Predicting Casting Aluminum Alloy Fluidity with AI: A New Model for Defect-Free Production

This technical summary is based on the academic paper "PREDICTION OF FLUIDITY OF CASTING ALUMINUM ALLOYS USING ARTIFICIAL NEURAL NETWORK" by Yuan Gao, Hengcheng Liao, Xiaojing Suo, and Qigui Wang, published in Contributed Papers from Materials Science and Technology 2019 (MS&T19) (2019). It has been analyzed and summarized for technical experts by CASTMAN.

Keywords

- Primary Keyword: Casting Aluminum Alloy Fluidity

- Secondary Keywords: Artificial Neural Network, Fluidity Prediction Model, Alloy Composition, Pouring Temperature, HPDC Process Optimization

Executive Summary

- The Challenge: Poor fluidity in casting aluminum alloys is a primary cause of mold filling issues, leading to casting defects and compromising final product quality and soundness.

- The Method: Researchers developed a back-propagation (BP) artificial neural network model with an 8-9-1 structure to predict alloy fluidity based on seven key elemental compositions and the pouring temperature.

- The Key Breakthrough: The validated model accurately predicts the fluidity of casting aluminum alloys with a low average error of 6.56%, enabling the precise study of how different elements affect binary and multicomponent alloys.

- The Bottom Line: This AI-driven prediction model provides a powerful tool for designing optimal alloy compositions and process parameters to ensure excellent mold filling and produce high-quality, defect-free castings.

The Challenge: Why This Research Matters for HPDC Professionals

In the high-stakes automotive and aerospace industries, casting aluminum alloys are indispensable for their low density and high specific strength. However, a critical property governing the success of any casting process is fluidity—the alloy's ability to fill a mold cavity completely. If fluidity is poor, the result is incomplete shapes, dull outlines, and critical casting defects. If fluidity is satisfactory, it becomes possible to produce castings with accurate dimensions and sharp details. The fluidity of cast aluminum alloys is affected by a complex interplay of factors, including alloy composition, pouring temperature, and mold properties. Understanding and controlling these variables is essential, making the study and prediction of fluidity a necessary step toward achieving higher quality and production efficiency.

The Approach: Unpacking the Methodology

To tackle the complex, nonlinear relationships governing alloy fluidity, the researchers employed an artificial neural network. The study was built on a dataset generated from a series of experiments.

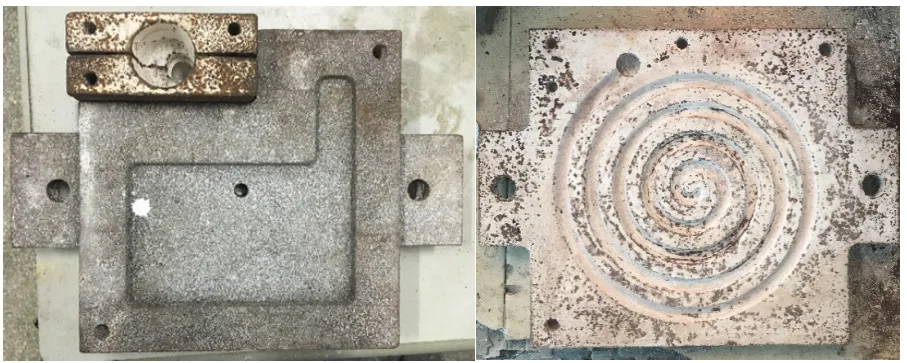

- Materials & Experiments: A total of 154 experiments were designed using common Binary Alloys, Ternary Alloys, and widely used commercial alloys such as A201, A332, A356, and A383. For each alloy, melts were prepared and poured into a spiral iron mold (Fig. 1) at two different superheat temperatures (70°C and 120°C above liquidus). This process generated 141 sets of valid data.

- Modeling: A back-propagation (BP) neural network was constructed with a specific 8-9-1 architecture:

- 8 Inputs: The weight percentages of Al, Si, Fe, Cu, Mn, Mg, Zn, and the pouring temperature.

