This introduction paper is based on the paper "Subsurface Microstructural Evolution of High-Pressure Diecast A365: From Cast to Cold-Sprayed and Heat-Treated Conditions" published by "Metals".

1. Overview:

- Title: Subsurface Microstructural Evolution of High-Pressure Diecast A365: From Cast to Cold-Sprayed and Heat-Treated Conditions

- Author: Alino Te, Bryer C. Sousa, Brajendra Mishra, and Danielle L. Cote

- Year of publication: 2021

- Journal/academic society of publication: Metals

- Keywords: high-pressure die-casting; alloyed aluminum; cold spray processing; alloy surface modification; intermetallic compounds; bimetallic systems and processing; copper; nickel; titanium; atomic diffusion; heat treating

2. Abstract:

The use of cold spray deposition, coupled with diffusion-driven thermal postprocessing, is considered herein as a surface modification process such that near-surface microstructural, micromechanical, and microchemical property improvements can be procured for cost-effective and common aluminum alloy castings. Since the present work was an exploratory investigation into the realm of cold spray induced, high-pressure diecast aluminum subsurface property development and evolution, as well as surface modification, one significant aim was to formalize a set of fundamental observations for continued consideration of such an approach to achieving premium aluminum alloy properties from cost-effective alternatives. Nickel, copper, and titanium cold spray modified near-surface regions of the cost-effective high-pressure diecast A365 system was considered. Near-surface, subsurface, and surface evolution was documented across each of the three pure metal coatings. The analysis was continued across two postprocessing coating-substrate atomic diffusion inspired heat-treated conditions as well. Using energy-dispersive X-ray spectroscopy, field-emission scanning electron microscopy, optical microscopy, and various insights gleaned from an original contextualization of the relevant cold spray literature, noteworthy results were recorded and discussed herein. When copper feedstock was employed alongside thermal postprocessing, diverse surface-based intermetallic compounds formed alongside exotic diffusion zones and severely oxidized regions, thus eliminating thermally activated copper cold-sprayed consolidations from future work too. However, both nickel and titanium cold spray surface modification processing demonstrated potential and promise if correct processing stages were performed directly and chronologically. Consequently, a platform is presented for further research on cold sprayed surface microstructural and property modification of cost-effective alloyed aluminum castings.

3. Introduction:

Cold gas dynamic spray (CGDS), or cold spray, is a solid-state materials consolidation technology where particulate feedstock is accelerated by a heated carrier gas through a de Laval nozzle to supersonically impact a substrate, forming a coating [1]. CGDS is utilized for creating coatings with specific properties, in remanufacturing, repair [3], and additive manufacturing [4]. This study explores CGDS-based surface modification as a pathway to improve near-surface properties (e.g., fracture/impact toughness, strength) of cost-effective high-pressure diecast (HPDC) A365 aluminum alloy, commonly used in the automotive industry. The motivation is to achieve properties comparable to premium aluminum alloys like A201, but with lower cost and easier processing. The research aims to provide insights into structure-processing-property relationships for CGDS-modified A365, focusing on microstructural, micromechanical, and microchemical evolution.

4. Summary of the study:

Background of the research topic:

The automotive industry seeks cost-effective cast components with improved mechanical properties. Premium alloys like A201 offer excellent toughness and high-temperature properties but are costly and difficult to process. Surface modification of common alloys like A365, A356, and E357 presents an alternative. A365 was selected due to its pervasiveness in aluminum foundries. CGDS is a promising technique for such modifications, allowing deposition of strengthening or toughening agents.

Status of previous research:

Previous CGDS thermal postprocessing work often focused on self-similar substrate-feedstock combinations (e.g., Rokni et al. on Al 7075 [14, 15]). Research has shown CGDS can improve properties like impact resistance, fracture toughness, fatigue crack propagation performance (Yang et al. [17]), wear resistance [18], tribological performance [19], hardness [20], and corrosion resistance [21]. Jafarlou et al. [16] improved properties of AM stainless steel with a CGDS coating. Huang et al. [22] discussed a balance between wear/corrosion resistance and ductility. The current work aims to build on these by exploring dissimilar material systems (pure metals on A365) and their subsurface evolution.

Purpose of the study:

This exploratory investigation aimed to:

- Inspect CGDS-based material surface modification of HPDC A365 aluminum alloy.

- Evaluate copper, nickel, and titanium as cold spray coating materials for near-surface property improvement.

- Document near-surface, subsurface, and surface microstructural and microchemical evolution after CGDS deposition and subsequent thermal postprocessing (solution treatment and T6 heat treatment).

- Provide a platform for further research into the practical effects of CGDS coating and thermal postprocessing on coating-substrate regional properties.

- Formalize fundamental observations for achieving premium aluminum alloy properties from cost-effective alternatives.

Core study:

The core of the study involved:

- Depositing pure copper, nickel, and titanium feedstock powders onto HPDC A365 aluminum alloy substrates using CGDS.

- Subjecting the coated samples to thermal postprocessing:

- Solution treatment (500 °C for 80 minutes).

