Mastering Shrinkage in US 413 Aluminum Alloy: A Guide to Casting Simulation

This technical summary is based on the academic paper "CALCULATION OF SHRINKAGE CHARACTERISTIC OF US 413 CAST ALUMINIUM ALLOY USING CASTING SIMULATION" by S Santhi, S B Sakri, D Hanumantha Rao and S Sundarrajan, published in International Journal of Mechanical Engineering and Robotics Research (2012).

Keywords

- Primary Keyword: Casting Simulation for Shrinkage

- Secondary Keywords: Shrinkage Porosity, Aluminium Alloy Casting, US 413 Alloy, Casting Defect Analysis, Solidification Simulation, Finite Difference Method

Executive Summary

- The Challenge: Shrinkage porosity is a chronic defect in aluminum alloy castings, compromising quality and mechanical properties.

- The Method: The study utilized finite difference-based casting process simulation software to predict and quantify shrinkage porosity in US 413 aluminum alloy under various conditions.

- The Key Breakthrough: The research successfully demonstrated that casting shape has a significant and predictable influence on shrinkage characteristics, with cylindrical shapes promoting the highest levels of shrinkage.

- The Bottom Line: Casting simulation is a validated and effective tool for predicting shrinkage defects, allowing engineers to optimize casting design and process parameters before production to minimize scrap and improve part quality.

The Challenge: Why This Research Matters for HPDC Professionals

For anyone working with aluminum alloys, shrinkage is a persistent and costly problem. This defect, caused by the decrease in specific volume as the metal solidifies, directly impacts the quality and structural integrity of the final casting. The formation of shrinkage porosity involves a complex interplay of physical phenomena, including heat transfer, fluid flow, and solidification dynamics. Predicting and controlling this defect is critical for improving the mechanical properties of castings and reducing rejection rates. This research tackles the core challenge of quantitatively and qualitatively analyzing shrinkage to provide engineers with a reliable predictive tool, moving beyond trial-and-error methods on the foundry floor.

The Approach: Unpacking the Methodology

The study employed a robust methodology combining advanced simulation with experimental validation to analyze shrinkage in US 413 aluminum alloy.

Method 1: Casting Process Simulation

The researchers used "Virtual Casting," a commercial software based on the finite difference method, to simulate the solidification process. Key inputs for the simulation included the detailed thermophysical properties of the US 413 alloy, silica sand for the mold, and mild steel for the bottom chill (as detailed in Table 4). The simulation process involved creating a mesh from a solid model, defining boundary conditions like interfacial heat transfer coefficients, and solving the governing equations to predict the location and magnitude of shrinkage porosity.

