This technical brief is based on the academic paper "A STATISTICAL ANALYSIS OF JOINT STRENGTH OF DISSIMILAR ALUMINIUM ALLOYS FORMED BY FRICTION STIR WELDING USING TAGUCHI DESIGN APPROACH, ANOVA FOR THE OPTIMIZATION OF PROCESS PARAMETERS" by Mohammed Yunus & Mohammad S. Alsoufi, published in [IMPACT: International Journal of Research in Engineering & Technology (IMPACT: IJRET)] (2015). It is summarized and analyzed for HPDC professionals by the experts at CASTMAN.

Keywords

- Primary Keyword: Friction Stir Welding (FSW) process optimization

- Secondary Keywords: Dissimilar aluminum alloys (AA7075, AA6061), Taguchi design method, ANOVA, Joint yield strength, Welding process parameters (Rotational speed, Axial Load, Welding Speed), S/N Ratio

Executive Summary

- The Challenge: Achieving high and consistent joint strength when welding dissimilar aluminum alloys, such as AA7075 and AA6061, has been a significant challenge for critical industries like aviation and automotive.

- The Method: Researchers employed the Taguchi design method (L18 orthogonal array) and Analysis of Variance (ANOVA) to systematically evaluate five key process parameters influencing the Friction Stir Welding (FSW) of these dissimilar alloys.

- The Key Breakthrough: Tool rotational speed was identified as the most critical factor affecting yield strength, accounting for 45.51% of the total variation.

- The Bottom Line: The study successfully identified an optimal set of process parameters (A1, B3, C2, D3, E1) that results in a predictable and superior yield strength of 241 MPa, proving the reliability of the FSW process.

The Challenge: Why This Research Matters for HPDC Professionals

In modern manufacturing, the need for material joining processes to be fast, efficient, and environmentally friendly is paramount. For industries like automotive and aerospace, this often involves joining dissimilar aluminum alloys, such as AA7075 and AA6061, to reduce weight while increasing strength. Traditional fusion welding methods suffer from drawbacks like melt-related defects, low joint strength, and filler-induced defects. Friction Stir Welding (FSW), a solid-state joining process that doesn't melt the material, has emerged as a promising alternative to these issues. However, optimizing the FSW process for dissimilar alloys to consistently achieve peak mechanical properties remained a significant hurdle, which this research aimed to overcome.

The Approach: Unpacking the Methodology

To tackle this problem, the researchers adopted the statistically robust Taguchi design method. The base materials used in the study were AA7075 and AA6061 aluminum alloy plates with thicknesses of 3 mm and 4 mm. A vertical milling machine was used to perform the butt welds. For the experimental design, an L18 orthogonal array was utilized to test five key process parameters at different levels:

- Plate Thickness (2 levels: 3 mm, 4 mm)

- Axial Load (3 levels: 2, 2.5, 3 KN)

- Rotational Speed (3 levels: 600, 900, 1200 rpm)

- Welding Speed (3 levels: 75, 90, 115 mm/min)

- Tilt Angle (3 levels: 3, 4, 5 degrees)

The results were analyzed using the signal-to-noise (S/N) ratio and Analysis of Variance (ANOVA) to quantify the impact of each parameter on the joint's yield strength and predict the optimal conditions.

The Breakthrough: Key Findings & Data

The study delivered clear, actionable insights for FSW process optimization.

- Finding 1: Rotational Speed is King: The Analysis of Variance (ANOVA) revealed that tool rotational speed was the most significant parameter affecting yield strength, with a contribution of 45.51%. In contrast, plate thickness was the least significant factor (0.667% contribution).

- Finding 2: The Optimal Process Recipe: The research identified the optimal combination of parameters to achieve maximum yield strength: a plate thickness of 3 mm, an axial load of 3 KN, a rotational speed of 900 rpm, a welding speed of 115 mm/min, and a tilt angle of 3°.

- Finding 3: Predictive Model Validated: A confirmation experiment conducted using the optimal parameters achieved a yield strength of 240.713 MPa, which showed excellent agreement with the 232.006 MPa predicted by the Taguchi model. This validates the accuracy and reliability of the model.

