Silafont-36 vs. Mercaloy 367: A Head-to-Head Comparison for High-Integrity Structural Aluminum Casting

This technical summary is based on the academic paper "COMPARISON OF MICROSTRUCTURE AND TENSILE PROPERTY OF SILAFONT-36 AND MERCALOY 367 IN A REAR CROSS MEMBER PROTOTYPE CASTING USING HPDC PROCESS" by K Sadayappan, G Birsan, X Zeng, and S Shankar, published in Contributed Papers from Materials Science and Technology 2017 (MS&T17). It has been analyzed and summarized for technical experts by CASTMAN.

Keywords

- Primary Keyword: Structural Aluminum Casting

- Secondary Keywords: HPDC alloys, Silafont 36, Mercaloy 367, tensile properties, die soldering, automotive casting, Al-Si alloys

Executive Summary

- The Challenge: Automotive manufacturers require high-ductility, low-iron aluminum alloys for structural components, but these alloys are highly susceptible to die soldering, which damages tooling and halts production.

- The Method: Researchers manufactured an automotive rear cross member using High-Pressure Die Casting (HPDC) with two specialized low-iron alloys, Silafont-36 and Mercaloy 367, to directly compare their solidification, microstructure, and mechanical properties.

- The Key Breakthrough: Despite different chemical strategies to combat die soldering (higher Mn in Silafont-36, higher Sr in Mercaloy 367), both alloys produced castings with nearly identical tensile properties, fatigue behavior, and microstructures.

- The Bottom Line: For demanding structural aluminum casting applications, Mercaloy 367 is a proven and viable alternative to Silafont-36, delivering comparable mechanical performance and process outcomes.

The Challenge: Why This Research Matters for HPDC Professionals

In the automotive industry, the push for lightweighting has led to the replacement of iron and steel components with high-integrity aluminum alloys. For structural applications requiring high impact and fatigue strength, alloys with low iron content are essential. However, this presents a significant manufacturing challenge.

Conventional HPDC alloys contain higher iron levels (often >0.8%) specifically to counteract the high affinity of molten aluminum for iron, which otherwise leads to aggressive erosion and soldering on steel dies. Low-iron alloys, while mechanically superior, can cause costly production delays due to this die-soldering issue. This research addresses the critical need to validate modern low-iron alloys engineered to provide both excellent mechanical properties and robust manufacturability. The study focuses on two such alloys: Silafont-36, which uses manganese (Mn), and Mercaloy 367, which uses strontium (Sr), to reduce reaction with iron tools.

The Approach: Unpacking the Methodology

The research was conducted at the CanmetMATERIALS (CMAT) experimental casting laboratory, utilizing a fully automatic die casting production cell to ensure industrial relevance.

- Component: The casting was a rear cross member for a current Fiat Chrysler Auto (FCA) production light vehicle.

- Alloys: Two low-iron Al-Si alloys were tested: Silafont-36 (provided by ECP) and Mercaloy 367 (provided by Mercury Marine). The specific compositions are detailed in Table 1 of the paper.

- Process: A Stotek furnace with an 1100 kg capacity was used to melt the alloys to 710°C. The melt was degassed with Argon, and quality was checked with a Reduced Pressure Test (RPT). For each shot, approximately 9.5 kg of molten metal was transferred to the die.

- Simulation: Flow3D software was used to simulate mould filling and solidification, helping to identify critical locations for analysis and predict potential issues like knit lines.

