A Review of Japan's Evolving Ceramics Market: From High-Stress Engine Parts to High-Purity Electronics

This technical brief is based on the academic paper "Automotive and industrial applications of structural ceramics in Japan" by Akira Okada, published in the Journal of the European Ceramic Society (2008). It is summarized and analyzed for industry professionals by the experts at CASTMAN.

Keywords

- Primary Keyword: Structural Ceramics Applications

- Secondary Keywords: Japanese ceramics market, Silicon nitride automotive parts, High-purity alumina semiconductor, Silicon carbide applications, Cordierite honeycomb catalyst, Ceramic wear parts

Executive Summary

- The Challenge: Leveraging the superior properties of structural ceramics (light weight, high-temperature stability, wear resistance) in demanding industrial and automotive applications has been a long-standing goal, often hindered by the materials' inherent brittleness.

- The Method: The paper reviews over two decades of market data and specific industrial applications of structural ceramics in Japan, tracking the evolution of materials like alumina, silicon nitride, and silicon carbide.

- The Key Breakthrough: The Japanese market for structural ceramics has seen a significant shift. While the 1980s "ceramic fever" focused on high-stress silicon nitride engine components, the most substantial and sustained growth has occurred in high-purity alumina for semiconductor manufacturing and in cordierite/silicon carbide for automotive exhaust systems.

- The Bottom Line: The most successful recent applications of structural ceramics are in components operating in severe thermal and chemical environments, but often under lower mechanical stresses than originally targeted for engine parts. This provides a crucial insight for material selection and application development.

The Challenge: Why This Research Matters for Industry Professionals

For decades, engineers have been captivated by the potential of structural ceramics. Materials like silicon nitride and silicon carbide offer compelling advantages over traditional metals, including lower weight, superior chemical and thermal stability, and excellent wear resistance. However, a significant hurdle has always been their brittle nature, which can lead to unreliable performance and catastrophic failure under high mechanical stress.

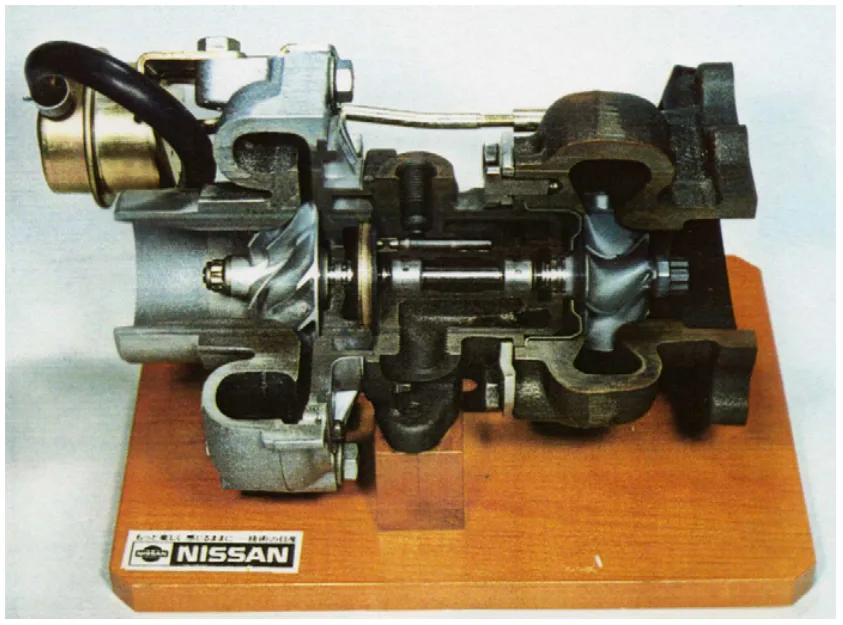

In the 1980s, a period described in the paper as the "ceramic fever" in Japan, intensive research and development focused on overcoming this limitation, with the goal of applying ceramics to high-stress automotive components like gas turbine and turbocharger rotors. This paper reviews the outcomes of that effort and tracks the subsequent evolution of the ceramics market, revealing where these advanced materials have truly found commercial success. For any engineer or manager considering ceramics, this review offers a data-driven history of what has worked, what hasn't, and why.

