Unlocking Superior Hardness in AlSi20 Castings: A Deep Dive into Water Mist Die Cooling

This technical summary is based on the academic paper "THE EFFECT OF WATER MIST COOLING OF CASTING DIE ON THE SOLIDIFICATION, MICROSTRUCTURE AND PROPERTIES OF AlSi20 ALLOY" by R. Władysiak, A. Kozuń, and T. Pacyniak, published in Arch. Metall. Mater. (2017). It has been analyzed and summarized for technical experts by CASTMAN.

Keywords

- Primary Keyword: Water Mist Die Cooling

- Secondary Keywords: AlSi20 Alloy, Hypereutectic Aluminum, Casting Microstructure, HPDC, Solidification Rate

Executive Summary

- The Challenge: Conventional die cooling methods for aluminum alloys either offer low efficiency (pressured air) or poor control and high cost (internal water channels), limiting the ability to precisely shape microstructure and enhance mechanical properties.

- The Method: Researchers cast an unmodified hypereutectic AlSi20 alloy in a steel die equipped with a computer-controlled, multi-point Water Mist Die Cooling system that activates upon metal pouring.

- The Key Breakthrough: This method cut solidification time by nearly 50%, increased the eutectic hardness by 24%, and created a novel pre-eutectic silicon dendrite microstructure not previously reported in similar studies.

- The Bottom Line: Water Mist Die Cooling is a highly effective and controllable technique for significantly improving the solidification characteristics, microstructure, and mechanical hardness of hypereutectic Al-Si alloys.

The Challenge: Why This Research Matters for HPDC Professionals

In the world of high-performance aluminum casting, controlling the cooling rate is paramount. For hypereutectic Al-Si alloys like AlSi20—critical for components like heavy-duty pistons—rapid solidification is key to refining microstructure and boosting mechanical properties. However, existing industrial methods present a trade-off. Pressured air cooling is simple but offers a low heat flux, limiting its effectiveness. Conversely, internal cooling channels with running water are highly efficient but expensive to implement, offer a small range of control, and make it difficult to achieve diverse cooling rates across different parts of the casting.

This research addresses a critical gap: the need for a cost-effective, highly controllable cooling method that can deliver rapid solidification. By investigating the direct effect of Water Mist Die Cooling on the die itself during casting, the study explores a new frontier for shaping the final properties of the alloy, aiming to achieve the benefits of rapid cooling without the drawbacks of conventional systems.

The Approach: Unpacking the Methodology

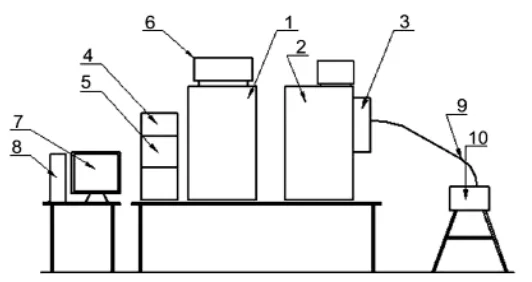

The study was conducted using a dedicated research station designed for precise, sequential cooling.

- Material: The researchers used a synthetic, unmodified hypereutectic AlSi20 alloy, a material valued for its excellent casting properties, corrosion resistance, and performance at elevated temperatures.

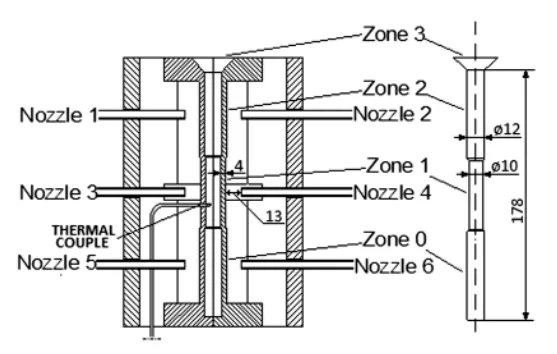

- Equipment: The core of the experiment was a steel (X38CrMoV51) research mould with a 4 mm wall thickness. The mould was fitted with three symmetrical sections of cylindrical nozzles, allowing for zoned cooling. A computer-controlled system generated a fine water mist by mixing compressed air (0.3 MPa) and water (0.35 MPa) at precise proportions (350 l/min and 0.156 l/min, respectively).