- 9 Hidden Neurons: A single hidden layer with 9 neurons using a tan-sigmoid (tansig) transfer function.

- 1 Output: The fluidity of the alloy (in mm).

- Training & Validation: The dataset was split into training and testing sets. The model was trained using a Bayesian Regularization algorithm to adjust the connection weights until the predicted outputs closely matched the experimental values. The model's accuracy was then validated against the test dataset.

The Breakthrough: Key Findings & Data

The trained BP neural network model successfully mapped the complex relationships between inputs and outputs, demonstrating strong predictive power.

Finding 1: High Predictive Accuracy of the Neural Network Model

The developed model showed excellent agreement with experimental measurements. When validated against the test dataset, the model achieved an average prediction error of 6.56% and a maximum prediction error of 11.81%. Figure 2 from the paper clearly illustrates the close correlation between the predicted fluidity values and the actual experimental values, confirming the model's reliability for practical use.

Finding 2: Precise Prediction of Compositional Effects on Fluidity

The model was used to predict how specific alloying elements affect fluidity, offering valuable insights for alloy design.

- Al-Si Alloys: As shown in Figure 4, the model predicts that for Al-Si alloys at a 70°C superheat, fluidity first decreases and then increases as Si content rises from 0 to 15 wt.%, reaching a minimum fluidity at around 6 wt.% Si. This prediction closely matches experimental data for Si content below 14 wt.%.

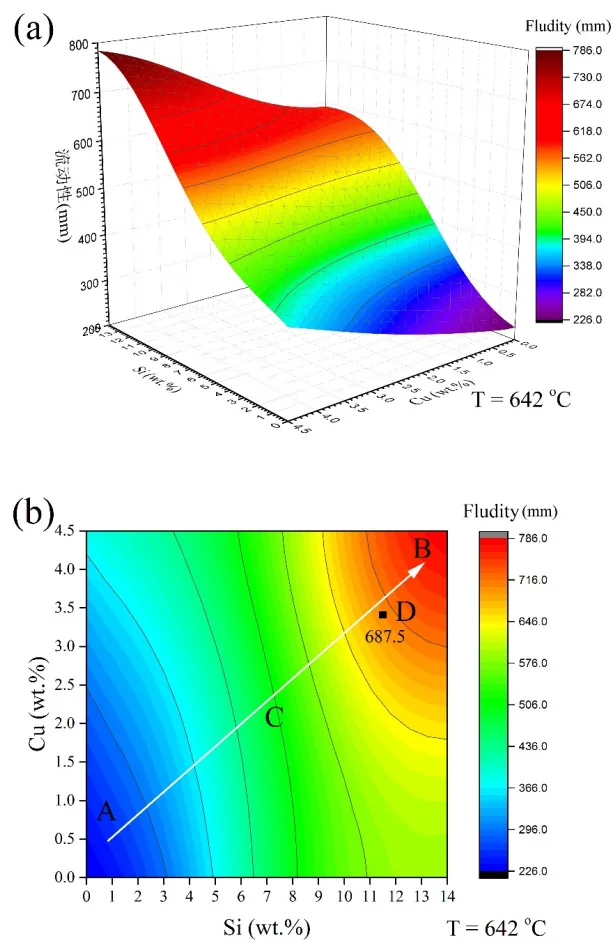

- Al-Si-Cu Alloys: The model can generate 3D and 2D plots (Figure 6) showing the combined effect of Si and Cu on fluidity. It successfully identifies regions of poor fluidity (low Si and Cu) and good fluidity (high Si and Cu). The prediction error for a specific experimental point (D) on the graph was only 2.42%, demonstrating its effectiveness for multicomponent systems.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that adjusting pouring temperature and carefully controlling the content of key alloying elements (Si, Cu, Mg) can directly and predictably improve mold filling, reducing fluidity-related defects.

