Optimizing Electrical Resistivity in Al-Alloy 99.7: New Research on Casting and Filtering

This technical summary is based on the academic paper "INFLUENCE OF DIFFERENT CASTING CONDITIONS AND THE FILTERING PROCESS ON THE ELECTRICAL RESISTANCE OF Al-ALLOY 99.7" by Terezija Poženel Kovačič, Mitja Petrič, Vitoslav Bratuš, and Maja Vončina, published in Materials and technology (2018). It has been analyzed and summarized for technical experts by CASTMAN with the assistance of AI.

Keywords

- Primary Keyword: Electrical Resistivity in Al-Alloy

- Secondary Keywords: Casting Conditions, Aluminum Die Casting, Porosity in Aluminum, Al 99.7, Induction Motor Rotor

Executive Summary

A 30-second overview for busy professionals.

- The Challenge: Optimizing the electrical conductivity of Al-Alloy 99.7 in cast components like motor rotors is critical for efficiency, but the precise effects of casting conditions and defects are not fully understood.

- The Method: Researchers melted Al 99.7 in an induction furnace and cast samples under different atmospheres (air vs. argon) and with/without filtration, measuring electrical resistivity both in-situ during solidification and on the final parts.

- The Key Breakthrough: The study found that while casting conditions did not affect the fundamental solidification temperature, the sample cast in air unexpectedly showed lower electrical resistivity (via the four-point method) than the sample cast in a protective argon atmosphere.

- The Bottom Line: This counterintuitive result was attributed not to atmospheric conditions but to a 6% larger cross-sectional area in the air-cast sample, highlighting the dominant role of final part geometry on bulk electrical resistance measurements.

The Challenge: Why This Research Matters for HPDC Professionals

In the manufacturing of high-efficiency electric motors, every watt counts. The induction motor rotor, often produced using aluminum high-pressure die casting, is a critical component where electrical losses can significantly impact performance. The material of choice is often a commercially pure aluminum like Al-Alloy 99.7, valued for its balance of conductivity, weight, and cost.

However, the "as-cast" electrical properties of this alloy can be degraded by two key factors:

1. Impurities: Even small amounts of elements like iron (Fe) and silicon (Si) can form intermetallic phases (e.g., Al13Fe4) during solidification. These phases disrupt the crystal structure and scatter electrons, increasing electrical resistivity.

2. Porosity: Voids within the casting reduce the effective cross-sectional area for current flow, which also increases resistance and can compromise mechanical integrity.

This research was undertaken to systematically investigate how different casting conditions—specifically the casting atmosphere (air vs. inert gas) and the use of filtration—influence the final electrical resistivity of Al-Alloy 99.7, providing valuable data for optimizing components where conductivity is a primary design driver.

The Approach: Unpacking the Methodology

To isolate the effects of casting variables, the researchers performed a series of controlled experiments in a laboratory setting.

- Material: The study used a single input material: Al-Alloy 99.7, with its chemical composition verified according to the EN 576 standard.

- Process: The alloy was melted and gravity cast in an induction vacuum furnace. Three distinct casting conditions were tested:

- Casting in Air (

997_z): Simulating a standard atmospheric casting environment. - Casting in Argon (

997_Ar): Using an inert gas atmosphere to minimize oxidation. - Casting in Air with Filtration (

F997_z): Using an Al2O3 ceramic foam filter to remove non-metallic inclusions.

- Casting in Air (

- Measurement & Analysis: A multi-faceted approach was used to characterize the samples:

- In-situ Measurement: A custom-built cell using the four-point measuring method simultaneously recorded temperature and electrical resistivity during solidification and cooling.

- Post-Casting Analysis: Solidified samples were analyzed for electrical conductivity using an eddy-current tester (Autosigma 3000), which measures surface properties.

- Defect and Microstructure Analysis: Porosity levels were examined using X-ray and optical microscopy, while the microstructure and phase composition were analyzed with SEM/EDS.

- Thermodynamic Modeling: The ThermoCalc software was used to predict the equilibrium phase diagram and solidification sequence for the alloy.

The Breakthrough: Key Findings & Data

The study yielded several crucial insights into the behavior of Al-Alloy 99.7 during casting.