The Approach: Unpacking the Methodology

This paper presents a comprehensive review by Akira Okada of the Nissan Research Center. The analysis is built on two pillars:

- Market Trend Analysis: The author uses shipment data from the Japanese ceramics industry (Table 1, Table 2) to quantify the growth and relative importance of different ceramic materials and application sectors from 1985 to 2005.

- Application Case Studies: The paper details specific, successful applications across key industries, including semiconductor production, steel manufacturing, aluminum casting, and automotive systems. These examples are supported by figures showing the components in their real-world context (e.g., Figure 1, Figure 5, Figure 9).

This approach provides a clear, evidence-based overview of the technological and commercial landscape for structural ceramics in one of the world's most advanced manufacturing economies.

The Breakthrough: Key Findings & Data

The review highlights a clear divergence between early expectations and eventual market reality. The most significant growth has not been in the high-stress engine components that once generated excitement, but in other demanding applications.

- Finding 1: Alumina and Exhaust Components Dominate the Market: High-purity alumina has become the market leader, primarily due to its widespread use in equipment for manufacturing semiconductors and liquid crystal displays. This segment's value exceeds that of zirconia, silicon nitride, and silicon carbide combined (Table 1). The other major growth area is cordierite honeycomb substrates for automotive catalysts.

- Finding 2: Success in Semiconductor Manufacturing: The semiconductor industry requires components that can withstand corrosive plasma and reactive gases while maintaining extreme purity. High-purity, reaction-sintered silicon carbide coated with CVD SiC is used for wafer boats (Figure 1, Figure 2) due to its high thermal stability and conductivity. High-purity alumina is used for parts like electrostatic wafer chucks and process chamber components (Figure 3).

- Finding 3: A Shift in Automotive Applications: The use of silicon nitride for engine parts like turbocharger rotors (Figure 9) and tappets (Figure 10) has not grown as expected. Instead, the dominant automotive applications are now cordierite catalyst honeycombs (Figure 8) and silicon carbide diesel particulate filters. The success of these components hinges on thermal properties and intricate design (e.g., thin walls) rather than extreme mechanical strength.