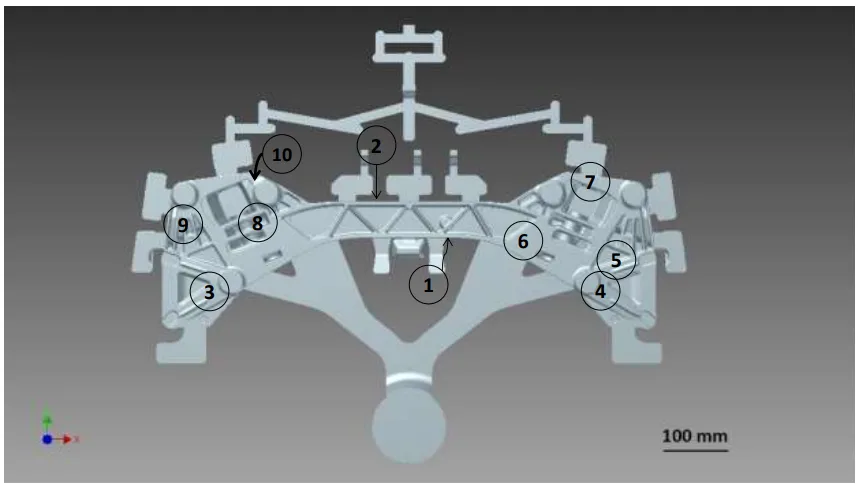

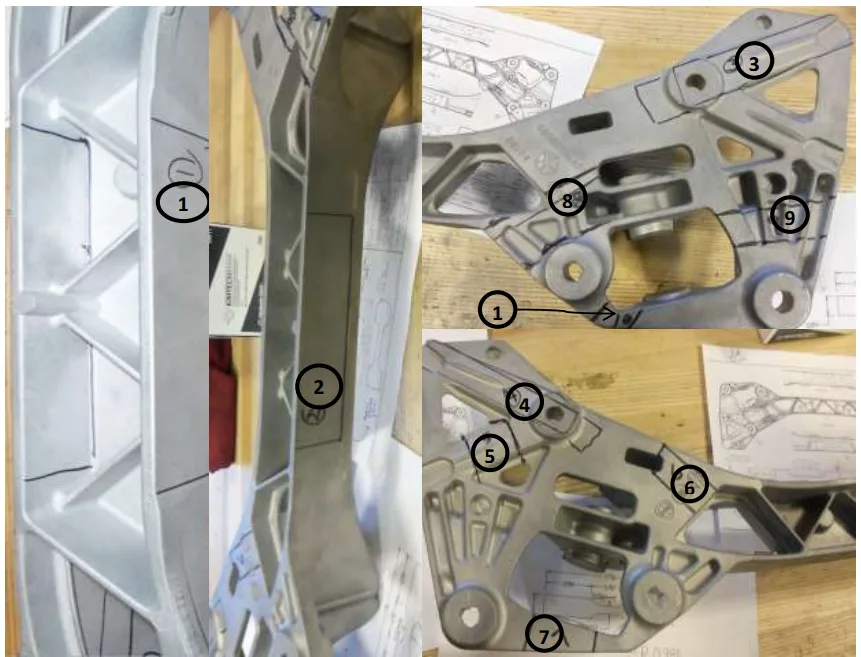

- Analysis: Castings were systematically evaluated. Tensile and high-cycle fatigue specimens were machined from locations 1 and 2, preserving the as-cast surfaces. Microstructure and micro-hardness evaluations were performed on samples from eight different locations (3 through 10) to compare the structure across the component.

The Breakthrough: Key Findings & Data

The comprehensive analysis revealed that both alloys performed remarkably similarly, providing confidence in their interchangeability for this type of structural component.

Finding 1: Virtually Identical Mechanical Properties

The tensile properties of both alloys, whether produced at the CMAT research lab or the ECP production facility, were found to be very similar. As shown in Table 2, the ultimate tensile strength (UTS) and elongation (El, %) values were statistically comparable.

- Silafont-36 (CMAT): UTS of 246.0 MPa, Elongation of 4.5%

- Mercalloy (CMAT): UTS of 252.2 MPa, Elongation of 5.6%

- Silafont-36 (ECP Production): UTS of 253.0 MPa, Elongation of 5.7%

The paper notes, "It is evident from the results that the alloys possess very similar mechanical properties. Neither the alloy nor the production site had any significant effect on the values." Furthermore, high-cycle fatigue tests indicated that both alloys exhibited similar behavior under dynamic loading.

Finding 2: Consistent Microstructure and Absence of Defect Bands

Microstructural analysis confirmed that both alloys produced sound castings. The structures consisted of primary aluminum dendrites surrounded by an Al-Si eutectic, with finer grains near the colder die walls and coarser grains toward the center, as expected.

Crucially, the study found that a "well-defined defect band structure is not observed for both alloys." This is a significant positive outcome, as defect bands—mixed structures between the skin and core—can compromise mechanical performance. Figure 5 in the paper clearly shows a cross-section of the casting from both alloys, illustrating a solid, defect-free structure. The authors assume that the lower-speed filling parameters used in the trial promoted this desirable outcome.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that while both alloys have similar overall castability, Mercaloy castings were "easily ejected after die opening," whereas Silafont-36 castings "were observed to stick to the die surface." This difference in ejection behavior could have implications for cycle time and tool maintenance in a mass production environment. The finding that lower-speed filling may promote a defect-band-free structure is a valuable parameter to consider for thick-walled structural castings.

