From Process Data to Perfect Parts: Using AI for Casting Process Optimization and Reject Reduction

This technical summary is based on the academic paper "Reduction of rejects by combining data from the casting process and automatic X-ray inspection" by Thomas STOCKER, Julius MEHRINGER, Dr. Henning FRECHEN, Dr. Frank SUKOWSKI, Felix SCHÄFER and Dennis FREIER, published in the e-Journal of Nondestructive Testing (2024).

Keywords

- Primary Keyword: Casting Process Optimization

- Secondary Keywords: light alloy wheels, X-ray inspection, neural networks, defect reduction, Industry 4.0, process feedback loop

Executive Summary

- The Challenge: Reducing the persistent single-digit percentage scrap rate in light alloy wheel production is increasingly difficult with conventional methods, leading to wasted energy and higher costs.

- The Method: Researchers combined sensor data from the low-pressure die casting process with results from automatic X-ray inspection to train a neural network.

- The Key Breakthrough: The AI model can accurately predict the size of the largest casting defect and, more importantly, identify the specific process parameters and time windows that are most critical to defect formation.

- The Bottom Line: This data-driven approach provides actionable recommendations to adjust casting machine settings in real-time, enabling foundries to reduce their reject rate before scrap is even produced.

The Challenge: Why This Research Matters for HPDC Professionals

In modern manufacturing, especially in Europe, the pressure is on. Rising energy and raw material prices, combined with the push for climate-neutral production, demand unprecedented efficiency. For producers of light alloy wheels, process-related scrap rates, while only in the single-digit percentage range, represent a significant source of waste and cost. While scrap rates have been steadily reduced over the years, further improvements using conventional methods have become increasingly challenging.

The Cast Control project, detailed in this paper, tackles this challenge head-on. The core problem is a data disconnect: casting machines generate vast amounts of process data, and X-ray inspection systems generate vast amounts of quality data. However, this information is typically condensed into a simple "good" or "bad" decision, and the rich, underlying data that could explain why a part is bad is discarded. This research aims to bridge that gap, creating a feedback loop to make Casting Process Optimization proactive rather than reactive.

The Approach: Unpacking the Methodology

To build a predictive model, the researchers created a comprehensive dataset by linking two critical sources of information for each cast wheel:

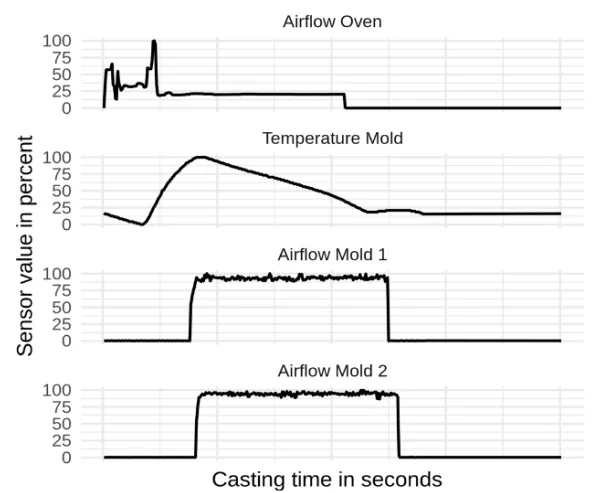

- Casting Process Data: For every wheel produced, measurements were taken from 20 different standard sensors integrated into the casting machines. This included time-series data (at 1 sample per second) for parameters like the temperature of the molten alloy, pressure during mold filling, and the flow of cooling air at various locations.

- X-ray Inspection Data: After casting, each wheel undergoes a mandatory automatic X-ray inspection. Instead of just using the final OK/NOK (scrap) decision, the researchers focused on a specific quantitative defect feature: the area of the largest void, measured in square millimeters (

max_A_sqmm), which showed the highest correlation with the final scrap decision.

With a cleaned dataset of 16,262 unique parts, they trained an ensemble of neural networks. The 20 sensor recordings served as the model's input, and the max_A_sqmm value was the target output it learned to predict. To understand the model's decision-making process, they applied two post-hoc explanation methods: Layer-wise Relevance Propagation (LRP) and sensitivity analysis. These techniques create visual heatmaps that reveal which sensor inputs, at which specific times, have the most significant impact on the predicted defect size.

The Breakthrough: Key Findings & Data

The research yielded two powerful results that demonstrate the viability of this AI-driven approach for Casting Process Optimization.

