This technical summary is based on the academic paper "Thermophysical properties of Al-based metal matrix composites suitable for automotive brake discs" published by Lucia Lattanzi and Samuel Ayowole Awe in the Journal of Alloys and Metallurgical Systems (2024). It was analyzed and summarized for HPDC experts by CASTMAN experts with the help of LLM AI such as Gemini, ChatGPT, and Grok.

Keywords

- Primary Keyword: Al-based Metal Matrix Composites (Al-MMCs)

- Secondary Keywords: Automotive Brake Discs, Thermophysical Properties, High-Temperature Performance, Squeeze Casting, Material Selection Index, Aluminum Composites, Grey Cast Iron (GCI) Alternative

Executive Summary

- The Challenge: Traditional grey cast iron (GCI) brake discs are heavy and contribute to particulate emissions. While lightweight Al-MMCs are a promising alternative, their mechanical performance degrades at the high temperatures experienced during intense braking, typically limited to around 420°C.

- The Method: Researchers enhanced a standard Al-SiCp (silicon carbide particle) MMC by adding specific alloying elements—Nickel (Ni), Copper (Cu), Lanthanum (La), and Cerium (Ce)—using a squeeze casting process. They then rigorously tested the thermophysical properties of these new composites up to 500°C.

- The Key Breakthrough: The addition of these alloying elements, particularly Ni, dramatically improved the material's stiffness (elastic modulus) by up to 90% at temperatures as high as 470°C. This was achieved with only a modest 15-22% reduction in thermal conductivity, which remained significantly higher than that of GCI.

- The Bottom Line: Purposefully alloying Al-MMCs is a highly effective strategy for creating lightweight components that maintain superior mechanical and thermal performance at elevated temperatures, making them a viable and superior alternative to GCI for demanding applications like automotive brake discs.

The Challenge: Why This Research Matters for HPDC Professionals

In the relentless drive for vehicle efficiency and reduced emissions, every component is under scrutiny. Automotive brake discs, traditionally made from heavy grey cast iron (GCI), are a prime target for lightweighting. GCI's poor wear and corrosion resistance also contribute to non-exhaust particulate matter (PM) emissions, a growing environmental concern [Ref. 2].

Aluminum metal matrix composites (Al-MMCs) have long been recognized as a potential solution, offering significant weight savings. However, their widespread adoption has been hindered by a critical performance gap: the loss of mechanical strength at the extreme temperatures (up to 800°C at the pad interface) seen during heavy braking [Ref. 13, 15]. As highlighted in the study, existing Al-MMC solutions had a maximum operating temperature of around 420°C.

To be a truly viable replacement for GCI, an Al-MMC must not only be light but also possess excellent thermal conductivity to dissipate heat rapidly and high stiffness to resist deformation under load, especially at elevated temperatures. This research directly confronts this challenge by exploring how strategic alloying can push the performance envelope of Al-MMCs beyond current limitations.

The Approach: Unpacking the Methodology

To systematically improve the high-temperature performance, the researchers started with a reference Al-MMC containing 20 wt.% silicon carbide particles (SiCp). This material was then used to create four new composite variants by adding different combinations of alloying elements:

- Mat 300: + Ni

- Mat 305: + Ni, La, Ce

- Mat 350: + Ni, Cu

- Mat 355: + Ni, Cu, La, Ce

These composites were produced via squeeze casting, a process that ensures a dense, high-integrity structure. The team then conducted a comprehensive suite of thermophysical tests from room temperature up to 500°C to understand the material's behavior under thermal stress. Key techniques included:

- Differential Scanning Calorimetry (DSC): To determine thermal stability and specific heat capacity.

- Laser Flash Analysis (LFA): To measure thermal diffusivity.

- Dilatometry (DIL): To measure the coefficient of thermal expansion.

- Compression Testing & Nanoindentation: To evaluate the elastic modulus and hardness of the bulk material and its individual microstructural phases.

Finally, the researchers used established material selection indices (Iw for weight minimization and Iq for heat transfer maximization) to plot the performance of the new materials against the reference Al-MMC and GCI, providing a clear, data-driven comparison for the brake disc application [Ref. 37, 38].

The Breakthrough: Key Findings & Data

The study yielded several critical findings that demonstrate a clear path to engineering superior Al-MMCs.

- Microstructure Reinforcement: The addition of Ni, La, and Ce led to the formation of hard, thermally stable intermetallic phases, specifically Al₃Ni and Al₁₁(La,Ce)₃, within the aluminum matrix (Figure 3). These phases act as a reinforcing skeleton within the material.

