Redefining HPDC Castability: How Effective Flow Length (EFL) Unlocks Ductility in Extra-Large Structural Components

This technical summary is based on the academic paper "Effect of high pressure die casting on the castability, defects and mechanical properties of aluminium alloys in extra-large thin-wall castings" by Zhichao Niu, Guangyu Liu, Tian Li, and Shouxun Ji, published in the Journal of Materials Processing Technology (2022).

Keywords

- Primary Keyword: Effective Flow Length (EFL)

- Secondary Keywords: High Pressure Die Casting (HPDC), Aluminium alloys, Mechanical properties, Thin-wall castings, Casting defects, Castability

Executive Summary

- The Challenge: Manufacturing ductile, extra-large, thin-wall aluminum castings using HPDC that are free from defects and possess consistent mechanical properties throughout the entire component.

- The Method: Systematically varying HPDC process parameters—melt temperature, die temperature, and in-gate velocity—on a 16,000 kN machine to produce a 1230 mm long casting and analyzing its properties.

- The Key Breakthrough: The introduction of Effective Flow Length (EFL), a new concept that defines castability by considering both the geometrical soundness of the part and the homogeneity of its mechanical properties, especially elongation.

- The Bottom Line: To guarantee the performance of large structural HPDC parts, engineers must optimize for EFL to ensure consistent ductility, not just focus on achieving complete mold filling.

The Challenge: Why This Research Matters for HPDC Professionals

The automotive industry's shift towards electric vehicles (EVs) is driving demand for larger, lighter, and more complex structural components. High pressure die casting (HPDC) of Al-Si-Mg alloys is a leading choice for these parts due to its high productivity and low cost. The goal is to produce extra-large, thin-walled castings with excellent ductility directly in the as-cast condition, avoiding costly and distortion-inducing heat treatments.

However, this presents a significant manufacturing challenge. As molten aluminum flows over long distances in a thin (e.g., 2.8 mm) die cavity, it rapidly loses heat, degrading its fluidity. This can lead to incomplete filling, cold shuts, and other defects. More critically, even if the part fills completely, the mechanical properties—especially the ductility required for crash performance—can vary dramatically from one end of the casting to the other. Existing research has provided little information on this heterogeneity of mechanical properties, creating a knowledge gap for engineers designing and manufacturing these critical components. This study directly addresses that gap.

The Approach: Unpacking the Methodology

The research team conducted a systematic experimental study to understand the complex interplay between process parameters and final part quality in an extra-large, thin-wall casting.