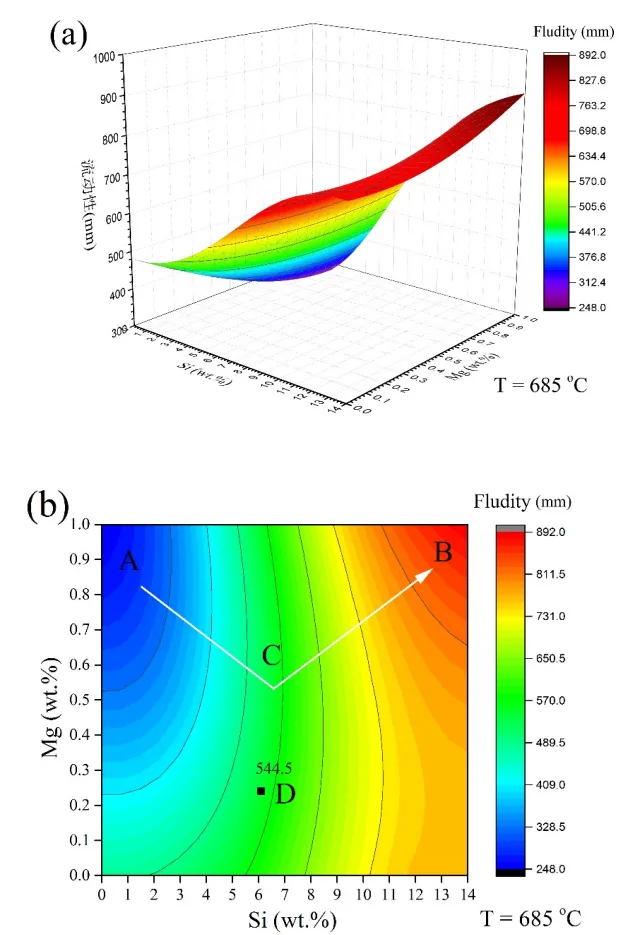

- For Quality Control Teams: The data in Figure 4, Figure 6, and Figure 7 of the paper illustrates the predictable relationship between composition and fluidity. This could inform new, more precise criteria for incoming material inspection and process monitoring to prevent defects before they occur.

- For Design Engineers: The findings indicate that specific combinations of Si, Cu, and Mg can be proactively designed to achieve desired fluidity for complex components. This allows for material selection and alloy design to be optimized for castability in the early design phase.

Paper Details

PREDICTION OF FLUIDITY OF CASTING ALUMINUM ALLOYS USING ARTIFICIAL NEURAL NETWORK

1. Overview:

- Title: PREDICTION OF FLUIDITY OF CASTING ALUMINUM ALLOYS USING ARTIFICIAL NEURAL NETWORK

- Author: Yuan Gao, Hengcheng Liao, Xiaojing Suo, Qigui Wang

- Year of publication: 2019

- Journal/academic society of publication: Contributed Papers from Materials Science and Technology 2019 (MS&T19)

- Keywords: Fluidity; Casting aluminum alloy; Artificial neural network; Pouring temperature; Composition

2. Abstract:

Based on BP (back-propagation algorithm) neural network and training dataset of fluidity of casting aluminum alloys, a prediction model with a structure of 8-9-1 has been constructed to predict the fluidity of casting aluminum alloys. The model inputs are contents of Al, Si, Fe, Cu, Mn, Mg, Zn and pouring temperature, and the output is fluidity of casting aluminum alloys. The test dataset of fluidity of casting aluminum alloys was used to check the accuracy of the model. Results show that the developed fluidity model can well predict the fluidity of casting aluminum alloys, with a maximum error of 11.81% and an average error of 6.56%. Also, based on the prediction model of fluidity of casting aluminum alloys, how the compositions effect the fluidity of binary and multicomponent casting aluminum alloys has been studied.

