Eliminating Hidden Oxide Defects in HPDC: A New Bottom-Fill Shot Sleeve Concept for Superior Component Performance

This technical summary is based on the academic paper "Contribution to Solving an Inherent Problem When High Pressure Die-Casting Aluminium and its Alloys" by Herbert Smetan, published in Journal of Materials Science and Engineering B (2016). It has been analyzed and summarized for technical experts by CASTMAN.

![Fig. 1 Principles of oxide formation on the surfaces of liquid aluminum alloys exposed to oxygen containing gases [1], (b) and (c) oxide formation during uncontrolled filling of the mould [1], (d) and (e) occlusion of oxide and air during uncontrolled filling of the mould [1].](https://castman.co.kr/wp-content/uploads/image-2932.webp)

Keywords

- Primary Keyword: High Pressure Die Casting (HPDC)

- Secondary Keywords: Oxide films, fatigue strength, aluminium alloys, shot sleeve, bottom-filling, structural components

Executive Summary

- The Challenge: Dispersed, ultrafine oxide films formed during the filling of the shot sleeve severely limit the ductility and fatigue strength of HPDC aluminum components, preventing alloys from reaching their full potential.

- The Method: The paper proposes a novel concept of filling the shot sleeve from below using a dockable feed tube under an inert nitrogen gas atmosphere, adapting proven principles from low-pressure die-casting.

- The Key Breakthrough: This approach promises to virtually eliminate the formation of new oxide films during the critical shot sleeve filling stage, which the author identifies as the primary source of these hidden defects in conventional HPDC.

- The Bottom Line: The proposed bottom-fill concept, combined with proven vacuum technology for the mold cavity, could enable the production of HPDC components with exceptional metallurgical quality and mechanical properties.

The Challenge: Why This Research Matters for HPDC Professionals

For decades, engineers have accepted that the mechanical properties of components produced by High Pressure Die Casting (HPDC) remain significantly behind the actual potential of the aluminum alloys used. This discrepancy leads to a wide scatter in fracture strength, elongation, and fatigue strength values, forcing designers to apply additional safety margins that negate the weight advantages of aluminum.

The author argues that while macroscopic oxide inclusions are easily detected, the true culprit for this underperformance is the dispersed, ultrafine oxide films that are hidden within the component's matrix. The paper posits that most of these strength-limiting defects are not formed during the fast filling of the mold, but earlier in the process: during the turbulent, oxygen-exposed filling of the shot sleeve. Current methods focus on mitigating the symptoms in the mold cavity (e.g., with vacuum), but fail to address this root cause, leaving a significant opportunity for quality improvement on the table.

The Approach: Unpacking the Methodology

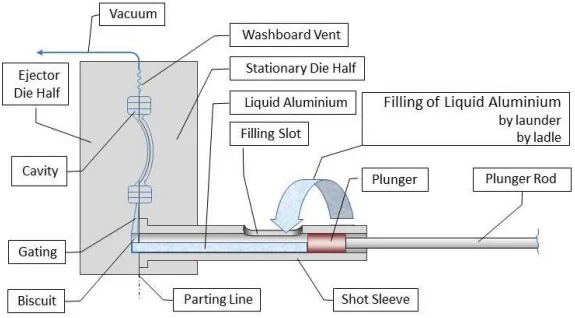

To solve this inherent problem, the author proposes a new conceptual design for the HPDC shot sleeve filling process, transferring technology from the low-pressure die-casting field. The proposed system eliminates the conventional open-air ladling or pouring of metal into the shot sleeve.

The core of the methodology is a bottom-up filling process in a sealed, controlled environment:

- Sealed System: The shot sleeve is hermetically sealed. The traditional filling slot is repurposed to house a LASER system for precise measurement of metal level and temperature.

- Inert Gas Flushing: Between cycles, the shot sleeve is flooded with gaseous nitrogen, which is then fed into the mold during closing to expel oxygen from the entire system.

