Predicting and Preventing Skin Inclusion in Semi-Solid Casting: An LS-DYNA SPH Approach

This technical summary is based on the academic paper "Application of LS-DYNA SPH Formulation to Model Semi-Solid Metal Casting" by F. Pineau and G. D'Amours, published in the 8th European LS-DYNA Users Conference (May 2011).

Keywords

- Primary Keyword: Semi-Solid Metal Casting

- Secondary Keywords: LS-DYNA, SPH simulation, skin inclusion, die casting defects, high pressure die casting (HPDC), aluminum casting, automotive components, thixotropic flow

Executive Summary

- The Challenge: Contaminated external skin on semi-solid billets gets incorporated into the final casting during injection, causing critical defects that lead to part rejection.

- The Method: The study utilizes the Smoothed Particle Hydrodynamics (SPH) solver in LS-DYNA to model the injection phase and track the movement of the contaminated billet skin.

- The Key Breakthrough: SPH simulation effectively visualizes skin inclusion and demonstrates that a two-piece plunger design (based on the ACCURAD principle) can significantly reduce the amount of skin entering the final part compared to a standard, single-piece plunger.

- The Bottom Line: The design of the injection sleeve and plunger assembly is a critical control point for preventing skin-related defects, and SPH simulation is a powerful tool for optimizing this design.

The Challenge: Why This Research Matters for HPDC Professionals

Semi-solid metal casting is an advanced technology for producing near-net-shape parts with superior mechanical properties, making it ideal for structural automotive components. However, the process faces a critical challenge: surface contamination.

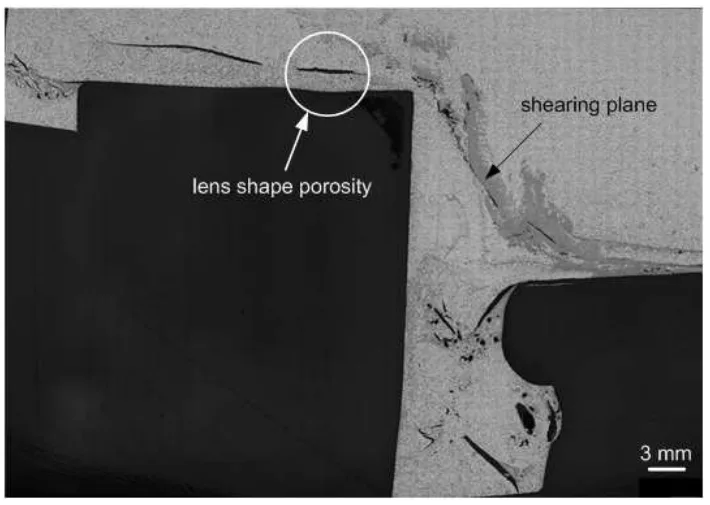

The feedstock material, a semi-solid billet, develops an external "skin" that is often contaminated with oxides from air contact and lubricants from the shot sleeve. During the high-pressure injection phase, this contaminated skin can be folded into the casting. After heat treatment, the trapped lubricant decomposes and forms "lens shape" porosities, which are detrimental to the part's structural integrity and a major cause of rejection. To improve yield and ensure component reliability, it is essential to predict and control the path of this skin during injection.

The Approach: Unpacking the Methodology

To investigate this complex flow problem, the researchers developed a simulation model using the Smoothed Particle Hydrodynamics (SPH) solver in LS-DYNA. SPH is a meshfree, particle-based method well-suited for tracking free surface flows, fragmentation, and the movement of contaminants like oxides.

