From 13% Rejection to Near-Zero Defects: A 3-Step Guide to HPDC Hydraulic Circuit Optimization

This technical summary is based on the academic paper "REDESIGN OF HYDRAULIC CIRCUIT TO IMPROVE QUALITY IN HIGH PRESSURE ALUMINUM DIE CASTING MACHINE" by K. NAGASUBRAMANIAM and P. CHANDRAMOHAN, published in the Journal of Engineering Science and Technology (2014). It has been analyzed and summarized for technical experts by CASTMAN.

Keywords

- Primary Keyword: HPDC Hydraulic Circuit Optimization

- Secondary Keywords: Die Casting Quality, Rejection Rate Reduction, Intensifier Design, Regenerative Circuit, Nitrogen Bottle, Aluminum Die Casting, Casting Defects

Executive Summary

- The Challenge: An aluminum die casting machine was experiencing high component rejection rates of 11-13% due to inadequate pressure and velocity control from its existing hydraulic circuit.

- The Method: Researchers implemented three sequential modifications: adding a dedicated nitrogen bottle, redesigning the intensifier output passage to increase velocity, and introducing a regenerative intensifier circuit.

- The Key Breakthrough: The final modification, a regenerative circuit, sustained the high-pressure injection phase for 1.2-1.6 seconds, boosting overall system efficiency to 98% and virtually eliminating defects.

- The Bottom Line: Strategic, iterative modifications to an existing HPDC machine's hydraulic circuit can dramatically reduce rejection rates and improve component quality, offering a cost-effective alternative to complete system replacement.

The Challenge: Why This Research Matters for HPDC Professionals

In high-pressure die casting (HPDC), pressure and velocity are the primary factors determining the quality and integrity of the final component. Inadequate control over these parameters often leads to costly defects such as blow holes, oxides, burrs, and surface imperfections, resulting in high rejection rates. This study addresses a common industrial scenario: a 120T locking force HPDC machine producing aluminum components with an average rejection rate between 11% and 13%. The core problem was that the machine's basic hydraulic design could not deliver the optimal pressure and velocity needed for intricate parts, leading to premature solidification and other defects. This research was undertaken to find a cost-effective way to improve machine efficiency and product quality by modifying the existing hydraulic system rather than investing in a new one.

The Approach: Unpacking the Methodology

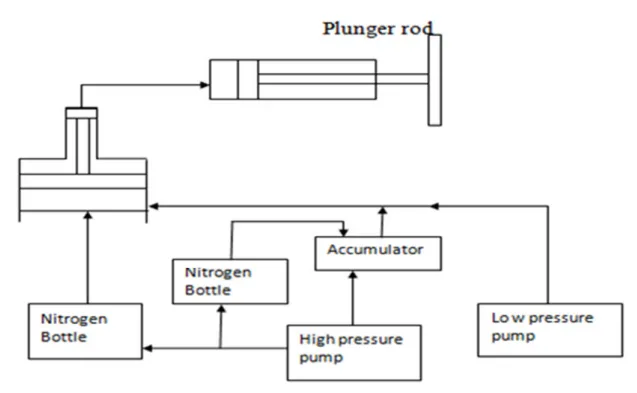

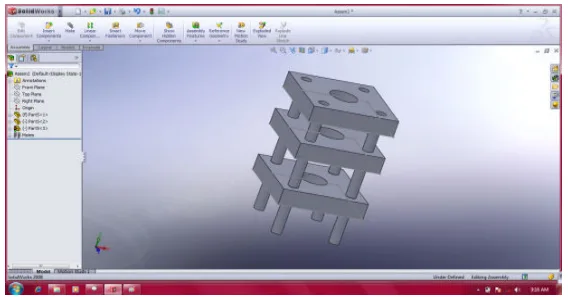

The researchers conducted a rejection analysis on a machine producing various textile and automotive components from LM-24 and AD C 12 aluminum alloys. They identified that insufficient pressure and velocity were the root causes of defects. To solve this, they implemented and tested three sequential design modifications on the machine's hydraulic circuit, using "Automation studio" software to simulate the changes before implementation.