Method 1: State-of-the-Art HPDC Cell

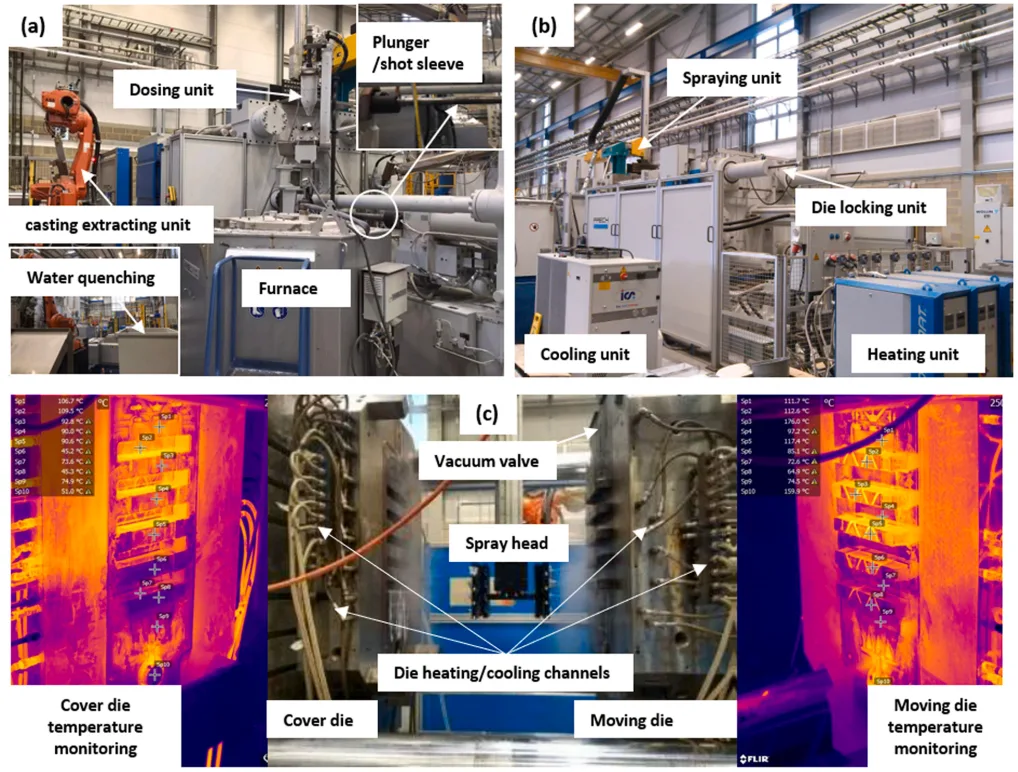

A fully automatic, 16,000 kN Frech vacuum-assisted cold chamber HPDC cell was utilized. The integrated system included an 800 kg electric heating furnace, an automatic dosing system, an ABB robot for casting extraction, and an automatic spraying system. Crucially, the die was equipped with thermal cameras for real-time temperature monitoring and control.

Method 2: Purpose-Designed Extra-Large Casting

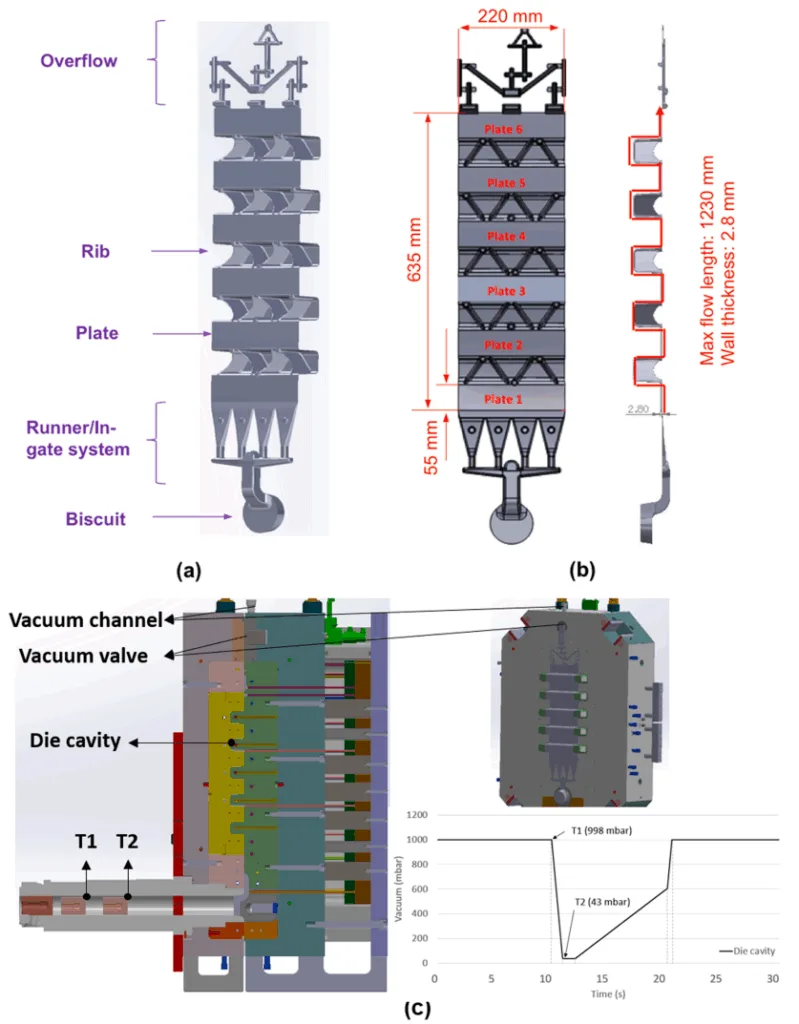

A special die was designed to produce a component with a maximum flow length of 1230 mm in a 2.8 mm thick channel. This geometry, featuring flat plates and ribs, was representative of real-world structural products. The material used was a commercial Al-Si-Mg alloy.

Method 3: Systematic Variation of Process Parameters

To isolate the effects on castability and properties, three key process parameters were systematically varied:

- Melt Temperature: 700 °C, 720 °C, and 740 °C

- Die Temperature: 100 °C, 150 °C, and 200 °C

- In-gate Velocity: Ranging from 20 m/s to 50 m/s (corresponding to cavity fill times from 102.9 ms to 41.1 ms)

Samples were then extracted from six different locations along the casting's flow path for comprehensive microstructural and mechanical analysis.

