Balancing Act: Optimizing Heat Treatment for High Conductivity Aluminum Casting Alloys

This technical summary is based on the academic paper "The Influence of Chemical Composition and Parameters of Heat Treatment on the Mechanical Properties and Electrical Conductivity in Hypoeutectic Aluminium Silicon Alloys" by J. Wiecheć, P. Uliasz, T. Knych, M. Piwowarska–Uliasz, and R. Jarosz, published in ARCHIVES of FOUNDRY ENGINEERING (2013).

![Fig. 1. Effect of Si content on the mechanical properties of AlSi casting alloy; modified (1) and unmodified (2) [3]](https://castman.co.kr/wp-content/uploads/image-3173.webp)

Keywords

- Primary Keyword: High Conductivity Aluminum Casting

- Secondary Keywords: hypoeutectic aluminum silicon alloys, electrical conductivity, mechanical properties, heat treatment parameters, AlSi5Mg

Executive Summary

- The Challenge: Standard aluminum casting alloys are optimized for mechanical strength, often sacrificing the high electrical conductivity needed for applications in the electrotechnics and automotive sectors.

- The Method: The study systematically analyzed the effects of varying silicon content (5%, 7%, 11%) and artificial aging parameters (180-220°C for 1-24 hours) on the hardness and electrical conductivity of three hypoeutectic Al-Si-Mg alloys.

- The Key Breakthrough: The research revealed that achieving optimal electrical conductivity requires a controlled over-aging (T7) heat treatment and, critically, that minimizing trace elements like titanium has a more significant positive impact on conductivity than reducing silicon content alone.

- The Bottom Line: For high-conductivity aluminum casting applications, specifying not only the primary alloy composition but also strict limits on impurities like titanium, combined with a carefully tailored over-aging process, is essential to achieving the best balance of electrical and mechanical properties.

The Challenge: Why This Research Matters for HPDC Professionals

In modern engineering, from automotive components to conductive elements in switchgears, the demand for lightweight, corrosion-resistant, and electrically conductive materials is surging. Aluminum casting alloys are a prime candidate to replace heavier, more expensive metals like copper. However, a significant industry pain point persists: the properties that make an alloy mechanically strong often hinder its electrical performance.

Standard specifications for aluminum casting alloys, such as EN AC-42100 (AlSi7Mg0,3), focus heavily on mechanical properties like tensile strength and hardness, typically achieved through a T6 heat treatment (supersaturated and artificially aged for peak strength). Electrical conductivity is often listed as a wide, approximate range, making it unreliable for designing high-performance electrical components. As illustrated in Figure 4 of the paper, most traditional alloys fall into categories of high hardness/low conductivity or low hardness/low conductivity. This leaves a critical gap for applications that demand both good mechanical integrity and high electrical conductivity—a combination that standard alloys and treatments fail to deliver consistently. This research was necessary to define the precise processing parameters that can unlock this dual performance.

The Approach: Unpacking the Methodology

To build a reliable process for achieving superior electrical properties, the researchers conducted a rigorous, controlled study. Their methodology provides a clear and credible foundation for the results.

- Materials: The study focused on three common hypoeutectic silumin alloys with varying silicon content: AlSi11Mg0,3, AlSi7Mg0,3, and AlSi5Mg0,3. The castings were produced via gravity casting into a metal chill mould after the liquid metal underwent refinement, modification, and alloying.

- Heat Treatment Protocol: Each alloy was subjected to a two-stage heat treatment. First, a supersaturation treatment was performed at 535°C for 8 hours. This was followed by an artificial aging process where two key variables were tested:

- Aging Temperature: 180°C, 200°C, and 220°C.

- Aging Time: Samples were tested at intervals from 1 to 24 hours.

- Property Measurement:

- Mechanical Properties: Hardness was measured using the Brinell (HB) test method on a WPM Leipzig HPO-250 tester.

- Electrical Properties: Electrical conductivity was measured using the eddy current method with a SIGMATEST® instrument, which is highly accurate for this application.

This systematic approach allowed the researchers to map the evolution of both hardness and conductivity over time at different aging temperatures, revealing the critical trade-offs between them.