The three modifications were:

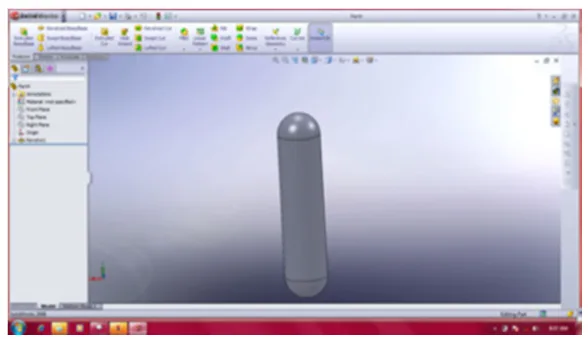

1. Addition of a Nitrogen Bottle: The original circuit had one nitrogen bottle shared between the accumulator and intensifier. A second, dedicated nitrogen bottle was added to the intensifier circuit to provide a more direct and sustained pressure boost.

2. Modification of the Intensifier Output Passage: The original intensifier had a uniform 16 mm diameter output passage. This was redesigned to a 16-30-16 mm profile to increase fluid velocity during the injection phase.

3. Implementation of a Regenerative Intensifier Circuit: A regenerative circuit was added, which redirects a portion of the intensifier's output fluid back to its input. This modification was designed to build up and sustain higher pressure for a longer duration during the final injection phase.

Production and rejection data were collected for a period of 3 months before the modifications and after each implementation to quantify the improvements.

The Breakthrough: Key Findings & Data

The study demonstrated a clear, step-by-step improvement in machine efficiency and a corresponding reduction in component rejection rates with each modification.

Finding 1: Adding a Nitrogen Bottle Boosts Pressure and Cuts Rejections

The first modification directly addressed the system's pressure deficit. Adding a dedicated nitrogen bottle to the intensifier circuit increased the system's efficiency from an initial 88% to 92%. This pressure increase had a significant impact on quality. As shown in Table 3, the average rejection rate across all components dropped from the 11-13% range to a more acceptable 7-9% range. This confirmed that insufficient pressure was a primary contributor to the initial defects.

Finding 2: Increasing Passage Diameter Enhances Velocity and Reduces Solidification Defects

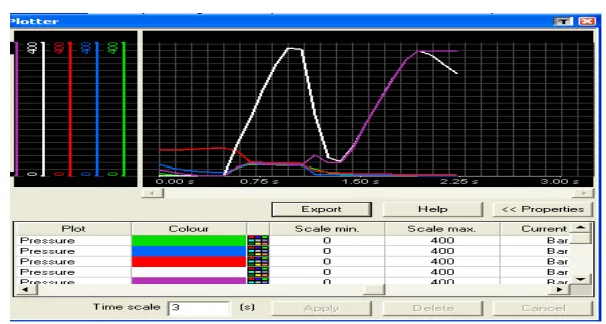

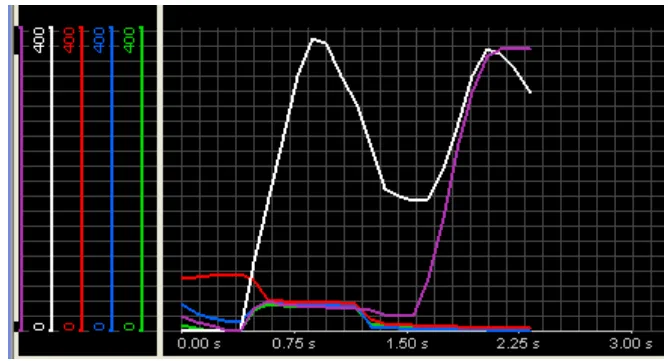

The second modification focused on injection velocity. By changing the intensifier output passage from a uniform 16 mm to a 16-30-16 mm design, the pressure build-up time was reduced from 1.0 second to just 0.6 seconds (Figure 5a vs. 5b). This indicates a significant increase in the velocity of the molten metal. This faster injection helped prevent premature solidification, a key cause of blow holes. This change further improved machine efficiency to 94% and, as detailed in Table 4, reduced the average rejection rate to the 5-7% range.

