Optimizing HPDC: How Plunger Speed and Specific Pressure Impact Aluminum Casting Quality

This technical summary is based on the academic paper "Pressing Speed, Specific Pressure and Mechanical Properties of Aluminium Cast" by S. Gaspar and J. Pasko, published in ARCHIVES of FOUNDRY ENGINEERING (2016). It has been analyzed and summarized for technical experts by CASTMAN.

Keywords

- Primary Keyword: High Pressure Die Casting (HPDC)

- Secondary Keywords: Aluminum Casting, Plunger Speed, Specific Pressure, Mechanical Properties, Die Casting Defects, Process Optimization

Executive Summary

- The Challenge: To produce high-quality, defect-free aluminum die castings with superior mechanical properties to meet the growing demands of industries like automotive for lightweighting and cost reduction.

- The Method: An experimental study was conducted on an EN AC 47100 aluminum alloy, systematically varying two key HPDC parameters—plunger pressing speed and specific pressure—while measuring the resulting permanent deformation of the cast part.

- The Key Breakthrough: The research identified a precise optimal plunger speed (2.8 m·s⁻¹) that minimizes permanent deformation and confirmed that increasing specific pressure consistently improves the mechanical integrity and internal homogeneity of the casting.

- The Bottom Line: The mechanical properties of aluminum die castings are not arbitrary; they are directly controlled by the precise optimization of plunger speed and specific pressure, which significantly impacts internal quality and defect formation.

The Challenge: Why This Research Matters for HPDC Professionals

In today's manufacturing landscape, particularly in the automotive and aerospace sectors, the pressure is relentless. We are tasked with producing lighter components to meet stringent emission standards (e.g., a 100 kg weight saving can reduce CO₂ emissions by 9g/km) while simultaneously reducing costs and maintaining safety and performance. Aluminum alloys are a key solution, and High Pressure Die Casting (HPDC) is the ideal technology for mass-producing complex aluminum parts.

However, the final performance of a die-cast part is subject to a large number of technological factors. Achieving high mechanical properties and internal soundness consistently is a significant challenge. This research tackles this head-on by isolating two of the most critical, yet often debated, process parameters: plunger pressing speed and specific pressure. Understanding their precise impact is essential for moving from trial-and-error setups to data-driven process control that delivers reliable, high-quality components.

The Approach: Unpacking the Methodology

To build confidence in the findings, the researchers established a controlled and rigorous experimental framework.

- Material: The study used EN AC 47100 aluminum alloy, a common material in the industry.

- Equipment: Castings were produced on a "Müller Weingarten 600" horizontal cold chamber die casting machine. Mechanical properties were evaluated using a TIRAtest 28200 device to measure permanent deformation.

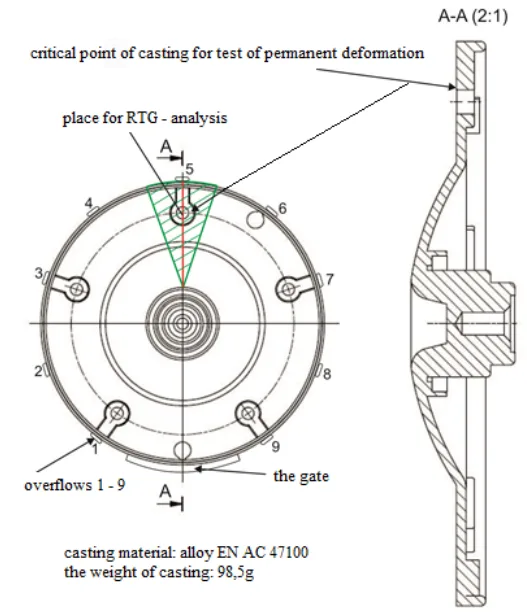

- Test Sample: The experimental sample was a flange of an alternator, a representative industrial component.

- Key Metric: The primary indicator of quality was permanent deformation (s). A lower value signifies better mechanical properties and higher resistance to load.

- Controlled Variables: To isolate the effects of speed and pressure, other critical parameters were held constant:

- Liquid Alloy Temperature: 705 °C ± 5 °C

- Mold Temperature: 200 °C ± 5 °C

- Pressing Chamber Diameter: 70 mm

- Investigated Variables: Two sets of experiments were conducted:

- Plunger Speed Variation: Speed was adjusted from 2.0 to 3.2 m·s⁻¹ while specific pressure was held constant at 25 MPa.

- Specific Pressure Variation: Pressure was adjusted from 13 to 25 MPa while plunger speed was held constant at 2.6 m·s⁻¹.

The Breakthrough: Key Findings & Data

The study yielded clear, actionable data on how process parameters directly influence casting quality.