Finding 1: AI Model Successfully Predicts Defect Size

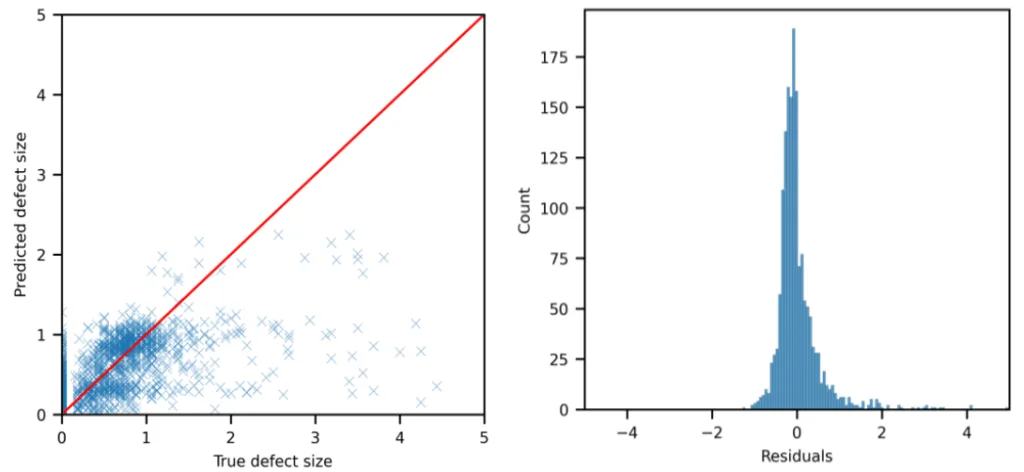

The trained ensemble model proved capable of accurately predicting the maximum defect size in wheels it had never seen before. As shown in Figure 2 of the paper, the model's predictions (y-axis) closely align with the true target values (x-axis), clustering around the ideal diagonal line. The right side of the figure shows the distribution of residuals (the difference between predicted and true values), which is almost normally distributed around zero. This confirms that the model does not systematically over- or underestimate defect size, making it a reliable tool for quality prediction, even if it sometimes fails to capture extreme values.

Finding 2: Pinpointing Critical Process Parameters and Timings

The true innovation lies in understanding the "why" behind the model's predictions. By using LRP and sensitivity analysis, the researchers could visualize the relationship between process parameters and defect outcomes. Figure 3 in the paper presents heatmaps for a specific mold design, showing the average sensitivity and LRP attributions over the casting time.

- LRP (Bottom Heatmap): This qualitatively identifies which sensor readings at which times are most significant to the model's prediction. Red areas indicate high importance.

- Sensitivity (Top Heatmap): This quantitatively shows the direction of the relationship. Dark red areas indicate that increasing the sensor value at that time would increase the defect size, while dark blue areas indicate that an increase in the sensor value would decrease the defect size.

For example, the paper highlights that for the oven air flow (OAF), the first ~20 seconds of the casting process are colored red in both the LRP and sensitivity plots. This provides a clear, actionable insight: this early phase of oven air flow is highly significant, and reducing its value is predicted to reduce the final defect size.

Practical Implications for R&D and Operations

The findings from this study offer a roadmap for moving towards a more intelligent and proactive production environment.

- For Process Engineers: This study suggests that adjusting specific process parameters, such as the oven air flow during the initial 20 seconds, may contribute to reducing defect sizes. The methodology provides a tool to identify the most impactful parameters and timings for each unique mold design, allowing for targeted optimization.

- For Quality Control Teams: The data in Figure 2 illustrates a strong link between live process data and a key X-ray defect metric (

max_A_sqmm). This could inform a more nuanced understanding of defect formation, moving beyond a simple pass/fail paradigm to a predictive quality model. - For Design Engineers: The findings, which are specific to "Mold Design 1" as shown in Figure 3, indicate that the influence of process parameters on defect formation is tied to the specific geometry of the part. This suggests that co-optimizing process parameters alongside mold design is a valuable consideration in the early development phase.

Paper Details

Reduction of rejects by combining data from the casting process and automatic X-ray inspection

1. Overview:

- Title: Reduction of rejects by combining data from the casting process and automatic X-ray inspection

- Author: Thomas STOCKER, Julius MEHRINGER, Dr. Henning FRECHEN, Dr. Frank SUKOWSKI, Felix SCHÄFER and Dennis FREIER

- Year of publication: 2024

- Journal/academic society of publication: e-Journal of Nondestructive Testing (20th WCNDT)

- Keywords: Industry 4.0; process feedback loop; casting inspection; process optimization; neuronal networks; ai