The Breakthrough: Key Findings & Data

Finding 1: Geometric Filling is Necessary, But Not Sufficient

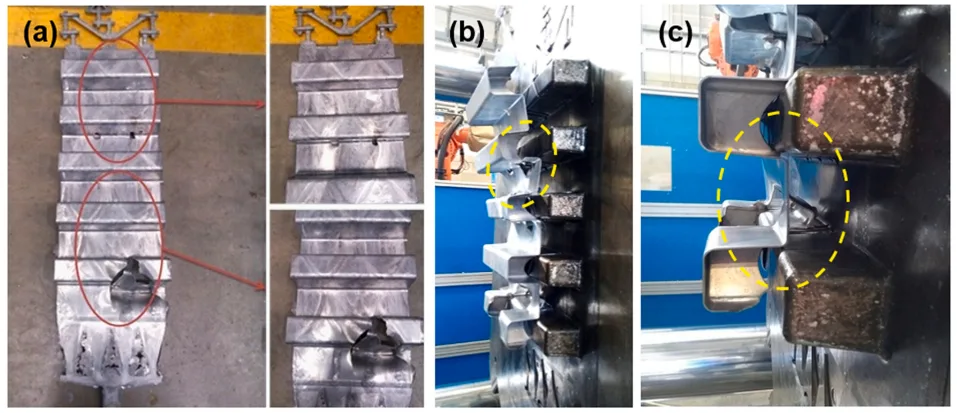

The study confirmed that achieving a geometrically complete casting is highly dependent on process parameters. As shown in Figure 5, complete castings (including runners and overflows) could only be obtained at in-gate velocities of 30 m/s, 40 m/s, and 50 m/s. At lower velocities of 25 m/s and 20 m/s, the overflows were partially or entirely unfilled, indicating insufficient fluidity. This establishes a clear process window for achieving basic geometrical soundness. However, the subsequent findings show that this is only the first step.

Finding 2: The Critical Drop-Off in Ductility Along the Flow Path

The most significant finding is the dramatic heterogeneity of mechanical properties, even in a perfectly filled casting. Figure 13 shows the tensile properties of samples taken at different distances from the in-gate under optimal casting conditions (720°C melt temp, 200°C die temp, 50 m/s in-gate velocity).

- Yield Strength (YS): Remained relatively stable, staying above 110 MPa across the entire 1230 mm length.

- Elongation: Showed a critical drop-off. For the first three plates, up to a flow length of 525 mm, elongation was excellent, remaining above 10%. However, at the fourth plate (760 mm), it plummeted to just 4.5%, and continued to fall to 2.5% at the end of the casting.

This data proves that a casting that looks perfect can have regions with insufficient ductility for structural applications, posing a significant quality risk. This behavior was linked to an increase in microporosity at locations further from the gate, as seen in Figure 10.

Finding 3: A New Metric for Real-World Performance: Effective Flow Length (EFL)

Based on these findings, the paper proposes a new, more practical concept for assessing castability: Effective Flow Length (EFL). EFL is defined as the maximum melt flow length that can achieve both acceptable casting geometry and specified mechanical properties.

- For this alloy and geometry, with a strict requirement of elongation > 10%, the EFL is 525 mm.

- If the requirement is relaxed to elongation > 4.5%, the EFL increases significantly to 995 mm.

EFL provides a powerful, data-driven metric that moves beyond simple "fillability" and directly addresses the performance requirements of the final component.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that adjusting process parameters should aim to maximize the EFL, not just the fill rate. For this component, the optimal combination of a 200°C die temperature, 720°C melt temperature, and 50 m/s in-gate velocity delivered the best balance of properties and castability.

- For Quality Control Teams: The data in Figure 13 illustrates that mechanical property testing must be conducted at multiple locations along the flow path, especially at the furthest points from the gate. Relying on samples taken only near the runner system can provide a dangerously optimistic view of the part's overall ductility.

- For Design Engineers: The findings indicate that the EFL is a critical design constraint. For structural parts requiring high ductility (>10%), critical features should be designed to fall within the 525 mm EFL of the gating system. This may influence gate placement and overall part design in the early stages.