Finding 1: The "Goldilocks Zone" for Plunger Speed

The relationship between plunger speed and casting quality is not linear. Too slow is bad, but too fast is also detrimental. The research identified an optimal "sweet spot" for the filling speed.

As shown in Figure 2, the lowest permanent deformation (i.e., the highest quality) was achieved at a plunger pressing speed of 2.8 m·s⁻¹, with a deformation value of 0.033 mm. At lower speeds like 2.0 m·s⁻¹, deformation was significantly higher at 0.068 mm. Interestingly, increasing the speed beyond the optimum to 3.2 m·s⁻¹ also degraded quality, with deformation rising to 0.052 mm. This demonstrates that a precise, optimal filling regime is critical.

Finding 2: The Decisive Impact of Specific Pressure on Internal Soundness

While plunger speed requires optimization, the effect of specific pressure was unambiguous: higher pressure leads to better castings.

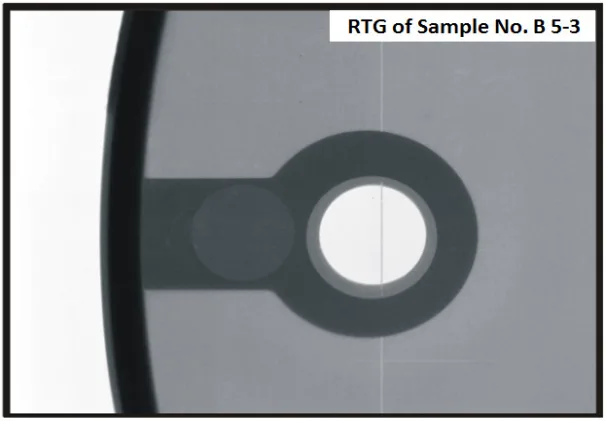

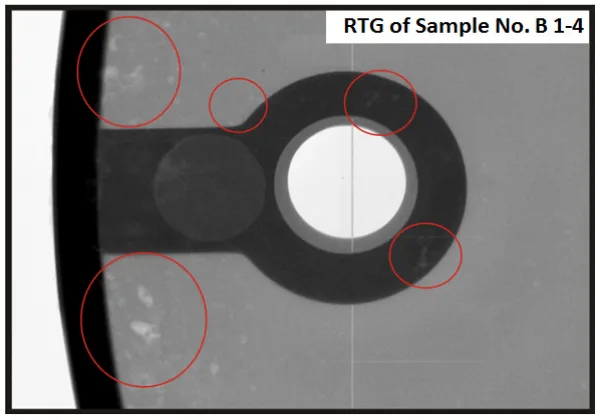

The data in Figure 3 shows a clear downward trend. At the lowest specific pressure of 13 MPa, the permanent deformation was at its highest value of 0.089 mm. As pressure was increased, the deformation consistently decreased, reaching its lowest point of 0.037 mm at the maximum tested pressure of 25 MPa. This was visually confirmed by RTG analysis. Figure 5 shows that a sample produced at low pressure (B 1.4) had obvious internal defects (light spots), while Figure 4 shows a sample produced at high pressure (B 5.3) was internally sound and defect-free.

Practical Implications for R&D and Operations

This research provides valuable, data-backed insights for different roles within a manufacturing organization.

- For Process Engineers: This study suggests that adjusting plunger speed to the identified optimum of 2.8 m·s⁻¹ may contribute to minimizing defects. Furthermore, maximizing specific pressure (within machine limits) is a direct lever for improving casting homogeneity and reducing porosity.

- For Quality Control Teams: The data in Figure 3 and the RTG images (Figures 4 & 5) of the paper illustrate the strong correlation between high specific pressure and low internal defects. Permanent deformation testing can serve as a reliable proxy for assessing the internal soundness of castings, potentially informing new quality inspection criteria.

- For Design Engineers: The findings indicate that the mold filling regime, determined by plunger speed, could influence defect formation during solidification. This suggests that considering melt flow dynamics and ensuring the process can accommodate the part geometry are valuable considerations in the early design phase.

Paper Details

Pressing Speed, Specific Pressure and Mechanical Properties of Aluminium Cast

1. Overview:

- Title: Pressing Speed, Specific Pressure and Mechanical Properties of Aluminium Cast

- Author: S. Gaspar, J. Pasko

- Year of publication: 2016

- Journal/academic society of publication: ARCHIVES of FOUNDRY ENGINEERING, Volume 16, Issue 2/2016

- Keywords: Die casting, Plunger pressing speed, Specific pressure, Mechanical properties

2. Abstract:

Recent research in the process of aluminum alloy die castings production, which is nowadays deeply implemented into the rapidly growing automobile, shipping and aircraft industries, is aimed at increasing the useful qualitative properties of the die casting in order to obtain its high mechanical properties at acceptable economic cost. Problem of technological factors of high pressure die casting has been a subject of worldwide research (EU, US, Japan, etc.). The final performance properties of die castings are subjected to a large number of technological factors. The main technological factors of high pressure die casting are as follows: plunger pressing speed, specific (increase) pressure, mold temperature as well as alloy temperature. The contribution discusses the impact of the plunger pressing speed and specific (increase) pressure on the mechanical properties of the casting aluminum alloy.

