and reliable use. The above mentioned requirements and expectations regarding the contemporary materials are met by the non-ferrous metals alloys used nowadays, including the magnesium and aluminium alloys.

3. Introduction:

Recent dynamic development in the automobile industry is largely based on innovative constructional solutions and modern materials that directly influence vehicle mass, performance, and fuel consumption. Magnesium and aluminium alloys are a primary group of materials used to achieve these goals. Magnesium alloys are distinguished by a useful technological parameter: a high strength-to-density ratio. They also possess a relatively low elasticity modulus, which results in very good vibration damping ability. Furthermore, magnesium alloys offer excellent castability for thin-walled, large-surface elements with high dimensional stability and extraordinary machinability. Similarly, aluminium alloys are widely used in the automotive and aviation industries due to their low density, good mechanical properties, corrosion resistance, and good machinability. The development of advanced casting technologies has further promoted their application. This paper aims to present the investigation results of the microstructure of selected casting magnesium and aluminium alloys in their as-cast state.

4. Summary of the study:

Background of the research topic:

The research is set against the backdrop of the automotive industry's continuous demand for lightweight, high-strength materials to reduce vehicle mass and, consequently, fuel consumption. Magnesium and aluminum alloys are primary candidates to meet these demands.

Status of previous research:

The paper acknowledges the existing body of work on magnesium and aluminum alloys, citing numerous references related to their properties, processing, and applications. It notes that casting methods have been improved to enhance plasticity and resistance properties, and advanced sand casting technologies like Cosworth, CPS, BAXI, and HWS have emerged for aluminum alloys.

Purpose of the study:

The goal of the paper is to present the investigation results of the microstructure of MCMgAl9Zn1, MCMgAl6Zn1 magnesium alloys and ACAlSi9Cu, ACAlSi9Cu4 aluminium alloys in the as-cast state.

Core study:

The core of the study is a detailed metallographic investigation of the four specified alloys. It involves characterizing the constituent phases, their morphology, and their distribution within the as-cast microstructure using a combination of light microscopy, scanning electron microscopy, and X-ray microanalysis.

5. Research Methodology

Research Design:

The study employs a descriptive and analytical research design to characterize the as-cast microstructure of selected commercial magnesium and aluminium alloys.

Data Collection and Analysis Methods:

Data was collected through metallographic examinations of alloy specimens. The methods included:

* Light Microscopy: Observations were made on a LEICA MEF4A microscope.

* Scanning Electron Microscopy (SEM): High-resolution imaging was performed on Opton DSM-940 and ZEISS SUPRA 25 microscopes using secondary electron detection.

* X-ray Microanalysis: Qualitative and quantitative elemental analysis and surface distribution mapping were conducted using an EDS dispersive radiation spectrometer on the SEMs and a JEOL JCXA 733 x-ray microanalyser.

Sample preparation involved mounting in thermohardening resins and etching with 5% molybdenic acid and 1% HBF4 acid.

Research Topics and Scope:

The investigation was performed on test samples of MCMgAl9Zn1, MCMgAl6Zn1 magnesium alloys and ACAlSi9Cu, ACAlSi9Cu4 aluminium alloys in the as-cast state. The chemical compositions of the investigated materials are detailed in the paper's Tables 1 and 2.

6. Key Results:

Key Results:

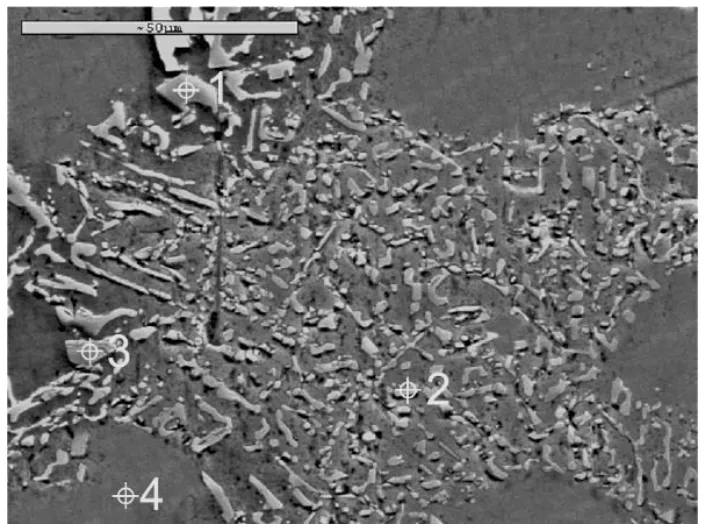

- Magnesium Alloys (MCMgAl9Zn1, MCMgAl6Zn1): The microstructure is composed of a solid solution α-Mg matrix and a discontinuous intermetallic phase, γ–Mg17Al12, which appears as plates located mostly at grain boundaries. In the vicinity of this phase, needle-like eutectics (α + γ) are present. The structure also contains angular precipitations of the Mg2Si compound, which increases the hardness of the castings.