- T6 heat treatment (natural room temperature aging for 24 hours, then artificial aging at 170 °C for 150 minutes).

- Characterizing the microstructural and microchemical evolution at the near-surface and subsurface regions of the A365 substrate and the coating-substrate interface.

- Analysis using optical microscopy, field-emission scanning electron microscopy (FESEM), and energy-dispersive X-ray spectroscopy (EDS).

5. Research Methodology

Research Design:

The research was designed as an exploratory study. HPDC A365 aluminum alloy (composition in Table 1) was used as the substrate material. Three pure metal feedstocks – copper, nickel, and titanium – were selected for CGDS coating. The methods of electroplating, electroless plating, hot-dip galvanizing, and CGDS were initially considered, with CGDS chosen for its coating continuity and lab-scale reproducibility. Coatings were applied to one face of the substrate samples. Post-deposition, samples underwent solution treatment and T6 heat treatments to facilitate diffusion and observe microstructural changes. Uncoated A365 samples were also processed as references.

Data Collection and Analysis Methods:

- Substrate Preparation: HPDC A365 plates were faced to 2.5 mm uniform thickness, then waterjet cut. Samples were wire brushed and cleaned with isopropyl alcohol before CGDS.

- CGDS Processing: Nickel, titanium, and copper feedstocks were deposited using a VRC GEN III CGDS system at Pennsylvania State University. Nitrogen was the carrier gas for copper and nickel; helium for titanium. Target coating thickness was 100 µm.

- Heat Treatment:

- Solution treatment: 500 °C for 80 min, forced-air cool.

- T6 treatment: Room temperature aging for 24 h, then artificial aging at 170 °C for 150 min.

- Characterization:

- Samples were compression mounted in phenolic thermosetting resin.

- Standard metallographic grinding and polishing were performed.

- Optical microscopy: Inverted metallurgical microscope with an Olympus Microscope Camera DP73.

- FESEM and EDS: JEOL JSM-7000F field emission SEM with an Oxford Instruments X-MaxN EDS detector.

Research Topics and Scope:

The research focused on the surface and subsurface microstructural and microchemical development and evolution of HPDC A365 aluminum alloy when surface modified by CGDS with copper, nickel, or titanium, followed by heat treatments. Key topics included:

- Substrate erosion and plastic deformation during CGDS.

- Interfacial bonding and mixing between coating and substrate.

- Atomic diffusion and intermetallic compound formation during thermal postprocessing.

- Thermal recrystallization of the A365 subsurface.

- Comparison of the effects of the three different coating materials.

The scope was limited to microstructural and microchemical characterization, without macro-mechanical testing due to coating only on two broad faces.

6. Key Results:

Key Results:

As-Cast and CGDS Processed (Pre-Heat Treatment):

- As-cast A365 (Figure 3A): Showed a refined grain size distribution towards the casting's surface and a coarser dendritic microstructure away from the surface. This was consistent with "primary eutectic α-Al dendrite grains with needle-like or acicular eutectic Si particles".

- Copper CGDS on A365 (Figure 3B): Resulted in less pronounced near-surface dendritic grain-scale texture. Evidence of Kelvin-Helmholtz interfacial instabilities, indicating hydrodynamic flowing of substrate material into the coating and vice-versa. Significant substrate erosion was inferred due to the coarse grain size observed in the subsurface region, potentially from thick Cu oxide films on air-atomized Cu powder.

- Titanium CGDS on A365 (Figure 3C): Showed limited substrate erosion, retaining the fine grain size distribution near the casting's surface. Deposited Ti particulates showed insufficient particulate-particulate bonding. Limited mechanical interlocking and interfacial mixing.

- Nickel CGDS on A365 (Figure 3D): Microstructural texture was more pronounced than copper-coated samples and less gradually transitional than as-cast A365. Less interfacial intermixing than copper.

Solution Heat-Treated Samples (Figure 4):

- Subsurface Al 365 microstructure underwent thermal recrystallization in all coated samples. The dendritic texture was no longer present.

- Copper-coated A365 (Figure 4A): Revealed a diverse intermetallic-rich region with secondary phases and precipitates in the substrate's diffusion zone, followed by a precipitate-free band of Cu-enriched FCC alpha-Al. Showed more porosity near the interface, likely due to diffusion.

- Nickel-coated A365 (Figure 4B) and Titanium-coated A365 (Figure 4C): Diffusion of Ti and Ni into HPDC A365 was much more reserved than Cu. Ni and Ti deposits demonstrated more porosity in the coating(s) and little porosity in the substrate nearest the interface.

T6 Heat-Treated Samples (Figure 5, Figure 6, Figure 7, Figure 8, Figure 9, Figure 10):

- Uncoated A365-T6 (Figure 5A): Showed rounding, spheroidization, and ripening of eutectic silicon-rich regions. Presence of alpha-Fe (Al15(Fe, Mn)3Si2) script-like precipitates. Subsurface microstructure was more homogenous compared to as-cast.