Paper Details

Effect of high pressure die casting on the castability, defects and mechanical properties of aluminium alloys in extra-large thin-wall castings

1. Overview:

- Title: Effect of high pressure die casting on the castability, defects and mechanical properties of aluminium alloys in extra-large thin-wall castings

- Author: Zhichao Niu, Guangyu Liu, Tian Li, Shouxun Ji

- Year of publication: 2022

- Journal/academic society of publication: Journal of Materials Processing Technology

- Keywords: Aluminium alloys, Microstructures, Mechanical properties, High pressure die casting, Castability, Effective flow length (EFL)

2. Abstract:

The manufacturing of extra-large thin-wall castings using high pressure die casting is one of the most significant challenges for structural applications requiring excellent ductility. The present study aims to understand the effect of process parameters on the castability, defect formation and mechanical properties of aluminium alloys in extra-large thin-wall castings with a maximum flow length of 1230 mm in the 2.8 mm thick channel. Numerical simulation and experimental verification were carried out to tailor the process parameters in high pressure die casting. It is found that the process parameters can significantly affect the castability and mechanical properties of as-cast components. For a complete casting, the yield strength is slightly increased but the elongation is significantly decreased at the locations further away from runners. A new concept of effective flow length (EFL) is proposed and used to assess the castability in extra-large thin-wall high pressure die castings. Under the optimum casting condition, the EFL can reach 525 mm, at which the ratio of EFL to wall thickness is 187 and the yield strength and elongation are greater than 120 MPa and 10%, respectively. Although the extra-large thin-wall castings can be geometrically filled under several conditions, the heterogeneity of mechanical properties is the most significant concern, in which the variation of elongation is overwhelmingly important for the structural applications requiring excellent ductility under as-cast conditions. Therefore, the criteria of casting quality should consider both geometrical soundness and the homogeneity of mechanical properties in the casting body.

3. Introduction:

Cast Al-Si-Mg alloys are extensively used in the transport manufacturing industry due to their high strength-to-weight ratio, excellent castability, and low cost. There is an increasing trend towards developing thin-wall, complex structural components via HPDC for use after solution and aging treatments. However, heat treatment is energy-intensive, costly, and can cause distortion in large components. Consequently, extra-large thin-wall castings made from high-ductility alloys that can be used in the as-cast condition are highly desirable. The castability in HPDC is known to be related to die temperature, in-gate velocity, and casting pressure. However, current research primarily focuses on castability from a geometrical soundness perspective. There is limited information available on the heterogeneity of mechanical properties within extra-large thin-wall castings. This study aims to address this gap by systematically investigating the effects of HPDC process parameters on the castability, defects, and mechanical property heterogeneity in an extra-large (1230 mm flow length) thin-wall Al-Si-Mg casting.

4. Summary of the study:

Background of the research topic:

The study addresses the industrial need for manufacturing extra-large, thin-wall, high-ductility aluminum alloy castings for structural applications, particularly for the automotive sector. The focus is on achieving these properties in the as-cast condition to reduce manufacturing costs and complexity.

Status of previous research:

Previous studies have established the influence of process parameters like die temperature, melt velocity, and pressure on the geometrical integrity of HPDC components. Research has also explored the effects of runner design, vacuum assistance, and shot sleeve parameters on minimizing defects and improving mechanical properties. However, a significant gap exists in the understanding and assessment of the heterogeneity of mechanical properties across the body of extra-large castings.

Purpose of the study:

The primary purpose was to understand the effect of HPDC process parameters (melt temperature, die temperature, in-gate velocity) on the castability, defect formation, and mechanical properties of an extra-large thin-wall aluminum casting. A key objective was to develop a more comprehensive criterion for assessing castability that accounts for both geometrical filling and the homogeneity of mechanical properties required for structural applications.

Core study:

The core of the study involved an experimental investigation using a 16,000 kN vacuum-assisted HPDC cell to produce a casting with a 1230 mm flow length and 2.8 mm wall thickness. Process parameters were systematically varied, and the resulting castings were comprehensively analyzed. The analysis included visual inspection for macro-defects, Macro-CT for internal porosity, and microstructural characterization. Mechanical properties (yield strength, UTS, elongation) were measured at six distinct locations along the flow path to quantify property heterogeneity. Based on these results, a new concept, Effective Flow Length (EFL), was proposed and defined.