3. Introduction:

Casting aluminum alloys are widely used in automobile and aerospace industry because of their low density, high specific strength and good thermal conductivity. Fluidity is an important castability property of casting aluminum alloys, which affects the quality and soundness of the cast products. If the fluidity of the alloy is satisfactory, which means that the alloy has good mold filling ability, it is easily accessible to obtain the castings with accurate dimensions, complete shapes and sharp outlines; If the fluidity is not good, the mold filling ability is poor and the casting defects easily form in the casting. Therefore, it is necessary to study the fluidity of casting aluminum alloys.

4. Summary of the study:

Background of the research topic:

Casting aluminum alloys are critical materials in the automotive and aerospace sectors. Their performance in casting is heavily dependent on fluidity, a key property that determines mold filling ability and the final quality and soundness of the cast product.

Status of previous research:

Prior research, such as studies by Gowri et al. and Taghaddos et al., investigated the influence of individual alloying elements like Cu, Mg, Zn, and Fe on the fluidity of specific aluminum alloys. However, a comprehensive model capable of predicting fluidity based on the complex, nonlinear interactions of multiple elements and process parameters was needed.

Purpose of the study:

The primary purpose was to develop and validate a predictive model using a back-propagation (BP) artificial neural network to accurately forecast the fluidity of casting aluminum alloys based on their chemical composition and pouring temperature.

Core study:

The core of the study involved constructing an 8-9-1 neural network model. This model was trained and tested using an experimental dataset of 141 valid measurements from various binary, ternary, and commercial aluminum alloys. The validated model was then used to study and visualize the effects of composition on the fluidity of both binary (Al-Si, Al-Cu) and multicomponent (Al-Si-Cu, Al-Si-Mg) aluminum alloy systems.

5. Research Methodology

Research Design:

The study employed an experimental approach to generate a robust dataset, which was then used to train and test a predictive BP artificial neural network model designed to map the relationship between alloy properties and fluidity.

Data Collection and Analysis Methods:

154 experiments were designed using a range of aluminum alloys. Fluidity was measured using a spiral iron mold at two superheat temperatures (70°C and 120°C). The final chemical compositions of the cast alloys were analyzed using a MAXx LMF15 spark emission spectrometer. This resulted in 141 sets of valid data. The data was normalized and split into training and testing sets to build and validate the neural network model, with performance evaluated by Mean Squared Error (MSE), linear regression coefficient (R), and Average Absolute Relative Error (AARE).

Research Topics and Scope:

The model's inputs included the weight percentages of Al, Si, Fe, Cu, Mn, Mg, Zn, and the pouring temperature. The single output was the fluidity, measured in millimeters. The scope of the study covered the prediction of fluidity for various casting aluminum alloys and a subsequent analysis of how Si, Cu, and Mg contents influence the fluidity of binary and multicomponent alloy systems.

6. Key Results:

Key Results:

- The optimal fluidity prediction model uses an 8-9-1 architecture with "tansig" and "purelin" transfer functions and the "trainbr" training algorithm.

- The developed model can accurately predict the fluidity of cast aluminum alloys, with a maximum prediction error of 11.81% and an average prediction error of 6.56%.

- In Al-Si alloys, fluidity reaches a minimum when the Si content is around 6 wt.%.

- In Al-Cu alloys (0-5% Cu), fluidity changes very little, remaining in the 600-660 mm range at a 70°C superheat.

- The model enables the design of reasonable compositions for multicomponent aluminum alloys to ensure good fluidity.