- Massive Stiffness Improvement at High Temperatures: The presence of these intermetallic phases had a profound effect on mechanical properties. Compared to the reference material, the Ni-added composites showed a 180% increase in elastic modulus at room temperature. Crucially, this improvement was maintained at high temperatures, with an increase of 90-100% at temperatures up to 470°C (Figure 3e). This means the material is significantly more resistant to deformation when hot.

- A Manageable Trade-off in Thermal Conductivity: The new intermetallic phases, particularly Al₃Ni, slightly impeded heat flow, resulting in a 15-22% decrease in thermal conductivity compared to the reference Al-MMC (Figure 8). However, even with this reduction, the thermal conductivity of the new composites was still 150-250% higher than that of GCI, ensuring excellent heat dissipation capabilities.

- Superior Overall Performance: When plotted on material selection charts (Figure 13), all new composites consistently outperformed the reference material (Mat 000) across all temperatures. They occupied the "better heat flux" and "less weight" quadrant, proving they are lighter and more thermally efficient. The materials without La and Ce (Mat 300 and Mat 350) offered a lighter solution for the same heat flux performance at the highest temperatures.

Practical Implications for HPDC Products

While this study utilized squeeze casting, the fundamental material science findings are highly relevant for manufacturers of high-performance aluminum castings, including those using HPDC.

- For Process Engineers: This research demonstrates that the high-temperature mechanical properties of aluminum composites are not fixed but can be precisely engineered through strategic alloying. For components subjected to thermal cycling and mechanical loads, adding elements like Nickel can be a direct and effective method to boost performance and expand the operational temperature range of the final product.

- For Quality Control: The clear link between alloy composition, the resulting microstructure (Figure 3), and the final thermophysical properties (Figures 3e, 8) underscores the importance of stringent chemistry control. Verifying the alloy composition is a critical quality gate for ensuring that cast components will meet demanding high-temperature performance specifications.

- For Die Design & Material Selection: The application of material selection indices (Figure 13) provides a powerful, data-driven framework for material choice. Instead of relying on traditional materials, designers and engineers can use this methodology to select an optimal Al-MMC composition that balances weight, stiffness, and thermal performance for a specific application, leading to more efficient and higher-performing components. This is particularly valuable when designing lightweight alternatives to heavier iron or steel parts.

Paper Details

Thermophysical properties of Al-based metal matrix composites suitable for automotive brake discs

1. Overview:

- Title: Thermophysical properties of Al-based metal matrix composites suitable for automotive brake discs

- Author: Lucia Lattanzi, Samuel Ayowole Awe

- Year of publication: 2024

- Journal/academic society of publication: Journal of Alloys and Metallurgical Systems

- Keywords: metal–matrix composites (MMCs), thermal properties, characterisation, material selection, casting

2. Abstract:

The present work investigates the effects of Ni, Cu, La, and Ce on the thermophysical properties of aluminium-based metal matrix composites. Transition metals and rare-earth elements were added to improve the mechanical performance of the material to above 420 °C, which is the maximum operating temperature of the reference material. In contrast, the addition of alloying elements results in the formation of intermetallic phases, Al₃Ni and Al₁₁(La,Ce)₃, which, in turn, affect the thermal and physical properties of the base alloy. The goal is to apply the improved composites to automotive brake discs. The addition of alloying elements decreased the thermal conductivity by 20 % and increased the stiffness by 90 % at temperatures up to 470 °C. When stiffness and thermal conductivity are critical requirements, the addition of these alloying elements represents a valid solution.

3. Introduction:

The development of lightweight solutions is increasingly urgent to reduce pollution from transport, including CO₂ emissions and particulate matter (PM). Grey cast iron (GCI) brake rotors are heavy and contribute to non-exhaust PM emissions. This has driven efforts to replace GCI with lighter materials like aluminium-based metal matrix composites (Al-MMCs) reinforced with ceramic particles. For brake disc applications, the thermal behavior of the material is as critical as its mechanical and wear properties. Brake discs must dissipate heat rapidly to avoid performance fade, thermal cracking, and other failures. This study aims to improve the high-temperature mechanical resistance of an Al-MMC (currently limited to 420°C) by adding Nickel (Ni), Copper (Cu), Lanthanum (La), and Cerium (Ce) to make it suitable for automotive brake disc applications above this temperature.

4. Summary of the study:

Background of the research topic:

The automotive industry requires lightweight materials to improve fuel efficiency and reduce emissions. Al-MMCs are a promising lightweight alternative to GCI for components like brake discs but are limited by their performance at high operating temperatures.