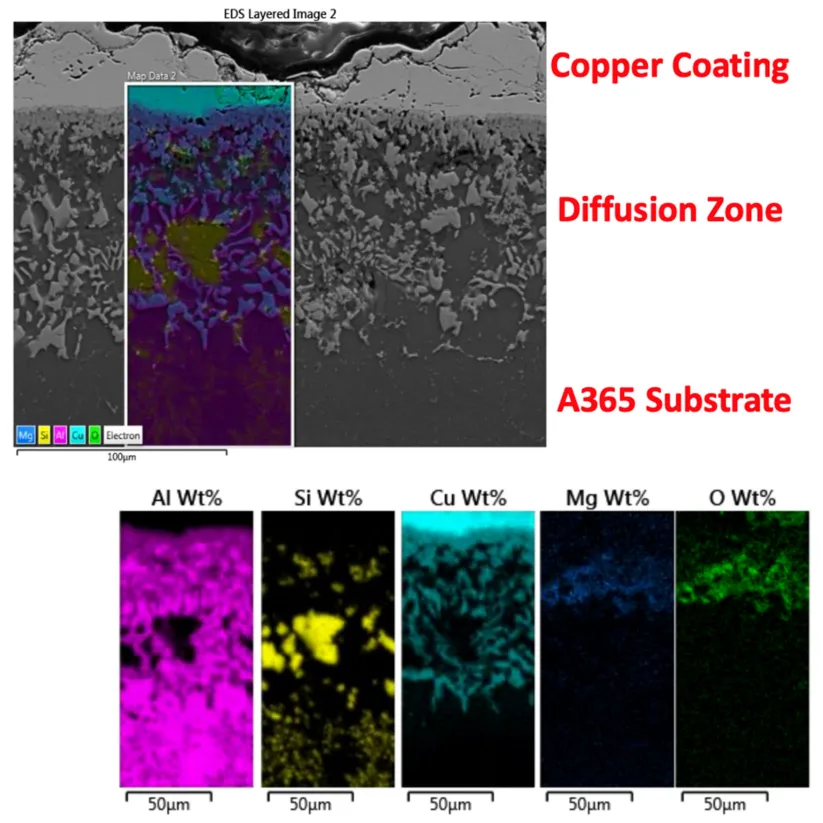

- Copper CGDS on A365-T6 (Figure 5B, Figure 6, Figure 7):

- Copper coating was dense with little porosity. Black streaks were bands of copper oxide.

- A continuous aluminum-copper phase (Al2Cu) formed at the interface.

- Diffusion zone showed discontinuous finger-like Al2Cu phases. Large silicon phases agglomerated in this zone. Magnesium oxide (black "holes") was detected.

- Copper was found in solid solution (approx. 5 wt. %) up to 100 µm below the interface.

- This evolution was deemed deleterious.

- Nickel CGDS on A365-T6 (Figure 5D, Figure 8, Figure 9):

- Intermetallics of nickel and aluminum formed (potential phases: Ni2Al3, NiAl3, NiAl).

- The intermetallic layer was continuous and relatively smooth compared to copper's.

- Very little, if any, nickel was held in solid solution in the aluminum matrix.

- Titanium CGDS on A365-T6 (Figure 5C, Figure 10):

- No significant diffusion of titanium into the aluminum substrate surface was observed by EDS.

- No secondary Ti-Al intermetallic compounds were found to have nucleated.

- Atomic Ti enriched the A365 solid solution in the subsurface region of the thermally postprocessed bimetallic system.

Figure Name List:

- Table 1. Nominal composition of HPDC A365 base material provided by Rio Tinto.