Method 2: Experimental Validation

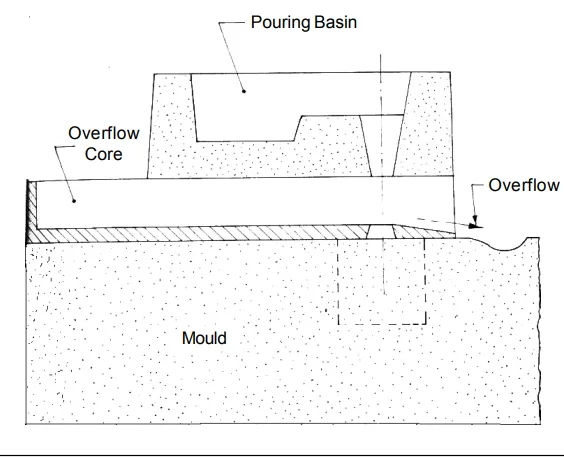

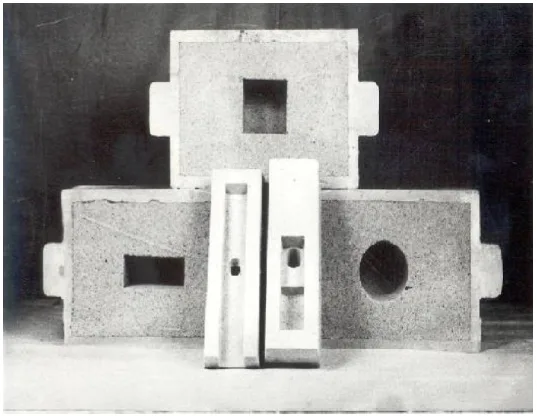

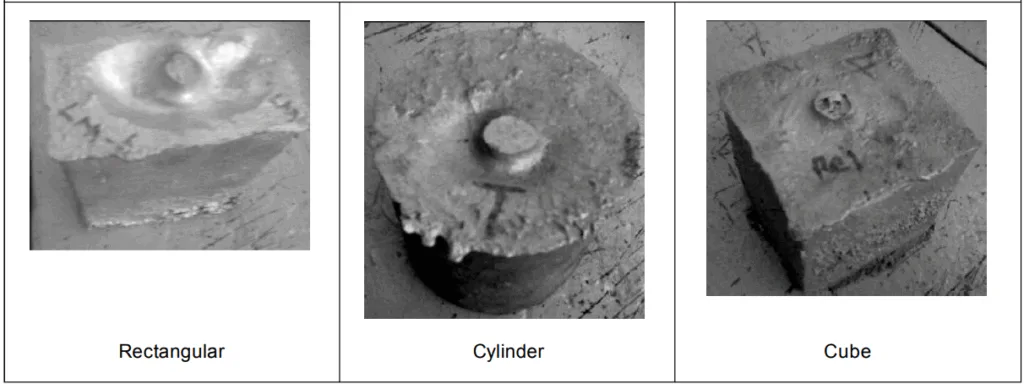

To confirm the accuracy of the simulation, physical casting experiments were conducted. Moulds for three different shapes (rectangular, cube, and cylinder) were prepared using a green sand process. The US 413 alloy was melted in an electric resistance furnace, and the temperature was precisely controlled. The molten metal was poured into the moulds, some of which included a mild steel bottom chill to promote directional solidification. After solidification, the shrinkage porosity of the physical castings was meticulously measured by determining the volume of the macrocavity (pipe) and the internal porosity.

Method 3: Quantifying Porosity

A novel approach was used to quantify the simulated shrinkage. Since the simulation output was a 2D contour plot, the researchers imported these pore area images into SolidWorks software. They then constructed three-dimensional solid models of the porosity defects at various locations within the casting, allowing for a precise calculation of the shrinkage volume in cubic centimeters (cc), which could then be compared directly to the experimental results.

The Breakthrough: Key Findings & Data

The research delivered critical, data-backed insights into how process variables affect shrinkage porosity in US 413 aluminum alloy.