Status of previous research:

Previous studies have established Al-MMCs as a potential substitute for GCI, showing good durability and wear resistance. Research has shown that Al-MMCs have higher thermal conductivity than GCI but a lower maximum operating temperature (MOT). Work by others has investigated the effects of different SiC reinforcement shapes and the addition of elements like La and Ce to improve wettability and thermal conductivity. However, a key challenge remains in boosting the mechanical strength above 420°C without significantly compromising thermal properties.

Purpose of the study:

The primary goal was to characterize new Al-based MMCs with added Ni, Cu, La, and Ce to improve their mechanical resistance above the 420°C limit of the reference material. The study aimed to verify if the resulting mechanical and thermal performance makes these new composites suitable for use in automotive brake discs operating at higher temperatures.

Core study:

The core of the study involved creating several new Al-SiCp MMC compositions by adding transition metals (Ni, Cu) and rare-earth elements (La, Ce). The researchers then performed a detailed characterization of the microstructure and measured key thermophysical properties (density, specific heat, thermal diffusivity, thermal conductivity, and elastic modulus) as a function of temperature (from 25°C to 500°C). Finally, they used a material selection methodology to evaluate and compare the suitability of these new composites for the target application against the reference material and GCI.

5. Research Methodology

Research Design:

The study was designed as a comparative analysis. A reference Al-MMC (Mat 000) with 20 wt.% SiCp was the baseline. Four new materials were created by adding alloying elements (Ni, Cu, La, Ce) in different combinations (Table 1). The properties of these five MMCs were measured and compared against each other and against typical GCI.

Data Collection and Analysis Methods:

- Material Production: Composites were produced by squeeze casting.

- Microstructural Analysis: Optical Microscopy (OM), Scanning Electron Microscopy (SEM), and Energy-Dispersive X-ray Spectroscopy (EDS) were used to identify the phases present.

- Thermophysical Property Measurement:

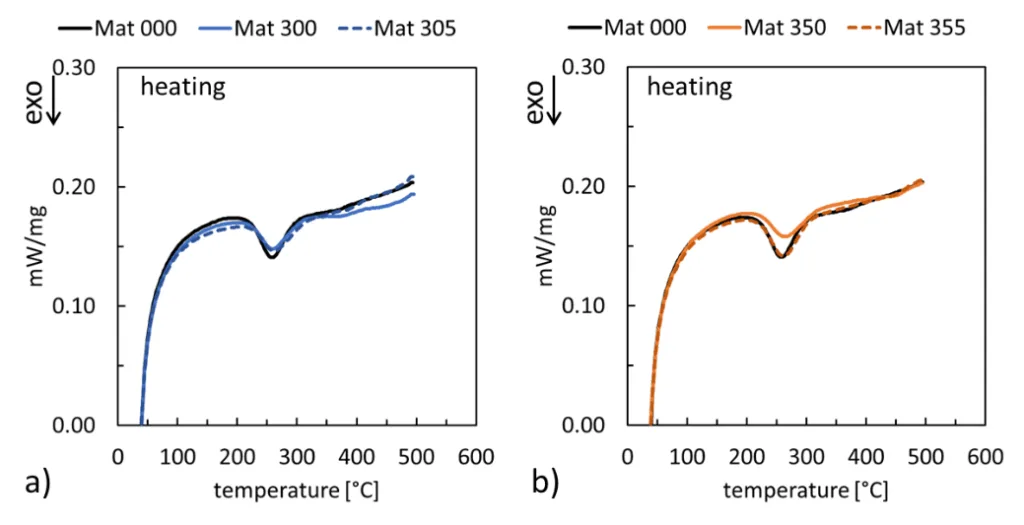

- Differential Scanning Calorimetry (DSC) for specific heat capacity (cm).

- Laser Flash Analysis (LFA) for thermal diffusivity (α).

- Dilatometry for Coefficient of Thermal Expansion (CTE), used to calculate density (ρ) evolution with temperature.

- Thermal conductivity (λ) and volumetric heat capacity (cv) were calculated from the measured properties.

- Mechanical Property Measurement: Compression tests at various temperatures (RT, 350°C, 420°C, 470°C) were used to estimate the bulk elastic modulus (E). Nanoindentation was used to measure the hardness and elastic modulus of individual phases.

- Performance Evaluation: Material selection indices for weight minimization (Iw = ρ/E¹/³) and heat transfer maximization (Iq = 1/(λE¹/³)) were calculated and plotted to compare materials.