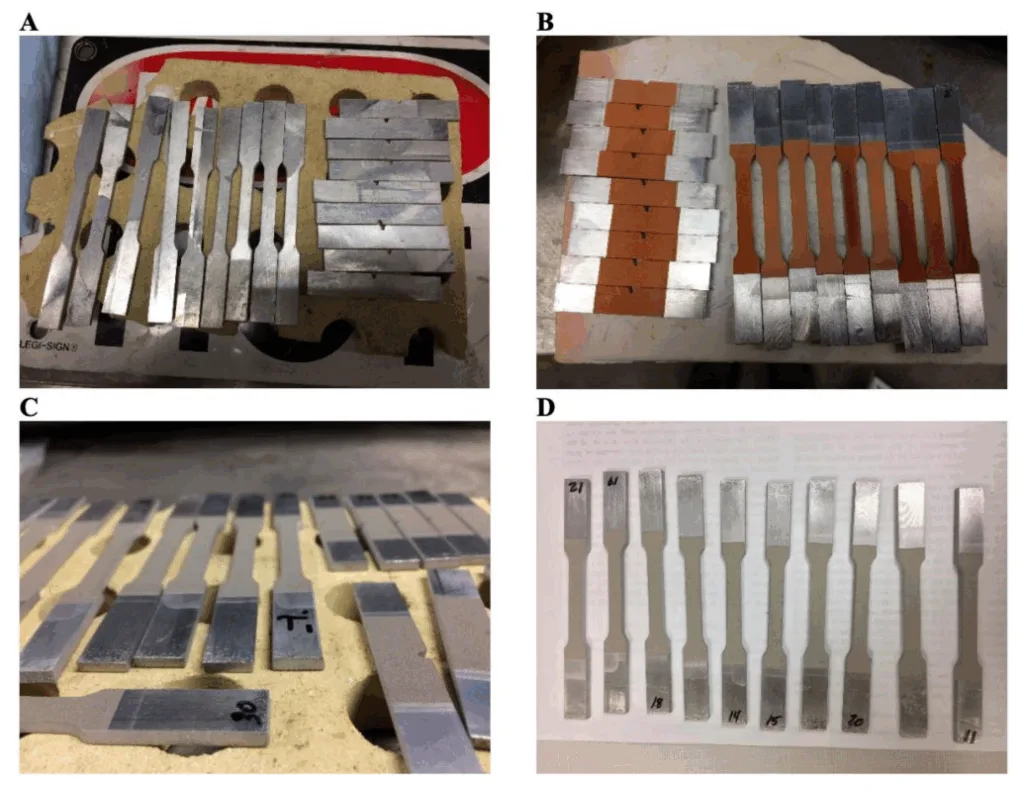

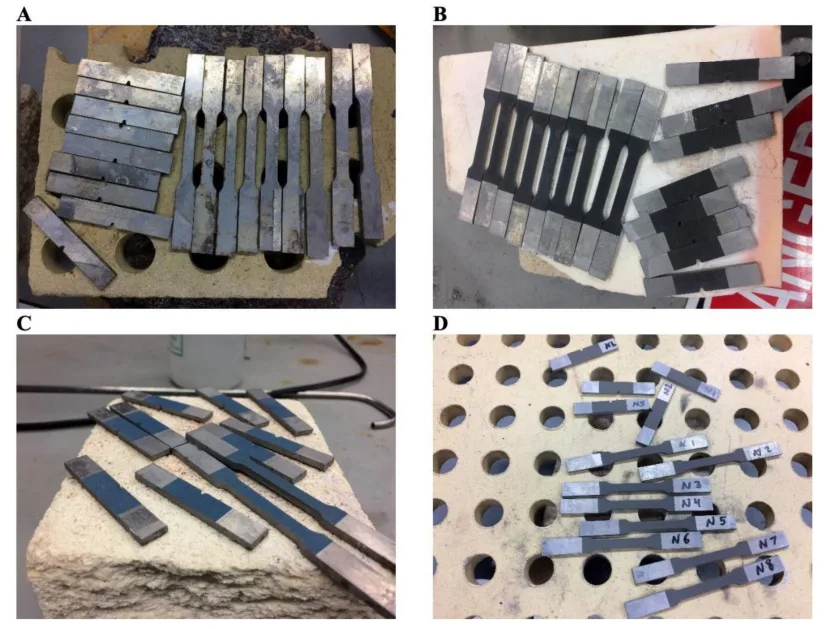

- Figure 1. (A) Digital image of the waterjet cut HPDC A365 substrate/base material as reference specimens that therefore did not undergo cold gas dynamic spray (CGDS) processing. (B) Digital photo of the thinly coated and Cu CGDS processed A365 HPDC substrate specimens. (C,D) Digital images are similar to (B), where Ni and Ti were utilized as feedstock, respectively. For reference, the thickness of the base material (see (C) with the properly oriented specimen labeled “30”) was 2.5 mm before CGDS processing or postprocessing after that.

- Figure 2. (A) Digital image of the thermally postprocessed HPDC A365 reference specimens procured during the current research effort. (B) Digital photo of the thermally postprocessed Cu CGDS coated HPDC A 365 substrate system. (C) Digital photo of the thermally postprocessed Ti CGDS coated HPDC A 365 substrate system. (D) Digital image of the thermally postprocessed Ni CGDS coated HPDC A 365 substrate system. Note that the same dimensional reference provided in Figure 1 holds here as well.

- Figure 3. (A) Optical micrograph of the as-cast A365 HPDC. (B) Optical micrograph of the copper CGDS processed A365 HPDC sample. (C) Optical micrograph of the titanium CGDS processed A365 HPDC sample. (D) Optical micrograph of the nickel CGDS processed A365 HPDC sample. Black portions within the micrographs capture the mounting material. Various degrees of subsurface modification are observable within each micrograph provided. The scale bar embedded within each micrograph presented represents 50 µm.

- Figure 4. (A) Optical micrograph of the copper CGDS processed A365 HPDC system following solution heat-treating. (C) Optical micrograph of the titanium CGDS processed A365 HPDC system following solution heat-treating. (B) Optical micrograph of the nickel CGDS processed A365 HPDC system following solution heat-treating. Black portions within the micrographs capture the mounting material. The scale bars embedded within each micrograph presented represent 50 µm.