5. Research Methodology

Research Design:

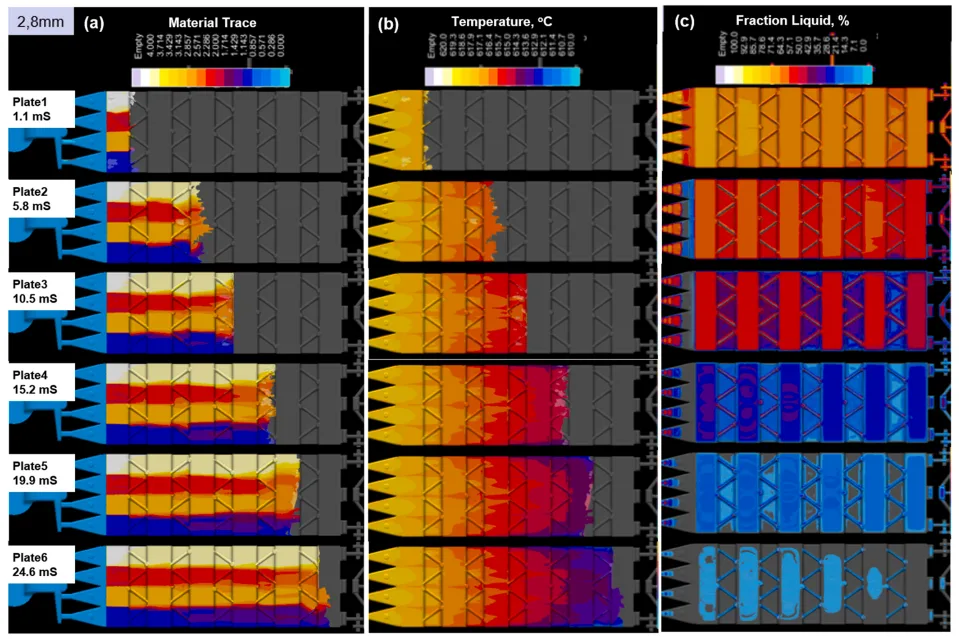

The study employed a systematic experimental research design. Key process parameters—melt temperature, die temperature, and cavity fill time (in-gate velocity)—were varied independently to investigate their effects on the casting outcomes. Numerical simulation using Magmasoft was initially used to optimize runner and overflow design.

Data Collection and Analysis Methods:

- Casting Production: A Frech 16,000 kN vacuum-assisted cold chamber HPDC machine was used to produce castings from a commercial Al-Si-Mg alloy.

- Defect Analysis: Castings were visually inspected for macro-defects. A Zeiss Xradia 410 Versa X-ray (Macro-CT) was used to identify internal porosities larger than 0.2 mm.

- Microstructural Characterization: Samples were analyzed using a Zeiss Scope A1 optical microscope and a Zeiss Supra 35 field-emission scanning electron microscope (FESEM) equipped with EDS.

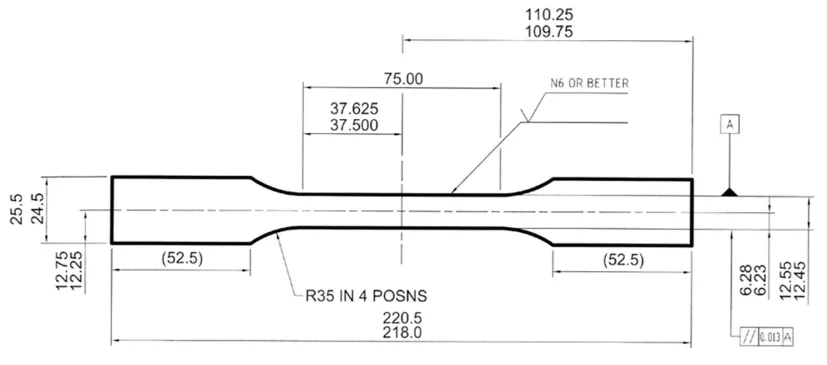

- Mechanical Testing: Flat tensile samples were extracted from the center of six plates along the casting's flow path. Tensile tests were conducted at room temperature according to ASTM E8/E8M using an Instron 5500 system to determine yield strength (YS), ultimate tensile stress (UTS), and elongation.

Research Topics and Scope:

The research focused on a single Al-Si-Mg alloy cast into a specific extra-large, thin-wall geometry. The scope of the investigation covered the influence of three primary process parameters on castability (geometrical soundness), defect formation (cracks, misruns, soldering, porosity), microstructure (grain size, intermetallics), and the spatial distribution of mechanical properties along the casting's flow length.

6. Key Results:

Key Results:

- The optimal process parameters for producing a geometrically sound casting with a 1230 mm flow length were identified as a melt temperature of 720 °C, a die temperature of 200 °C, and an in-gate velocity of 50 m/s (41.1 ms fill time).