2. Abstract:

Automatic inspection of castings with X-rays (radiographic and computed tomography) is widespread for parts that are relevant for safety or have high quality requirements. Examples in the automotive sector are aluminum wheels, chassis parts and new parts within the electric power train. Those parts are automatically inspected, which means that both the image acquisition and the evaluation of the images is done fully automatically. Today, in most industrial implementations, the generated data with a size up to several gigabytes per part is summarized to a simple good or bad decision, according to specification. All other data is dismissed, although this information can be valuable to optimize production processes and thus minimize rejects. This contribution gives an overview about the results of the project Cast Control, which is a collaboration of Fraunhofer Development Center for X-ray Technology EZRT, Fraunhofer Center for Applied Research on Supply Chain Services SCS and industry partner RONAL GROUP. RONAL GROUP is a major aluminum wheel manufacturer, mainly for the OEM market. Within the project we combined serial production data from the low pressure die casting process from a foundry of the RONAL GROUP with the data generated in the automatic X-ray inspection. After collecting a large base of sample data, we were able train a neural network for the prediction of error metrics obtained by X-ray inspection. We apply a combination of layer-wise relevance propagation and dimensionality reduction to find correlations between data of the casting machines (process and sensor) and the characteristics of anomalies detected during X-ray inspection. With this information, it is possible to adjust the casting process in an early stage – even before rejects are produced. This enables the foundry to reduce their rejects rate, which saves costs and energy and results in a better competitiveness.

3. Introduction:

Reducing personnel costs by lowering manufacturing process supervision times is particularly necessitated in Europe. Additionally, the sharp rise in prices for energy and raw materials, combined with the goal of climate-neutral production, make it necessary to reduce the consumption of energy for production as far as possible. The Cast Control project is making a direct, significant contribution to the latter challenge and an indirect, soft contribution to the former. In the production of light alloy wheels, process-related scrap rates currently lie in the single-digit percentage range. Scrap always means higher energy consumption and additional costs. The scrap rate has been steadily reduced in recent years by various measures. However, further improvement using conventional methods is becoming increasingly difficult. The Cast Control project aims to further reduce scrap in the production of light alloy wheels by combining data from the foundry with data from X-ray inspection. For this we apply a combination of layer-wise relevance propagation and dimensionality reduction to find correlations between the two data sources.

4. Summary of the study:

Background of the research topic:

The production of light alloy wheels involves high energy and material costs, and process-related scrap rates contribute significantly to this inefficiency. Reducing these scrap rates is critical for cost savings, energy conservation, and competitiveness.

Status of previous research:

While scrap rates have been steadily reduced over the years by various measures, further improvement using conventional methods is becoming increasingly difficult, necessitating new, data-driven approaches.

Purpose of the study:

To further reduce scrap in the production of light alloy wheels by combining process data from the foundry with quality data from X-ray inspection, using artificial intelligence to find correlations and provide actionable insights for process optimization.

Core study:

The study involved collecting process sensor data and X-ray inspection results from a large-scale production environment. A neural network was trained to predict a key defect metric based on the sensor data. Layer-wise relevance propagation (LRP) and sensitivity analysis were then used to interpret the model's decisions and identify which process parameters were most influential in causing defects.

5. Research Methodology

Research Design:

The research followed an industrial data science approach. Serial production data from a low-pressure die casting process was combined with corresponding automatic X-ray inspection data. This combined dataset was used to train and validate a predictive machine learning model.

Data Collection and Analysis Methods:

Data was collected from 20 standard sensors in casting machines (1 sample/sec) and from an automatic X-ray inspection system (ISAR). The target variable for prediction was max_A_sqmm (area of the largest void). The dataset was cleaned, preprocessed, and used to train a neural network. Layer-wise Relevance Propagation (LRP) and a sensitivity analysis were performed to explain the model's predictions.

Research Topics and Scope:

The scope was limited to the low-pressure die casting of aluminum wheels at a RONAL GROUP foundry. The study focused on correlating 20 specific process sensor signals with a single defect metric derived from X-ray inspection. It did not include metadata such as environmental data or aluminum alloy quality.

6. Key Results:

Key Results:

- An ensemble neural network model was successfully trained to predict the maximum defect size (

max_A_sqmm) in a cast wheel based on 20 sensor recordings from the casting process. - The model's predictions are reliable, with residuals being almost normally distributed around zero, indicating no systematic over- or underestimation of defect size (Figure 2).

- Using Layer-wise Relevance Propagation (LRP) and sensitivity analysis, it is possible to create visual heatmaps that identify which specific sensor values at specific times are most significant for defect prediction (Figure 3).

- This analysis provides both qualitative (what's important) and quantitative (how it's important) insights, which can be translated into recommendations for adjusting process parameters to reduce scrap.