Finding 1: Eutectic Solidification is Consistent Across Casting Conditions

Thermal analysis of the cooling curves revealed that the fundamental metallurgy of the alloy was unaffected by the casting atmosphere or filtration. As shown in Figure 3, regardless of the casting condition (air, argon, or filtered), the eutectic reaction (α-Al + Al13Fe4) consistently occurred at a temperature of 644 °C. This indicates that the formation of the iron-bearing intermetallic phase is an intrinsic property of the alloy's composition and is not significantly altered by these specific process variables.

Finding 2: Casting Atmosphere and Geometry Have a Counterintuitive Effect on Measured Resistivity

When comparing the final electrical properties, the results depended heavily on the measurement technique.

- The eddy-current method, which is sensitive to surface quality, showed the sample cast in argon (

997_Ar) had the highest electrical conductivity (59.23 % IACS) and lowest resistivity (29.15 nΩm). This aligns with expectations, as the inert atmosphere would reduce surface oxidation and related defects. - However, the four-point method, which measures bulk resistance, produced a surprising result. As detailed in Table 2, the sample cast in air (

997_z) had a lower extrapolated resistivity (31.52 nΩm) than the argon-cast sample (33.08 nΩm), despite having slightly higher impurity levels and porosity (0.51% vs 0.39%).

The paper concludes this discrepancy was due to a geometric factor: the cross-sectional area of the sample cast in air was measured to be 6% larger than the other two samples. Since electrical resistivity (ρ) is calculated from resistance (R) and geometry (ρ = R * A/l), this larger area (A) in the air-cast sample resulted in a lower calculated bulk resistivity, overriding the negative effects of its slightly higher porosity and impurities.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that for components where bulk electrical resistance is the critical parameter, controlling the final cast geometry and ensuring a consistent cross-section may be more impactful than controlling the casting atmosphere. Dimensional precision is paramount.

- For Quality Control Teams: The data in Table 2 illustrates the critical difference between surface-sensitive (eddy-current) and bulk (four-point) measurement techniques. The choice of QC method should be carefully aligned with the component's end-use. An eddy-current test might be better for evaluating surface integrity, while a bulk resistance measurement is needed to verify overall conductance.

- For Design Engineers: The findings underscore the high sensitivity of electrical resistance to geometric variations. This reinforces the need to specify and maintain tight dimensional tolerances in the design of electrical conductors, as even minor variations in cross-sectional area can significantly alter performance.

Paper Details

INFLUENCE OF DIFFERENT CASTING CONDITIONS AND THE FILTERING PROCESS ON THE ELECTRICAL RESISTANCE OF Al-ALLOY 99.7

1. Overview:

- Title: INFLUENCE OF DIFFERENT CASTING CONDITIONS AND THE FILTERING PROCESS ON THE ELECTRICAL RESISTANCE OF Al-ALLOY 99.7

- Author: Terezija Poženel Kovačič, Mitja Petrič, Vitoslav Bratuš, Maja Vončina

- Year of publication: 2018

- Journal/academic society of publication: Materiali in tehnologije / Materials and technology

- Keywords: electrical resistivity, impurities, porosity, casting conditions

2. Abstract:

There are different types of electric motors; one of them is the induction motor. Such a motor consists of a winded stator and an induction rotor. The rotor squirrel cage is made with aluminium high-pressure die casting technology. Besides relatively low motor-producing costs and good repeatability, the motor efficiency and torque/speed characteristics are also important. One of the loss factors for the rotor is the loss of conductance of die cast material. This study researches how different casting conditions influence the material's electrical resistivity of Al 99.7. With melting of the alloy in an induction vacuum furnace and testing various casting conditions during the solidification (such as the vacuum, air and filtering), the temperature and electrical resistivity of the castings were measured using the four-point measuring method. The porosity proportions of the samples were examined with X-ray, as well as with optical microscopy. The presence of Fe-eutectic (α-Al + Al13Fe4) was confirmed in the investigated samples' microstructures, as was predicted by a calculation of the equilibrium phase diagram. The electrical resistivity values were additionally measured with an eddy-current measuring method. The results show a good correlation with the four-point measuring method and are in a range 29–33 nΩm at 20 °C. Based on the obtained results, the influence of impurities and porosity on the electrical properties of aluminium was evaluated.