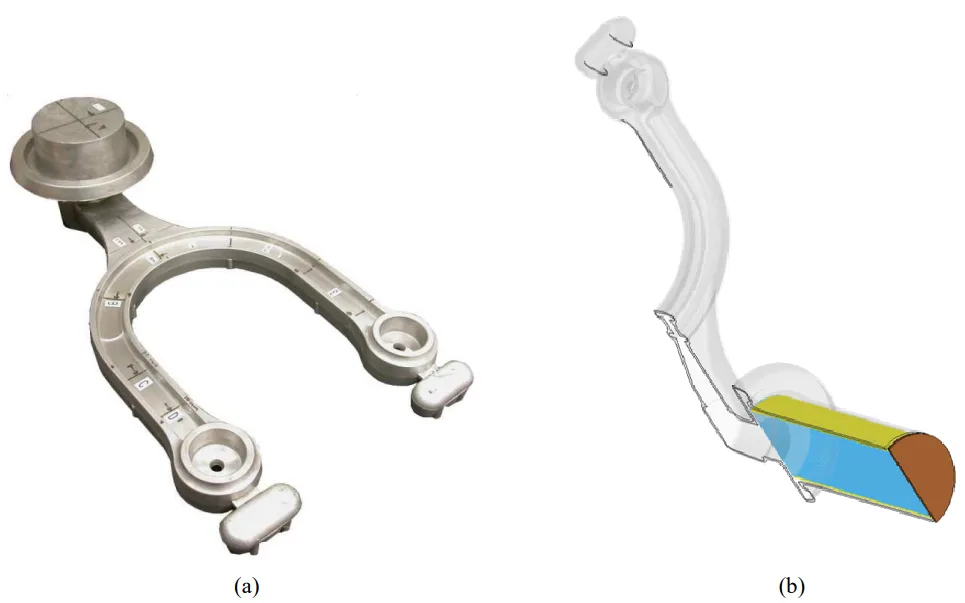

The study modeled the casting of an automotive suspension arm. The key components of the SPH model are depicted in Figure 2 and include the shot sleeve, the semi-solid billet, the plunger, and the mould contours.

Method 1: Standard Injection Process

The initial simulation (Case 1) modeled a standard injection process with a single-piece plunger. The contaminated skin on the billet was represented by yellow particles to track its movement throughout the filling sequence. The model used 123,341 SPH particles and assumed a constant dynamic viscosity of 1.0x10⁻³ MPa.ms for the semi-solid aluminum.

Method 2: Modified Injection with a Two-Piece Plunger

A second simulation (Case 2) was performed using a modified plunger based on the "ACCURAD principle." This design features a two-piece plunger tip (inner and outer). The simulation tested whether this configuration could more effectively prevent the contaminated skin from being injected into the final part.

The Breakthrough: Key Findings & Data

The SPH simulations provided clear visual evidence of how plunger design directly impacts skin inclusion.

