- 28 Accesses

- Explore all metrics

Abstract

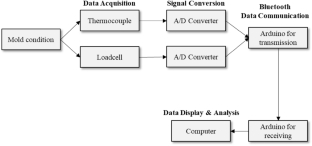

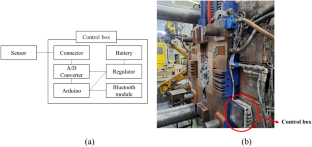

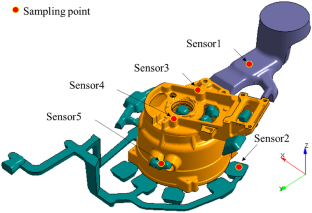

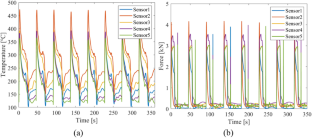

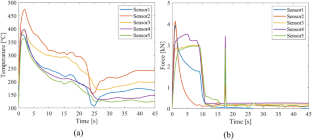

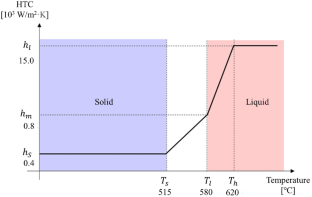

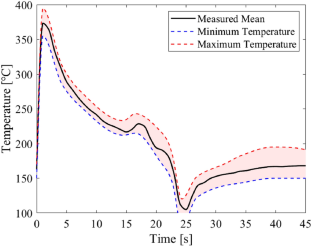

This research presents the design and implementation process of a remote monitoring system for temperature and force-induced pressure measurements in the mold cavity of high-pressure die casting (HPDC). A K-type thermocouple sensor was chosen to gauge the aggressive environment inside the mold cavity. An ejector pin was adapted for the installation of this sensor, collecting data which was then visualized as a real-time graph. To evaluate the accuracy and reliability of temperature data collected from multiple points, this study conducted measurements at five specific locations. By strategically positioning sensors at various desired locations, this study enabled detailed temperature monitoring, allowing for the observation of localized temperature variations and potential issues arising from specific points. The rationality of the obtained data was cross verified using finite difference method (FDM) casting simulation as a reverse engineering method. Additionally, this research outlines a method for utilizing the collected data to identify and predict defects in the casting process. By analyzing temperature and pressure data patterns, the system can detect anomalies indicative of potential defects, thereby aiming to reduce defect rates and enhance the quality of the manufactured products. The proposed system proficiently measures and monitors the temperature and pressure within the mold, detecting any anomalies in the casting process, and applying this data to improve overall manufacturing quality.

Keywords

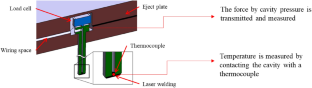

- Figure 1

View in article

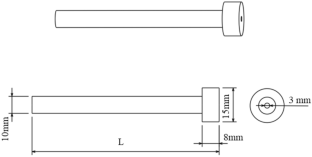

View in article - Figure 2

View in article

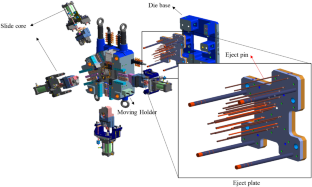

View in article - Figure 3

View in article

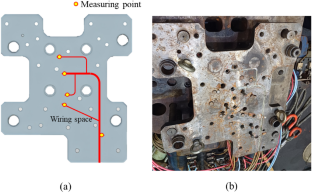

View in article - Figure 4

View in article

View in article - Figure 5

View in article

View in article - Figure 6

View in article

View in article - Figure 7

View in article

View in article - Figure 8

View in article

View in article - Figure 9

View in article

View in article - Figure 10

View in article

View in article - Figure 11

View in article

View in article - Figure 12

View in article

View in article - Figure 13

View in article

View in article - Figure 14

References

- F. Bonollo, N. Gramegna, G. Timelli, High-pressure die-casting: contradictions and challenges. JOM 67, 901–908 (2015). https://doi.org/10.1007/s11837-015-1333-8Article Google Scholar

- L. Wang, M. Makhlouf, D. Apelian, Aluminium die casting alloys: alloy composition, microstructure, and properties-performance relationships. Int. Mater. Rev. 40(6), 221–238 (1995)Article CAS Google Scholar

- G.P. Syrcos, Die casting process optimization using Taguchi methods. J. Mater. Process. Technol. 135, 68–74 (2003)Article CAS Google Scholar