3. Introduction:

Current consumption of aluminium alloys constantly grows due to demands in sectors of electrotechnical, aviation, and automotive industries. The automotive industry is pushed by environmental acts to implement stricter emission limits. This makes the utilization of light aluminium alloys for weight saving essential. The pressure to reduce costs also drives the need for new, competitive, and reliable materials and technologies. The growing demand for aluminium alloys is also connected to global warming, as automobile weight saving directly reduces CO2 emissions. For instance, a weight saving of 100 kg is equivalent to a reduction of produced CO2 by 9g per km.

4. Summary of the study:

Background of the research topic:

The production of high-quality aluminum alloy die castings is critical for modern industries, especially automotive. The final mechanical properties of these castings are highly dependent on a range of technological factors during the HPDC process.

Status of previous research:

The problem of technological factors in high pressure die casting has been a subject of worldwide research. It is known that factors like plunger pressing speed and specific pressure are critical, but their precise impact requires detailed investigation.

Purpose of the study:

To investigate and quantify the impact of two main technological factors—plunger pressing speed and specific (increase) pressure—on the mechanical properties of an aluminum alloy casting.

Core study:

The study involved casting experimental samples of an aluminum alloy (EN AC 47100) on a die casting machine while systematically varying the plunger pressing speed and the specific pressure. The resulting quality of the castings was evaluated by measuring their permanent deformation and conducting RTG analysis to inspect for internal defects.

5. Research Methodology

Research Design:

The research was an experimental study where two key process parameters were varied independently to observe their effect on a specific mechanical property. Constant parameters were maintained to ensure the validity of the results.

Data Collection and Analysis Methods:

Permanent deformation tests were conducted on a TIRAtest 28200 device according to GME 60156 and GME 06007 standards. The results were recorded, tabulated, and plotted to show the relationship between the process variables and the outcome. RTG analysis was used for qualitative assessment of internal casting homogeneity.

Research Topics and Scope:

The scope was limited to the EN AC 47100 aluminum alloy and the specific geometry of an alternator flange. The variables studied were plunger speed (2.0-3.2 m·s⁻¹) and specific pressure (13-25 MPa). The primary measured output was permanent deformation.

6. Key Results:

Key Results:

- An optimal plunger pressing speed of 2.8 m·s⁻¹ was identified, which resulted in the lowest permanent deformation (0.033 mm) and thus the highest quality castings. Speeds both lower and higher than this optimum resulted in poorer mechanical properties.

- Increasing the specific pressure consistently improved the mechanical properties of the castings. The lowest permanent deformation (0.037 mm) was recorded at the highest pressure (25 MPa), while the highest deformation (0.089 mm) occurred at the lowest pressure (13 MPa).

- RTG analysis confirmed these findings, showing that castings with the lowest permanent deformation were free of internal defects, whereas those with high deformation exhibited significant internal porosity.

Figure Name List:

- Fig. 1. Experimental sample – flange of alternator

- Fig. 2. Dependence of average values of permanent deformation on the change of plunger pressing speed

- Fig. 3. Dependence of average values of permanent deformation on the change of specific pressure

- Fig. 4. RTG picture of sample No. B 5.3

- Fig. 5. RTG picture of sample No. B 1.4

7. Conclusion:

The experimental analysis concluded that both plunger pressing speed and specific pressure have a significant influence on the casting quality. The non-homogeneity of die castings is primarily caused by defects like cavities, which depend on the mold filling performance. This filling performance is directly determined by the pressing speed and specific pressure. The study confirmed that increased specific pressure positively affects the tightness and uniformity of the die casting. Die castings of optimal quality can only be produced when these parameters are optimally set.

8. References:

- [1] Gaspar, S., Pasko, J. & Malik, J. (2011). Inner quality of die castings made from silumin'at pressure die casting process. Manufacturing Technologies.16(3), 3-7.

- [2] Malik, J., Eperjesi, L., Fecko, D. & Gaspar, S. (2011). The influence of the tablet height and final pressure on the final quality of the casting. Archives of Foundry Engineering. 11(1), 37-40.

- [3] Podrocká, R, Malik, J. & Bolibruchová, D. (2015). Defects in high pressure die casting process. Manufacturing Technologies. 15(4), 674-678.