- Docking Feed Tube: A ceramic feed tube, connected to a low-pressure furnace below, docks with the shot sleeve using a self-centering spherical connection. This connection is robust and proven in low-pressure casting applications.

- Controlled Bottom-Filling: Low pressure is applied to the furnace, gently raising the molten aluminum through the feed tube and filling the shot sleeve from below with minimal turbulence. This prevents the constant breaking and reforming of the protective oxide skin.

- Decoupling and Injection: Once the precise amount of metal is in the sleeve (verified by the LASER), the plunger moves past the fill opening. The feed tube is then lowered and mechanically disconnected before the high-speed shot takes place, isolating the furnace and feed system from injection shockwaves.

This entire sequence (shown in Figures 8d-8g of the paper) is designed to occur in parallel with the plunger's movement, adding no extra time to the casting cycle.

The Breakthrough: Key Findings & Data

While the paper presents a conceptual design, it provides compelling data from other casting methods to quantify the immense potential of producing components from an oxide-free melt.

Finding 1: The Untapped Potential of Oxide-Free Aluminum Alloys

To demonstrate the performance ceiling of aluminum alloys when oxides are minimized, the author presents data from components produced using a dynamic tilt-casting method with exceptionally low oxide content. As shown in Table 1, the mechanical properties are significantly higher than typical benchmarks. For example, for alloy AC-AlSi10MgCu in a T6W condition, the average tensile strength (Rm) reached 334 MPa with an elongation (A5) of 4.0%, values rarely achieved in complex HPDC components.

Finding 2: Drastic Improvement in Fatigue Strength

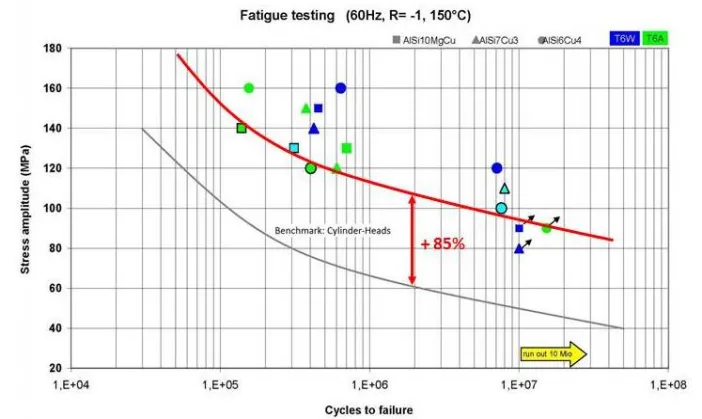

The impact of oxide films on dynamic properties is even more pronounced. Figure 2 of the paper shows fatigue strength data at 150°C for components made with the low-oxide tilt-casting method. The results show an 85% improvement in fatigue strength compared to the benchmark for conventionally produced cylinder heads. This highlights that the dispersed oxide films, acting as internal notches, are a primary driver of premature fatigue failure. Eliminating their formation is therefore critical for producing durable, high-performance structural parts.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that focusing optimization efforts on the shot sleeve filling stage—specifically by preventing turbulence and oxygen exposure—may yield far greater improvements in final part quality than solely focusing on mold evacuation. Adopting a bottom-fill, inert gas approach could fundamentally reduce defects.

- For Quality Control Teams: The data in Table 1 and Figure 2 of the paper illustrates the dramatic effect of minimizing oxide films on mechanical and fatigue properties. This justifies investment in advanced melt cleanliness analysis methods (like the PoDFA® method mentioned in the paper) to better quantify and control the presence of fine, dispersed oxides.

- For Design Engineers: The findings indicate that the inherent limitations of conventional HPDC, which necessitate large safety margins, could be overcome. Accessing the full mechanical potential of aluminum alloys would allow for the design of lighter, more efficient, and higher-performance structural components without compromising safety.