- M. Muhič, J. Tušek, D. Klobčar, Analysis of die casting tool material. Stroj. Vestnik/J. Mech. Eng. 56, 351–356 (2010)Google Scholar

- N. Teli, P. Gunaki, S.N. Teli, Productivity improvement by value stream mapping in die casting industry. J emerg. Technol. Innov. Res. 2(6), 2049–2064 (2015)Google Scholar

- B.Y. Jeong, S.W. Park, M.H. Kim, A method for improvement in productivity and life-time of die casting mold. J. Korea Foundry Soc. 18, 511–517 (1998)Google Scholar

- C.-C. Tai, The optimization accuracy control of a die-casting product part. J. Mater. Process. Technol. 103, 173–188 (2000)Article Google Scholar

- Y. Song, Y. Yan, R. Zhang, Q. Lu, D. Xu, Three dimensional non-linear coupled thermo-mechanical FEM analysis of the dimensional accuracy for casting dies in rapid tooling. Finite Elements Anal. Des. 38(1), 79–91 (2001)Article Google Scholar

- D.H. Wu, M.S. Chang, Use of Taguchi method to develop a robust design for the magnesium alloy die casting process. Mater. Sci. Eng. A 379, 366–371 (2004). https://doi.org/10.1016/j.msea.2004.03.006Article CAS Google Scholar

- L. Kovačević, P. Terek, A. Miletić, D. Kukuruzović, B. Škorić, P. Panjan, Industrial evaluation of duplex PVD hard coatings for HPDC. J. Braz. Soc. Mech. Sci. Eng. 40, 1–8 (2018). https://doi.org/10.1007/s40430-018-1190-9Article CAS Google Scholar

- Fan, S., Wang, X., Wang, G.G., Weiler, J.P.: Applications of High-Pressure Die-Casting (HPDC) Magnesium Alloys in Industry. Magnesium Alloys - Processing, Potential and Applications. IntechOpen. (2023)

- M.A. Wahab, J.H. Park, M.S. Alam, S.S. Pang, Effect of corrosion prevention compounds on fatigue life in 2024–T3 aluminum alloy. J. Mater. Process. Technol. 174, 211–217 (2006). https://doi.org/10.1016/j.jmatprotec.2006.01.009Article CAS Google Scholar

- Kong, L.X., She, F.H., Nahavandi, S., Kouzani, A.Z.: Die Temperature Monitoring of High Pressure Die Casting. In: In Smc 2000 conference proceedings. 2000 ieee international conference on systems. pp. 1756–1761 (2000)

- H.P. Park, B.S. Cha, J.S. Tae, J.H. Choi, B.O. Rhee, Comparative analysis of injection molding process by on-line monitoring in cylinder of injection molding machine and in cavity of mold. Trans. Korean Soc. Mech. Eng. A 34, 1513–1519 (2010). https://doi.org/10.3795/KSME-A.2010.34.10.1513Article Google Scholar

- Tavakoli, S., Ranc-Darbord, I., Wagner, D.: Thermal behavior of the mold surface in HPDC process by infrared thermography and comparison with simulation. In: International Conference on Quantitative Infrared Thermography (2014)

- Kimura, T., Yamagata, H., Tanikawa, S.: FEM stress analysis of the cooling hole of an HPDC die. In: IOP Conference Series: Materials Science and Engineering. Institute of Physics Publishing (2015)

- M. Shanmugaraja, M. Nataraj, N. Gunasekaran, Defect control analysis for improving quality and productivity: an innovative Six Sigma case study. Int. J. Qual. Innov. 1(3), 259–282 (2011)Article Google Scholar

- Gariboldi, Elisabetta, Franco Bonollo, M. Rosso: Proposal of a classification of defects of high-pressure diecast products. la metallurgia italiana. (2007)

- Y. Lu, F. Taheri, M.A. Gharghouri, H.P. Han, Experimental and numerical study of the effects of porosity on fatigue crack initiation of HPDC magnesium AM60B alloy. J. Alloys Compd. 470, 202–213 (2009). https://doi.org/10.1016/j.jallcom.2008.03.008Article CAS Google Scholar

- M. Zamani, S. Seifeddine, A.E.W. Jarfors, Effects of microstructure and defects on tensile and fracture behaviour of a Hpdc component: potential properties and actual outcome of en AC-44300 alloy. Light Metals (2014). https://doi.org/10.1007/978-3-319-48144-9_180Article Google Scholar

- U. Godwal, S. Bhagavath, B. Ghaffari, M. Li, P.D. Lee, S. Karagadde, Numerical modelling of porosity with combined gas and shrinkage effects in HPDC. IOP Conf Ser Mater Sci Eng. 1274, 012028 (2023). https://doi.org/10.1088/1757-899x/1274/1/012028Article Google Scholar