- Process: The mould was preheated to 175°C ± 25°C. Upon pouring the liquid metal, a thermocouple inside the casting die automatically triggered the water mist application, which was sustained for 60 seconds. A control casting was also produced without any cooling for comparison.

- Analysis: The resulting castings were analyzed for changes in solidification temperature and time using thermocouple data. Microstructure was examined with a Nikon MA200 microscope, and hardness was measured via microindentation with an HV-1000B Tester.

The Breakthrough: Key Findings & Data

The application of Water Mist Die Cooling produced dramatic and measurable improvements in the casting's solidification process and final properties.

Finding 1: Accelerated Solidification and Transformed Microstructure

The most immediate effect was a drastic acceleration of the solidification process. As shown in Table 2, Water Mist Die Cooling reduced the solidification time by nearly 50%, from 44.5 s to just 22.5 s. This corresponded to a 126% increase in the solidification rate, from 2.953 K/s to 6.678 K/s.

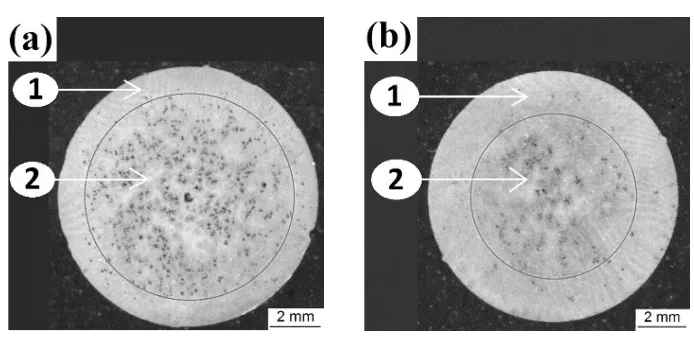

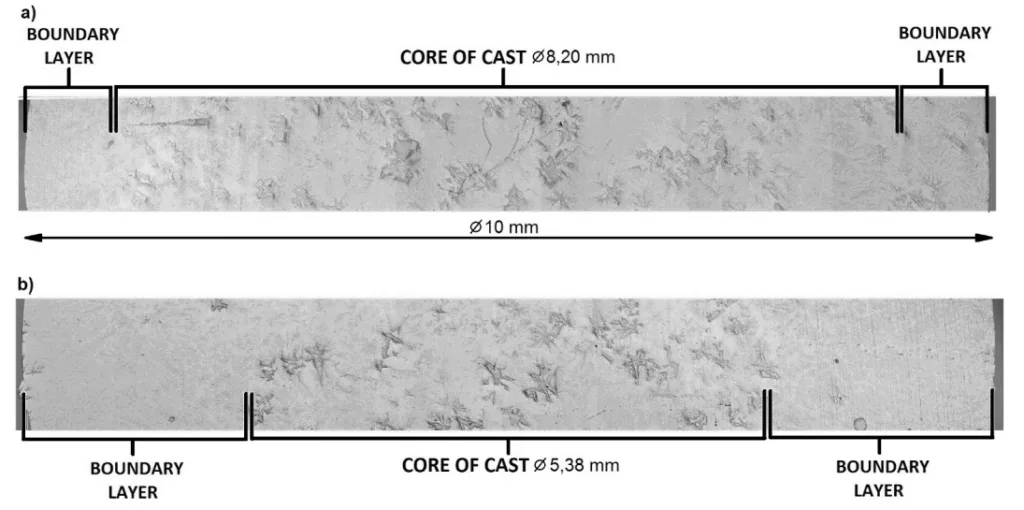

This rapid cooling fundamentally altered the casting's cross-sectional structure.

- As shown in Figure 4, the cooled casting exhibited a 34% thicker boundary layer composed of desirable columnar crystals.

- Concurrently, the central core zone, containing equiaxed crystals, shrank in diameter from 8.20 mm to 5.38 mm.