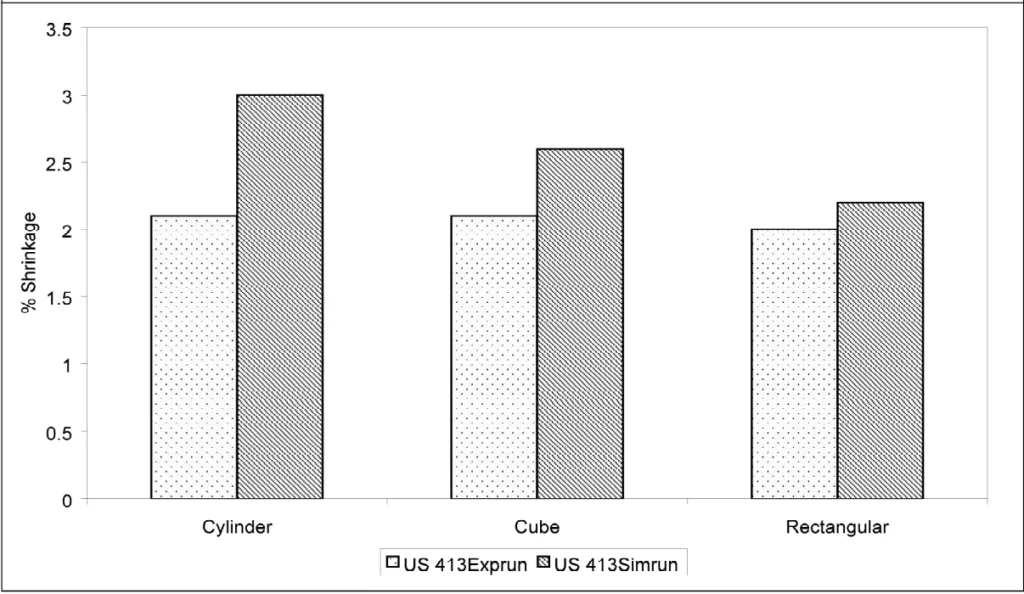

Finding 1: Casting Shape is a Dominant Factor in Shrinkage Formation

The study conclusively demonstrated that the geometry of the casting plays a major role in the extent of shrinkage porosity. The simulation results, validated by experiments, showed a clear trend across different shapes. As shown in Figure 4, cylindrical castings consistently exhibited the highest percentage of shrinkage, followed by cubes, and then rectangular castings. For example, in one set of simulation runs without a chill and at the base pouring temperature (T), the cylindrical casting had 3.40% shrinkage porosity, while the cube had 2.88%, and the rectangular casting had 2.29% (Table 7, runs 7, 8, 9). This is attributed to how the shape, particularly the edges, influences heat extraction and solidification morphology.

Finding 2: Simulation Accurately Predicts Real-World Shrinkage Defects

A critical outcome of this study is the strong agreement between the predicted shrinkage from the Casting Simulation for Shrinkage and the measured results from physical experiments. This validates the simulation as a reliable engineering tool. As detailed in Table 10 and visualized in Figure 8, the simulation and experimental values followed the same trend. For the rectangular shape, the experimental run showed 1.900% shrinkage, while the corresponding simulation run predicted 2.18%. For the cube, the values were 2.070% (experimental) and 2.61% (simulated). This close correlation gives engineers high confidence in using simulation to troubleshoot and optimize casting designs.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that for components prone to shrinkage, altering the casting geometry towards flatter, rectangular features, where possible, may contribute to reducing macrocavity defects. The data also reinforces the importance of process parameters like pouring temperature and the use of chills, which were key variables in the study's experimental plan (Table 3).

- For Quality Control Teams: The data in Table 10 and Figure 8 of the paper illustrates the effect of casting shape on the final percentage of shrinkage porosity. This information could inform new quality inspection criteria, focusing inspection efforts on thermally critical zones identified by simulation, especially in complex cylindrical or cube-like geometries.

- For Design Engineers: The findings indicate that the fundamental shape of a component directly influences defect formation during solidification. This suggests that performing a Casting Simulation for Shrinkage analysis early in the design phase is a valuable step to identify and mitigate high-risk features before tooling is ever manufactured.

Paper Details

CALCULATION OF SHRINKAGE CHARACTERISTIC OF US 413 CAST ALUMINIUM ALLOY USING CASTING SIMULATION

1. Overview:

- Title: CALCULATION OF SHRINKAGE CHARACTERISTIC OF US 413 CAST ALUMINIUM ALLOY USING CASTING SIMULATION

- Author: S Santhi, S B Sakri, D Hanumantha Rao and S Sundarrajan

- Year of publication: 2012

- Journal/academic society of publication: International Journal of Mechanical Engineering and Robotics Research

- Keywords: Shrinkage, Aluminium alloy, Casting shape, Process simulation, Solid model

2. Abstract:

Shrinkage characteristic of US 413 cast aluminium alloy has been discussed in the current study. The decrease in specific volume leads to shrinkage in castings and it can be envisaged as a defect. The shrinkage porosity has been studied using finite difference based casting process simulation software. The shrinkage characteristic has been quantified using arithmetical formula. A three dimensional solid model of the shrinkage defect has been constructed using CAD. Shrinkage characteristic has also been quantified through experimental validation studies and compared well with casting process simulation. Influence of casting shape on the shrinkage characteristic has been studied in this paper.