Finding 3: Regenerative Circuit Achieves Near-Perfect Quality with Sustained Pressure

The final and most impactful modification was the addition of a regenerative circuit. The previous designs could only sustain peak pressure for 0.6-0.8 seconds. The regenerative circuit extended this critical period to 1.2-1.6 seconds (Figure 8b). This sustained pressure ensured complete die filling and packing, leading to sound castings. This breakthrough pushed the machine's efficiency to 98%. The results in Table 5 are remarkable, showing the rejection rate plummeting to an average of 0-3%, with some components achieving zero rejections over a three-month period.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that adjusting the duration of the intensification pressure phase, not just its peak value, may contribute to significantly reducing defects like blow holes and porosity. The success of the regenerative circuit highlights a powerful tool for process optimization.

- For Quality Control Teams: The data in Tables 2 through 5 of the paper illustrates a direct correlation between specific hydraulic modifications and the reduction of casting defects. This could inform new quality inspection criteria focused on signs of insufficient velocity (flow lines) or pressure (porosity).

- For Design Engineers: The findings indicate that the hydraulic circuit's ability to deliver rapid and sustained pressure is critical for producing sound, intricate components. This reinforces the need for collaboration between part designers and machine engineers to ensure the casting machine's capabilities match the component's design complexity.

Paper Details

REDESIGN OF HYDRAULIC CIRCUIT TO IMPROVE QUALITY IN HIGH PRESSURE ALUMINUM DIE CASTING MACHINE

1. Overview:

- Title: REDESIGN OF HYDRAULIC CIRCUIT TO IMPROVE QUALITY IN HIGH PRESSURE ALUMINUM DIE CASTING MACHINE

- Author: K. NAGASUBRAMANIAM¹, P. CHANDRAMOHAN²´*

- Year of publication: 2014

- Journal/academic society of publication: Journal of Engineering Science and Technology, Vol. 9, No. 5 (2014) 605-619

- Keywords: Nitrogen bottle, Accumulator, Intensifier, Pressure, Velocity.

2. Abstract:

Pressure/velocity remains as main factors in a high pressure die casting machine to produce intricate components from the die. Rejection analysis was carried out in a die casting machine used in producing Aluminum components with a higher rejection rate. Three modifications have been carried out in the basic hydraulic design of the machine to increase the efficiency and in turn reduce the rejection of the components. The three modifications include (i) addition of nitrogen bottle to the system design (ii) Reducing the passage diameter of the Intensifier output (iii) Regeneration of Intensifier output. The first modification resulted with increase in pressure and the second with increase in velocity and finally the third one with optimum increase in both pressure and velocity. This has resulted in the improvement of machine efficiency thereby reducing the overall rejection of the components with intricate design.

3. Introduction:

Pressure die casting machine (m/c) is the process which is used to produce accurate castings of automobile parts and other mechanical components [1]. Aluminum, zinc, copper are some of the materials with which die casting process can be carried out successfully. The type of products manufactured from these machines mainly range between industrial goods to automobile (2 wheelers and 4 wheelers) that includes sprockets, starter motor assembly, etc. [2, 3]. Production of casting depends on the parameters like velocity, pressure and temperature which are involved with the system [4].

4. Summary of the study:

Background of the research topic:

The research focuses on improving the quality of components produced by a high-pressure die casting (HPDC) machine. The quality of die-cast parts is heavily dependent on key process parameters, primarily the pressure and velocity of the molten metal injection. High rejection rates are a significant issue in the industry, leading to increased costs and reduced efficiency.