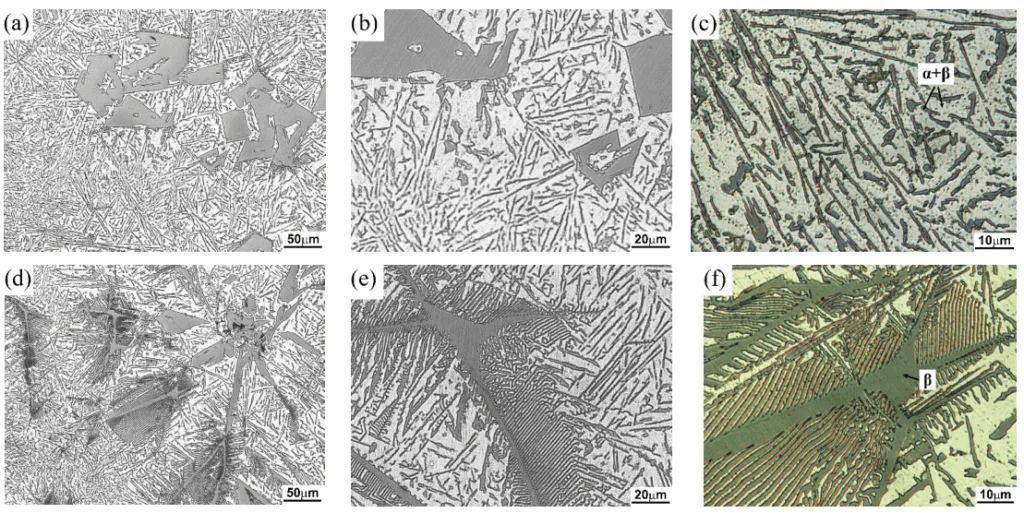

- Most notably, the high cooling rate produced a novel microstructure in the core: pre-eutectic crystallized silicon dendrites (Figure 7d-f), a form not typically observed in Al-Si alloys, which usually feature brick-shaped primary silicon.

Finding 2: A 24% Increase in Hardness and Superior Uniformity

The microstructural changes translated directly into improved mechanical properties. The average hardness of the eutectic structure in the water mist cooled sample was 85.8 HV, a 24% increase over the 69.2 HV measured in the uncooled sample.

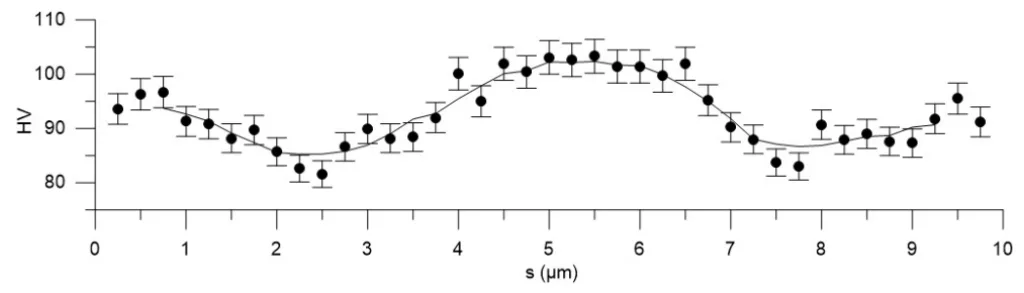

Furthermore, the hardness distribution became far more regular.

- As detailed in Figure 10, the uncooled sample showed a sharp drop in hardness (from over 800 HV to 66.8 HV) in the area immediately surrounding the hard primary silicon crystals, creating potential weak points.

- In contrast, the cooled sample with silicon dendrites showed a much more gradual and uniform decrease in hardness (from 643.9 HV to 71.5 HV). This regular distribution of hardness is crucial for improving tensile strength and predictable material behavior. The boundary layer also saw a significant hardness increase, reaching a maximum of 96.7 HV at the edge of the probe (Figure 9).

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that implementing a zoned Water Mist Die Cooling system can significantly reduce cycle times by cutting solidification time in half. The ability to control cooling rates precisely allows for targeted microstructural engineering to meet specific performance requirements.

- For Quality Control Teams: The data in Figure 10 and the measured 24% increase in eutectic hardness illustrate the effect of controlled cooling on mechanical properties. A more uniform hardness profile across the microstructure could serve as a new, valuable quality inspection criterion for ensuring component reliability and preventing failure at weak points.