3. Introduction:

Aluminium is the most common choice for a rotor conductance material due to its good ratio between conductivity, weight, price and technology parameters. Commercially pure aluminium from 1xxx series is the most common, with varying degrees of purity. Such aluminium typically achieves up to 60 % IACS. For the induction motor, the electrical conductivity of the cast material is important to reduce the current losses in the rotor cage. Commercially pure aluminium contains impurities, mainly iron and silicon, which can form non-metallic inclusions and intermetallic phases like Al13Fe4. Porosity is another additional factor that deteriorates the electrical and mechanical properties of aluminium. Electrical conductivity is very sensitive to composition, crystalline states, and processing conditions.

4. Summary of the study:

Background of the research topic:

The electrical conductivity of cast aluminum is a critical factor for the efficiency of induction motors. This property is negatively affected by impurities (Fe, Si), non-metallic inclusions (Al2O3), and structural defects like porosity.

Status of previous research:

Most available research on electrical resistivity focuses on aluminum alloys with silicon (Al-Si alloys), which are widely used in high-pressure die casting. However, alloys from the 1xxx series (commercially pure aluminum), which are crucial for electrical applications, are rarely studied in the context of die casting processes.

Purpose of the study:

The study aimed to determine how different casting conditions (vacuum/argon atmosphere, air atmosphere, and filtering) influence the electrical resistivity of cast Al-Alloy 99.7.

Core study:

The core of the study involved melting Al 99.7 and casting it under three different conditions. During solidification, temperature and electrical resistivity were measured in-situ. The resulting solid samples were then analyzed for their final electrical properties, porosity, and microstructure to correlate the process conditions with the material outcomes.

5. Research Methodology

Research Design:

The research was an experimental study comparing three groups of samples cast under different conditions: in an argon atmosphere (997_Ar), in an air atmosphere (997_z), and in air with a ceramic foam filter (F997_z).

Data Collection and Analysis Methods:

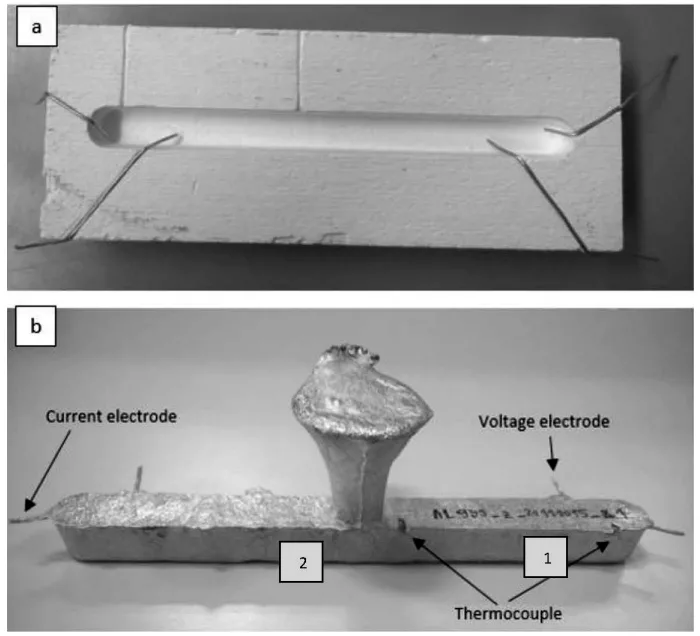

- In-situ Measurement: A custom-made measuring cell with type-K thermocouples and a four-point electrode setup was used to collect temperature and electrical resistivity data at 10 Hz during solidification.

- Conductivity Measurement: An Autosigma 3000 Eddy Current Tester was used to measure electrical conductivity (% IACS) on the final samples.

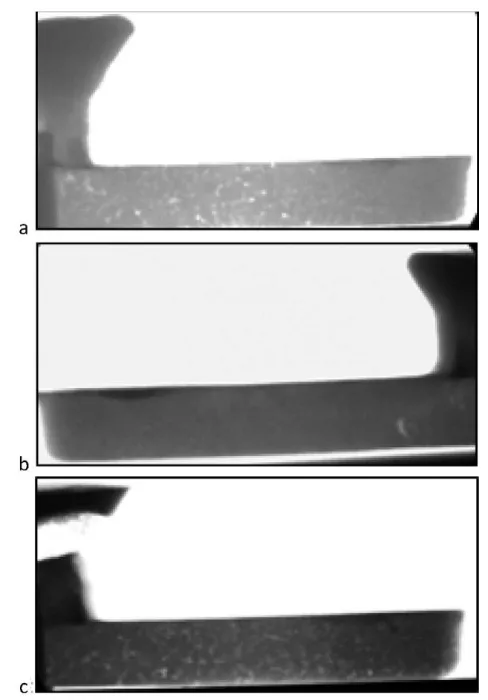

- Porosity Analysis: X-ray imaging and optical microscopy were used to assess porosity levels.