Status of previous research:

Previous literature has established pressure as a primary parameter for improving product quality, with methods like adding nitrogen bottles and accumulators being explored. Other studies have focused on increasing velocity using multiple accumulators. Modifications to the intensifier unit, such as back-to-back models and regeneration, have also been investigated. However, many attempts involve adding expensive new accessories or lack a systematic, iterative approach to modifying existing designs for cost-effective improvement.

Purpose of the study:

The purpose of this work was to systematically redesign the existing hydraulic circuit of an HPDC machine to improve its efficiency and reduce the high rejection rate of its aluminum components. The study aimed to achieve this through three targeted, sequential modifications and to simulate their effects before implementation.

Core study:

The core of the study involved a three-phase modification of the hydraulic circuit of a 120T HPDC machine.

1. Phase 1: An additional nitrogen bottle was added to the circuit to increase the system pressure.

2. Phase 2: The diameter of the intensifier output passage was modified to increase the velocity of the hydraulic fluid.

3. Phase 3: A regenerative circuit was added to the intensifier to achieve an optimum increase in both pressure and velocity, and to sustain the pressure for a longer duration.

The rejection rates of five different components were tracked before and after each modification to quantify the improvement in quality.

5. Research Methodology

Research Design:

The study employed an experimental research design based on sequential, iterative improvements. A baseline was established by analyzing production and rejection data for three months from an existing 120T HPDC machine. Three distinct modifications were then implemented one after the other. After each modification, data was collected for another three months to measure its specific impact on rejection rates and machine efficiency.

Data Collection and Analysis Methods:

Data on production quantity, good castings, and rejected castings were collected for five different aluminum components. Rejection percentage was calculated to measure quality improvement. The hydraulic circuit's performance, specifically pressure and time, was analyzed using graphs generated by "Automation studio" simulation software, which was also used to design and validate the circuit modifications.

Research Topics and Scope:

The research was scoped to a single 120T high-pressure aluminum die casting machine. The investigation focused exclusively on improving component quality by modifying the hydraulic circuit's pressure and velocity characteristics. The study did not vary other parameters like metal composition, temperature, or die design, which were kept constant to isolate the effects of the hydraulic modifications.

6. Key Results:

Key Results:

- The initial machine efficiency was 88%, with an average rejection rate of 11-13%.

- Modification 1 (Nitrogen Bottle): Increased efficiency to 92% and reduced the rejection rate to an average of 7-9%.

- Modification 2 (Intensifier Passage): Increased efficiency to 94% and reduced the rejection rate to an average of 5-7%. The pressure build-up time decreased from 1.0 s to 0.6 s, indicating higher velocity.

- Modification 3 (Regenerative Circuit): Increased efficiency to 98% and reduced the rejection rate to an average of 0-3%. The duration of sustained high pressure increased from 0.6-0.8 s to 1.2-1.6 s.

Figure Name List:

- Fig. 1. Modified Circuit Diagram-Addition of N.B.

- Fig. 2. Design-Nitrogen Bottle.

- Fig. 3(a). System without the Addition of N.B.

- Fig. 3(b). System with the Addition of N.B.

- Fig. 4(a). Model with Same Passage Diameter.

- Fig. 4(b). 16-16-16 mm Intensifier Design.

- Fig. 5(a). 16-16-16 mm- Pressure Graphs.

- Fig. 5(b). 16-30-16 mm Pressure Graphs.

- Fig. 6(a). 16-30-16 mm Intensifier Design.

- Fig. 6(b). Model with Increased Passage Diameter.

- Fig. 7. Hydraulic Circuit of High Pressure Aluminum Pressure Die Casting Machine.

- Fig. 8(a). Intensification Unit without Regenerative Circuit.

- Fig. 8(b). Intensification Unit with Regenerative Circuit.