- For Design Engineers: The findings indicate that a thicker, harder boundary layer can be reliably produced. As shown in Figure 4, the 34% increase in the boundary layer's thickness means a larger machining allowance can be designed into the part, ensuring the final functional surface lies within this zone of superior, directionally solidified material, potentially improving wear resistance.

Paper Details

THE EFFECT OF WATER MIST COOLING OF CASTING DIE ON THE SOLIDIFICATION, MICROSTRUCTURE AND PROPERTIES OF AlSi20 ALLOY

1. Overview:

- Title: THE EFFECT OF WATER MIST COOLING OF CASTING DIE ON THE SOLIDIFICATION, MICROSTRUCTURE AND PROPERTIES OF AlSi20 ALLOY

- Author: R. WŁADYSIAK, A. KOZUŃ, T. PACYNIAK

- Year of publication: 2017

- Journal/academic society of publication: Archives of Metallurgy and Materials

- Keywords: silicon dendrites, casting die cooling, water mist, hypereutectic Al-Si alloy

2. Abstract:

Unmodified AlSi20 alloy were casted at the research station, allowing for sequential multipoint cooling using a dedicated computer-controlled program. This method allows for the formation of the microstructure of hypereutectic AlSi20 alloy and also increases hardness. Primary silicon dendrites were found in the microstructure of cooled samples. Based on these dendrites, the formation of primary silicon particles is explained. Cooling of casting die with a water mist stream causes changes in solidification, which leads to expansion of the boundary layer with columnar crystals and shrinkage of the core zone with equiaxed crystals. It also causes more regular hardness distribution around pre-eutectic Si crystals, which can lead to tensile strength and machinability improvement.

3. Introduction:

The paper introduces the challenge of efficiently cooling aluminum alloy dies to improve casting quality and mechanical properties. It reviews existing methods like pressurized air (low efficiency) and internal water channels (high cost, low controllability). It highlights that while water mist has been used to cool castings after solidification, there is a lack of research on using it to cool the die during the solidification process. This method promises high heat transfer efficiency and better control over the cooling rate (CR) across different parts of the casting.

4. Summary of the study:

Background of the research topic:

The performance of hypereutectic Al-Si alloys, used in demanding applications like engine pistons, is highly dependent on their microstructure, which is controlled by the solidification process. Rapid cooling is known to refine primary Si particles and reduce dendrite arm spacing, leading to improved mechanical properties.

Status of previous research:

Previous studies have confirmed the benefits of intensive die cooling using various methods. Water cooling channels can achieve high cooling rates (110 K/s), and copper molds have reached even higher rates (292 K/s), but these methods lack flexibility. Water mist has been used for quenching profiles post-solidification but not for controlling the primary solidification in a die.

Purpose of the study:

The aim of the study was to investigate the effect of water mist cooling of the casting die on the solidification process, microstructure, and hardness of a hypereutectic AlSi20 alloy.

Core study:

The study compares the properties of AlSi20 alloy cast in a die under two conditions: without cooling and with a computer-controlled water mist cooling system applied to the die surface during solidification. The core analysis focuses on changes in solidification time, microstructure (boundary layer vs. core, crystal morphology), and hardness distribution.

5. Research Methodology

Research Design:

A comparative experimental design was used. An AlSi20 alloy was cast into a steel mould under two conditions: natural cooling and forced cooling using a water mist system.

Data Collection and Analysis Methods:

- Temperature: A thermocouple placed in the central area of the casting die measured the temperature profile during solidification to determine cooling rates and solidification times.

- Microstructure: Samples were taken from the central area of the castings for metallographic analysis using a Nikon MA200 microscope to observe segregation, crystal structures, and phase morphology.

- Hardness: Microindentation hardness testing (ISO-6507-2) was performed across the diameter of the cast probe and around primary silicon crystals to measure changes in hardness and its distribution.

Research Topics and Scope:

The research focused on an unmodified hypereutectic AlSi20 alloy. The scope included:

- The change in solidification parameters (time, rate, liquidus/solidus temperatures).

- The resulting microstructure, specifically the segregation between the boundary layer and core, and the morphology of primary silicon.