Figure Name List:

- Fig. 1 Spiral fluidity test mold

- Fig. 2 Comparison of predicted and experimental fluidity for the test dataset

- Fig. 3 Graphical user interface (GUI) for casting aluminum alloy fluidity prediction software

- Fig. 4 Fluidity of Al-Si alloys with Si content (superheat degree 70°C)

- Fig. 5 Fluidity of Al-Cu alloys with Cu content (superheat temperature 70°C)

- Fig. 6 Effect of Si content and Cu content on the fluidity of Al-Si-Cu alloys (T = 642°C) (a) 3D view (b) plane projection (the solid black line in the figure is the temperature scale)

- Fig. 7 Effect of Si and Mg contents on the fluidity of Al-Si-Mg alloys ( T = 685°C) (a) 3D view (b) plane projection (the solid black line in the figure is the temperature scale)

7. Conclusion:

Based on the present study, the following conclusions can be drawn:

(1) For the fluidity prediction model of casting aluminum alloys, the overall performance of the model is optimal when the transfer function from the input layer to the hidden layer is "tansig", the transfer function from the hidden layer to the output layer is "purelin", the training algorithm is "trainbr", and the number of hidden layer neurons is 9.

(2) The developed fluidity prediction model can predict well the fluidity of cast aluminum alloys, with a maximum prediction error of 11.81% and an average prediction error of 6.56%.

(3) The result of fluidity prediction model shows in Al-Si alloys, fluidity can reach a minimum when the Si content is around 6 wt.%. And with the Cu content varying from 0 to 5%, the predicted fluidity of the Al-Cu alloy changes in a very small extent, within the range of 600-660 mm when the superheat temperature is 70°C. By using the model, a reasonable composition of multicomponent aluminum alloy can be designed to ensure good fluidity.

8. References:

- J. A. Liu et al., “Development and application of aluminum products in automobile and research direction of key new materials,” Aluminum Fabrication (in Chinese), 2012, (5), 4-15.

- Z. Q. Zhan, “Application situation and demand prospect of aluminum automobile body sheet,” Nonferrous Metals Processing (in Chinese), 2012, 41(6), 1-6.

- K. R. Ravi et al., “Fluidity of aluminum alloys and composites: A review,” Journal of Alloys & Compounds, 2008, 456(1-2), 201-210.

- W. Prukkanon, N. Srisukhumbowornchai, and C. Limmaneevichitr, “Influence of Sc modification on the fluidity of an A356 aluminum alloy,” Journal of Alloys & Compounds, 2009, 487(1-2), 453-457.

- S. Gowri, and F. H. Samuel, “Effect of alloying elements on the solidification characteristics and microstructure of Al-Si-Cu-Mg-Fe 380 alloy," Metallurgical & Materials Transactions A, 1994, 25(2), 437-448.

- E. Taghaddos et al., “Effect of iron-intermetallics on the fluidity of 413 aluminum alloy," Journal of Alloys & Compounds, 2009, 468(1-2), 539-545.

- D. Huang et al, “Effect of Fe content on microstructure and fluidity of hypereutectic Al-Si alloys," Science & Technology and Innovation (in Chinese), 2016(21), 11-12.

- K. L. Sahoo, and C. S. Sivaramakrishnan, “Some studies on Al-8.3Fe-0.8V-0.9Si alloy for near net shape casting,” Journal of Materials Processing Technology, 2003, 135(2-3), 253-257.

- W. Sha, and K. L. Edwards, “The use of artificial neural networks in materials science based research,” Materials & Design, 2007, 28(6), 1747-1752.

- A. M. Hassan et al., “Prediction of density, porosity and hardness in aluminum-copper-based composite materials using artificial neural network,” Journal of Materials Processing Technology, 2009, 209(2), 894-899.

- H. K. Durmuş, E. Özkaya, and C. Meri Ç, “The use of neural networks for the prediction of wear loss and surface roughness of AA 6351 aluminium alloy,” Materials & Design, 2006, 27(2), 156-159.

- S. Guessasma, and C. Coddet, “Microstructure of APS alumina-titania coatings analysed using artificial neural network,” Acta Materialia, 2004, 52(17), 5157-5164.

- A. Powar, and P. Date, “Modeling of microstructure and mechanical properties of heat treated components by using Artificial Neural Network,” Materials Science & Engineering A, 2015, 628, 89-97.