- Aluminium Alloys (ACAlSi9Cu, ACAlSi9Cu4): These alloys are characterized by a dendritic structure of the α solid solution (matrix) and a discontinuous β-Si phase that forms α+β eutectic grains. The morphology of these grains depends on the silicon and copper concentration. The microstructure also contains needle-shaped precipitations of the Al5FeSi phase and complex eutectics, including α+Al₂Cu+β and α+Al₂Cu+AlCuMgSi+β. The Al₂Cu phase occurs both within the triple eutectic and as separate, irregular precipitates.

Fig. 4. The area analysis of chemical elements alloy MCMgAl6Zn1 in as-cast state: image of the secondary electrons (A) and maps of elements' distribution

Figure Name List:

- Fig. 1. Examples of automotive components made of Mg alloys a) engine block, b) oil pump

- Fig. 2. a), b) Microstructure of MCMgAl6Zn1 magnesium alloys in as-cast state

- Fig. 3. a), b) Microstructure of MCMgAl9Zn1 magnesium alloys in as-cast state

- Fig. 4. The area analysis of chemical elements alloy MCMgAl6Zn1 in as-cast state: image of the secondary electrons (A) and maps of elements' distribution

- Fig. 5. a), b) Microstructure of ACAlSi9Cu casting alloy

- Fig. 6. Microstructure of ACAlSi9Cu4 casting alloy

- Fig. 7. Microstructure of ACAlSi9Cu4 casting alloy

- Fig. 8. The area analysis of chemical elements alloy ACAlSi9Cu4: image of secondary electrons (A) and maps of elements' distribution

- Fig. 9. Microstructure of ACAlSi9Cu casting alloys

7. Conclusion:

The results of the metallographic examinations confirm that the MCMgAl9Zn1 magnesium cast alloy is characterized by a microstructure of the solid solution α constituting the alloy matrix, as well as the γ–Mg17Al12 discontinuous intermetallic phase in the form of plates located mostly at grain boundaries. In the vicinity of the γ intermetallic phase precipitations, the presence of needle eutectics (α + γ) has been revealed. Chemical analysis confirmed concentrations of Mg, Si, Al, Mn, and Fe, suggesting the occurrence of precipitations containing Mg and Si with angular contours, as well as phases with high Mn and Al concentrations.

The ACAlSi9Cu and ACAlSi9Cu4 cast aluminium alloys are characterised by a dendritic structure of the α solid solution as the alloy matrix, and by a discontinuous β-Si phase occurring in the form of big irregular plates, forming the α+β eutectic grains. The occurrence of the α+Al₂Cu+β, α+Al₂Cu+AlCuMgSi+β eutectics and the Al5FeSi phase was also confirmed.

8. References:

- [1] E.F. Horst, B.L. Mordike, Magnesium Technology. Metallurgy, Design Data, Application, Springer-Verlag, Berlin Heidelberg 2006.

- [2] A. Fajkiel, P. Dudek, G. Sęk-Sas, Foundry engineering XXI c. Directions of metallurgy development and Ligot alloys casting, Publishers Institute of Foundry engineering, Cracow, 2002.

- [3] K.U. Kainem, Magnesium – Alloys and Technology, Wiley-VH, Weinheim, Germany, 2003.

- [4] H. Westengen, Magnesium Alloys: Properties and Applications Encyclopaedia of Materials: Science and Technology, 2008, 4746-4753.

- [5] M. Greger, R. Kocich, L. Čížek, L.A. Dobrzański, I. Juřička, Possibilities of mechanical properties and microstructure improvement of magnesium alloys, Archives of Materials Science and Engineering 28/2 (2007) 83-90.

- [6] W. Kasprzak, J.H. Sokołowski, M. Sahoo, L.A. Dobrzański, Thermal characteristic of the AM50 magnesium alloys, Journal of Achievements in Materials and Manufacturing Engineering 29/2 (2008) 179-182.

- [7] L.A. Dobrzański, T. Tański, Influence of aluminium content on behaviour of magnesium cast alloys in bentonite sand mould, Solid State Phenomena 147-149 (2009) 764-769.

- [8] L.A. Dobrzański, M. Król, T. Tański, R. Maniara, Effect of cooling rate on the solidification behaviour of magnesium alloys, Archives of Computational Materials Science and Surface Engineering 1/1 (2009) 21-24.

- [9] L.A. Dobrzański, T. Tański, J. Trzaska, Optimization of heat treatment conditions of magnesium cast alloys, Materials Science Forum 638-642 (2010) 1488-1493.