- For Quality Control Teams: The data in Table 2 provides a clear benchmark for the expected tensile properties of sound castings made from either Silafont-36 or Mercaloy 367. The microstructures shown in Figures 3, 4, and 5 serve as an excellent visual reference for grain structure and the absence of defect bands in acceptable parts.

- For Design Engineers: The findings confirm that Mercaloy 367 is a mechanically equivalent alternative to Silafont-36 for this application. This allows for greater flexibility in material specification based on factors like cost, availability, or specific process characteristics like die release, without compromising the designed performance of the structural component.

Paper Details

COMPARISON OF MICROSTRUCTURE AND TENSILE PROPERTY OF SILAFONT-36 AND MERCALOY 367 IN A REAR CROSS MEMBER PROTOTYPE CASTING USING HPDC PROCESS

1. Overview:

- Title: COMPARISON OF MICROSTRUCTURE AND TENSILE PROPERTY OF SILAFONT-36 AND MERCALOY 367 IN A REAR CROSS MEMBER PROTOTYPE CASTING USING HPDC PROCESS

- Author: K Sadayappan, G Birsan, X Zeng and S Shankar

- Year of publication: 2017

- Journal/academic society of publication: Contributed Papers from Materials Science and Technology 2017 (MS&T17)

- Keywords: Al-Si Alloys, die casting, Silafont 36, Mercaloy, structural casting

2. Abstract:

An automotive structural casting was manufactured through high-pressure die casting process using two Al-Si alloys Silafont 36 and Mercaloy 367. The objective was to compare the two alloys using the dependant parameters such as, filling and solidification, microstructure and uniaxial tensile properties of casting at various critical locations. The analysis includes simulations of mould filling and solidification using Flow3D software. The two Al-Si based alloys lend themselves to structural castings because of their low Fe content; resulting in an increase in the component ductility. The drawback of reducing the Fe content in these alloys were the high susceptibility to die tool soldering of Al which was alleviated by increasing levels of Mn in Silafont-36 and Sr in Mercaloy 367. This report presents the process details, characterization and properties of these two alloy components.

3. Introduction:

Aluminum alloys have been replacing iron components used in automotive applications for a long time. The recent trend is to use high integrity aluminum alloys with low iron content such as Silafont 36 and Aural 2 for structural components in place of steel. Iron in aluminum reduces impact and fatigue strength hence the need for alloys with low iron contents. High Pressure Die Casting (HPDC) process is suitable for mass production. The aluminum alloys conventionally used for HPDC process usually contain iron contents higher than 0.8%. This is because of the high affinity of molten aluminum to iron leading to erosion of steel tools used for HPDC operation. However, higher iron contents result in reduced ductility and fatigue strength, both of which are necessary for components used in structural applications. Efforts are being made to develop aluminum alloys with low iron contents but also have low reaction with iron tools. Recent research by Mercury Marine has resulted in development of Mercaloy series of alloys. These alloys have strontium, which reduces the molten aluminum's affinity to iron. Etobicoke Casting Plant (ECP) of Fiat Chrysler Auto (FCA) is currently using Silafont 36 for structural applications. The research team wanted to test the use of new alloy variants in place of Silafont. This report presents the result of development work carried out at the Canmet MATERIALS (CMAT) lab of Natural Resources Canada. The discussion includes the process details, characterization and properties of these two alloy components.

4. Summary of the study:

Background of the research topic:

The automotive industry is increasingly using low-iron, high-integrity aluminum alloys for structural components to reduce weight while maintaining strength. However, these low-iron alloys are prone to die soldering in the HPDC process.

Status of previous research:

Efforts have been made to develop low-iron aluminum alloys that have low reactivity with steel tools. Silafont-36 is an established alloy used for structural applications. Mercury Marine has recently developed the Mercaloy series of alloys, which use strontium to reduce the molten aluminum's affinity to iron.

Purpose of the study:

The objective was to directly compare the performance of Silafont-36 and a new alternative, Mercaloy 367, in the HPDC manufacturing of a complex automotive structural casting. The comparison focused on process parameters, microstructure, and uniaxial tensile properties at critical locations.