The Breakthrough: Key Findings & Data

The research yielded two pivotal findings that challenge conventional approaches to specifying and heat-treating aluminum alloys for electrical applications.

Finding 1: The Inverse Relationship Between Peak Hardness and Peak Conductivity

The study confirmed that the heat treatment conditions that produce the best mechanical properties (hardness) are detrimental to electrical conductivity.

- At an aging temperature of 180°C, all alloys reached a hardness plateau, characteristic of the T6 temper, after a few hours (Figure 5).

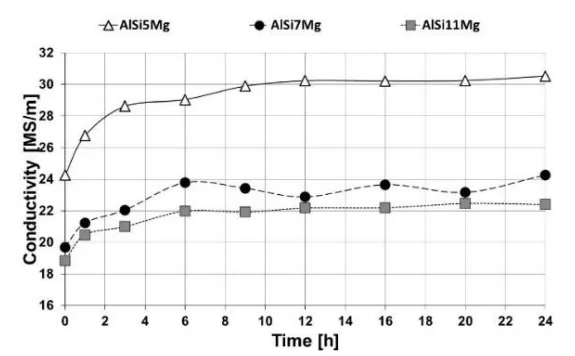

- However, electrical conductivity continued to rise with longer aging times and higher temperatures (Figures 6, 8, and 10). The best electrical properties were achieved under conditions corresponding to an over-aged (T7) temper, where hardness has begun to decline from its peak.

- As shown in the summary graphs (Figure 11 and Figure 12), the T6 temper consistently yields the highest hardness but the lowest conductivity, while the T7 temper provides a significant boost in conductivity at the cost of a moderate reduction in hardness.

Finding 2: The Overlooked Impact of Trace Elements on Electrical Performance

Perhaps the most significant breakthrough was the discovery that trace element impurities can play a more decisive role in electrical conductivity than the primary alloying elements.

- Contrary to expectations, the difference in conductivity between the AlSi11Mg and AlSi7Mg alloys was minimal (average of 1 MS/m), despite a 4% difference in silicon content.

- The AlSi5Mg alloy, however, demonstrated vastly superior electrical conductivity, stabilizing at nearly 30 MS/m at 220°C, compared to just ~23 MS/m for the other two alloys (Figure 10).

- The paper attributes this dramatic improvement not to the lower silicon content, but to the alloy's chemical composition detailed in Table 2 (page 4). The AlSi5Mg alloy contained only 0.001% Titanium (Ti), whereas the AlSi7Mg and AlSi11Mg alloys contained over 100 times more (0.11% and 0.12% Ti, respectively). This demonstrates that even minute quantities of impurities like titanium can severely degrade electrical performance.

Practical Implications for R&D and Operations

These findings offer clear, actionable guidance for engineering and manufacturing teams working with high-performance aluminum castings.

- For Process Engineers: This study suggests that achieving a target combination of strength and conductivity requires moving beyond standard T6 treatments. A controlled over-aging process (T7 temper) is necessary. Adjusting aging time and temperature is a powerful tool for balancing these competing properties to meet specific application requirements.

- For Quality Control Teams: The data in Table 2 and Figure 10 of the paper illustrates the critical effect of trace elements on electrical properties. This indicates that for high-conductivity applications, incoming material inspection should include verification of not just primary elements like Si and Mg, but also strict limits on detrimental impurities like Titanium (Ti), Manganese (Mn), and Chromium (Cr).

- For Design Engineers: The findings indicate that simply specifying a standard alloy like AlSi7Mg may not be sufficient for components requiring high conductivity. Specifying an alloy with inherently low impurity levels, such as the AlSi5Mg composition tested, could be a crucial design consideration to ensure performance goals are met.