- [4] Białobrzeski, A. (1992). Pressure die casting. Machinery, equipment and technology. Warszawa WNT. (in Polish).

- [5] Vinarcik, E., J. (2003). High Integrity Die Casting Processes. New York: John Wiley and Sons.

- [6] Reikher, A. & Barkhudarov, M. (2007). Casting an analytical approach, Springer Verlag.

- [7] Orlowicz, A.W., Tupaj, M., Mroz, M. & Trytek, A. (2015). Combusion engine cylinder liners made of Al-Si alloys. Archives foundry engineering. 15(2), 71-74.

- [8] Tillova, E., Chalupova, M. & Konecna, R. (2001). Structural study of silumin AlSi7MgTi. Acta Metallurgica Slovaca. 7, 456-458.

- [9] Zyska, A., Konopka, Z. Lagievska, M. & Nadolski, M. (2015). The Influence of Technological Parameters on the Properties of Castings Produced by the Vacuum Assisted Pressure Die Casting Method. Archives of Foundry Engineering. 15(1), 164-168.

- [10] GME 60007, Aluminiumteile für Treibwerklagerung und Aluminiumnenkerne von Dämpfungsblocken, Conti Tech Vegum VC.

- [11] GME 60156, Test Method for Determinig the Compression Properties of centre Tubes, Vauxhall Motors LTD, 2001.

Expert Q&A: Your Top Questions Answered

Q1: Why was permanent deformation chosen as the primary quality metric for this study?

A1: Permanent deformation was selected because it is a direct measure of a key mechanical property, governed by established industry standards (GME 60156 and GME 06007). It quantifies the casting's ability to withstand a specific load without permanent change. As the RTG analysis confirmed, lower permanent deformation values correlate strongly with higher internal soundness and fewer defects, making it an excellent and practical indicator of overall casting quality.

Q2: The results show an optimal plunger speed. Why does performance get worse at speeds higher than 2.8 m·s⁻¹?

A2: The paper explains this phenomenon in Section 3. While a certain speed is needed to fill the mold cavity properly, excessive speed can be detrimental. A very high alloy flow speed can cause the gradual washing off of the initially formed protective crust on the mold wall. This can lead to dry friction between the molten alloy and the mold material, causing a rapid temperature increase and diffusion of alloy elements into the mold surface, which manifests as intense alloy adhesion and degrades the final casting quality.

Q3: The study suggests that higher specific pressure is always better. Are there any practical trade-offs or limitations to consider?

A3: While the research clearly shows that higher specific pressure (up to 25 MPa) leads to better casting quality by improving tightness and uniformity, the conclusion section of the paper alludes to a critical trade-off. It notes that while increased pressure values are beneficial for the casting, they also "reduce the life of high pressure die casting machines." Therefore, process engineers must balance the quest for maximum casting quality with the economic and maintenance considerations of machine longevity.

Q4: What is the direct link between the permanent deformation values and the RTG images in Figures 4 and 5?

A4: The RTG images provide the visual proof that validates permanent deformation as a reliable quality metric. Sample B 1.4, which was produced under low specific pressure (13 MPa), exhibited a high permanent deformation value (0.081 mm in that specific test). Its RTG image (Figure 5) clearly shows internal defects (porosity) as light spots. Conversely, sample B 5.3, produced at high pressure (25 MPa), had a very low deformation value (0.035 mm), and its RTG image (Figure 4) shows a clean, homogeneous internal structure, free of defects.

Q5: Why was it important to keep factors like alloy and mold temperature constant during the experiments?

A5: Holding the liquid alloy temperature (705 °C) and mold temperature (200 °C) constant was a critical part of the scientific method used in this study. By keeping these influential parameters stable, the researchers could isolate the effects of the variables they were testing—plunger speed and specific pressure. This ensures that the observed changes in permanent deformation are directly attributable to the changes in speed and pressure, and not caused by fluctuations in other thermal conditions, making the conclusions robust and reliable.

Conclusion: Paving the Way for Higher Quality and Productivity

This research cuts through the complexity of the High Pressure Die Casting (HPDC) process to deliver a clear message: optimal quality is not a matter of chance, but of precise control. The study demonstrates that by identifying the ideal plunger speed and maximizing specific pressure, manufacturers can significantly enhance the mechanical properties and internal soundness of aluminum components. The findings provide a data-driven roadmap for reducing defects, improving part performance, and ultimately, meeting the stringent demands of modern industry.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components.

Copyright Information

- This content is a summary and analysis based on the paper "Pressing Speed, Specific Pressure and Mechanical Properties of Aluminium Cast" by "S. Gaspar, J. Pasko".

- Source: https://doi.org/10.1515/afe-2016-0024

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.