Core study:

An automotive rear cross member was produced using both Silafont-36 and Mercaloy 367 via HPDC. The process was simulated using Flow3D software. The resulting castings were subjected to extensive analysis, including mechanical testing (tensile and fatigue) and microstructural evaluation at multiple locations to provide a comprehensive comparison of the two alloys.

5. Research Methodology

Research Design:

The study was an experimental comparison of two aluminum alloys used to produce the same structural component under similar HPDC process conditions. The research combined physical casting trials, software simulation, and materials characterization.

Data Collection and Analysis Methods:

- Casting: 85 castings of each alloy were produced.

- Simulation: Mould filling and solidification were simulated using Flow3D software.

- Compositional Analysis: Ingot compositions were tested with Optical Emission Spectroscopy (Table 1).

- Mechanical Testing: Three uniaxial tension and three high-cycle fatigue specimens were obtained from locations 1 and 2 of selected castings.

- Microstructure Evaluation: Samples from locations 3 through 10 were sectioned, mounted, and prepared for optical metallography and micro-hardness testing.

Research Topics and Scope:

The research scope covered the entire HPDC process chain for a specific automotive component, from melting and casting to final property evaluation. It compared two specific low-iron Al-Si alloys, Silafont-36 and Mercaloy 367, focusing on their castability, microstructure, and mechanical properties.

6. Key Results:

Key Results:

- Both Silafont-36 and Mercaloy 367 exhibited very similar tensile properties (UTS, YS, Elongation), with no significant difference between the alloys or the production site (research lab vs. production facility).

- High-cycle fatigue tests indicated both alloys exhibit similar behavior under dynamic loading.

- While Silafont-36 castings tended to stick to the die surface, Mercalloy castings were easily ejected. However, the final surface finish of both was very similar.

- The microstructures were typical for Al-Si alloys, with finer grains at the surface and coarser grains at the center.

- A well-defined "defect band" was not observed in the castings from either alloy, which is a positive outcome attributed to the use of lower-speed mold filling.

Figure Name List:

- Figure 1 - Schematic Image of the Component with Gating system and locations for analyses.

- Figure 2 - Locations of samples sectioned for tensile tests and microstructure analyses

- Figure 3: Microstructures from centre sections of different locations obtained from castings; (a) and (c) are from sample locations 4 and 7 of Silafont 36 alloy casting, respectively, and (b) and (d) are from locations 4 and 7 of Mercaloy castings.

- Figure 4: Microstructures from wall sections of different locations obtained from castings; (a) and (c) are from sample locations 4 and 10 of Silafont 36 alloy casting, respectively, and (b) and (d) are from locations 4 and 10 of Mercaloy castings.

- Figure 5: A cross-sectional microstructure image of the section obtained from the section 9 of the two alloy castings; (a) silafont 36 (b) Mercalloy

7. Conclusion:

- Casting trials conducted for Silafont 36 and Mercalloy did not reveal any difference in the castability of the two alloys.

- The mechanical properties, both tensile and high cycle fatigue, were found to be similar for two alloys.

8. References:

- 1 J. R. Davis, J. R. Davis & Associates, ASM International. Handbook Committee “Aluminum and Aluminum Alloys” ASM International, 1993 pages 22-28

- 2 R.H. Stevens, ed.: Aluminum Alloys, ASM International, Materials Park, OH, USA, 1985

- 3 Aluminium. Properties and Physical Metallurgy. Ed. Hatch J.E., ASM Metals Park, Ohio 1984

- 4 H. Ye, “An overview of the development of Al-Si-alloy based material for engine applications," Journal of materials engineering and performance, vol. 12, no. June, pp. 288-297, 2003.

- 5 R. Donahue and P. Fabiyi, “Manufacturing feasibility of all-aluminum automotive engines via application of high silicon aluminum alloy,” Society of Automotive Engineers, 2000.

- 6 W. Miller, L. Zhuang, and J. Bottema, “Recent development in aluminium alloys for the automotive industry,” Materials Science and, vol. 280, pp. 37-49, 2000.

- 7 J. Hirsch, D. Bassan, and C. Lahaye, “Aluminium in innovative light-weight car design,” Materials Transactions, pp. 101-114, 2011.