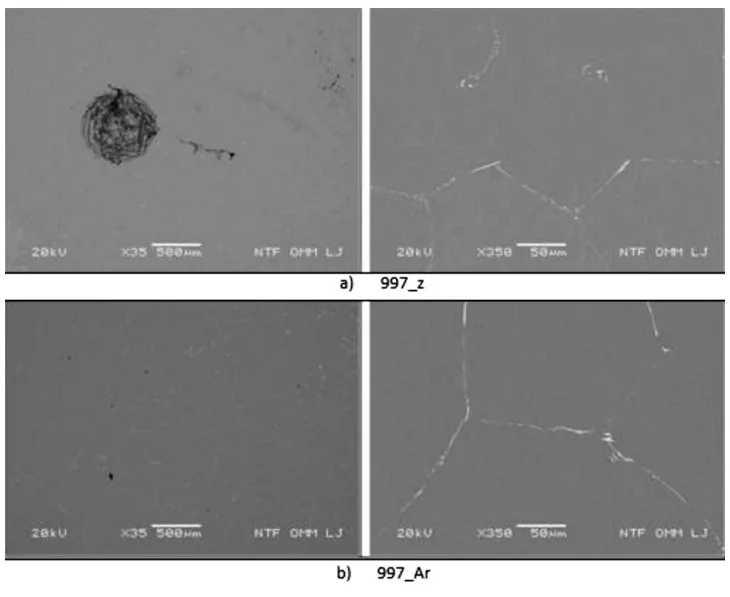

- Microstructure Analysis: Samples were prepared for metallography and examined using an optical microscope and a JEOL SEM with EDS for microstructural and phase analysis.

- Thermodynamic Calculation: ThermoCalc software with the TCAL4 database was used to calculate the equilibrium phase diagram.

Research Topics and Scope:

The research focused on Al-Alloy 99.7. The scope included melting, gravity casting, and analysis of the influence of casting atmosphere and filtration on the solidification behavior, microstructure, porosity, and electrical resistivity of the cast material.

6. Key Results:

Key Results:

- The eutectic solidification temperature was consistently 644 °C across all tested casting conditions.

- The electrical resistivity of the alloy is approximately 246 nΩm in the liquid phase and drops to around 30 nΩm at 20 °C.

- The sample cast in an argon atmosphere (

997_Ar) showed the highest conductivity (lowest resistivity) when measured with a surface-sensitive eddy-current method. - The sample cast in air (

997_z) showed the lowest bulk resistivity when measured with the four-point method. This was attributed to its 6% larger cross-sectional area, which had a greater influence on the calculated result than its slightly higher porosity and impurity content. - Filtering with a ceramic foam filter did not significantly impact porosity or electrical resistivity in these experiments.

- The presence of the Fe-eutectic phase (α-Al + Al13Fe4) was confirmed in the microstructure, as predicted by thermodynamic calculations.

Figure Name List:

- Figure 1: Calcium silicate measuring cell: a) casting from the measuring cell with marked positions of thermocouples and b) electrodes

- Figure 2: Isoplete equilibrium phase diagrams calculated from the chemical composition of cast sample 997_z at 0.178 w/% Fe and 0.040 w/% Si, solidification at: a) higher temperatures and b) at lower temperatures

- Figure 3: Cooling curve of three experimental samples Al 99.7 with different casting and cooling conditions; temperature marks for the liquidus and the eutectic reaction are shown

- Figure 4: Specific electric resistivity in correlation to the temperature made for all samples

- Figure 5: Microstructure of the cross-section area 1 for the sample cast in air

- Figure 6: X-ray images of: a) sample 997_z, b) sample 997_Ar and c) sample F997_z