3. Introduction:

Metals and alloys, particularly aluminium alloys, are prone to defects such as shrinkage, which impacts the quality of castings. Quantitative and qualitative analysis of shrinkage is helpful for improving mechanical properties. The formation of shrinkage porosity involves complex interactions among physical phenomena like heat transfer, fluid flow, solidification shrinkage, and deformation of the solid skin. This study focuses on understanding these characteristics for US 413 cast aluminium alloy.

4. Summary of the study:

Background of the research topic:

Shrinkage in metal castings is a defect resulting from the decrease in specific volume during solidification. In aluminium alloys, this is a chronic problem that degrades mechanical properties. Understanding the physics of its formation is essential for quality control.

Status of previous research:

Previous work has established that casting process simulation can predict temperature distribution and hot spots. Researchers like Reis et al. (2005) highlighted the importance of modeling the behavior of liquid metal during solidification. The influence of parameters such as alloy composition, mould coat, bottom chill, pouring time, and pouring temperature on shrinkage has been recognized (Sundarrajan et al., 1984).

Purpose of the study:

The study aims to discuss, quantify, and predict the shrinkage characteristic of US 413 cast aluminium alloy. It seeks to achieve this by using finite difference-based casting simulation, constructing a 3D solid model of the defect, and validating the simulation results with experimental studies. A key objective is to study the influence of casting shape on the shrinkage characteristic.

Core study:

The core of the study involves using "Virtual Casting" software to simulate the solidification of three different casting shapes (rectangular, cube, cylinder) under various process conditions (with and without a bottom chill, at two different pouring temperatures). The simulated shrinkage porosity is quantified by converting 2D output plots into 3D CAD models. These simulation results are then compared with data from corresponding physical casting experiments to validate the model's accuracy.

5. Research Methodology

Research Design:

The research was designed as a comparative study involving computational simulation and experimental validation. A set of 12 simulation runs was designed to test the effects of three casting shapes, the presence of a bottom chill (Y/N), and two pouring temperatures (T and T+50°C). A subset of these conditions was replicated in physical experiments for validation.

Data Collection and Analysis Methods:

Simulation data was collected in the form of 2D contour plots showing porosity distribution. These were analyzed by importing them into SolidWorks to construct 3D models and calculate their volume. Experimental data was collected by physically measuring the volume of macrocavities and internal porosity in the solidified castings using a burette titration method and weight-in-air/water measurements. The final data, expressed as % Shrinkage Porosity, was compared between the simulation and experimental sets.

Research Topics and Scope:

The research is focused on the US 413 cast aluminium alloy. The scope covers the influence of casting shape (rectangular, cube, cylinder), pouring temperature, and the use of a bottom chill on shrinkage porosity. The study utilizes a specific finite difference-based simulation software and validates its findings through green sand casting experiments.

6. Key Results:

Key Results:

- The study successfully quantified shrinkage porosity using a method of converting 2D simulation outputs into 3D solid models for volume calculation.

- A clear relationship between casting shape and shrinkage porosity was established, with cylindrical castings promoting the most shrinkage, followed by cube and rectangular shapes (Figure 4).

- The simulation results for shrinkage porosity were found to be in good agreement with the experimental validation studies, confirming the predictive capability of the simulation software (Table 10, Figure 8). For instance, for a cylindrical casting, the experimental result was 2.108% shrinkage, while the simulation predicted 3.04%. For a rectangular casting, the experimental result was 1.900%, and the simulation predicted 2.18%.