Paper Details

Contribution to Solving an Inherent Problem When High Pressure Die-Casting Aluminium and its Alloys

1. Overview:

- Title: Contribution to Solving an Inherent Problem When High Pressure Die-Casting Aluminium and its Alloys

- Author: Herbert Smetan

- Year of publication: 2016

- Journal/academic society of publication: Journal of Materials Science and Engineering B 6 (5-6)

- Keywords: Cast structural components, inherent limitations of HPDC, impact of oxide films on fatigue strength, creation of dispersed oxide films, concept for bottom-filling the slot sleeve.

2. Abstract:

The demands on ductility and fatigue strength of structural components are higher than for other parts made with cold-chamber die-casting. While macroscopic oxide inclusions can be detected and removed, the dispersed, ultrafine oxides are an underestimated source of damage. The author proposes that most of these oxide films are formed when filling the aluminum into the shot-sleeve. This has led to a search for solutions where the shot-sleeve is filled from below. Comparative studies show that components made by filling the mold cavity from below, with strong evacuation, produced the lowest porosity. The author proposes a concept of bottom-filling the shot sleeve under inert-gas protection to produce high-standard components of exceptional quality. Combined with vacuum technology and other advanced methods, this should make it possible to achieve exceptionally high component properties.

3. Introduction:

Manufacturers of aluminum die-castings for lightweight bodywork and chassis parts face new challenges due to high demands on ductility and fatigue strength. It is widely accepted that the full potential of aluminum foundry alloys is not exploited in real components, with a wide scatter in mechanical properties. This forces designers to use safety margins that offset the weight advantage of aluminum. The paper aims to examine these inherent limitations from a metallurgical and practical standpoint.

4. Summary of the study:

Background of the research topic:

In HPDC of aluminum, the mechanical properties of final components are significantly lower and more variable than the alloy's theoretical potential. This is primarily due to non-metallic discontinuities, especially dispersed oxide films.

Status of previous research:

Current HPDC derivatives focus on compensating for the symptoms of fast, turbulent mold filling, for example, by using vacuum systems to reduce trapped gas volume. However, the author argues that the root cause—the formation of oxide films during the initial filling of the shot sleeve—is largely unaddressed. Existing solutions like the Vacural-Process® are a step forward but are still limited by the amount of residual oxygen in the system.

Purpose of the study:

To propose an ultimate approach to solving the inherent problem of oxide film formation in HPDC by transferring proven experience and systems from the field of low-pressure die-casting to the high-pressure process.

Core study:

The paper presents a detailed conceptual design for a new HPDC machine setup. This design replaces conventional top-filling of the shot sleeve with a controlled, low-turbulence, bottom-filling method using a dockable feed tube connected to a low-pressure furnace. The entire process is conducted under a protective inert nitrogen gas atmosphere to prevent the formation of new oxide films. The system is designed to integrate into a standard HPDC cycle without increasing cycle time.

5. Research Methodology

Research Design:

The study is a conceptual proposal based on transferring and adapting existing, proven technologies from low-pressure die-casting to solve a known problem in high-pressure die-casting. The author uses data from other advanced casting processes to provide evidence for the potential benefits.

Data Collection and Analysis Methods:

The paper analyzes existing knowledge about defect formation in aluminum casting and presents comparative data (strength and fatigue values from Table 1 and Figure 2) from components produced via a low-oxide dynamic tilt-casting process to serve as a benchmark for what is metallurgically achievable.

Research Topics and Scope:

The scope is focused on the cold-chamber HPDC process for aluminum and its alloys. The primary research topic is the formation of dispersed oxide films during the shot sleeve filling stage and a proposed machine concept to eliminate this root cause of defects.

6. Key Results:

Key Results:

- The paper proposes a comprehensive concept for a bottom-filling shot sleeve under an inert gas atmosphere for HPDC machines, detailed in Figures 8 and 9.