Figure Name List:

- Fig. 1 Typical Sensor Recordings from a Casting Process

- Fig. 2 Root-mean-square Deviation Distribution on the Test Set

- Fig. 3 Mean of sensitivity (top) and LRP attributions (bottom) of the ensemble per time and input node for a mold

7. Conclusion:

The proposed approach is a versatile method for using all available sensor recordings to create an effective abstraction of the production environment with artificial neural networks. The model is capable of predicting the size of the largest defect in a wheel and can provide recommendations on which sensor values impact defect sizes. This information can be used to optimize production parameters to reduce scrap. A prototype system giving real-time recommendations is currently being evaluated in production at RONAL.

8. References:

- [1] K. Hornik, M. Stinchcombe and H. White, “Multilayer feedforward networks are universal approximators.”, Neural Networks, Volume 2, Issue 5, pp 359–366 (1989)

- [2] E. A. Barnes, B. Toms, J. W. Hurrell, I. Ebert-Uphoff, C. Anderson and D. Anderson, “Indicator patterns of forced change learned by an artificial neural network.”, Journal of Advances in Modeling Earth Systems, Volume 12, Issue 9 (2020)

- [3] J. Mehringer, H. Frechen, N. Beck, F. Sukowski, T. Stocker, D. Freier and F. Schäfer, “Cast Control: AI-based Explanations of Casting Defects Linking Process and Quality Inspection Data”, Proceedings of the 2nd Congress for intelligent Combining of Design, Casting, Computer Simulation, Checking and Cyclic Behaviour for efficient Cast Components (2023)

Expert Q&A: Your Top Questions Answered

Q1: Why was the "area of the largest void" (max_A_sqmm) chosen as the specific target for the AI model, instead of just the final "scrap" or "no scrap" decision?

A1: The researchers performed a point-biserial correlation analysis to identify which X-ray defect features had the strongest relationship with the final OK/NOK decision. The max_A_sqmm was found to have the highest correlation in their dataset. Using a continuous value like area, rather than a binary scrap/no-scrap label, allows the model to learn a more nuanced relationship between process variations and defect severity, making it more sensitive for process optimization.

Q2: Figure 2 shows the model sometimes fails to predict extreme defect values. Why does this happen, and does it limit the model's usefulness?

A2: The paper does not specify the exact cause, but in machine learning, difficulty with extreme values (outliers) can occur due to their low frequency in the training data. However, the model remains highly useful because the distribution of its prediction errors (residuals) is centered around zero. This means that, on average, the model is accurate and does not have a systemic bias toward over- or under-predicting, making it a reliable tool for identifying trends and guiding process adjustments for the vast majority of production cases.

Q3: What is the practical difference between the LRP and sensitivity analysis heatmaps shown in Figure 3? Why are both needed?

A3: They provide two complementary views. The LRP heatmap (bottom) is qualitative; it highlights which sensor at which time is most important for the model's decision, regardless of the direction of the effect. The sensitivity heatmap (top) is quantitative; it shows how a change in a sensor value would affect the outcome. A red area means increasing the sensor value increases the defect size, while blue means it decreases it. Using both together is powerful: LRP points to the critical moments, and sensitivity analysis tells you what adjustment to make.

Q4: The paper mentions cleaning the dataset. What kind of data was removed and why?

A4: The dataset was cleaned by removing entries with probable erroneous sensor values and by omitting data from infrequently used wheel molds. This is a standard and crucial step in data science to ensure the model learns from high-quality, representative data. Erroneous values could mislead the model, while molds with very few samples would not provide enough data for the model to learn reliable patterns.

Q5: This study focused on low-pressure die casting for wheels. How applicable is this methodology to High Pressure Die Casting (HPDC) for other components?

A5: The paper explicitly states, "In the future we plan to adapt our method to other casting applications and other production methods." The fundamental approach—linking time-series process sensor data with quantitative NDT results to train an explainable AI model—is highly versatile. It could certainly be adapted for HPDC, provided that sufficient sensor data and consistent quality inspection data are available to train the model.

Conclusion: Paving the Way for Higher Quality and Productivity

This research demonstrates a powerful shift from reactive scrap analysis to proactive quality control. By intelligently combining existing data from the casting process and automatic X-ray inspection, it is possible to build a feedback loop that provides clear, actionable insights. The ability of an AI model to not only predict defects but also to highlight their root causes in the process data is a significant step forward for Casting Process Optimization. This approach enables foundries to make targeted adjustments, reducing waste and improving competitiveness before rejects are even produced.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components.

Copyright Information

- This content is a summary and analysis based on the paper "Reduction of rejects by combining data from the casting process and automatic X-ray inspection" by "Thomas STOCKER, Julius MEHRINGER, Dr. Henning FRECHEN, Dr. Frank SUKOWSKI, Felix SCHÄFER and Dennis FREIER".

- Source: https://doi.org/10.58286/29884

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.