- Figure 7: SEM microphotograph for: a) 997_z and b) 997_Ar

- Figure 8: SEM images and EDS analysis of phases in sample 997_z

7. Conclusion:

The main research aim was to analyse the influence of the casting conditions on the electrical resistivity for castings made from Al-alloy 99.7. The Fe-eutectic (α-Al + Al13Fe4) presence in the investigated samples microstructure was confirmed. The casting conditions do not influence the temperature of the eutectic solidification, which was about 644 °C for all samples. The electrical resistivity ρ values are approximately 246 nΩm at casting temperatures and at 20 °C about 30 nΩm. The electrical resistivity results from the four-point measuring method and the eddy-current method are comparable. Sample 997_z cast in air had the lowest resistivity values obtained by the four-point measuring method, although it had the largest amount of impurities and porosity. It is believed that this was a consequence of the larger cross-section surface A, which was measured to be 6% more than on the other two samples.

8. References:

- ¹J. S. Agapiou, Inertia welding for assembly of copper squirrel cages, Journal of Manufacturing Processes, 16 (2014), 276-283, doi:10.1016/j.jmapro.2013.09.009

- ²J. L. Kirtley, Jr., H. W. Beaty, Electric Motor Handbook, McGraw-Hill Book Company, 1998

- ³J. R. Davis, Aluminum and Aluminum Alloys, ASM international – The Materials Information Society, 1994

- ⁴Properties and selection: Nonferrous Alloys and Special-Purpose Materials. ASM international - The Materials Information Society, 1990

- ⁵I. J. Polmear, Light Alloys, Metallurgy of the Light Metals (3rd ed.), Butterworth-Heinemann, 1995

- ⁶J. A. Taylor, Iron-containing intermetallic phases in Al-Si based casting alloys, Procedia Materials Science, 1 (2012), 19-33, doi:10.1016/j.mspro.2012.06.004

- ⁷H. Lopes de Moraes, J. R. de Oliveira, D. C. Romano Espinosa, J. A. Soares Tenorio, Removal of iron from molten recycled aluminium through intermediate phase filtration, Materials Transactions 47 (2006), 1731-1736, doi:10.2320/matertrans.47.1731

- ⁸M. Torkar, B. Breskvar, M. Tandler, Đ. Mandrino, M. Doberšek, EPMA and HRAES Determination of complex inclusions in primary aluminium, Vacuum, 62 (2001), 379-385

- ⁹B. Farhoodi, R. Raiszadeh, M. Ghanaatian, Role of double oxide film defects in the formation of gas porosity in comercial purity and Sr-containing Al alloys, Journal of Materials Science & Technology, 30 (2014), 154-162

- ¹⁰J. Campbell, Castings, Butterworth-Heinemann Ltd, 1991

- ¹¹L. Zhao, Y. Pan, H. Liao, Q. Wang, Degassing of aluminum alloys during re-melting, Materials Letters, 66 (2012), 328-331, doi:10.1016/j.matlet.2011.09.012

- ¹²M. Petrič, Sprememba dimenzij in električne upornosti med strjevanjem litin iz sistema Al-Si, PhD thesis, Ljubljana, 2013

- ¹³X. Cui, Y. Wu, X. Liu, Q. Zhao, G. Zhang, Effects of grain refinement and boron treatment on electrical conductivity and mechanical properties of AA1070 aluminum, Materials and design, 86 (2015), 397-403, doi:10.1016/j.matdes.2015.06.149

- ¹⁴X. Cui, Y. Wu, G. Zhang, Y. Liu, X. Liu, Study on the improvement of electrical conductivity and mechanical properties of low alloying electrical aluminum alloys, Composites Part B, 110 (2017), 381-387, doi:10.1016/j.compositesb.2016.11.042

- ¹⁵J. W. Gao, D. Shu, J. Wang, B. D. Sun, Effect of boron on removal of iron from aluminium melts, Materials Science and Technology, 25 (2009), 1462-6, doi:10.1179/174328408X382181

- ¹⁶R. Brandt, G. Neuer, Electrical resistivity and thermal conductivity of pure aluminum and aluminum alloys up to and above the melting temperature, International Journal of Thermophysics, 28 (2007), 1429-1446, doi:10.1007/s10765-006-0144-0