- The effect on hardness, both overall and in the local vicinity of silicon crystals.

6. Key Results:

Key Results:

- Water mist cooling reduced solidification time by nearly 50% (from 44.5 s to 22.5 s) and increased the solidification rate by 126%.

- The thickness of the cast boundary layer increased by 34%, while the diameter of the core zone decreased from 8.20 mm to 5.38 mm.

- A novel microstructure of pre-eutectic silicon dendrites was formed in the core of the cooled casting, in contrast to the typical brick-like silicon in the uncooled sample.

- The average hardness of the eutectic was increased by 24% (from 69.2 HV to 85.8 HV).

- Hardness distribution around silicon crystals became significantly more uniform in the cooled sample, which may improve tensile strength.

Figure Name List:

- Fig. 1. A scheme of the research station: modules: 1, 2 – air and water dosing; 3 - mixing of components; 4, 5 – supplying of air and water solenoid valves; 6 - computer-controlled cooling; 7, 8 – PC; 9 – cooling circuit; 10 - research chill

- Fig. 2. Research mould, casting zones and nozzles

- Fig. 3. Temperature obtained for the casting core: a) without cooling; b) with water mist cooling system

- Fig. 4. Segregation of casting obtained: a) without cooling;b) with water mist cooling system method; 1 – boundary layer; 2 – cast core

- Fig. 5. Segregation of casting obtained a) without cooling; b) with water mist cooling system method

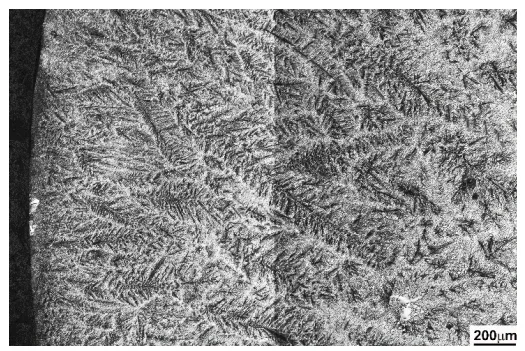

- Fig. 6. Microstructure as a result of directional solidification

- Fig. 7. Microstructure of researched Al-Si alloycasted in mould (Fig. 2) uncooled (a-c); cooled with water mist (d-f); phase β (Si), eutectic α + β (Al + Si)

- Fig. 8. The four stages of growth of primary silicon

- Fig. 9. Hardness alongside the diameter of the water mist cooled probe; s – distance from the edge of the probe

- Fig. 10. Hardness around Si pre-eutectic crystal a); b) in uncooled probe; c) in water mist cooled probe; s – distance from the centre of the crystal

7. Conclusion:

The study concludes that using water mist to cool the casting die is a highly effective method for improving hypereutectic AlSi20 alloy. This technique:

- Shortens solidification time by up to 50%.

- Causes the formation of novel pre-eutectic silicon dendrites.

- Expands the boundary layer with columnar crystals by 34%.

- Increases the hardness of the eutectic by 24%.

- Creates a more regular hardness distribution around crystals.

These combined effects may lead to improved tensile strength and machinability of castings.

8. References:

- [1] R. Władysiak, A. Kozuń, Effect of Water Mist Cooling on Microstructure of Hypereutectic Al-Si Alloy, Arch. Foundry Eng. 14, 3, 117-122 (2014).

- [2] R. Władysiak, Computer Control the Cooling Process in Permanent Mold Casting of Al-Si Alloy, Arch. Metall. Mater. 58, 3, 10-13 (2013).

- [3] H. Yamagata, W. Kasprzak, M. Aniolek, H. Kurita, J.H. Sokolowski, The effect of average cooling rates on the microstructure of the Al-20% Si high pressure die casting alloy used for monolithic cylinder blocks, J. Mater. Process. Technol. 203, 3, 333-341 (2008).

- [4] S.G. Shabestari, M. Malekan, Thermal analysis study of the effect of the cooling rate on the microstructure and solidification parameters of 319 aluminum alloy, Can. Metall. Q. 44, 3, 305-312 (2005).

- [5] Z.G. Shen, C. Lü, Experimental tests of investment casting air jet cooling process, Zhuzao/Foundry 63, 6, 567-570, (2014).