- [10] Z. Górny, J. Sobczak, Non-ferrous metals based novel materials in foundry practice, ZA-PIS, Cracow, 2005.

- [11] J.G. Kauffman, E. L. Rooy, Aluminum Alloy Castings, ASM International, Ohio, 2005.

- [12] A.K. Dahle, K. Nogita, S.D. McDonald, C. Dinnis, L. Lu, Eutectic Modification on Microstructure Development in Al-Si Alloys, Materials Science and Engineering A 413 (2005) 243-248.

- [13] Z. Muzaffer, Effect of copper and silicon content on mechanical properties in Al-Cu-Si-Mg alloys, Journal of Materials Processing Technology 169 (2005) 292-298.

- [14] P. Ouellet, F.H. Samuel, Effect of Mg on the ageing behaviour of Al-Si-Cu 319 type aluminium casting alloys, Journal of Materials Science 34 (1999) 4671 - 4697.

- [15] P.D. Lee, A. Chirazi, R.C. Atwood, W. Wan, Multiscale modelling of solidification microstructures, including microsegregation and microporosity, in an Al-Si-Cu alloy, Materials Science and Engineering A365 (2004) 57-65.

- [16] ASM Handbook, Aluminum and Aluminum Alloys, ASM International, Ohio, 1993.

- [17] L. Bäckerud, G. Chai, J. Tamminen, Solidification Characteristics of Aluminum Alloys, Vol. 2, AFS/SKANALUMINIUM, Illinois, 1990.

Expert Q&A: Your Top Questions Answered

Q1: Why were these specific alloys (e.g., MCMgAl6Zn1, ACAlSi9Cu) chosen for this investigation?

A1: The paper selected these alloys because they are representative of the magnesium and aluminum alloys widely used as constructional materials in the automotive industry. The research was driven by the industry's desire to create lighter vehicle constructions to reduce fuel consumption, and these alloys are key to achieving that goal.

Q2: What specific etching reagents were used to reveal the microstructures, and why was that combination chosen?

A2: The researchers used a combination of 5% molybdenic acid and 1% HBF4 acid as the etching reagent. This specific formulation was chosen for its effectiveness in disclosing the grain boundaries and, critically, for distinguishing the particular precipitations and phases within the complex microstructures of both the magnesium and aluminum alloys.

Q3: The paper identifies the γ–Mg17Al12 phase in the magnesium alloys. Where does this phase typically form and what is its morphology?

A3: According to the findings, the γ–Mg17Al12 is a discontinuous intermetallic phase. It primarily forms in the shape of plates located at the grain boundaries of the α-Mg matrix. Additionally, it is a constituent of the needle-like eutectic structure (α + γ) that forms in the areas surrounding these primary plate-like precipitates.

Q4: How does the microstructure of the aluminum alloys change with different copper concentrations, as seen between ACAlSi9Cu and ACAlSi9Cu4?

A4: The paper states that the morphology of the α+β eutectic grains in the aluminum alloys depends on the silicon and copper mass concentration. While both alloys feature a dendritic α solid solution and a discontinuous β-Si phase, the significantly higher copper content in ACAlSi9Cu4 (4.64% vs 1.05%) would lead to a greater volume fraction of copper-containing phases, such as the Al₂Cu phase, within the eutectic structures.

Q5: The paper identifies an Mg2Si compound in the magnesium alloys. What is its significance for the final component?

A5: The paper observes the Mg2Si compound precipitating as angular, grey-green phases within the magnesium alloy structure. The stated significance of this compound is that its precipitation increases the hardness of the castings. This implies that controlling the formation of Mg2Si can be a method to tailor the mechanical properties of the final component.

Conclusion: Paving the Way for Higher Quality and Productivity

The push for lightweighting in the automotive sector makes a fundamental understanding of materials more critical than ever. This study provides an essential foundation by delivering a detailed Light Alloy Microstructure Analysis for four key magnesium and aluminum alloys. By clearly identifying the phases, like γ–Mg17Al12 and β-Si, that form during casting and defining their morphology, this research gives engineers the knowledge needed to connect process variables to final component quality. These insights are invaluable for optimizing casting parameters, improving quality control, and ultimately producing more reliable, high-performance lightweight components.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components.

Copyright Information

This content is a summary and analysis based on the paper "Microstructures of Mg-Al-Zn and Al-Si-Cu cast alloys" by T. Tański, L.A. Dobrzański, and R. Maniara.

Source: Tański, T., Dobrzański, L.A., & Maniara, R. (2010). Microstructures of Mg-Al-Zn and Al-Si-Cu cast alloys. Journal of Achievements in Materials and Manufacturing Engineering, 38(1), 64-71.

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.