- Figure 5. (a) Optical micrograph of the A365 HPDC system in the T6 condition. (B) Optical micrograph of the copper CGDS processed A365 HPDC system in the T6 condition. (C) Optical micrograph of the titanium CGDS processed A365 HPDC system in the T6 condition. (D) Optical micrograph of the nickel CGDS processed A365 HPDC system in the T6 condition. Black portions within the micrographs capture the mounting material. The scale bar embedded within each micrograph presented represents 50 µm.

- Figure 6. Presentation of the EDS line scan recorded for the Cu CGDS coated HPDC A365 substrate system in the thermally postprocessed condition.

- Figure 7. Presentation of the EDS mapping recorded for the Cu CGDS coated HPDC A365 substrate system in the thermally postprocessed condition.

- Figure 8. Presentation of the EDS line scan recorded for the Ni CGDS coated HPDC A365 substrate system in the thermally postprocessed condition.

- Figure 9. Presentation of the EDS mapping recorded for the Ni CGDS coated HPDC A365 substrate system in the thermally postprocessed condition.

- Figure 10. Presentation of the EDS line scan recorded for the Ti CGDS coated HPDC A365 substrate system in the thermally postprocessed condition.

7. Conclusion:

This work substantiated Ti and Ni CGDS deposition as promising surface modification techniques for cost-effective near-surface property enhancement of A365 aluminum alloy HPDC materials.

- Copper (Cu) CGDS was eliminated as a prospective coating material because thermally mediated Cu CGDS atomic diffusion into the HPDC A365 subsurface resulted in deleterious microstructural and property evolution (diverse intermetallics, exotic diffusion zones, severe oxidation).

- Titanium (Ti) CGDS surface modification was identified as a viably integrative manufacturing step. CGDS processing induced subsurface property enhancement, followed by standard T6 thermal treatment. No secondary Ti-Al intermetallic compounds were found; atomic Ti enriched the A365 solid solution in the subsurface region.

- Nickel (Ni) CGDS processing was found to be less successful. Thermal postprocessing of Ni CGDS coated HPDC A365 formed Ni-Al intermetallics. Diffusion zone formation promoted polygonization and dislocation rearrangement. Impact-induced substrate surface erosion and partial removal of as-cast texture occurred with Ni deposition. It is suggested that A365 material in the T6 condition (strengthened relative to as-cast) should be used before Ni CGDS surface modification to potentially avoid impact-induced erosion.

- Future work should include tensile and fatigue testing of properly prepared specimens, thermal processing optimization, CGDS processing parameter optimization, and deposition of spherical Ti powder (rather than sponge granules) for further property enhancement.

8. References:

- [1] Alkhimov, A.; Papyrin, A.; Kosarev, V. Gas-Dynamic Spraying Method for Applying a Coating. US Patent 5302414, 12 April 1994.

- [2] Stoltenhoff, T.; Kreye, H.; Richter, H.J. An Analysis of the Cold Spray Process and Its Coatings. J. Therm. Spray Technol. 2002, 11, 542–550. [CrossRef]

- [3] Petráčková, K.; Kondás, J.; Guagliano, M. Fixing a hole (with cold spray). Int. J. Fatigue 2018, 110, 144–152. [CrossRef]

- [4] Sova, A.; Grigoriev, S.; Okunkova, A.; Smurov, I. Potential of cold gas dynamic spray as additive manufacturing technology. Int. J. Adv. Manuf. Technol. 2013, 69, 2269–2278. [CrossRef]

- [5] Wang, X.; Feng, F.; Klecka, M.A.; Mordasky, M.D.; Garofano, J.K.; El-Wardany, T.; Nardi, A.; Champagne, V.K. Characterization and modeling of the bonding process in cold spray additive manufacturing. Addit. Manuf. 2015, 8, 149–162. [CrossRef]

- [6] Yin, S.; Suo, X.; Liao, H.; Guo, Z.; Wang, X. Significant influence of carrier gas temperature during the cold spray process. Surf. Eng. 2014, 30, 443–450. [CrossRef]

- [7] Sinclair-Adamson, R.; Luzin, V.; Duguid, A.; Kannoorpatti, K.; Murray, R. Residual Stress Distributions in Cold-Sprayed Copper 3D-Printed Parts. J. Therm. Spray Technol. 2020, 29, 1525–1537. [CrossRef]

- [8] Irissou, E.; Legoux, J.-G.; Ryabinin, A.N.; Jodoin, B.; Moreau, C. Review on Cold Spray Process and Technology: Part I—Intellectual Property. J. Therm. Spray Technol. 2008, 17, 495–516. [CrossRef]

- [9] Singh, H.; Sidhu, T.S.; Kalsi, S.B.S.; Karthikeyan, J. Development of cold spray from innovation to emerging future coating technology. J. Brazilian Soc. Mech. Sci. Eng. 2013, 35, 231–245. [CrossRef]

- [10] Saboori, A.; Biamino, S.; Valente, A.; Gitardi, D.; Basile, G.; Lombardi, M.; Fino, P. The capacity of cold spray additive manufacturing technology for metallic part repairing. In Proceedings of the Europe PM 2018 Congress and Exhibition, Bilbao, Spain, 14–18 October 2018.