- N. S. Reddy et al., “Artificial neural network modeling on the relative importance of alloying elements and heat treatment temperature to the stability of a and ẞ phase in titanium alloys," Computational Materials Science, 2015(107), 175-183.

- N. S. Reddy et al., “Prediction of grain size of Al-7Si Alloy by neural networks,” Materials Science & Engineering A, 2005, 391(1-2), 131-140.

- N. Haghdadi et al., “Artificial neural network modeling to predict the hot deformation behavior of an A356 aluminum alloy,” Materials & Design, 2013, 49, 386-391.

- X. Xia et al., “An artificial neural network for predicting corrosion rate and hardness of magnesium alloys,” Materials & Design, 2016, 90, 1034-1043.

- Y. Zhang, X. Gao, and S. Katayama, “Weld appearance prediction with BP neural network improved by genetic algorithm during disk laser welding," Journal of Manufacturing Systems, 2015, 34, 53-59.

Expert Q&A: Your Top Questions Answered

Q1: Why was an 8-9-1 architecture with 9 hidden neurons specifically chosen for the BP neural network?

A1: The paper states that the 8-9-1 architecture was determined to be the "optimum model" based on its performance during training. This specific structure produced the best combination of evaluation metrics for the training data: a Mean Squared Error (MSE) of 0.021, a linear regression coefficient (R) of 0.885, and an Average Absolute Relative Error (AARE) of 7.04%.

Q2: The paper notes that Al-Si alloy fluidity is lowest around 6 wt.% Si. Does it explain the metallurgical reason for this?

A2: The paper presents this as a key finding from the prediction model, which is visualized in Figure 4 and aligns with experimental values. However, the study focuses on the development and validation of the predictive model itself and does not provide a detailed metallurgical explanation for why the fluidity minimum occurs at this specific silicon concentration.

Q3: What specific transfer functions were used in the different layers of the neural network?

A3: The model employed two different transfer functions. A tan-sigmoid ('tansig') transfer function was applied to the hidden layer, which is a common choice for capturing complex, non-linear relationships. For the output layer, a linear transfer function ('purelin') was used to produce the final continuous value for fluidity.

Q4: How reliable is the model for predicting fluidity in complex, multicomponent alloys compared to simpler binary alloys?

A4: The model demonstrates very high reliability for multicomponent alloys. For an Al-Si-Cu alloy shown in Figure 6, the prediction error at an experimental validation point (D) was only 2.42%. Even more impressively, for an Al-Si-Mg alloy shown in Figure 7, the prediction error at its validation point (D) was just 0.73%, indicating that the model's predictions agree very well with experimental data for these more complex systems.

Q5: How were the diverse input variables, like temperature and elemental percentages, handled by the model?

A5: All input and output variables were normalized to a consistent range of -1 to 1 before being fed into the network. The paper provides the specific normalization formula used: yi = (ymax - ymin) × (xi - xmin) / (xmax - xmin) + ymin. This process ensures that no single variable with a large numerical range (like temperature) disproportionately influences the model's training process compared to variables with smaller ranges (like minor element percentages).

Conclusion: Paving the Way for Higher Quality and Productivity

The challenge of controlling Casting Aluminum Alloy Fluidity is a persistent hurdle in achieving flawless, high-performance components. This research demonstrates a significant leap forward by applying an artificial neural network to create a highly accurate predictive tool. By understanding the complex interplay between alloy composition and pouring temperature, this model empowers engineers to move from reactive problem-solving to proactive design and process optimization. It provides a clear path to designing alloys and defining process windows that guarantee superior mold filling, reduce scrap rates, and enhance the overall quality and soundness of final castings.

"At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components."

Copyright Information

- This content is a summary and analysis based on the paper "PREDICTION OF FLUIDITY OF CASTING ALUMINUM ALLOYS USING ARTIFICIAL NEURAL NETWORK" by "Yuan Gao, Hengcheng Liao, Xiaojing Suo, Qigui Wang".

- Source: https://doi.org/10.7449/2019/MST_2019_1103_1112

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.