- The author identifies the filling of the shot sleeve, not the mold cavity, as the primary stage for the formation of strength-limiting dispersed oxide films.

- Data from a low-oxide tilt-casting process (Table 1, Figure 2) is presented to demonstrate that eliminating oxide films can lead to dramatic improvements in mechanical properties, including an 85% increase in fatigue strength at elevated temperatures compared to conventional casting benchmarks.

Figure Name List:

- Fig. 1 Principles of oxide formation on the surfaces of liquid aluminum alloys exposed to oxygen containing gases [1], (b) and (c) oxide formation during uncontrolled filling of the mould [1], (d) and (e) occlusion of oxide and air during uncontrolled filling of the mould [1].

- Fig. 2 Fatigue strength values at elevated temperature obtained from actual cylinder heads in various aluminium casting alloys produced using a new tilt-casting method in comparison with conventional component values.

- Fig. 3 Any interruption of the protective oxide skins on molten aluminium results in newly built, extremely thin oxide films.

- Fig. 4 Schematic representation of a die-casting unit with mould on a cold chamber die-casting machine for aluminium foundry alloys.

- Fig. 5 Schematic representation of the filling of molten aluminium alloys into the shot sleeve of a cold chamber die-casting machine.

- Fig. 6 Example for careless filling of the slot sleeve.

- Fig. 7 Principle of the Vacural-Process® [6].

- Fig. 8 (a) Principle of a process- stable docking geometry for joining the feed tube to the shot sleeve of a die-casting machine, (b) between cycles, the shot sleeve is flooded with gaseous nitrogen and the melt maintained at the upper end of the feed tube, (c) at the cycle's start the shot sleeve is continuously flushed with nitrogen and the feed tube docked onto the shot sleeve, (d) the melt is raised out of the feed tube, resulting in a protected low-turbulence filling of the shot sleeve, (e) when the plunger passes over the filling opening of the shot sleeve, the level of melt in the feed tube is lowered again, (f) when the plunger has passed the upper opening in the shot sleeve, the vacuum is activated in the mould, (g) the plunger is actuated according to a pre-set programme to implement the actual filling of the mould cavity and (h) for maintenance and inspection purposes the shot sleeve can be opened and the holding furnace withdrawn.

- Fig. 9 Schematic representation of a high-pressure die-casting unit with mould on a cold chamber high-pressure die-casting machine for casting aluminium foundry alloys, designed for low pressure filling of the shot sleeve and nitrogen gas flushing of the cavity.

![Fig. 7 Principle of the Vacural-Process® [6]](https://castman.co.kr/wp-content/uploads/image-2937-1024x637.webp)

7. Conclusion:

The author is convinced that the proposed concept of bottom-filling the shot sleeve under inert-gas protection is ideally suited to producing high-standard components of exceptional metallurgical quality. When combined with proven vacuum technology, die tempering, and water-free spraying methods, it should be possible to achieve exceptionally high component properties that fully exploit the potential of aluminum alloys. This innovation is presented as a necessary step forward for aluminum foundry technology.

8. References:

- [1] Campbell, J. 2013, Complete Casting Handbook, Elsevier.

- [2] Brand Names of ABB Inc. Analytical Measurements, Quebec, Canada.

- [3] Smetan, H. 2014. "Simply be Better is Enough- About the Simplicity of Casting." Giesserei,01.

- [4] Smetan, H., Rathner, T., Plank, K.H. 2014. “New, Innovative Casting Process for Production of High Performance Components Made of Aluminum Alloys and its Application in Manufacturing." Österreichische Giesserei Rundschau, 61.

- [5] Nielsen, F. 1979. Gating and Feeding Principles. Giesserei-Verlag GmbH Düsseldorf.

- [6] Cold-Chamber Vacural Technology by Oskar Frech GmbH + Co. KG Company Profile. Accessed July 2014. http://www.frech.com/produkte/kaltkammer/vacural-technologie.html.