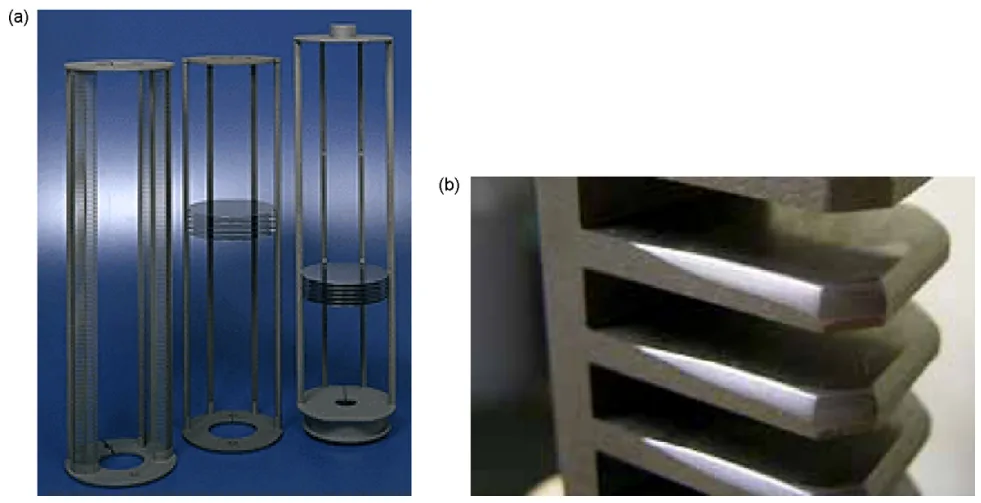

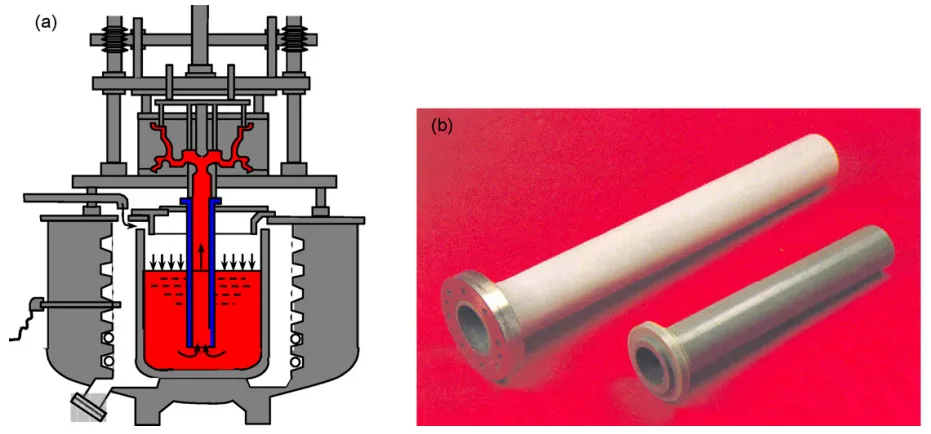

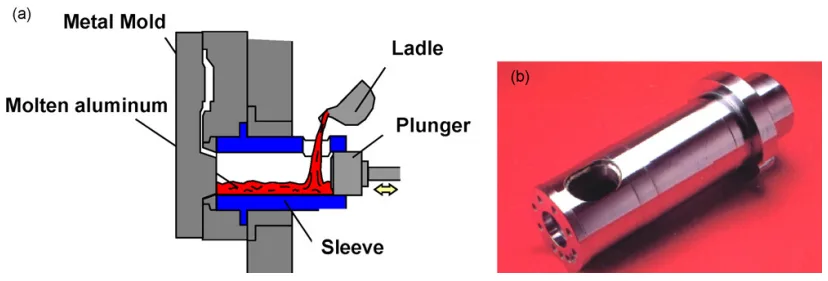

- Finding 4: Robust Solutions for Metal Casting: Ceramics have proven highly effective in handling molten metal. SiAlON, a derivative of silicon nitride, is used for stalks and sleeves in low-pressure aluminum casting (Figure 5) and die-casting (Figure 6). These components offer a longer lifetime than previous cast iron parts by preventing iron immigration into the aluminum melt and reducing the need for lubricants.

Practical Implications for Your Operations

The findings from this comprehensive review offer valuable, data-backed insights for modern engineering and manufacturing.

- For Process Engineers (Semiconductor/LCD): The paper's findings on aluminum nitride (AlN) susceptors are particularly relevant. The close match between the thermal expansion coefficient of AlN and silicon wafers leads to reduced frictional movement during heating cycles. This, in turn, lowers particle generation, a critical factor for improving yield in semiconductor fabrication.

- For Quality Control (Automotive Emissions): The evolution of catalyst honeycombs detailed in Table 3 provides a clear process improvement roadmap. The data shows a direct correlation between reducing the honeycomb's wall thickness (from 300 µm in 1976 to 50 µm in 1999) and increasing the surface area, which is essential for improving the catalyst's light-off speed and overall efficiency.

- For Die Design (Metal Casting): The successful application of ceramic-lined sleeves in aluminum die-casting (Figure 6) demonstrates a powerful strategy for process optimization. By incorporating a ceramic tube, the amount of lubricant required can be "considerably reduced," which not only saves costs but is also "effective in eliminating casting defects." This suggests a direct design path to higher quality castings and more efficient production.

Paper Details

Automotive and industrial applications of structural ceramics in Japan

1. Overview:

- Title: Automotive and industrial applications of structural ceramics in Japan

- Author: Akira Okada

- Year of publication: 2007 (Available online), 2008 (Journal issue)

- Journal/academic society of publication: Journal of the European Ceramic Society

- Keywords: Structural applications; Wear parts; Engine components; Al2O3; Si3N4

2. Abstract:

This paper reviews the status of structural ceramics in Japan. Until around 1980, successful applications of these materials were limited to wear-resistant parts and structural components working under very low stresses. Considerable work has been done over the years on applying ceramics to mechanical parts used under higher stresses. This led to some successful applications of silicon nitride to automotive components, including turbocharger rotors and glow plugs. However, the recent market for silicon nitride automotive components has not been as large as was expected. Cordierite honeycombs for catalysts and diesel particulate filters made of silicon carbide are becoming more important applications in Japan. It is noteworthy that the Japanese market for structural ceramics has been steadily increasing since 1985, with the leading applications being apparatus for purifying the exhaust gas of automotive engines and parts for semiconductor manufacturing equipment. Alumina, for example, is widely used for vacuum process chambers. High-purity alumina is also used for the components of liquid crystal device manufacturing equipment and various mechanical parts. The recent applications of structural ceramics in Japan summarized in this review include vacuum process chambers for manufacturing semiconductor and liquid crystal devices, wear-resistant ceramics used for steel-making, optical lens forming and cutting tools, refractory tubes for casting aluminum alloys, and automotive applications.