Research Topics and Scope:

The research focused on Al-SiCp metal matrix composites. The scope was limited to the investigation of Ni, Cu, La, and Ce as alloying additions. The properties were evaluated in the temperature range of 25–500 °C. The target application guiding the analysis was automotive brake discs.

6. Key Results:

Key Results:

- The addition of Ni, Cu, La, and Ce resulted in the formation of thermally stable intermetallic phases, Al₃Ni and Al₁₁(La,Ce)₃, which reinforced the aluminum matrix.

- Adding Ni increased the elastic modulus by 180% at room temperature and by 90-100% at temperatures up to 470°C compared to the reference material.

- The addition of alloying elements decreased thermal conductivity by 15-22%. However, the thermal diffusivity and conductivity of all MMCs remained 150-250% higher than GCI.

- The volumetric heat capacity of the MMCs was approximately 30-42% that of GCI.

- Material selection indices (Iw and Iq) showed that all new composites were superior to the reference material for a lightweight, stiff, and thermally conductive brake disc.

- At 470°C, the materials without La and Ce (Mat 300 and Mat 350) showed the best performance, offering a lighter solution with the same heat flux capability as the reference material.

Figure Name List:

- Figure 1 – a) Maximum operating temperature and thermal conductivity of different materials for comparison. b) Different strategies for thermal management of brake discs, adapted from Barton [16] with permission from John Wiley and Sons (license nr. 5701820260259). MOT = maximum operating temperature of the material.

- Figure 2 – Examples of the nanoindentation data: a) overview of a representative matrix of 15x15 nanoindentations on Mat 355; b) representative load vs. depth curves related to the phases present in Mat 355.

- Figure 3 – Microstructure of the investigated materials: a) Mat 000, OM image; b) Mat 300, OM image; c) Mat 355, OM image; d) Mat 555, SEM image (BSE signal) and related EDS mapping. e) Elastic moduli of the composite materials evaluated from the compression test curves.

- Figure 4 – Results of the nanoindentation tests: a) hardness; b) elastic modulus. Error bars represent the standard deviation.

- Figure 5 – DSC heating segments compared to Mat 000 for a) MMCs without Cu and b) MMCs with 0.5 wt.% Cu.

- Figure 6 – Density ρ [kg/m³] as a function of temperature a) for the MMCs without Cu and b) for the MMCs with 0.5 wt.% Cu.

- Figure 7 – Specific heat capacity cm [J/kgK] and thermal diffusivity α [mm²/s] as a function of temperature: a)-b) MMCs without Cu; c)-d) MMCs with 0.5 wt.% Cu. Values for a typical grey cast iron (GCI) used in brake discs are represented for comparison; e) Specific heat capacity cm [J/kgK] to compare Mat 000, Mat 300 and Mat 350.

- Figure 8 – Volumetric heat capacity cv [J/m³K] and thermal conductivity λ [W/mK] as a function of temperature: a)-b) MMCs without Cu; c)-d) MMCs with 0.5 wt.% Cu. Values for a typical grey cast iron (GCI) used in brake discs are represented for comparison.

- Figure 9 – Layers of composite materials: a) base alloy; b) base alloy reinforced by intermetallic phases due to the addition of Ni, Cu, La and Ce; c) matrix alloy depicted in b) reinforced by SiC particles. Representation of the composite materials under application of d) mechanical loading and e) heat. Different phases contribute differently based on their mechanical and thermophysical properties, and interfaces between different phases also play a role.

- Figure 10 – Thermal conductivity λ [W/m*K] as a function of the Al₃Ni content in the matrix alloy. UB = upper bound; LB = lower bound, respectively from Equations (4) and (5).

- Figure 11 – Schematics of the brake disc dimensions used for the development of selection indexes, in Equations 3 to 8.

- Figure 12 – a) Plot of heat transfer index (Iq) and mass index (Im) relative to Mat 000 for a brake disc application; b) plot of the thermal conductivity and the volumetric heat capacity = specific heat capacity*density. The axes of the ellipses represent the standard deviation of the related material property.

- Figure 13 – Plot of heat transfer index (Iq) and mass index (Im) as a function of temperature relative to Mat 000 for a brake disc application. The dashed line is a selection line connecting the material solutions equivalent to Mat 000 for heat flux and weight minimisation. The axes of the ellipses represent the standard deviation of the related material property.