- [6] R. Władysiak, Effect of water mist on cooling process of casting die and microstructure of alsi11 alloy, Arch. Metall. Mater. 55, 3, 93-9946 (2010).

- [7] J. Cho, C. Kim, Al-Si casting alloys in high pressure die casting 8, 1, 49-56, (2014).

- [8] S.M.H. Hejazi, F. Majidi, G.H. Akbari, A Cu-Cr alloy with nano and microscale Cr particles produced in a water-cooled copper mold, Int. J. Miner. Metall. Mater. 17, 5, 629-634 (2010).

- [9] G. Wang, G. Zhao, X. Wang, Development and evaluation of a new rapid mold heating and cooling method for rapid heat cycle molding, Int. J. Heat Mass Transf. 78, 99-111 (2014).

- [10] M. Nowak, O. Golovko, F. Nürnberger, I. Frolov, M. Schaper, Water-Air Spray Cooling of Extruded Profiles: Process Integrated Heat Treatment of the Alloy EN AW-6082, J. Mater. Eng. Perform. 22, 9, 2580-2587 (2013).

- [11] J. Kang, X. Hao, G. Nie, H. Long, B. Liu, Intensive riser cooling of castings after solidification, J. Mater. Process. Technol. 215, 278-286 (2015).

- [12] C. Rapiejko, B. Pisarek, T. Pacyniak, Effect Of Cr and V Alloy Additions on the Microstructure and Mechanical Properties of Am60 Magnesium Alloy, Arch. Metall. Mater. 59, 2, 10-14 (2014).

- [13] L. Heusler and W. Schneider, Influence of alloying elements on the thermal analysis results of Al-Si cast alloys, J. Light Met. 2, 1, 17-26, Feb. (2002).

- [14] R.M. Pillai, K.S. Biju Kumar, B.C. Pai, A simple inexpensive technique for enhancing density and mechanical properties of Al-Si alloys, J. Mater. Process. Technol. 146, 3, 338-348 (2004).

- [15] R. Xu, L. Li, L. Zhang, B. Zhu, X. Liu, X. Bu, Influence of pressure and surface roughness on the heat transfer efficiency during water spray quenching of 6082 aluminum alloy, J. Mater. Process. Technol. 214, 12, 2877-2883 (2014).

- [16] G. Duggan, M. Tong, D.J. Browne, Modelling the creation and destruction of columnar and equiaxed zones during solidification and melting in multi-pass welding of steel, Comput. Mater. Sci. 97, 285-294 (2015).

- [17] K. Ghedjati, E. Fleury, M.S. Hamani, M. Benchiheub, K. Bouacha, B. Bolle, Elaboration of AlSi10Mg casting alloys using directional solidification processing, Int. J. Miner. Metall. Mater. 22, 5, 509-515 (2015).

- [18] K.J. Kubiak, T.W. Liskiewicz, T.G. Mathia, Surface morphology in engineering applications: Influence of roughness on sliding and wear in dry fretting, Tribol. Int. 44, 11, 1427-1432 (2011).

- [19] H. Yamagata, H. Kurita, M. Aniolek, W. Kasprzak, J.H. Sokolowski, Thermal and metallographic characteristics of the Al-20% Si high-pressure die-casting alloy for monolithic cylinder blocks, J. Mater. Process. Technol. 199, 1-3, 84-90 (2008).

- [20] H. Kaya, E. Çadırlı, M. Gündüz, Dendritic Growth in an Aluminum-Silicon Alloy, J. Mater. Eng. Perform. 16, 1, 12-21 (2007).

- [21] M. Chen, T.Z. Kattamis, Dendrite coarsening during directional solidification of Al-Cu-Mn alloys, Mater. Sci. Eng. A 247, 1-2, 239-247 (1998).

- [22] M. Bamberger, I. Minkoff, and M.M. Stupel, Some observations on dendritic arm spacing in Al-Si-Mg and Al-Cu alloy chill castings, J. Mater. Sci. 21, 8, 2781-2786 (1986).