3. Introduction:

Structural ceramics like alumina, silicon nitride, silicon carbide, and zirconia offer significant advantages over steel, such as light weight, chemical and thermal stability, and excellent wear resistance. However, their strong chemical bonds also lead to brittle mechanical properties, which has historically restricted their application in structural components. Early successes before 1980 were limited to low-stress parts like thread guides and cutting tools. The 1980s saw a major push to apply silicon nitride to higher-stress automotive parts like turbocharger rotors, driven by advances in fracture mechanics and processing technology. Despite these efforts, applications in automotive engines decreased in the 1990s, while the use of high-purity alumina expanded significantly in equipment for producing semiconductors and liquid crystal displays.

4. Summary of the study:

Background of the research topic:

The Japanese market for structural ceramics began around 1980 and has expanded steadily. This study reviews the trends and key applications that have defined this market's growth.

Status of previous research:

The paper notes that until the 1980s, applications were limited to low-stress wear parts. Intensive R&D in the 1980s, spurred by work on ceramic gas turbines, led to advances in fracture toughness, processing, and component design. This enabled the initial application of silicon nitride to automotive engines.

Purpose of the study:

The purpose is to review the recent advances and current status of structural ceramic applications in Japan, highlighting the most commercially significant uses in automotive and industrial sectors.

Core study:

The paper analyzes market shipment data for various ceramics (Alumina, Zirconia, Si3N4, SiC) and application categories. It then details specific use cases in:

- Industrial Production Equipment: Focuses on semiconductor and liquid crystal display manufacturing, where high-purity alumina, silicon carbide, and aluminum nitride are used for components like wafer boats, susceptors, and process chamber parts due to their purity and resistance to corrosive environments.

- Steel Making and Aluminum Casting: Describes the use of alumina and silicon nitride liners for wear protection in material transfer tubes, and SiAlON for rollers, stalks, and sleeves in handling molten metals.

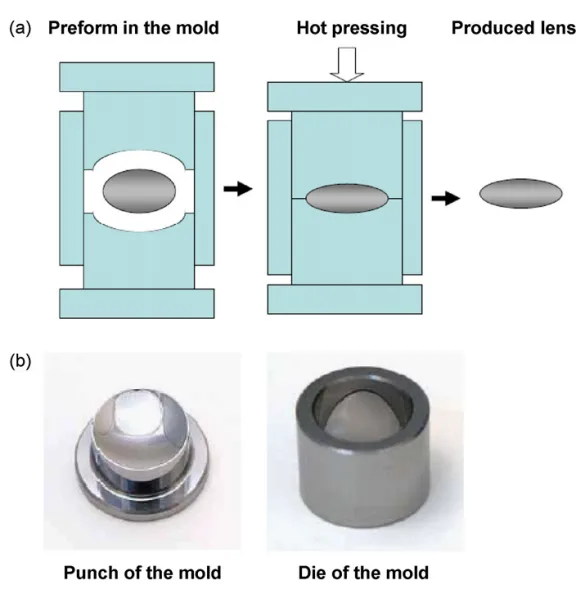

- Ceramic Molds and Cutting Tools: Discusses the use of SiC for high-temperature lens molding and the status of various ceramic cutting tools for high-speed machining.

- Automotive Applications: Reviews the history of silicon nitride engine parts (glow plugs, turbochargers) and highlights the current importance of cordierite honeycomb catalysts and silicon carbide diesel particulate filters.

5. Research Methodology

Research Design:

The study is a descriptive review based on publicly available industry data and documented case studies of ceramic applications.