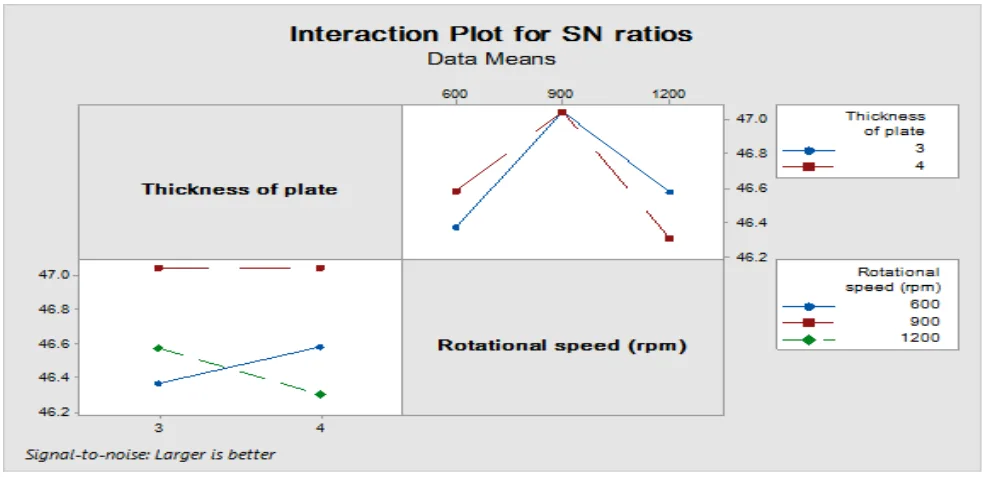

- Finding 4: Interaction Effects are Minor: With the exception of an interaction between plate thickness and axial load, interactions between other factors were found to have no major effect on the joint quality, suggesting that parameters can be optimized largely independently.

Practical Implications for HPDC Products

While this research focuses on FSW, its findings offer crucial lessons for engineers and managers who must integrate HPDC components into larger assemblies.

- For Process Engineers: The findings suggest that precisely controlling the tool rotational speed to around 900 rpm is the most effective lever for improving yield strength when joining dissimilar aluminum alloys.

- For Quality Control: The S/N ratio analysis, shown in Figure 1, provides a clear graphical representation of how each parameter affects the process, which can be used to establish more robust process control windows and reduce variability.

- For Design Engineers: This study demonstrates that an optimized FSW process can create strong, reliable joints free from the defects associated with fusion welding, offering greater flexibility when designing complex assemblies that include HPDC parts.

Paper Details

A STATISTICAL ANALYSIS OF JOINT STRENGTH OF DISSIMILAR ALUMINIUM ALLOYS FORMED BY FRICTION STIR WELDING USING TAGUCHI DESIGN APPROACH, ANOVA FOR THE OPTIMIZATION OF PROCESS PARAMETERS

1. Overview:

- Title: A STATISTICAL ANALYSIS OF JOINT STRENGTH OF DISSIMILAR ALUMINIUM ALLOYS FORMED BY FRICTION STIR WELDING USING TAGUCHI DESIGN APPROACH, ANOVA FOR THE OPTIMIZATION OF PROCESS PARAMETERS

- Author: MOHAMMED YUNUS¹ & MOHAMMAD S. ALSOUFI²

- Year of publication: 2015

- Journal/academic society of publication: IMPACT: International Journal of Research in Engineering & Technology (IMPACT: IJRET)

- Keywords: Design of Experiments (DOE), Taguchi Design Method, Signal To Noise (S/N) Ratio, Optimization, FSW, ANOVA, Confirmation Tests