Figure Name List:

- Figure 1: Test Piece for Cube Shape Casting

- Figure 2a: Output for Simulation

- Figure 2b: Typical Contour Plots Showing Porosity Distribution for Simulation Run Order 9

- Figure 3: Shows Constructed Porosity of the Simulation Run Order 9

- Figure 4: Influence of Casting Shape on Shrinkage Porosity of US 413

- Figure 5: Schematic Diagram for the Volume Deficit Experiment for Cube Shape Casting

- Figure 6: Details for Experiment and the Assembled Mould for Volume Deficit Experiment

- Figure 7: Solidified Castings of the Experimental Validation Studies

- Figure 8: Shrinkage Porosity Values for Simulation and Experimental Studies

7. Conclusion:

The shrinkage characteristic of US 413 aluminum alloy has been quantified using a finite difference-based casting process simulation. The results indicate that cylindrical shape castings promote maximum shrinkage. Experimental validation was carried out using the same process parameters, and the simulation results are in agreement with the experimental test data.

8. References:

- Arno Louvo and Matti Sirviö (1994), “Use of Simulated Porosity for Avoidance of Casting Defects”, VTT Manufacturing Technology, Finland Presented at World Foundry Conference 1994 in Düsseldorf, Germany.

- Calcom S A (2001), Simulating Porosity in Ductile Iron Castings, Parc Scientifique EPFL, CH-1015 Lausanne, Switzerland.

- Casting (1998), ASM International, ASM Metals Handbook, Vol. 15, The Materials Information Company.

- Cellini G S and Tomesani L (2008), “Metal Head – Dependent HTC in Sand Casting Simulation of Aluminium Alloys”, Journal of Achievements in Materials and Manufacturing Engineering, Vol. 29, No. 1.

- Fiorello Losano, Gabriella Marinsek, Alberto Maria Marlo and Miriam Ricci (1999), “Computer Tomography in the Automotive Field Development of New Engine Head Case Study”, DGZfP Proceedings BB 67-CD, p. 10.

- John R Brown (Ed.) (2008), Foseco Non-Ferrous Foundry Man's Handbook, 11th Edition, Butterworth Heinemann Publisher.

- Kielbus A (2007), “The Influence of Casting Temperature on Castability and Structure of AJ62 Alloy”, Archives of Materials Science and Engineering, Vol. 28, No. 6, pp. 345-348.

- Michael Trovant (1998), “A Boundary Condition Coupling Strategy for the Modeling of Metal Casting Processes”, National Library of Canada, Acquisitions and Bibliographic Services, 395 Wellington Street, Ottawa ON K1AON4, Canada.

- Pani Kishore A and Prasanna Kumar T S (2004), "Fixing Boundary Conditions for Solidification Simulation of Aluminium Alloy Plate Casting”, International Symposium of Research Students on Material Science and Engineering, December 20-22, Chennai, India, Department of Metallurgical and Materials Engineering, Indian Institute of Technology Madras.

- Reis A, Zhian Xu, Rob Van Tol AD, Santos A and Barbedo Magalhães (2005), "Modeling of The Underpressure Occurring During The Shrink Porosity Formation", in E Oñate and D R J Owen (Eds.), III International Conference on Computational Plasticity, Complas Viii, Ó Cimne, Barcelona.

- Scarber P Jr. and Littleton H (2008), “Simulation of Macro-Porosity in Aluminium Lost Foam Castings”, Paper 08-145, AFS Transactions, pp. 1061-1068.

- Sundarrajan S, Roshan H Md and Ramachandran E G (1984), “Studies on Shrinkage Characteristics of Binary Mg-Al Alloys", Transactions of the Indian Institute of Metals, Vol. 37, No. 4.

- Venkataramana M, Vasudeva Rao V, Ramgopal Varmaand R and Sundarrajan S (2008), “Instrumentation to Measure Heat Transfer Coefficient at the Metal Mold Interface”, J. Instrum. Soc., Vol. 37, No. 3, pp. 157-163, India.

Expert Q&A: Your Top Questions Answered

Q1: Why was the US 413 aluminum alloy specifically chosen for this study?