Data Collection and Analysis Methods:

The author compiled and analyzed shipment data for structural ceramics in the Japanese market, as presented in Table 1 (by material type, 1985-2003) and Table 2 (by product category, 2004-2005). This quantitative data is supplemented with qualitative descriptions and photographic examples of specific ceramic components.

Research Topics and Scope:

The scope covers the Japanese market for structural ceramics from approximately 1980 to 2007. It focuses on applications in automotive, semiconductor manufacturing, metal casting, and other industrial sectors.

6. Key Results:

Key Results:

The market for structural ceramics in Japan grew from 160 million euros in 1985 to 715 million euros in 2003. High-purity alumina accounts for the largest portion of this market, driven by semiconductor applications. The market for silicon nitride, once expected to be large due to automotive engine parts, has remained relatively small. In contrast, silicon carbide has seen recent growth due to its use in diesel particulate filters. The largest application sectors by value are semiconductor production equipment and automobile parts (primarily exhaust-related).

Figure Name List:

- Fig. 1. Typical silicon carbide wafer boats for heat treatment of Si wafers.

- Fig. 2. A scanning electron micrograph of the cross-section of the SiC material.

- Fig. 3. Examples of dense ceramic components of manufacturing equipment for semiconductor devices and liquid crystal display panels.

- Fig. 4. Ceramic-lined tubes used for transferring powdery materials in the steel-making process.

- Fig. 5. SiAlON stalks for the low-pressure casting process of molten aluminum.

- Fig. 6. Die-casting and SiAlON sleeve.

- Fig. 7. Precision ceramics for lens molding.

- Fig. 8. Catalyst honeycombs with different cell densities.

- Fig. 9. Ceramic turbocharger rotors.

- Fig. 10. Tappets as wear parts used for cam followers.

7. Conclusion:

The market for structural ceramics has steadily increased, but research activities have declined since the "ceramic fever" of the 1980s. The most significant recent growth has come from applications in semiconductor/LCD manufacturing equipment (high-purity alumina) and automotive exhaust systems (cordierite honeycombs, diesel particulate filters). In these successful applications, the ceramics are subjected to severe environments but relatively low mechanical stress compared to the originally targeted gas turbine and turbocharger rotors. The paper concludes that the next step for ceramic applications is to find uses in severe environments under higher stresses.

8. References:

- [The references 1 through 15 from the original paper are listed here verbatim.]

- Okada, A., Challenges of ceramics for structural application. Bull. Ceram. Soc. Jpn., 2005, 40, 259–275 [in Japanese].

- Okada, A., Current status of structural ceramics-application to engines and automobiles. Eng. Mater. (Kogyo Zairyo), 2005, 53(8), 23-27 [in Japanese].

- Sugimoto, T., 2003 activity of ceramic industries in Japan. Bull. Ceram. Soc. Jpn., 2004, 39, 700-740 [in Japanese].

- Sugimoto, T., 2004 activity of ceramic industries in Japan. Bull. Ceram. Soc. Jpn., 2005, 40, 703-741 [in Japanese].

- Sugimoto, T., 2005 activity of ceramic industries in Japan. Bull. Ceram. Soc. Jpn., 2006, 41, 703-744 [in Japanese].

- Urashima, K. and Kuramoto, N., Handbook of Ceramics (2nd ed.). Ceramic Society of Japan, Gihodo, Tokyo, 2002, pp. 1250-1256 [in Japanese].

- Sotoya, E., Fine ceramics for semiconductor manufacturing process. Bull. Ceram. Soc. Jpn., 2005, 40, 438-442 [in Japanese].

- Sakamaki, M., Kishi, Y. and Iniguchi, M., High density ceramics for semi-conductor manufacturing devices. Bull. Ceram. Soc. Jpn., 2003, 38, 287-290 [in Japanese].

- Kawasaki, K., Application of aluminum ceramics for semiconductor fabrication apparatus. Bull. Ceram. Soc. Jpn., 2004, 39, 688-691 [in Japanese].

- Takahashi, T., Fine ceramic parts used for iron and steel-making process. Bull. Ceram. Soc. Jpn., 2005, 40, 423-429 [in Japanese].

- Kato, K., Large silicon nitride rollers for steel rolling. FC Report, 1999, 17(8), 194-195 [in Japanese].