- 8 S. Shankar, Y. W. Riddle, M. M. Makhlouf “Nucleation mechanism of the eutectic phases in aluminum-silicon hypoeutectic alloys”. Acta Materialia 52 (2004) 4447-4460

- 9 S. Shankar, Y. W. Riddle, and M. M. Makhlouf “Eutectic Solidification of Aluminum-Silicon Alloys” A Metallurgical and Materials Transactions , VOLUME 35A, SEPTEMBER 2004 page 3038

- 10 L.F. Mondolfo : Aluminum, Alloys: Structure and Properties, Butterworths and Co Ltd, London, UK., 1976

- 11 S. Shankar, PhD Thesis, WPI, Worcester, MA, USA, 2000.

Expert Q&A: Your Top Questions Answered

Q1: Why were the tensile test specimens machined only on their two narrow surfaces?

A1: According to the paper's "Mechanical Testing" section, this was done deliberately "to ensure loading is concentrated on the as-cast surface not on the machined surfaces." Preserving the original cast skin is critical for testing structural components, as the skin has a different microstructure (finer grains) and is the first surface to experience service loads, making its properties highly relevant to real-world performance.

Q2: The paper notes that Silafont-36 tended to stick while Mercaloy ejected easily. Why wasn't this difference in processing behavior explored further?

A2: The paper's primary objective was to compare the final properties of the castings. While it notes the difference in ejection, it also states the "surface finish of both alloys was very similar." The summary concludes there was no difference in "castability," suggesting that from a perspective of mold filling and final part quality, they were equivalent. The observation on ejection is a practical note, implying Mercaloy's Sr-based approach to reducing die affinity may have an advantage in this area, even if the final part quality is the same.

Q3: What specific process parameter is believed to be responsible for the desirable "defect band-free" structure in the castings?

A3: In the final paragraph of the results discussion, the paper states, "It is assumed that the lower speed filling used in making these samples promoted a defect band free structure." This suggests that for thick-walled castings, avoiding a spray-like fill and using a more controlled, slower injection velocity can prevent the formation of this detrimental microstructural feature.

Q4: The Abstract mentions that Mn was increased in Silafont-36 and Sr in Mercaloy 367. What was the specific purpose of these additions?

A4: The Abstract clearly states that the drawback of using low-iron alloys is their "high susceptibility to die tool soldering of Al." The paper explains that this issue was "alleviated by increasing levels of Mn in Silafont-36 and Sr in Mercaloy 367." Both elements are added to counteract the natural affinity of molten aluminum for the iron in the steel die, thereby protecting the tool and ensuring smoother production.

Q5: How did the mechanical properties of the trial castings (made at CMAT) compare to actual production castings (from ECP)?

A5: Table 2 provides a direct comparison for Silafont-36. The production castings from ECP showed slightly higher average UTS (253.0 MPa vs. 246.0 MPa) and elongation (5.7% vs. 4.5%) than the CMAT trial castings. However, the paper concludes that "Neither the alloy nor the production site had any significant effect on the values," indicating the differences were not considered statistically significant and that the trial results were representative of production quality.

Q6: What simulation software was used in this study, and what key insight did it provide?

A6: The study used Flow3D software for simulating mould filling and solidification. According to the "Simulation" section, the software was instrumental in identifying critical locations for analysis. For example, it predicted that locations 3 and 4 would be "an end point or knit line" because metal would enter from both sides. This allowed the researchers to strategically section samples from these areas to check for potential defects.

Conclusion: Paving the Way for Higher Quality and Productivity

This research provides a clear and practical validation of two leading low-iron alloys for high-performance Structural Aluminum Casting. The core finding—that Silafont-36 and Mercaloy 367 deliver nearly identical mechanical properties and microstructural integrity—is crucial for manufacturers seeking to optimize their material choices. It confirms that Mercaloy 367 is a robust alternative, giving engineers and procurement specialists valuable flexibility without compromising component performance. Furthermore, the insights regarding the impact of fill speed on defect formation offer actionable guidance for improving casting quality.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components.

Copyright Information

- This content is a summary and analysis based on the paper "COMPARISON OF MICROSTRUCTURE AND TENSILE PROPERTY OF SILAFONT-36 AND MERCALOY 367 IN A REAR CROSS MEMBER PROTOTYPE CASTING USING HPDC PROCESS" by "K Sadayappan, G Birsan, X Zeng and S Shankar".

- Source: https://doi.org/10.7449/2017/MST_2017_117_124

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.