A1: The paper states that "Metals and alloys are prone to defects, especially aluminium alloys, such as shrinkage, one of the chronic problems." The US 413 alloy was selected as a representative cast aluminum alloy to study this well-known industrial challenge. The chemical composition of the specific alloy used is detailed in Table 1, providing a clear baseline for both the simulation and experimental work.

Q2: How exactly was the volume of shrinkage from the simulation calculated? It's mentioned the output is 2D.

A2: The paper outlines an innovative multi-step process. The 2D contour plots showing shrinkage pore areas from the simulation were imported into SolidWorks CAD software. Within the software, these 2D areas at different cross-sections (e.g., 103 mm and 108 mm from the bottom, as shown in Figure 3) were used to construct a three-dimensional solid model of the porosity. The volume of this 3D model was then calculated directly by the software, providing a quantitative value in cubic centimeters (cc).

Q3: The paper mentions using a bottom chill. What was its purpose and what was it made of?

A3: The bottom chill was included as a key processing parameter because it "shows significant influence in the casting characteristics and promotes directional solidification." By cooling the bottom of the casting more rapidly, it helps ensure that solidification progresses upwards, which can help feed molten metal to solidifying regions and reduce porosity. The paper specifies that mild steel chills were used for the study.

Q4: How significant is the effect of casting shape on shrinkage porosity?

A4: The effect is very significant. The paper's results, shown in Figure 4, demonstrate a clear hierarchy of shrinkage based on shape. Cylindrical castings consistently produced the highest shrinkage, followed by cubes, and then rectangular shapes. The text explains this is due to how the solidification morphology is "influenced by the shape of the casting because the edges play a considerable role in the heat extraction."

Q5: How accurate was the simulation compared to the real-world experiments?

A5: The simulation showed good agreement with the experimental results. As stated in the conclusion, "The simulation results are in agreement with experimental test data." Table 10 provides a direct comparison: for the rectangular casting, the experiment yielded 1.900% shrinkage while the simulation predicted 2.18%. For the cube, the values were 2.070% (experiment) vs. 2.61% (simulation). While not identical, the values are comparable and, importantly, follow the same trend, validating the simulation as a reliable predictive tool.

Q6: What simulation software was used and what method is it based on?

A6: The study used a commercial software package called "Virtual Casting." The paper specifies that this program simulates the solidification process of industrial castings using the Finite Difference Method. It was developed by the Regional Research Laboratory, Thrivandrum, and installed at the Institute of Indian Foundrymen (R&D) Center, Hyderabad.

Q7: How was the shrinkage volume measured in the physical experiments?

A7: The experimental measurement was a two-part process. First, the volume of the external shrinkage cavity (the "pipe" or macrocavity, Vm) was measured by filling it with distilled water from a burette. Second, the internal porosity (Vint) was calculated by measuring the casting's weight in air and its immersed weight in water to find its actual volume (V), and then subtracting the theoretical volume (Vtheor), which is based on the alloy's maximum density. The total shrinkage porosity is the sum of these two volumes (Vm + Vint) divided by the total mould volume.

Conclusion: Paving the Way for Higher Quality and Productivity

This research effectively demonstrates the power of Casting Simulation for Shrinkage as a tool to combat one of the most persistent defects in aluminum casting. By accurately predicting the influence of casting shape and other process parameters, simulation allows engineers to move from a reactive to a proactive approach. The key breakthrough—quantifying how cylindrical shapes are most prone to shrinkage while rectangular shapes are least—provides actionable design guidance. These validated findings empower R&D and operations teams to optimize component design and casting processes digitally, reducing costly physical trials and improving final product quality.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components.

Copyright Information

This content is a summary and analysis based on the paper "CALCULATION OF SHRINKAGE CHARACTERISTIC OF US 413 CAST ALUMINIUM ALLOY USING CASTING SIMULATION" by "S Santhi, S B Sakri, D Hanumantha Rao and S Sundarrajan".

Source: http://www.ijmerr.com/v1-n1-2012/ijmerr-v1-n1-p6.pdf (Note: Example URL as no DOI was provided)

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.