- [23] B. Karpe, B. Kosec, A. Nagode, M. Bizjak, The influence of Si and V on the kinetics of phase transformation and microstructure of rapidly solidified Al-Fe-Zr alloys, J. Min. Metall. Sect. B Metall. 49, 1, 83-89 (2013).

- [24] N. Raghukiran, R. Kumar, Effect of scandium addition on the microstructure, mechanical and wear properties of the spray formed hypereutectic aluminum-silicon alloys, Mater. Sci. Eng. A. 641, 0, 138-147 (2015).

- [25] X. Zhu, R. Wang, J. Peng, C. Peng, Microstructure evolution of spray-formed hypereutectic Al-Si alloys in semisolid reheating process, Trans. Nonferrous Met. Soc. China 24, 6, 1766-1772 (2014).

- [26] O. Uzun, T. Karaaslan, M. Gogebakan, M. Keskin, Hardness and microstructural characteristics of rapidly solidified Al-8-16 wt.%Si alloys, J. Alloys Compd. 376, 1-2, 149-157 (2004).

- [27] H. Jones, Cooling rates during rapid solidification from a chill surface, Mater. Lett. 26, 3, 133-136 (1996).

Expert Q&A: Your Top Questions Answered

Q1: Why was a hypereutectic AlSi20 alloy chosen for this study?

A1: The paper states that castings made of these Al-Si alloys are used for heavy-duty pistons in combustion engines. This is because they possess a combination of desirable properties: good castability, corrosion resistance, good mechanical properties at elevated temperatures, abrasion resistance, and a low coefficient of thermal expansion. This makes AlSi20 an industrially relevant material for investigating advanced cooling techniques.

Q2: The paper mentions a novel "silicon dendrite" microstructure. Why is this significant?

A2: This finding is significant because, as the paper notes, the most common shape of primary Si is a brick. The authors state that even after searching the literature for rapidly solidified or spray-formed alloys—processes known for high cooling rates—no similar examples of pre-eutectic Si dendrites were found. This suggests that the specific thermal conditions created by Water Mist Die Cooling induce a unique crystallization path, leading to this novel morphology.

Q3: What specific process parameters were found to be optimal for generating the water mist?

A3: The paper cites previous work by the authors to establish the optimal parameters for achieving the highest heat flux. The methodology section specifies that the system applied a water pressure of 0.35 MPa and an air pressure of 0.3 MPa. The corresponding flow rates were 0.156 l/min for water and 350 l/min for compressed air.

Q4: How does the hardness distribution shown in Figure 10 impact the material's mechanical properties?

A4: Figure 10 shows that in the uncooled sample, there are areas of significantly lower hardness (66.8 HV) immediately surrounding the much harder primary Si crystals. The paper suggests these soft zones may cause weakness in the material. In contrast, the water mist cooled sample shows a much more gradual decrease in hardness. This more regular tension distribution is favorable and can possibly lead to an improvement in overall tensile strength.

Q5: The study expanded the boundary layer. What is the practical benefit of a thicker boundary layer?

A5: The boundary layer is characterized by directional solidification, resulting in columnar crystals as seen in Figure 6. The paper suggests this structure may have a positive influence on the wear resistance of Al-Si alloys. A thicker boundary layer, which increased by 34% in the study, provides the possibility of designing a larger machining allowance, ensuring that the final, functional surface of the component is located within this region of enhanced properties.

Conclusion: Paving the Way for Higher Quality and Productivity

This research clearly demonstrates that Water Mist Die Cooling is not just an alternative, but a superior method for controlling the solidification of hypereutectic AlSi20 alloy. By cutting cycle times in half, creating a refined and novel microstructure, and delivering a 24% boost in eutectic hardness with greater uniformity, this technique directly addresses the core challenges of modern high-performance casting. The findings pave the way for producing stronger, more reliable components with enhanced machinability and predictable performance.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components.

Copyright Information

- This content is a summary and analysis based on the paper "THE EFFECT OF WATER MIST COOLING OF CASTING DIE ON THE SOLIDIFICATION, MICROSTRUCTURE AND PROPERTIES OF AlSi20 ALLOY" by "R. Władysiak, A. Kozuń, and T. Pacyniak".

- Source: https://doi.org/10.1515/amm-2017-0026

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.