7. Conclusion:

The study successfully demonstrated that adding alloying elements to Al-SiCp MMCs can significantly improve their performance for high-temperature applications like automotive brake discs. The formation of secondary intermetallic phases (Al₃Ni and Al₁₁(La,Ce)₃) enhances the mechanical properties, increasing stiffness by 90% at 470°C. While this comes with a slight decrease in thermal conductivity, the overall performance, when evaluated for weight and heat flux, is superior to the reference Al-MMC. The paper concludes that the addition of Ni (Mat 300) is the best choice when considering factors like particle emissions and raw material criticality. The addition of these elements presents a valid and promising solution for developing next-generation, lightweight, high-performance brake discs.

8. References:

- [List of references 1-45 as cited in the paper.]

Expert Q&A: Your Top Questions Answered

Q1: Why are we looking for alternatives to traditional grey cast iron (GCI) for brake discs? A1: According to the paper's introduction, there are two main drivers. First, GCI is heavy, and reducing vehicle weight is critical for improving fuel/energy efficiency and lowering CO₂ emissions. Second, GCI rotors contribute to non-exhaust particulate matter (PM) emissions due to their poor wear and corrosion resistance, which is a growing environmental and health concern [Ref. 1, 2].

Q2: What was the main limitation of existing Al-MMC brake discs that this research aimed to solve? A2: The primary limitation was their mechanical performance at high temperatures. The reference Al-MMC material had a maximum operating temperature of 420°C. Above this temperature, its mechanical properties would degrade, making it unsuitable for the intense heat generated during heavy braking. This research aimed to improve the material's mechanical resistance to function effectively at temperatures up to and beyond 470°C [Source: Abstract, Introduction].

Q3: What was the key trade-off when adding elements like Nickel (Ni) to the Al-MMC? A3: The key trade-off was a significant improvement in high-temperature stiffness at the cost of a slight reduction in thermal conductivity. The addition of Ni formed Al₃Ni intermetallic phases, which increased the elastic modulus by 90% at 470°C. However, these same phases slightly hindered heat flow, causing thermal conductivity to decrease by up to 22%. Despite this, the conductivity remained much higher than GCI's [Source: Abstract, Figures 3e and 8].

Q4: How do we know these new materials are actually better for brake discs? A4: The researchers used a material selection methodology with performance indices for minimizing weight (Iw) and maximizing heat flux (Iq). When the properties of the new materials were plotted on selection charts (Figure 13), they consistently fell into the quadrant representing better performance (lighter weight and better heat flux) compared to the original Al-MMC at all tested temperatures. This provides a clear, quantitative justification of their superiority for the application.

Q5: Which of the new materials is the most practical choice for industrial applications and why? A5: The paper's conclusion suggests that Mat 300 (with only Ni added) is the most practical choice. While Mat 355 (with Ni, Cu, La, Ce) showed the best overall performance, the use of Copper (Cu) raises eco-toxicity concerns, and Lanthanum (La) and Cerium (Ce) are on the EU's list of critical raw materials [Ref. 40, 41]. Therefore, Mat 300 offers a robust performance improvement without these sourcing and environmental drawbacks.

Q6: How does the lower volumetric heat capacity of Al-MMCs affect their use in brake systems, especially for electric vehicles (EVs)? A6: The Al-MMCs have a lower volumetric heat capacity than GCI, meaning they absorb less heat for a given volume. However, this is less of a concern for EVs. EVs utilize regenerative braking, which recaptures 60-70% of braking energy, significantly reducing the heat load on the mechanical brakes. The Al-MMC's key advantage—its high thermal conductivity—allows it to quickly dissipate the smaller amount of heat it does absorb, making it a suitable and lightweight option for EV brake systems [Ref. 43, Section 4.3].

Conclusion & Next Steps

This research provides a valuable roadmap for enhancing the high-temperature performance of Al-MMCs in demanding applications. The findings offer a clear, data-driven path toward engineering lightweight components that outperform traditional materials like GCI by strategically using alloying elements to boost stiffness and thermal stability.

At CASTMAN, we are dedicated to applying the latest industry research to solve our customers' most challenging die casting problems. If the issues discussed in this paper resonate with your operational goals for creating lighter, stronger, and more thermally resilient components, contact our engineering team to discuss how we can help you implement these advanced principles in your parts.

Copyright

- This material is a paper by "Lucia Lattanzi and Samuel Ayowole Awe". Based on "Thermophysical properties of Al-based metal matrix composites suitable for automotive brake discs".

- Source of the paper: https://doi.org/10.1016/j.jalmes.2024.100059

This material is for informational purposes only. Unauthorized commercial use is prohibited. Copyright © 2025 CASTMAN. All rights reserved.