7. Conclusion:

The initial efficiency of the machine was 88% that led to the rejection rate of 11-13%. 3 design modifications were carried out in order to improve the system efficiency thereby reducing the rejection rate of the component. The first design modification, i.e., addition of nitrogen bottle led to the improvement in system efficiency of 92% which resulted in drop in rejection rate of 7-9%. Second modification, i.e., intensifier output passage diameter led to the improvement in the system efficiency of 94% which resulted in drop in rejection rate of 5-7 %. Third modification, i.e., addition of regenerative circuit led to the improvement in the system efficiency of 98% which resulted in drop in rejection rate of 0-3 %. All together the design modification carried out was successful in achieving the quality components in Aluminum high pressure die casting machine.

8. References:

- Cocks, D.L.; and Wall, A.J. (1984). Modern technology ensures zinc die casting meet market demands. Journal of Materials and Design, 5(4), 167-171.

- FSDM. (2008). Florosil machine-Reference Manual-FSDM-LF-120.

- HMT (2003). HMT-LF120-Reference Manual.

- Shawki, G.S.A and Kandeil, A.Y. (1988). A review of design parameters and machine performance for improved die casting quality. Journal of Mechanical Working Technology, 16(3), 315-333.

- Hiromi, T.; and Fumitaka, T. (1994). Method of discriminating quality of die cast articles and die casting process using same. USPO, 5, 363,899.

- Guilherme, O.V.; Rui, P.K.M.; and Marco, A.R. (2006). Influence of injection parameters on defects formation in die casting All2Sil, 3Cu alloy: Experimental results and numeric simulation. Journal of Materials Processing Technology, 179(1-3), 190-196.

- Donald, L.R.; and James, W.H. (1977). Intensified cylinder assembly. USPO, 4,030,299.

- Hiroshi, K.; Makoto, T.; and Noboru, F. (1998). Method for controlling injection in a die casting machine and apparatus for the same. USPO 5, 957,192.

- Keisuke, B.; Masakazu, S.; Bakugu, F.; and Kousuke, K. (1988). Hydraulic control method for implementation. USPO 4,884,621.

- António, F. de O. Falcão. (2007). Modeling and control of oscillating body wave energy converters with hydraulic power take-off and gas accumulator. Journal of Ocean Engineering, 34(14-15), 2021-2032.

- Jurgen, M. (1998). Device for saving energy. USPO 6,266,959.

- Kazushi, N.; Hiroshi, K.; and Satosh, K. (2001). Pressure intensifying apparatus for hydraulic cylinder. USPO 6,581,379.

- Richard, W.H.; Sven, S.; and Harbhajan, S.M, (1985). Regeneration system for a hydraulic intensifier unit. USPO 4,555,220.

- Ellsworth, W.L. (1976). Hydraulic pressure amplifier. USPO 3,952,516.

- Stephen, P. (2005). Software for fluid power technologies. Famic technologies, Automation studio-www.automationstudio.com-Canada.

- Świder, J.; Wszołek, G.; and Reclik, D. (2006). Didactic model of the high storage system, Journal of Achievements in Materials and Manufacturing Engineering, 16(1-2), 199-206.

- Cheng, L.; and Steve, H. (2007). Design of an automated wood-pallet machine. Journal of Applied Science and Engineering Technology, 1, 33-39.

- Petruzella, F.D. (2003). Programmable logic controllers. New York: McGraw-Hill, 20.

- Jose, M.; and Eurico, S. (2004). Competency-based education in automation teaching. Mechanical Engineering Department, University of Minho, Guimarães, Portugal.

- Jack, H. (1999). How are we doing in mechatronics. The Journal of Assembly Automation, 19(1), 25-29.

- Swider, J.; Wszołek, G.; and Reclik, D. (2006). Laboratory support for the didactic process of engineering processes automation. The Journal of Achievements in Materials and Manufacturing Engineering, 15(1-2), 199-206.