- In-gate velocities below 30 m/s were insufficient to achieve complete filling, while melt temperatures above 720 °C led to die soldering defects.

- For a fully filled casting produced under optimal conditions, the mechanical properties exhibited significant heterogeneity. Yield strength and UTS were relatively consistent for the first three plates (up to 525 mm flow length), being greater than 120 MPa and 250 MPa, respectively.

- Elongation was the most affected property, decreasing significantly at locations further from the gate. It was greater than 10% up to a flow length of 525 mm but dropped sharply to 4.5% at 760 mm and 2.5% at 1230 mm.

- The decrease in elongation was correlated with an increase in the size of micropores observed in the microstructure at longer flow lengths.

- A new concept, Effective Flow Length (EFL), was proposed to assess castability by incorporating both geometrical soundness and mechanical property requirements. The EFL was determined to be 525 mm for a criterion of YS > 120 MPa and elongation > 10%. This corresponds to a flow length to wall thickness ratio of 187.

- If the elongation criterion was relaxed to > 4.5%, the EFL could be extended to 995 mm.

Figure Name List:

to overflow with different overall liquid fractions during the solidification process, from plate 1 to plate 6, respectively.

- Fig. 1. Integrated fully automatic HPDC cell: (a) furnace, melt feeding and casting extraction; (b) heating, cooling and spraying units; (c) HPDC die and die temperature control systems.

- Fig. 2. 3D models and casting design for high pressure die castings, (a) models of different parts in the design, (b) geometry and schematic flow length of casting, (c) vacuum system and vacuum of full shot during the high pressure die casting process.

- Fig. 3. The geometry and dimension of samples for tensile property testing.

- Fig. 4. Simulation results showing (a) the material trace, (b) the temperature at gradually filling of the die cavity, and (c) the liquid fraction distribution from biscuit to overflow with different overall liquid fractions during the solidification process, from plate 1 to plate 6, respectively.

- Fig. 5. Casting photos obtained at the die temperature of 200 °C and melt temperature of 720 °C, under different cavity fill time/in-gate velocities of (a) 41.1 ms/50 m s⁻¹, (b) 51.4 ms/40 m s⁻¹, (c) 68.6 ms/30 m s⁻¹, (d) 82.3 ms/25 m s⁻¹, (e) 102.9 ms/20 m s⁻¹.

- Fig. 6. (a, b) The Macro-CT micrographs showing that no large (> 0.1 mm) porosities or large inoculations, (c) 3D X-ray tomography of the castings at the die and melt temperature of 150 °C and 720 °C under the cavity fill time of 51.4 ms/in-gate velocity of 40 m s⁻¹ (Scanning parameters: scanning speed (distance between two slices) 0.2 mm, resolution (pixel size) 0.4 mm.).

- Fig. 7. The photos of incomplete castings obtained at the melt temperature of 700 °C, with the die temperature of 200 °C and the varied cavity fill time/in-gate velocities of (a) 68.6 ms/30 m s⁻¹, (b) 51.4 ms/40 m s⁻¹, and (c) 41.4 ms/50 m s⁻¹.

- Fig. 8. The photos of incomplete castings obtained at the melt temperature of 740 °C, with varied die temperatures (100, 150 and 200 °C) and the in-gate velocities (30, 40 and 50 m s⁻¹)/ cavity fill time (68.6, 51.4, 41.1 ms).

- Fig. 9. The photos of the castings obtained at (a) respective melt temperature, die temperature, and the in-gate velocity of 720 °C, 100 °C, 55 m s⁻¹; and (b, c) the melt temperature, die temperature, and the in-gate velocity of 720 °C, 220 °C, 30 m s⁻¹.

- Fig. 10. Optical micrographs showing the microstructure of the 6 flat plates extracted from the casting part obtained at the process parameters: melt temperature of 720 °C, die temperature of 200 °C, and the cavity fill time of 41.1 ms (in-gate velocity of 50 m s⁻¹).

- Fig. 11. SEM micrographs showing the Fe-bearing intermetallic phase, Mg2Si intermetallic phase, and Al-Si eutectic in the microstructure of the first plates extracted from the casting part obtained at the process parameters: melt temperature of 720 °C, die temperature of 200 °C, and the cavity fill time of 41.1 ms (in-gate velocity of 50 m s⁻¹); (c) and (d) are the same area made in BSE-SEM and SE-SEM mode, respectively; (e) is extracted from the highlighted region in (d).