- [11] Cavaliere, P.; Silvello, A. Processing conditions affecting residual stresses and fatigue properties of cold spray deposits. Int. J. Adv. Manuf. Technol. 2015, 81, 1857–1862. [CrossRef]

- [12] Belsito, D. Application of Computational Thermodynamic and Solidification Kinetics to Cold Sprayable Powder Alloy Design. Ph.D. Thesis, Worcester Polytechnic Institute, Worcester, MA, USA, 2014.

- [13] Yeom, H.; Sridharan, K. Cold spray technology in nuclear energy applications: A review of recent advances. Ann. Nucl. Energy 2021, 150, 107835. [CrossRef]

- [14] Rokni, M.R.; Widener, C.A.; Champagne, V.K.; Crawford, G.A. Microstructure and mechanical properties of cold sprayed 7075 deposition during non-isothermal annealing. Surf. Coatings Technol. 2015, 276, 305–315. [CrossRef]

- [15] Rokni, M.R.; Widener, C.A.; Ozdemir, O.C.; Crawford, G.A. Microstructure and mechanical properties of cold sprayed 6061 Al in As-sprayed and heat treated condition. Surf. Coatings Technol. 2017, 309, 641–650. [CrossRef]

- [16] Jafarlou, D.M.; Walde, C.; Champagne, V.K.; Krishnamurty, S.; Grosse, I.R. Influence of cold sprayed Cr3C2-Ni coating on fracture characteristics of additively manufactured 15Cr-5Ni stainless steel. Mater. Des. 2018, 155, 134–147. [CrossRef]

- [17] Yang, J.; Yang, J.; Xie, J.; Wang, Q.; Qu, K. Improved fatigue crack propagation performance of Q355B steel with cold-sprayed A5052 and Al coatings. Surf. Coatings Technol. 2019, 378, 125000. [CrossRef]

- [18] Wolfe, D.; Eden, T. Cold spray particle deposition for improved wear resistance. In The Cold Spray Materials Deposition Process; Elsevier: Amsterdam, The Netherlands, 2007; pp. 264–301.

- [19] Chromik, R.R.; Alidokht, S.A.; Shockley, J.M.; Zhang, Y. Tribological Coatings Prepared by Cold Spray. In Cold-Spray Coatings; Springer International Publishing: Cham, Switzerland, 2018; pp. 321–348.

- [20] Murray, J.W.; Zuccoli, M.V.; Hussain, T. Heat Treatment of Cold-Sprayed C355 Al for Repair: Microstructure and Mechanical Properties. J. Therm. Spray Technol. 2018, 27, 159–168. [CrossRef]

- [21] Champagne, V.K.; Gabriel, B.; Villafuerte, J. Cold spray coatings to improve the corrosion resistance of magnesium (Mg) alloys. In Corrosion Prevention of Magnesium Alloys; Elsevier: Amsterdam, The Netherlands, 2013; pp. 414–445.

- [22] Huang, C.J.; Yan, X.C.; Li, W.Y.; Wang, W.B.; Verdy, C.; Planche, M.P.; Liao, H.L.; Montavon, G. Post-spray modification of cold-sprayed Ni-Ti coatings by high-temperature vacuum annealing and friction stir processing. Appl. Surf. Sci. 2018, 451, 56–66. [CrossRef]

- [23] Li, J.; Zhang, Y.; Cao, X.; Zeng, Q.; Zhuang, Y.; Qian, X.; Chen, H. Accelerated discovery of high-strength aluminum alloys by machine learning. Commun. Mater. 2020, 1, 73. [CrossRef]

- [24] Jozwik, P.; Polkowski, W.; Bojar, Z. Applications of Ni3Al Based Intermetallic Alloys—Current Stage and Potential Perceptivities. Materials 2015, 8, 2537–2568. [CrossRef]

- [25] Deevi, S.C.; Sikka, V.K. Nickel and iron aluminides: An overview on properties, processing, and applications. Intermetallics 1996, 4, 357–375. [CrossRef]

- [26] Chen, Z.; Yan, K. Grain refinement of commercially pure aluminum with addition of Ti and Zr elements based on crystallography orientation. Sci. Rep. 2020, 10, 16591. [CrossRef]

- [27] Arzamasov, B.N.; Babich, S.G.; Kirichenko, L.G.; Knyazheva, V.M.; Silaeva, V.I.; Solov’eva, T.V. Properties of aluminum alloys with a titanium nitride coating. Met. Sci. Heat Treat. 1994, 36, 308–312. [CrossRef]

- [28] Liu, F.; Zhao, H.; Yang, R.; Sun, F. Microstructure and Mechanical Properties of High Vacuum Die-Cast AlSiMgMn Alloys at as-Cast and T6-Treated Conditions. Materials 2019, 12, 2065. [CrossRef]