- Lal, A. (1982). Oil hydraulics in the service of industry. Allied Publishers, Nagpur, India.

- Verran, G.O.; Mendes, R.P.K and Dalla Valentina, L.V.O. (2008). DOE applied to optimization of aluminum alloy die castings. Journal of Materials Processing Technology, 200(1-3),120-125.

Expert Q&A: Your Top Questions Answered

Q1: Why was a nitrogen bottle added as the first step instead of simply using a more powerful pump?

A1: The paper notes that the original hydraulic circuit had a single nitrogen bottle shared between the accumulator and intensifier units, which proved insufficient. Adding a second, dedicated bottle was a targeted modification to boost the intensifier pressure directly. The paper also mentions that cost constraint is an important commercial aspect, making targeted modifications to the existing design a more efficient and practical approach than replacing major components like the main pump.

Q2: What specific defect was caused by the original uniform 16 mm intensifier passage, and how did the 16-30-16 mm design fix it?

A2: The paper states, "The main drawback of this design was that the metal gets partly solidified while travelling to the die itself. This led to the formation of blow holes in the output component." The modified 16-30-16 mm design increased the injection velocity, as evidenced by the pressure build-up time dropping from 1.0s to 0.6s (Figure 5). This higher velocity ensured the molten metal reached and filled the die cavity before partial solidification could occur, thus preventing blow holes.

Q3: How exactly does the regenerative circuit work to improve both pressure and efficiency so dramatically?

A3: In the modified circuit shown in Figure 7, solenoid 5 is activated to initiate regeneration. This process redirects a portion of the high-pressure fluid from the intensifier's output back to its input. This effectively pre-charges and builds up pressure within the intensifier unit itself. The result is a more powerful and, crucially, a more sustained injection phase (1.2-1.6 seconds) when the fluid is finally released to the plunger, leading to higher efficiency (98%) and better die filling.

Q4: What is the significance of the pressure sustaining for 1.2-1.6 seconds in the final design, compared to 0.6-0.8 seconds previously?

A4: The duration of the high-pressure phase (intensification) is critical for ensuring the casting is properly packed and dense, eliminating porosity. The initial 0.6-0.8 second duration was "noted to be a little short," resulting in castings that were "not sound" and a rejection rate of 6%. By extending this critical phase to 1.2-1.6 seconds, the regenerative circuit allowed enough time for the molten metal to completely fill intricate sections of the die and for the pressure to compact the material during solidification, resulting in a sound, defect-free casting.

Q5: What role did the "Automation studio" software play in this research?

A5: The paper states that "Automation studio, analysis software is used for carrying out the modification in the existing hydraulic circuit of the machine." This software was used to simulate the proposed hydraulic circuit changes before they were physically implemented on the machine. This allowed the researchers to visualize and confirm the expected improvements in pressure and velocity, de-risking the modifications and ensuring the changes would be effective.

Conclusion: Paving the Way for Higher Quality and Productivity

This research provides a powerful case study on tackling high rejection rates in aluminum die casting through systematic HPDC Hydraulic Circuit Optimization. By addressing the core issues of insufficient pressure, velocity, and pressure duration in three targeted steps, the researchers successfully transformed a machine with an 11-13% rejection rate into a highly efficient system with near-zero defects. The final implementation of a regenerative circuit, which boosted efficiency to 98%, stands out as a key breakthrough for achieving superior component quality. These findings demonstrate that significant gains in quality and productivity can be achieved by intelligently modifying existing equipment.

"At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components."

Copyright Information

- This content is a summary and analysis based on the paper "REDESIGN OF HYDRAULIC CIRCUIT TO IMPROVE QUALITY IN HIGH PRESSURE ALUMINUM DIE CASTING MACHINE" by "K. NAGASUBRAMANIAM and P. CHANDRAMOHAN".

- Source: https://www.tumpress.p-kit.us/jestec/jestec-vol9-num5-dec14/605-619-9-5-14.pdf

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.