Paper Details

The Influence of Chemical Composition and Parameters of Heat Treatment on the Mechanical Properties and Electrical Conductivity in Hypoeutectic Aluminium Silicon Alloys

1. Overview:

- Title: The Influence of Chemical Composition and Parameters of Heat Treatment on the Mechanical Properties and Electrical Conductivity in Hypoeutectic Aluminium Silicon Alloys

- Author: J. Wiecheć, P. Uliasz, T. Knych, M. Piwowarska–Uliasz, R. Jarosz

- Year of publication: 2013

- Journal/academic society of publication: ARCHIVES of FOUNDRY ENGINEERING, Volume 13, Special Issue 3/2013

- Keywords: heat treatment, hypo-eutectic aluminum silicon alloys, mechanical properties, electrical properties

2. Abstract:

The silumins are the aluminum alloys with the silicon as the main alloy addition. These are one of the most common types of casting alloys based on aluminum. They are widely used in technologies of casting such as sand casting, chill casting or pressure die casting. As their main characteristics we can include: very good castability, corrosion resistance, high mechanical properties and good thermal and electrical conductivity. Thanks to all these properties, the cast aluminum alloys have been used in various industries such as: automotive, engineering, heat exchangers or conductive elements. The last application requires a specific conditions of the process and the optimal chemical composition of the alloy, which allows to obtain high values of conductivity. The paper presents a study covering the impact of silicon content and heat treatment parameters on the electrical conductivity and mechanical properties (hardness HB) hypoeutetic silumin alloys such as AlSi11Mg, AlSi7Mg and AlSi5Mg. The aim of the study was to determine the optimal conditions for heat treatment parameters of various alloys providing to the most favorable mechanical and electrical properties.

3. Introduction:

In recent years, a steady growth in the demand for aluminum and aluminum alloys products has been observed. The trend is caused by attempts to improve product properties (weight, conductivity, corrosion resistance) or reduce prices by substituting for more expensive metals like copper. While widely used in aviation, automotive, and construction, aluminum products are also increasingly used in electrotechnics and electroenergetics. However, standard aluminum casting alloys are typically chosen for their mechanical properties, and additions that increase strength (like copper, zinc, silicon, magnesium) tend to decrease electrical conductivity. Existing standards provide detailed mechanical property requirements for various heat treatments but offer only approximate ranges for electrical conductivity, highlighting a knowledge gap for applications where both properties are critical.

4. Summary of the study:

Background of the research topic:

There is a growing industrial need for aluminum casting alloys that possess both high mechanical strength and high electrical conductivity for use in conductive elements. However, existing standards and common practices prioritize mechanical properties, leaving a lack of precise data on how to optimize for electrical performance.

Status of previous research:

Previous research and standards have established the mechanical properties of common Al-Si alloys under various heat treatments (e.g., T6). The general negative effect of alloying additions on electrical conductivity is known, but there is a lack of systematic data correlating specific heat treatment parameters (time, temperature) with the evolution of both mechanical and electrical properties simultaneously in hypoeutectic silumins.

Purpose of the study:

The aim of the study was to determine the optimal conditions for heat treatment parameters for various hypoeutectic Al-Si-Mg alloys (AlSi11Mg, AlSi7Mg, AlSi5Mg) to achieve the most favorable combination of mechanical and electrical properties, specifically for applications requiring high conductivity.

Core study:

The core of the study involved subjecting three alloys with different silicon contents to a solution heat treatment followed by artificial aging at three different temperatures (180°C, 200°C, 220°C) for durations up to 24 hours. At each stage, Brinell hardness and electrical conductivity were measured to map the relationship between chemical composition, heat treatment parameters, and the resulting properties.

5. Research Methodology

Research Design:

The research was designed as a comparative experimental study. Three distinct alloy compositions were used as the independent variable (chemical composition), while artificial aging time and temperature were the other key independent variables. The dependent variables were Brinell hardness and electrical conductivity.

Data Collection and Analysis Methods:

Castings were produced via gravity casting into a metal chill mould. Samples underwent solution heat treatment and then artificial aging. Hardness was measured using a Brinell hardness tester (WPM Leipzig HPO-250). Electrical conductivity was measured using an eddy current-based instrument (SIGMATEST®). The collected data was plotted on graphs showing hardness and conductivity as a function of aging time for each temperature and alloy.

Research Topics and Scope:

The research was scoped to three hypoeutectic aluminum-silicon-magnesium alloys. The investigation covered the influence of silicon content (5%, 7%, 11%) and artificial aging parameters on Brinell hardness and electrical conductivity. The aging temperatures ranged from 180°C to 220°C, and the aging time from 1 to 24 hours.