- ¹⁷W. K. Rhim, T. Ishikawa, Noncontact electrical resistivity measurement technique for molten metals, Review of scientific instruments, 69 (1998), 3628-3633, doi:10.1063/1.1149150

- ¹⁸G. Lohöfer, Electrical resistivity measurement of liquid metals, Measurement science and technology, 16 (2005), 417-425, doi:10.1088/0957-0233/16/2/012

- ¹⁹M. Petrič, S. Kastelic, P. Mrvar, Selection of electrodes for the "in situ" electrical resistivity measurements of molten aluminium, Journal of mining and metallurgy, Section B, Metallurgy, 49 (2013), 279-283, doi:10.2298/JMMB130118029P

- ²⁰M. Vončina, T. Poženel, M. Petrič, P. Mrvar, J. Medved, Vpliv livarskih napak na električne lastnosti ulitka iz aluminija, Livarski vestnik, 64 (2017), 172-179

Expert Q&A: Your Top Questions Answered

Q1: Why were both four-point and eddy-current methods used to measure resistivity?

A1: The two methods measure different aspects of the material. The eddy-current method is primarily sensitive to the properties of the material's surface ("skin" effect). The four-point method measures the bulk resistance across the entire cross-section. Using both allowed the researchers to distinguish between surface quality (where the argon-cast sample excelled) and bulk properties, which were heavily influenced by the part's final geometry.

Q2: The paper mentions filtering didn't seem to reduce porosity or improve resistivity. Why might that be?

A2: The paper confirms that, in this specific experimental setup, the ceramic foam filter did not yield a measurable improvement in porosity or electrical properties. While the paper doesn't speculate on the reason, this could imply that the initial melt was already of sufficient cleanliness, or that the solidification dynamics and gas evolution were the dominant sources of porosity, which a filter cannot mitigate.

Q3: What is the significance of the consistent eutectic solidification temperature of 644 °C shown in Figure 3?

A3: This consistency is significant because it demonstrates that the fundamental metallurgical transformation of the alloy is robust and not influenced by the casting atmosphere (air vs. argon). It suggests that process variations are more likely to affect macroscopic characteristics like porosity, surface oxidation, and final geometry, rather than altering the intrinsic phase structure of the Al-Fe system at this composition.

Q4: Can you clarify the contradictory findings for the sample cast in argon (997_Ar)? It had the best conductivity via eddy-current but higher resistivity via the four-point method.

A4: This apparent contradiction is a key finding. The eddy-current test, being a surface measurement, indicated the argon-cast sample had the best intrinsic material quality, likely due to lower surface oxidation. However, the four-point method calculates bulk resistivity using the formula ρ = R * (A/l). The paper concludes that the sample cast in air had a 6% larger cross-sectional area (A), and this geometric difference had a larger mathematical impact on the final calculated resistivity value than the material's slightly higher internal porosity.

Q5: The study confirmed the presence of Al13Fe4 eutectic. How does this phase impact electrical properties?

A5: The paper identifies the presence of the iron-eutectic (α-Al + Al13Fe4) as predicted by the phase diagram. In aluminum alloys, such intermetallic phases act as obstacles or "scattering centers" for the free-flowing electrons that constitute the electric current. This scattering effect disrupts the flow of electrons, which manifests as an increase in the material's overall electrical resistivity compared to a pure, defect-free aluminum crystal lattice.

Conclusion: Paving the Way for Higher Quality and Productivity

This research provides a critical reminder that when evaluating the Electrical Resistivity in Al-Alloy components, the full picture matters. While minimizing impurities and porosity through careful process control is essential, the final geometry of the cast part can play an unexpectedly dominant role in bulk resistance measurements. The counterintuitive finding—that a sample cast in air could outperform a sample cast in an inert atmosphere due to a slight dimensional difference—underscores the need for exceptional precision in the casting process.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components.

Copyright Information

- This content is a summary and analysis based on the paper "INFLUENCE OF DIFFERENT CASTING CONDITIONS AND THE FILTERING PROCESS ON THE ELECTRICAL RESISTANCE OF Al-ALLOY 99.7" by "Terezija Poženel Kovačič, Mitja Petrič, Vitoslav Bratuš, Maja Vončina".

- Source: doi:10.17222/mit.2017.123

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.