- Fig. 12. The tensile properties of castings obtained at the melt temperature of 720 °C, varied die temperatures (100, 150 and 200 °C) and cavity fill time (68.6, 51.4 and 41.1 ms)/in-gate velocities (30, 40, and 50 m s⁻¹).

- Fig. 13. The tensile results of different flow distances to the in-gate including the six plates extracted from the casting parts obtained at the melt temperature of 720 °C, die temperatures 200 °C, and cavity fill time of 41.1 ms (in-gate velocities of 50 m s⁻¹). The tensile test was conducted at room temperature.

7. Conclusion:

- The increase of melt and die temperatures is beneficial for the castability of extra-large castings. A sound casting with a flow length of 1230 mm and thickness of 2.8 mm can be achieved with a combination of 200 °C die temperature, 720 °C melt temperature, and a 50 m/s in-gate speed. Deviations from these optimal conditions can lead to defects such as die sticking (at higher temperatures) or cold shuts and cold flow (at lower temperatures).

- The mechanical properties of extra-large thin-wall castings are significantly heterogeneous. For the studied casting, the yield strength, UTS, and elongation were consistent up to a flow length of 525 mm (greater than 120 MPa, 250 MPa, and 10%, respectively). Beyond this length, the elongation significantly decreased, while the yield strength remained relatively unchanged. This heterogeneity is a major concern for structural applications.

- A new concept of effective flow length (EFL) is proposed to describe castability for structural HPDC applications. This concept uses both geometrical soundness and the mechanical properties of the casting body as criteria. For the studied casting, the EFL is approximately 525 mm when the tensile properties are set for yield strength > 120 MPa and elongation > 10%. If the elongation requirement is lowered to > 4.5%, the EFL can be increased to 995 mm.

8. References:

- Barkhudarov, M.R., President, V., 2009. Computer modelling simulation minimizing air entrainment in a & during slow-shot stagem Die Cast. Eng 34–37.

- Cleary, P.W., Ha, J., Prakash, M., Nguyen, T., 2006. 3D SPH flow predictions and validation for high pressure die casting of automotive components. Appl. Math. Model. 30, 1406–1427.

- Dong, X., Zhu, X., Ji, S., 2019. Effect of super vacuum assisted high pressure die casting on the repeatability of mechanical properties of Al-Si-Mg-Mn die-cast alloys. J. Mater. Process Technol. 266, 105–113.

- Dong, X., Youssef, H., Zhang, Y., Wang, S., Ji, S., 2020. High performance Al/TiB2 composites fabricated by nanoparticle reinforcement and cutting-edge super vacuum assisted die casting process. Compos. Part B: Eng. 177, 107453.

- Gunasegaram, D.R., Givord, M., O’Donnell, R.G., Finnin, B.R., 2013. Improvements engineered in UTS and elongation of aluminum alloy high pressure die castings through the alteration of runner geometry and plunger velocity. Mater. Sci. Eng. A. 559, 276–286.

- Hansen, N., 2004. Hall-Petch relation and boundary strengthening. Scr. Mater. 51 (8), 801–806.

- Ji, S., Watson, D., Fan, Z., White, M., 2012. Development of a super ductile diecast Al-Mg-Si alloy. Mater. Sci. Eng.: A 556, 824–833.

- Ji, S., Yang, W., Gao, F., Watson, D., Fan, Z., 2013. Effect of iron on the microstructure and mechanical property of Al-Mg-Si-Mn and Al-Mg-Si diecast alloys. Mater. Sci. Eng.: A 564, 130–139.

- Kong, L.X., She, F.H., Gao, W.M., Nahavandi, S., Hodgson, P.D., 2008. Integrated optimization system for high pressure die casting processes. J. Mater. Process. Technol. 201 (1–3), 629–634.

- Li, X.B., Xiong, S.M., Guo, Z.P., 2015. On the porosity induced by externally solidified crystals in high-pressure die-cast of AM60B alloy and its effect on crack initiation and propagation. Mater. Sci. Eng.: A 633, 35–41.

- Niu, X.P., Hua, B.H., Pinwilla, I., Li, H., 2000. Vacuum assisted high pressure die casting of aluminium alloys. J. Mater. Process. Technol. 105 (1–2), 119–127.

- Rowe, J., 2012. Advanced Materials in Automotive Engineering. Woodhead Publishing Limited.

- Srivastava, N., Chaudhari, G.P., 2016. Strengthening in Al alloy nano composites fabricated by ultrasound assisted solidification technique. Mater. Sci. Eng.: A 651, 241–247.