2. Abstract:

Friction Stir Welding (FSW) is a solid state joining process, eliminates the drawbacks of common fusion welding are widely used in ship building, aviation and automotive industries. In the present work an attempt has been made to optimize the process parameters of friction stir welding between two dissimilar aluminium alloys (AA7075 and AA6061) to evaluate the output quality characteristics using Taguchi design method. An interaction effect of input parameters is also studied to predict their influence on the output response. Five control factors of mixed levels (2 and 3 levels), L18 orthogonal array are selected to determine the optimum condition for process parameters to improve the performance of FSW. The performance of FSW for dissimilar alloys of aluminium is evaluated in terms of joint's yield strength, Taguchi technique has been employed using orthogonal array, S/N ratio followed by ANOVA (analysis of variance) to study contribution of each parameter and interaction of them on output and confirmation tests at 95 % confidence level to compare with experimental results. Optimal combination of parameters is presented with a good agreement found between the estimated and experimental results within the preferred significant level after verifying experimentally. It was confirmed that Taguchi design method with ANOVA and confirmation tests successfully improved the quality characteristics of yield strength of FSW process.

3. Introduction:

Due to rise of need in recent times for joining material processes to be fast, efficient and environmental friendly, possessing higher mechanical properties such as yield strength, hardness and tensile strength. With the recent advancements in science and technology, Friction stir welding (FSW) has become alternate to the welding process and it is a solid state joining without melting the metal but by using third member as a tool joining two butted faces of similar or dissimilar metals. The advantages of FSW are low defects, free from melt related defects, high joint strength; no filler induced defects, low hydrogen contents. Most of the present research focuses on similar aluminium sheets FSW and a little work carried on dissimilar.

4. Summary of the study:

- Background of the research topic: Joining dissimilar aluminum alloys presents a significant manufacturing challenge due to difficulties in maintaining mechanical properties.

- Status of previous research: Previous studies had largely focused on FSW of similar metals or analyzed dissimilar metals with a limited number of parameters and without ANOVA.

- Purpose of the study: The study aimed to optimize the process parameters for FSW of dissimilar AA6061 and AA7075 alloys using the Taguchi method and ANOVA to produce a weld joint with the highest tensile strength.

- Core study: An experimental investigation using an L18 orthogonal array to study the effects of five process parameters (plate thickness, axial load, rotational speed, welding speed, tilt angle) on the joint's yield strength.

5. Research Methodology:

- Research Design: An experimental design using a Taguchi L18 orthogonal array to evaluate five control factors at mixed (2 and 3) levels.

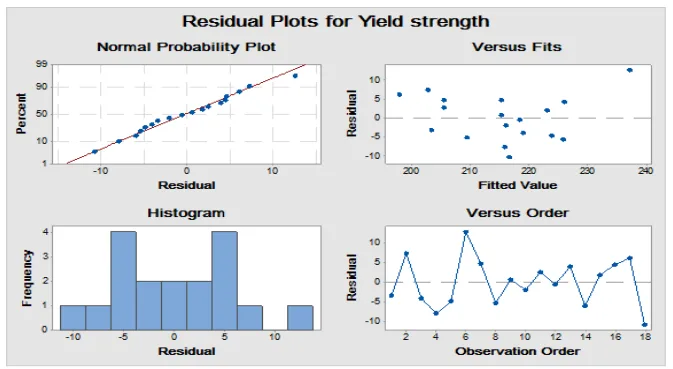

- Data Collection and Analysis Methods: The yield strength of the welded specimens was measured. Data was analyzed using the signal-to-noise (S/N) ratio (larger-the-better) and Analysis of Variance (ANOVA) to determine the significance of each parameter.

- Research Topics and Scope: The research focused on the butt welding of AA7075 and AA6061 aluminum alloys.

6. Key Results:

- Figure Name List:

- Figure 1: Main Effects Plot for S/N Ratio of Yield Strength

- Figure 2: Interaction Plot for S/N Ratio of Yield Strength

- Figure 3: Residual Plots for Yield Strength of a FSW Joint in ANOVA

7. Conclusion:

In this paper, optimization of process parameters of friction stir welding for joining two dissimilar metals have been carried out using Taguchi design method followed by ANOVA and confirmation test. From the analysis, the optimum conditions for mechanical yield strength are A1, B3, C2, D3, E1, i.e., Rotational speed of the tool (900 rpm) followed by Axial Load (3 KN), Welding Speed (115 mm/min), Tilt Angle (3º) and Thickness of plate (3 mm). The optimum yield strength can be obtained is 241 MPa with rotating speed of tool as the most significant factor while the thickness of plate as the least significant factor. From ANOVA results, the contribution ratio of each parameter indicates that rotational speed is major significant factor and thickness of plate is minor significant factor. A good agreement was noticed between predicted and the actual values, and by controlling the rotational speed, we can obtain very good FSW components of higher yield strength.