- [29] Padmanaban, S.; Subramanian, R.; Anburaj, J.; Thillairajan, K. Rheo-Die-Casting of Al-Si-Mg Alloy and Al-Si-Mg/ SiCp Composites: Microstructure and Wear Behavior. Mater. Res. 2020, 23. [CrossRef]

- [30] Viscusi, A.; Astarita, A.; Gatta, R.D.; Rubino, F. A perspective review on the bonding mechanisms in cold gas dynamic spray. Surf. Eng. 2019, 35, 743–771. [CrossRef]

- [31] Shivkumar, S.; Wang, L.; Keller, C. Impact properties of A356-T6 alloys. J. Mater. Eng. Perform. 1994, 3, 83–90. [CrossRef]

- [32] Wei, Y.-K.; Li, Y.-J.; Zhang, Y.; Luo, X.-T.; Li, C.-J. Corrosion resistant nickel coating with strong adhesion on AZ31B magnesium alloy prepared by an in-situ shot-peening-assisted cold spray. Corros. Sci. 2018, 138, 105–115. [CrossRef]

- [33] Sundberg, K.; Sousa, B.C.; Schreiber, J.; Walde, C.E.; Eden, T.J.; Sisson, R.D.; Cote, D.L. Finite Element Modeling of Single-Particle Impacts for the Optimization of Antimicrobial Copper Cold Spray Coatings. J. Therm. Spray Technol. 2020, 29, 1847–1862. [CrossRef]

- [34] Uchikoshi, T.; Sakka, Y.; Yoshitake, M.; Yoshihara, K. A study of the passivating oxide layer on fine nickel particles. Nanostruct. Mater. 1994, 4, 199–206. [CrossRef]

- [35] Mrowec, S.; Grzesik, Z. Oxidation of nickel and transport properties of nickel oxide. J. Phys. Chem. Solids 2004, 65, 1651–1657. [CrossRef]

- [36] Song, P.; Wen, D.; Guo, Z.X.; Korakianitis, T. Oxidation investigation of nickel nanoparticles. Phys. Chem. Chem. Phys. 2008, 10, 5057. [CrossRef]

- [37] Sousa, B.C.; Sundberg, K.L.; Gleason, M.A.; Cote, D.L. Understanding the Antipathogenic Performance of Nanostructured and Conventional Copper Cold Spray Material Consolidations and Coated Surfaces. Crystals 2020, 10, 504. [CrossRef]

- [38] Sousa, B.C.; Gleason, M.A.; Haddad, B.; Champagne, V.K.; Nardi, A.T.; Cote, D.L. Nanomechanical Characterization for Cold Spray: From Feedstock to Consolidated Material Properties. Metals 2020, 10, 1195. [CrossRef]

- [39] Razavipour, M.; Rahmati, S.; Zúñiga, A.; Criado, D.; Jodoin, B. Bonding Mechanisms in Cold Spray: Influence of Surface Oxidation During Powder Storage. J. Therm. Spray Technol. 2020. [CrossRef]

- [40] Shikalov, V.S.; Klinkov, S.V.; Kosarev, V.F. Cold spray deposition of aluminum coating onto an erodible material. Thermophys. Aeromech. 2019, 26, 729–737. [CrossRef]

- [41] Tiamiyu, A.A.; Sun, Y.; Nelson, K.A.; Schuh, C.A. Site-specific study of jetting, bonding, and local deformation during high-velocity metallic microparticle impact. Acta Mater. 2021, 202, 159–169. [CrossRef]

- [42] Ma, S.; Maniruzzaman, M.D.; MacKenzie, D.S.; Sisson, R.D. A Methodology to Predict the Effects of Quench Rates on Mechanical Properties of Cast Aluminum Alloys. Metall. Mater. Trans. B 2007, 38, 583–589. [CrossRef]

- [43] 365.0 (Silafont®-36) and A365.0 (Aural®-2/-3)[1]: Low-Iron Premium Die-Casting Alloys. In Properties and Selection of Aluminum Alloys; Anderson, K. (Ed.) A.S.M. International: New York, NY, USA, 2019; pp. 561–563.

- [44] Cai, Q.; Mendis, C.L.; Chang, I.T.H.; Fan, Z. Effect of short T6 heat treatment on the microstructure and the mechanical properties of newly developed die-cast Al-Si-Mg-Mn alloys. Mater. Sci. Eng. A 2020, 788, 139610. [CrossRef]

- [45] Ding, J.; Miao, S.; Ma, B.; Xia, X.; Qiu, C.; Chen, X. Effect of Solution Treatment on Microstructure and Mechanical Properties of A356.2 Aluminum Alloy Treated With Al-Sr-La Master Alloy. Adv. Eng. Mater. 2018, 20, 1701173. [CrossRef]

- [46] Yuan, Z.; Guo, Z.; Xiong, S. Microstructure evolution of modified die-cast AlSi10MnMg alloy during solution treatment and its effect on mechanical properties. Trans. Nonferrous Met. Soc. China 2019, 29, 919–930. [CrossRef]