- [7] Kallien, L. 2008. University of Applied Sciences Aalen, Yearly Summary High Pressure Die Casting, Edition 45, Part 2: Technology, Giesserei 95, 05.

- [8] Eck, S. E. and Radtke-Schrade, F. 1968. Pore-Free-Die-Casting, US-Patent No. 3,382,910.

Expert Q&A: Your Top Questions Answered

Q1: Why focus so heavily on the shot sleeve filling when modern vacuum systems already address gas and air in the mold cavity?

A1: The paper argues that this is a misconception of the problem. Most of the dispersed, ultrafine oxides are formed before the metal enters the mold, during the turbulent transfer into the shot sleeve. A vacuum system primarily reduces the volume of gases trapped during the turbulent mold fill, but it does not prevent oxide formation from the residual oxygen that is always present, even in a partial vacuum. The proposed method aims to prevent the oxides from ever forming in the first place.

Q2: The impressive fatigue data in Figure 2 is from tilt-casting, not HPDC. How relevant is this to the HPDC process?

A2: The author uses this data strategically to establish a clear benchmark for what is metallurgically possible with aluminum alloys when oxide film formation is minimized. It serves as powerful evidence of the severe damage caused by these defects and provides a compelling justification for pursuing a low-oxide High Pressure Die Casting (HPDC) process. The goal of the proposed concept is to bring HPDC component quality closer to this demonstrated potential.

Q3: Is the proposed mechanical docking system for the feed tube reliable enough for industrial production, especially considering the shockwaves from the shot?

A3: The paper addresses this directly. The proposed system is based on a proven, robust design used for process-capable coupling in low-pressure die-casting. Crucially, the design ensures that the feed tube is mechanically disconnected from the shot sleeve before the actual high-speed shot takes place (as shown in Figure 8g). This sequence isolates the feed tube and furnace from the shockwaves, ensuring process reliability.

Q4: How does this proposal improve upon existing advanced methods like the Vacural-Process®?

A4: The Vacural-Process®, as described in the paper, sucks metal into the shot sleeve by creating a vacuum. While an improvement, the author notes that the achievable vacuum (around 700 hPa absolute pressure) still leaves approximately 15 Vol-% oxygen in the system. This is more than enough to form oxide films on the turbulent metal. The proposed concept improves on this by first actively flushing the system with inert nitrogen gas to expel oxygen, and then using gentle, low-turbulence bottom-filling to prevent new oxides from forming.

Q5: The paper mentions that even a good vacuum leaves enough residual oxygen to form oxides. Can you explain the mechanism?

A5: Yes, the paper points out that the negative pressures used in die casting are far from a "technical vacuum." An absolute pressure of 700 hPa still contains a significant amount of oxygen. When the molten aluminum enters the cavity and shot sleeve turbulently, its protective surface skin is constantly broken, exposing fresh, highly reactive liquid metal to this residual oxygen. This instantly forms new, extremely thin oxide films that become folded and trapped in the melt, acting as crack-initiation sites in the final part.

Conclusion: Paving the Way for Higher Quality and Productivity

This paper presents a compelling argument that the accepted performance limits of High Pressure Die Casting (HPDC) are not dictated by the aluminum alloys themselves, but by a process-inherent flaw: the formation of dispersed oxide films during shot sleeve filling. The proposed concept of a bottom-filling shot sleeve under an inert gas atmosphere offers a fundamental solution to this root cause, rather than merely treating its symptoms. By preventing these hidden defects from ever forming, it may be possible to produce structural components with the exceptional ductility and fatigue strength that designers require, unlocking new possibilities for lightweighting and performance.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components.

Copyright Information

- This content is a summary and analysis based on the paper "Contribution to Solving an Inherent Problem When High Pressure Die-Casting Aluminium and its Alloys" by "Herbert Smetan".

- Source: doi: 10.17265/2161-6221/2016.5-6.003

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.