- Hamayoshi, S., Application of ceramics in aluminum casting and iron-steel making. Bull. Ceram. Soc. Jpn., 2005, 40, 430-433 [in Japanese].

- Nagano, M., Precision ceramic die materials for recent industrial applications. Bull. Ceram. Soc. Jpn., 2005, 40, 443-448 [in Japanese].

- Kanamori, T., DLC and Me-DLC coating technologies for automobile parts. Kikai Gigyutsu, 2006, 59(12), 20-27 [in Japanese].

- Ukai, E., Ceramic application for producing automobile parts. JFA (Bull. Japan Forging Assoc.), 2007, 18, 51-56 [in Japanese].

Conclusion & Next Steps

This research provides a valuable roadmap for understanding the real-world application of structural ceramics. The findings offer a clear, data-driven perspective on where these materials provide the most value, shifting the focus from high-stress mechanical parts to components that must survive extreme thermal and chemical environments.

CASTMAN is committed to applying cutting-edge industry research to solve our customers’ most challenging technical problems. If the challenges discussed in this paper align with your goals, please contact our engineering team to discuss how we can help you apply these advanced principles to your own applications.

Expert Q&A:

- Q1: What is the largest and fastest-growing segment of the structural ceramics market in Japan according to the paper? A1: According to the paper, high-purity alumina accounts for the largest portion of the structural ceramics market, with its shipment value in 2003 exceeding the total for zirconia, silicon nitride, and silicon carbide combined. This growth is primarily driven by its application in equipment for manufacturing semiconductor devices and liquid crystal display panels, as stated in the Abstract and supported by the data in Table 1.

- Q2: Why is silicon carbide (SiC) a preferred material for wafer boats in semiconductor manufacturing? A2: The paper states that SiC is used for wafer boats due to its thermal stability at elevated temperatures and a coefficient of thermal expansion closer to silicon than that of fused silica. This property suppresses the generation of debris that might result from sliding movement during heat cycles. Furthermore, high-purity SiC is required to prevent the migration of impurities into the silicon wafers during heat treatment, as detailed in Section 3.1, "Semiconductor production."

- Q3: Did the application of silicon nitride in automotive engines meet the high expectations of the 1980s? A3: No, it did not. The paper's Abstract clearly states, "the recent market for silicon nitride automotive components has not been as large as was expected." Section 4.3 further explains that while applications like turbocharger rotors were successfully developed, some ceramic parts were later removed from subsequent automobile models because the performance improvement did not justify the higher production cost.

- Q4: How have automotive catalyst honeycombs been improved over time to increase their effectiveness? A4: The primary improvement has been a reduction in the thickness of the honeycomb walls. As shown in Table 3, the wall thickness of NGK's cordierite honeycombs was reduced from 300 µm in 1976 to as low as 50 µm by 1999. This thinning of the walls reduces the thermal mass of the honeycomb, allowing the catalyst to heat up more rapidly to its "light-off" temperature, thus improving its efficiency right after the engine starts.

- Q5: What are the main advantages of using SiAlON for components in molten aluminum casting? A5: The paper highlights in Section 3.2 that SiAlON stalks used in low-pressure casting have a longer lifetime compared to the previously used cast iron stalks. This is because the ceramic material solves the problem of "iron immigration into the melt." For die-casting sleeves, using a ceramic-lined tube considerably reduces the need for lubricant and is effective in eliminating casting defects, as shown in Figure 6.

- Q6: What are the key material requirements for ceramic components used in the plasma etching chambers of semiconductor manufacturing? A6: As described in Section 3.1, the key requirements are: (i) excellent resistance to halogen gases in the plasma environment, (ii) freedom from hazardous elements that could degrade semiconductor performance, and (iii) not releasing any evaporating gases that would obstruct the vacuuming procedure. High-purity alumina is commonly used for these parts due to its excellent performance in such corrosive and plasma environments.

Copyright

- This material is an analysis of the paper "Automotive and industrial applications of structural ceramics in Japan" by Akira Okada.

- Source of the paper: https://doi.org/10.1016/j.jeurceramsoc.2007.09.016

- This material is for informational purposes only. Unauthorized commercial use is prohibited.

- Copyright © 2025 CASTMAN. All rights reserved.