- [47] Liang, Y.L.; Wang, Z.B.; Zhang, J.B.; Lu, K. Formation of interfacial compounds and the effects on stripping behaviors of a cold-sprayed Zn-Al coating on interstitial-free steel. Appl. Surf. Sci. 2015, 340, 89–95. [CrossRef]

- [48] Nikbakht, R.; Assadi, H.; Jodoin, B. Intermetallic Phase Evolution of Cold-Sprayed Ni-Ti Composite Coatings: Influence of As-Sprayed Chemical Composition. J. Therm. Spray Technol. 2020. [CrossRef]

- [49] Wang, Q.; Birbilis, N.; Zhang, M.-X. On the Formation of a Diffusion Bond from Cold-Spray Coatings. Metall. Mater. Trans. A 2012, 43, 1395–1399. [CrossRef]

- [50] Spencer, K.; Zhang, M.-X. Heat treatment of cold spray coatings to form protective intermetallic layers. Scr. Mater. 2009, 61, 44–47. [CrossRef]

- [51] Yin, S.; Xie, Y.; Suo, X.; Liao, H.; Wang, X. Interfacial bonding features of Ni coating on Al substrate with different surface pretreatments in cold spray. Mater. Lett. 2015, 138, 143–147. [CrossRef]

- [52] Huang, R.; Ma, W.; Fukanuma, H. Development of ultra-strong adhesive strength coatings using cold spray. Surf. Coatings Technol. 2014, 258, 832–841. [CrossRef]

- [53] Bu, H.; Yandouzi, M.; Lu, C.; Jodoin, B. Effect of heat treatment on the intermetallic layer of cold sprayed aluminum coatings on magnesium alloy. Surf. Coatings Technol. 2011, 205, 4665–4671. [CrossRef]

- [54] Ning, X.-J.; Kim, J.-H.; Kim, H.-J.; Lee, C. Characteristics and heat treatment of cold-sprayed Al–Sn binary alloy coatings. Appl. Surf. Sci. 2009, 255, 3933–3939. [CrossRef]

- [55] Wang, J.; Kong, L.; Li, T.; Xiong, T. High temperature oxidation behavior of Ti(Al,Si) 3 diffusion coating on γ-TiAl by cold spray. Trans. Nonferrous Met. Soc. China 2016, 26, 1155–1162. [CrossRef]

- [56] Lee, H.; Shin, H.; Ko, K. Effects of Gas Pressure of Cold Spray on the Formation of Al-Based Intermetallic Compound. J. Therm. Spray Technol. 2010, 19, 102–109. [CrossRef]

- [57] Wang, J.; Kong, L.; Li, T.; Xiong, T. Oxidation Behavior of Thermal Barrier Coatings with a TiAl3 Bond Coat on γ-TiAl Alloy. J. Therm. Spray Technol. 2015, 24, 467–475. [CrossRef]

- [58] Novoselova, T.; Celotto, S.; Morgan, R.; Fox, P.; O’Neill, W. Formation of TiAl intermetallics by heat treatment of cold-sprayed precursor deposits. J. Alloys Compd. 2007, 436, 69–77. [CrossRef]

- [59] Anupam, A.; Kumar, S.; Chavan, N.M.; Murty, B.S.; Kottada, R.S. First report on cold-sprayed AlCoCrFeNi high-entropy alloy and its isothermal oxidation. J. Mater. Res. 2019, 34, 796–806. [CrossRef]

- [60] Li, W.-Y.; Li, C.-J.; Liao, H.; Coddet, C. Effect of heat treatment on the microstructure and microhardness of cold-sprayed tin bronze coating. Appl. Surf. Sci. 2007, 253, 5967–5971. [CrossRef]

- [61] Dean, S.W.; Potter, J.K.; Yetter, R.A.; Eden, T.J.; Champagne, V.; Trexler, M. Energetic intermetallic materials formed by cold spray. Intermetallics 2013, 43, 121–130. [CrossRef]

- [62] Leshchinsky, E.; Sobiesiak, A.; Maev, R. Intermetallic Al-, Fe-, Co- and Ni-Based Thermal Barrier Coatings Prepared by Cold Spray for Applications on Low Heat Rejection Diesel Engines. J. Therm. Spray Technol. 2018, 27, 456–470. [CrossRef]

- [63] Won, J.; Kim, J.; Lee, S.; Lee, C.; Lee, S.; Kim, S.J. Effect of intermetallic compounds on the bonding state of kinetic sprayed Al deposit on Cu after heat-treatment. Surf. Coatings Technol. 2016, 302, 39–46. [CrossRef]

9. Copyright:

- This material is a paper by "Alino Te, Bryer C. Sousa, Brajendra Mishra, and Danielle L. Cote". Based on "Subsurface Microstructural Evolution of High-Pressure Diecast A365: From Cast to Cold-Sprayed and Heat-Treated Conditions".

- Source of the paper: https://doi.org/10.3390/met11030432

This material is summarized based on the above paper, and unauthorized use for commercial purposes is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.