- K.K. Seo, H.K. Kwon, Simulation study and application on HPDC process with automobile part. Adv. Mater. Res. 658, 281–286 (2013)Article Google Scholar

- Z. Ignaszak, J. Hajkowski, Gas-and shrinkage porosities in Al-Si high-pressure die-castings-virtualization and experimental validation. Defect Diffus. Forum 364, 80–91 (2015). https://doi.org/10.4028/www.scientific.net/DDF.364.80Article Google Scholar

- De-Jian, X., Yong-Peng, Y.: A Neural Network Based Defect Prediction Approach for Virtual High Pressure Die Casting. In: Journal of Physics: Conference Series. IOP Publishing Ltd (2021)

- J. Jakumeit, H. Behnken, R. Laqua, J. Gänz, L. Becker, M. Fehlbier, O. Middelmann, Combined defect prediction for large-area die-cast components using high-resolution multi-phase simulation. IOP Conf Ser Mater Sci Eng. 1281, 012027 (2023). https://doi.org/10.1088/1757-899x/1281/1/012027Article Google Scholar

- Saeedipour, M., Schneiderbauer, S., Pirker, S., Bozorgi, S.: Prediction of Surface Porosity Defects in High Pressure Die Casting. In: Advances in the Science and Engineering of Casting Solidification. pp. 155–163 (2016)

- S.K. Manjhi, R. Kumar, Transient surface heat flux measurement for short duration using K-type, E-type and J-type of coaxial thermocouples for internal combustion engine. Measurement (Lond). 136, 256–268 (2019). https://doi.org/10.1016/j.measurement.2018.12.070Article Google Scholar

- Feng, H., Zhao, C., Xie, Y., Wang, W., Zhang, X., Zhang, Z.: Research on Dynamic Calibration and Dynamic Compensation of K-type Thermocouple. In: 2014 IEEE International Instrumentation and Measurement Technology Conference (2014)

- S.L. dos Santos, R.A. Antunes, S.F. Santos, Influence of injection temperature and pressure on the microstructure, mechanical and corrosion properties of a AlSiCu alloy processed by HPDC. Mater. Des. 88, 1071–1081 (2015). https://doi.org/10.1016/j.matdes.2015.09.095Article CAS Google Scholar

- K. Dou, E. Lordan, Y. Zhang, A. Jacot, Z. Fan, A novel approach to optimize mechanical properties for aluminium alloy in High pressure die casting (HPDC) process combining experiment and modelling. J. Mater. Process. Technol. 296, 117193 (2021). https://doi.org/10.1016/j.jmatprotec.2021.117193Article CAS Google Scholar

- H.J. Kwon, H.K. Kwon, Computer aided engineering (CAE) simulation for the design optimization of gate system on high pressure die casting (HPDC) process. Robot. Comput. Integr. Manuf. 55, 147–153 (2019). https://doi.org/10.1016/j.rcim.2018.01.003Article Google Scholar

- S. Kwak, T. Kim, S. Park, K. Lee, Layout and sizing of ejector pins for injection mould design using the wavelet transform. Inst. Mech. Eng. Part B J. Eng. Manuf. 217, 463–473 (2003)Article Google Scholar

- H. Wang’, Numerical and experimental studies on the ejection of injection-molded plastic products. Polym. Eng. Sci. 40, 826–840 (2000)Article Google Scholar

- O.M. Bataineh, B.E. Klamecki, Prediction of local part-mold and ejection force in injection molding. J. Manuf. Sci. Eng. 127, 598–604 (2005). https://doi.org/10.1115/1.1951785Article Google Scholar

- G. Grangsjo, J. Sandbloii, H.R. Ulfendahl, M. Wolgast, Theory of the Heated Thermocouple Principle. Acta Physiol. Scand. 66, 366–373 (1966)Article CAS PubMed Google Scholar

- Louwsma, S.M., Van Tuijl, A.J.M., Vertregt, M., Nauta, B.: A 1.35 GS/s, 10 b, 175 mW time-interleaved AD converter in 0.13 μm CMOS. In: IEEE Journal of Solid-State Circuits. pp. 778–785 (2008)

- Clark, T.R., Dennis, M.L.: Toward a 100-GSample/s Photonic A-D Converter. In: IEEE Photonics Technology Letters (2001)

- Hwang, J.Y., Kang, J.M., Jang, Y.W., Kim, H.C.: Development of novel algorithm and real-time monitoring ambulatory system using Bluetooth module for fall detection in the elderly. In: IEEE engineering in medicine and biology society. pp. 2204–2207 (2004)