6. Key Results:

Key Results:

- All tested alloys respond well to precipitation hardening, with hardness increasing during artificial aging. Peak hardness (T6 condition) is achieved faster at higher temperatures, but the peak value diminishes, and over-aging (T7 condition) occurs more rapidly.

- Electrical conductivity consistently improves with increasing aging time and temperature, reaching a stable, higher value during the over-aging (T7) phase.

- There is an inverse relationship between peak hardness and electrical conductivity; the T6 temper gives the highest hardness but lower conductivity, while the T7 temper gives higher conductivity but lower hardness.

- The AlSi5Mg alloy exhibited significantly higher electrical conductivity (up to 30 MS/m) compared to AlSi7Mg and AlSi11Mg (around 23 MS/m). This superior performance is attributed to its substantially lower titanium content (0.001%) rather than its lower silicon content.

Figure Name List:

- Fig. 1. Effect of Si content on the mechanical properties of AlSi casting alloy; modified (1) and unmodified (2) [3]

- Fig. 3. Electrical conductivity of binary aluminum alloys (containing larger amounts of the alloying additions) as a function of concentration of the alloying element [5]

- Fig. 3. Electrical conductivity of as-cast binary aluminium alloys (containing larger amounts of the alloying additions) as a function of concentration of the alloying element [5]

- Fig. 4. Statement of the electrical conductivity and hardness values for the traditional aluminum casting alloys [6, 7]

- Fig. 5. The Brinell hardness as a function of the artificial ageing time for 180 °C

- Fig. 6. The electrical conductivity as a function of the artificial ageing time for 180 °C

- Fig. 7. The Brinell hardness as a function of the artificial ageing time for 200 °C

- Fig. 8. The electrical conductivity as a function of the artificial ageing time for 200 °C

- Fig. 9. The Brinell hardness as a function of the artificial ageing time for 220 °C

- Fig. 10. The electrical conductivity as a function of the artificial ageing time for 220 °C

- Fig. 11. Summary of the Brinell hardness results for alloys in tempers W, T6 and T7

- Fig. 12. Summary of the electrical conductivity results for alloys in tempers W, T6 and T7

- Fig. 13. Summary of the electrical conductivity and hardness values for tested alloys in tempers W, T6 and T7

![Fig. 3. Electrical conductivity of as-cast binary aluminium alloys (containing larger amounts of the alloying additions) as a function of concentration of the alloying element [5]](https://castman.co.kr/wp-content/uploads/image-3172.webp)

7. Conclusion:

The study successfully demonstrated that hypoeutectic Al-Si-Mg alloys respond well to heat treatment. A key conclusion is that achieving the best compromise between mechanical and electrical properties requires a controlled over-aging (T7) condition. The choice of optimal heat treatment parameters depends on the specific alloy composition. Most importantly, the research highlights the significant negative influence of titanium content on electrical conductivity, suggesting that for high-conductivity applications, controlling trace elements is as crucial as managing the primary alloying elements. The AlSi5Mg alloy with low titanium content was identified as the most promising material for reaching the desired property combination.

8. References:

- [1] Kaufman, J.G., Rooy, E.R. (2004). Aluminum Alloy Castings. Properties, Processes and Applications, ASM International.

- [2] Knych, T., Mamala, A., Uliasz, P., Błotnicki, M. (2010). Badania nad doborem warunków obróbki cieplnej stopów aluminum gat. AlSi7Mg0,3 i AlSi10Mg0,3 w celu polepszenia ich jakości i własności eksploatacyjnych, Rudy i Metale Nieżelazne, (R55), 1, s.18-25

- [3] Kammer, C. (2002). Aluminum Handbook 1, Fundamentals and Materials, Aluminum Verlag, Düsseldorf.

- [4] Hielscher, U. (1979). Ductile aluminum-silicon casting alloys for safety components in cars, Schweiz. Alum. Rundsch. 29, 13-15.

- [5] Nachtigall, E., Lang G. (1965). Electrical conductivity of aluminum castings, Mitt. Verein. Metallwerke Ranshofen-Berndorf, 16-19.