- Zhang, Z., Chen, D.L., 2008. Contribution of Orowan strengthening effect in particulate-reinforced metal matrix nanocomposites. Mater. Sci. Eng.: A 483, 148–152.

- Zhang, Y., Wang, S., Lordan, E., Wang, Y., Fan, Z., 2019. Improve mechanical properties of high pressure die cast Al9Si3Cu alloy via dislocation enhanced precipitation. J. Alloy. Compd. 785, 1015–1022.

- Zhu, X., Dong, X., Blake, P., Ji, S., 2021. Improvement in as-cast strength of high pressure die-cast Al-Si-Cu-Mg alloys by synergistic effect of Q-Al5Cu2Mg8Si6 and θ-Al2Cu phases. Mater. Sci. Eng.: A 802, 140612.

Expert Q&A: Your Top Questions Answered

Q1: Why was an in-gate velocity of less than 30 m/s found to be insufficient for this large, thin-wall casting?

A1: According to Section 3.3, at in-gate velocities lower than 30 m/s (corresponding to a cavity fill time greater than 68.8 ms), it was "unlikely to obtain a complete casting part." The melt front would freeze prematurely in the narrow 2.8 mm channels over the long flow distance. This issue could not be overcome even by increasing the die and melt temperatures, demonstrating a fundamental fluidity limit at lower velocities for this geometry.

Q2: What was the primary microstructural reason for the sharp drop in elongation at longer flow lengths?

A2: The paper links the drop in ductility directly to an increase in porosity. Section 3.4 and Figure 10 show that for the plates located further from the gate (plates 4-6), there was an increase in the presence of pores with dimensions of ~5–10 µm. The paper states that these larger pores, resulting from entrapped air and cooling conditions, were "detrimental to the ductility of the alloy" as they act as stress concentrators and crack initiation sites.

Q3: The paper introduces a new concept, "Effective Flow Length (EFL)." How is this different from traditional castability metrics?

A3: Traditional castability metrics typically focus on the ability to achieve geometrical soundness—that is, can the molten metal completely fill the die cavity without misruns or cold shuts. The EFL concept proposed in this paper (Section 3.5 and Conclusion) is more comprehensive. It defines castability as the maximum flow length that achieves both geometrical soundness and a predefined set of minimum mechanical properties (e.g., yield strength and, critically, elongation), making it a much more relevant metric for designing functional structural components.

Q4: What was the optimal combination of process parameters to achieve the maximum EFL of 525 mm with >10% elongation?

A4: The data presented in Figure 13, which defines the EFL based on the drop in elongation, was obtained under the study's optimal casting conditions. These parameters, detailed in Sections 3.4 and 3.5, were a melt temperature of 720 °C, a die temperature of 200 °C, and an in-gate velocity of 50 m/s (which corresponds to a cavity fill time of 41.1 ms).

Q5: The simulation in Figure 4 suggested higher melt temperatures near the runner, but the microstructure in Figure 10 showed more fine grains (indicating faster cooling) further from the runner. How is this explained?

A5: The paper addresses this apparent discrepancy in Section 3.4. While the simulation correctly predicted the initial temperature distribution during filling, the experimental results showed that the final microstructure was dominated by the solidification process within the die cavity itself. The flow further away from the runner experienced extremely high cooling rates from the die walls, which overrode the initial melt temperature and promoted the formation of fine α-Al(α₂) grains, leading to a finer microstructure despite the lower initial temperature predicted by the simulation at the melt front.

Conclusion: Paving the Way for Higher Quality and Productivity

The challenge of producing extra-large, thin-wall structural components with reliable ductility is a major hurdle in modern HPDC. This research provides a critical insight: a visually perfect casting is not necessarily a structurally sound one. The introduction of Effective Flow Length (EFL) as a key performance metric shifts the focus from merely filling the mold to ensuring homogenous mechanical properties throughout the part. By understanding and optimizing for EFL, engineers can make more informed decisions about process parameters and part design, mitigating the risk of unexpected failures in components subjected to dynamic loads.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components.

Copyright Information

This content is a summary and analysis based on the paper "Effect of high pressure die casting on the castability, defects and mechanical properties of aluminium alloys in extra-large thin-wall castings" by "Zhichao Niu, Guangyu Liu, Tian Li, Shouxun Ji".

Source: https://doi.org/10.1016/j.jmatprotec.2022.117525

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.