8. References:

- Roy, R.K., 2001, Design of Experiments using The Taguchi Approach: 16 Steps to Product and Process Improvement, John Wiley & Sons, Inc.

- T. Sakiyama, G. Murayama, Y. Naito, K. Saita, Y. Miyazaki, H. Oikawa, T. Nose, Dissimilar Metal Joining Technologies for Steel Sheet and Aluminum Alloy Sheet in Auto Body, Nippon Steel Technical Report (2013), Pp. 91-98.

- W. M. U. Thomas, E. D. Nicholas, Friction stir welding for the transportation industries, Material Design, 18 (1998), Pp. 269-273.

- J. F. Guo, H. C. Chen, C. N. Sun, G. Bi, Z. Sun, J. Wei, Friction stir welding of dissimilar materials between AA6061 and AA7075 Al alloys effects of process parameters, Material Design, 56 (2014), Pp. 185–192.

... [The list continues as in the paper] ... - M. Kumagai., 2003, Recent technological developments in welding of Aluminium and its alloys, Welding International, 17 (3), Pp.173-181.

Expert Q&A: Your Top Questions Answered

Q1: What was the single most critical factor identified in this study for improving yield strength?

A1: The study concluded that tool rotational speed was the most influential factor. This is detailed in the "Conclusion" and supported by the data in Table 6, which shows its contribution ratio was 45.51%.

Q2: How does this research compare to traditional methods for addressing this problem?

A2: The paper's Introduction notes that while traditional fusion welding can suffer from melt-related defects, FSW, the process used in this research, provides high joint strength, is free from melt-related defects, and has no filler-induced defects.

Q3: Is this finding applicable to all types of alloys, or a specific one?

A3: The research, as described in the EXPERIMENTAL METHODOLOGY section, was specifically conducted using AA7075 and AA6061 aluminum alloys. Applicability to other alloys would require further investigation.

Q4: What specific measurement or simulation technique did the researchers use to arrive at this conclusion?

A4: The researchers utilized the Taguchi design method (L18 orthogonal array) and Analysis of Variance (ANOVA) to quantify the results, as explained in the Taguchi Design Method section.

Q5: According to the paper, what is the main limitation or area for future research?

A5: The paper's Conclusion focuses on the successful application of the methodology and the key findings. It does not explicitly state limitations or areas for future research, but emphasizes that controlling rotational speed is the primary factor for obtaining high-yield-strength components.

Q6: What is the direct, practical takeaway from this paper for a die casting facility?

A6: The core takeaway is that by optimizing specific parameters—notably rotational speed (900 rpm), axial load (3 KN), and welding speed (115 mm/min)—it is possible to achieve a high yield strength of approximately 241 MPa. This conclusion is strongly supported by the overall results of the paper, "A STATISTICAL ANALYSIS OF JOINT STRENGTH OF DISSIMILAR ALUMINIUM ALLOYS...".

Conclusion & Next Steps

This research provides a valuable roadmap for enhancing joint strength in FSW. The findings offer a clear, data-driven path toward improving quality, reducing defects, and optimizing production.

At CASTMAN, we are dedicated to applying the latest industry research to solve our customers' most challenging die casting problems. If the issues discussed in this paper resonate with your operational goals, contact our engineering team to discuss how we can help you implement these advanced principles in your components.

Copyright

- This material is a paper by "MOHAMMED YUNUS & MOHAMMAD S. ALSOUFI". Based on "A STATISTICAL ANALYSIS OF JOINT STRENGTH OF DISSIMILAR ALUMINIUM ALLOYS FORMED BY FRICTION STIR WELDING USING TAGUCHI DESIGN APPROACH, ANOVA FOR THE OPTIMIZATION OF PROCESS PARAMETERS".

- Source of the paper: www.impactjournals.us

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.