- [6] PN-EN 1706, Aluminum i jego stopy. Odlewy. Skład chemiczny i własności mechaniczne, czerwiec 2010

- [7] www.matweb.com

- [8] Lewińska-Romicka, A. (1997). Defektoskopia wiroprądowa. Poradnik, Biuro Gamma, Warszawa.

Expert Q&A: Your Top Questions Answered

Q1: Why were these specific alloys (AlSi5Mg, AlSi7Mg, AlSi11Mg) chosen for the study?

A1: These three alloys were selected because they represent a practical range of silicon content within the widely used hypoeutectic Al-Si-Mg family. This allowed the researchers to systematically investigate the influence of silicon content—a primary alloying element—on both mechanical and electrical properties, providing a clear comparison across common compositions used in the casting industry.

Q2: Figure 10 shows AlSi5Mg reaching ~30 MS/m conductivity, while the others plateau around 23 MS/m. Is the 2-4% difference in silicon solely responsible for this large gap?

A2: No, and this is a key takeaway from the research. While lower silicon content contributes to higher conductivity, the paper strongly concludes that the primary reason for the AlSi5Mg alloy's superior performance is its dramatically lower titanium (Ti) content. As shown in Table 2, the AlSi5Mg alloy had 0.001% Ti, over 100 times less than the other two alloys (~0.12% Ti). This highlights that controlling trace element impurities is critical for maximizing electrical conductivity.

Q3: The paper recommends an over-aged (T7) condition for an optimal property balance. Isn't over-aging generally considered detrimental to mechanical properties?

A3: For applications where maximizing hardness and tensile strength is the only goal, yes, over-aging is detrimental. However, this research re-frames the T7 temper as a strategic compromise. For applications in High Conductivity Aluminum Casting, the significant gain in electrical conductivity achieved during over-aging far outweighs the moderate, controlled reduction in hardness. The goal is not peak strength, but the best balance of properties, which the T7 condition provides.

Q4: What is the practical significance of the four quadrants shown in Figure 4?

A4: Figure 4 serves as a material selection map. It plots hardness (mechanical property) against electrical conductivity. Quadrants I and III represent materials best suited for structural/mechanical use (high hardness, lower conductivity). Quadrants II and IV represent materials desirable for electrical applications (high conductivity). The study's ultimate goal was to find a material and process combination that would land in quadrant IV (good conductivity with acceptable hardness), a space where few standardized alloys exist. The low-Ti AlSi5Mg alloy in a T7 temper was shown to be a candidate for reaching this quadrant.

Q5: This study used gravity casting. Are these findings on heat treatment and composition directly applicable to High Pressure Die Casting (HPDC)?

A5: While the manufacturing process differs, the fundamental metallurgical principles are directly applicable. The precipitation of the Mg2Si phase, which governs the hardening response, and the negative effect of dissolved elements like titanium on conductivity are universal to these alloys. HPDC parts have faster solidification rates, which may slightly alter the as-cast microstructure, but the trends observed during heat treatment will be the same. Process engineers can use this study as an excellent starting point, but may need to fine-tune the specific aging times and temperatures to optimize the T7 properties for their unique HPDC components.

Conclusion: Paving the Way for Higher Quality and Productivity

This research provides a clear roadmap for overcoming a major hurdle in the use of aluminum for electrical applications. It proves that achieving an optimal balance of mechanical strength and electrical performance is not only possible but can be systematically engineered. The key lies in moving beyond conventional T6 heat treatments and embracing a controlled over-aging (T7) process. More importantly, it shines a spotlight on the critical role of chemical composition, demonstrating that for High Conductivity Aluminum Casting, minimizing trace impurities like titanium is paramount.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components.

Copyright Information

- This content is a summary and analysis based on the paper "The Influence of Chemical Composition and Parameters of Heat Treatment on the Mechanical Properties and Electrical Conductivity in Hypoeutectic Aluminium Silicon Alloys" by "J. Wiecheć, et al.".

- Source: ARCHIVES of FOUNDRY ENGINEERING, Volume 13, Special Issue 3/2013, pp. 179-184.

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.