- A.E. Amoran, A.S. Oluwole, E.O. Fagorola, R.S. Diarah, Home automated system using Bluetooth and an android application. Sci. Afr. 11, e00711 (2021). https://doi.org/10.1016/j.sciaf.2021.e00711Article Google Scholar

- Dabade, U.A., Bhedasgaonkar, R.C.: Casting defect analysis using design of experiments (DoE) and computer aided casting simulation technique. In: Procedia CIRP. pp. 616–621. Elsevier B.V. (2013)

- L.A. Dobrzański, M. Krupiński, J.H. Sokolowski, P. Zarychta, A. Włodarczyk-Fligier, Methodology of analysis of casting defects. J. Achiev. Mater. Manuf. Eng. 18, 267–270 (2006)Google Scholar

- J.S.S. Babu, H.Y. Seo, P.K. Seo, C.G. Kang, Simulation and experimental investigation of die design for the fabrication of spider Arm component by AlSi10Mg27 alloy. Int. J. Metalcast. 16, 1606–1618 (2022). https://doi.org/10.1007/s40962-021-00709-1Article Google Scholar

- Ö. Boydak, M. Savaş, B. Ekici, A numerical and an experimental investigation of a high-pressure die-casting aluminum alloy. Int. J. Metalcast. 10, 56–69 (2016). https://doi.org/10.1007/s40962-015-0004-4Article Google Scholar

- R. Helenius, O. Lohne, Heat transfer to the die wall during high pressure die casting of two aluminium alloys, part 1. Int. J. Metalcast. 9, 51–59 (2015)Article Google Scholar

- G.D. Stieven, D.S. Stieven, E.P. Oliveira, E.F. Lins, Performance analysis of metaheuristic optimizers on the estimation of the interfacial heat transfer coefficient in Aluminum–Silicon permanent mold casting. Int. J. Metalcast. 18(1), 303–330 (2024)Article Google Scholar

- D.K. Nathan, K.N. Prabhu, Effect of mold contour on interfacial heat transfer during solidification of AlSi11Cu3Fe alloy (ADC-12). Int. J. Metalcast. (2023). https://doi.org/10.1007/s40962-023-01163-xArticle Google Scholar

- T. Vossel, N. Wolff, B. Pustal, A. Bührig-Polaczek, M. Ahmadein, Heat transfer coefficient determination in a gravity die casting process with local air gap formation and contact pressure using experimental evaluation and numerical simulation. Int. J. Metalcast. 16, 595–612 (2022). https://doi.org/10.1007/s40962-021-00663-yArticle CAS Google Scholar

- K.D. Carlson, C. Beckermann, Prediction of shrinkage pore volume fraction using a dimensionless Niyama criterion. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 40, 163–175 (2009). https://doi.org/10.1007/s11661-008-9715-yArticle CAS Google Scholar

- C. Monroe, C. Beckermann, Prediction of hot tearing using a dimensionless Niyama criterion. JOM 66, 1439–1445 (2014). https://doi.org/10.1007/s11837-014-0999-7Article CAS Google Scholar

- X.Y. Jiao, P.Y. Wang, Y.X. Liu, J.J. Jiang, W.N. Liu, A.X. Wan, L.J. Shi, C.G. Wang, S.M. Xiong, Effect of shot speeds on the microstructural framework and abnormal eutectic bands in a high pressure die casting hypoeutectic AlSi10MnMg alloy. J. Mater. Process. Technol. 326, 118312 (2024). https://doi.org/10.1016/j.jmatprotec.2024.118312Article CAS Google Scholar

- A. Monroe, P. Sanders, The need for a new approach to soldering in high pressure die casting. Int. J. Metalcast. 15, 391–397 (2021). https://doi.org/10.1007/s40962-020-00504-4Article CAS Google Scholar

- Zabala, B., Timelli, G., Zabala, B., Igartua, A., Raone, C., Timelli, G., Bonollo, F., Scarpis, V., Peggiato, M., Girot, F.: Evaluation HPDC Lubricant Spraying for Improved Cooling and Die Protection. In: LUBMAT . pp. 1–6 (2016)

- E. Anglada, A. Meléndez, I. Vicario, J.K. Idoiaga, A. Mugarza, E. Arratibel, Prediction and validation of shape distortions in the simulation of high pressure die casting. J. Manuf. Process. 33, 228–237 (2018). https://doi.org/10.1016/j.jmapro.2018.05.019Article Google Scholar