Finding 1: Standard Plunger Pushes Contaminated Skin into the Casting

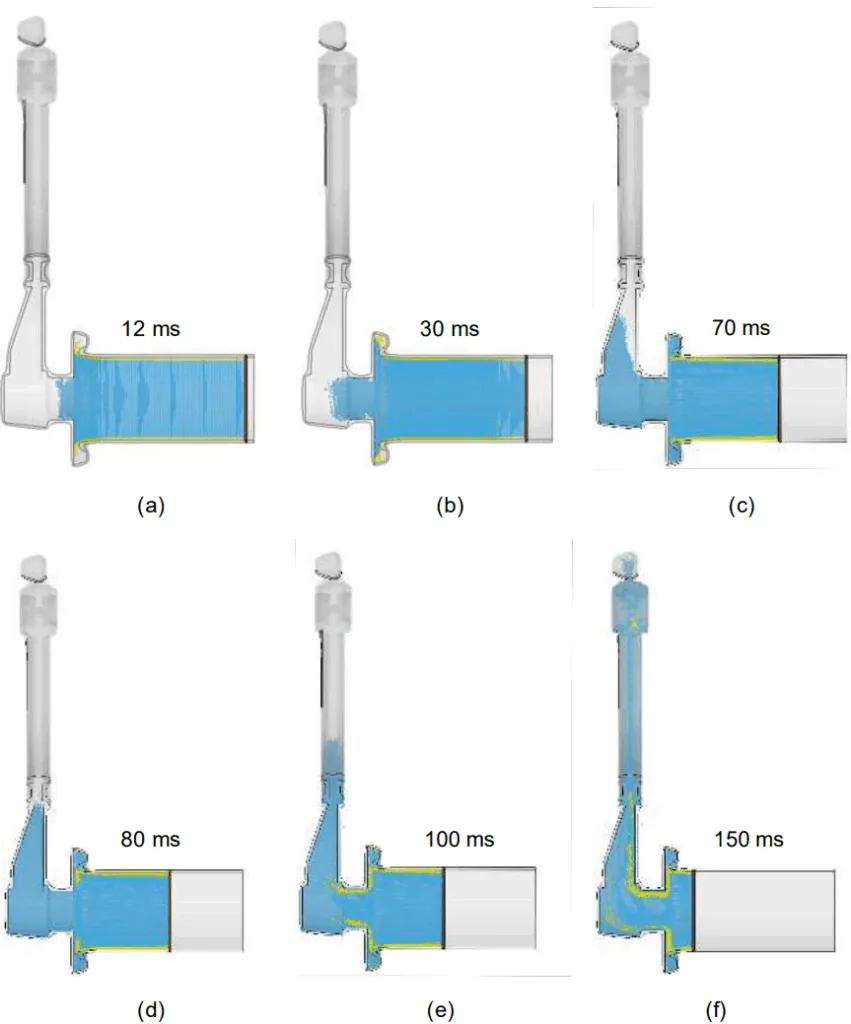

In the simulation with a standard plunger, the oxide remover device (oxide ring) initially works well to trap skin. However, as shown in Figure 3, at t=80 ms, the skin is forced inward and directed into the feeding channel. Figure 4 shows the final distribution of the skin particles at 172 ms, revealing that a significant amount of the contaminated material has been incorporated into the final cast part, creating potential defect locations. The simulation clearly shows that most skin inclusion occurs at the end of the plunger stroke.

Finding 2: Two-Piece Plunger Design Effectively Traps and Isolates Skin

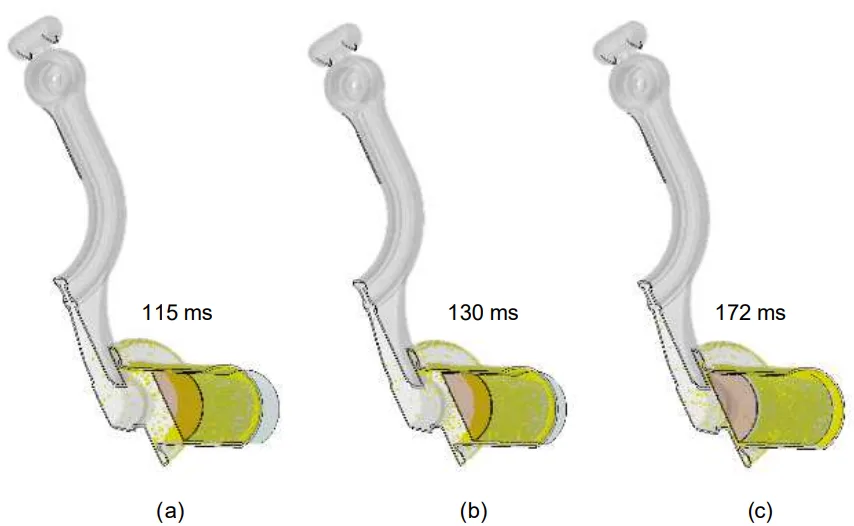

The modified injection method using a two-piece plunger, depicted in Figure 5, yielded dramatically better results. In this configuration, the outer plunger stops partway through the stroke, trapping the skin against the shot sleeve wall. The inner plunger then continues, pushing the clean, core material into the mould. As shown in Figure 6, the final skin particle distribution at 172 ms demonstrates that skin inclusion in the finished part is significantly less than in the first case. This design effectively isolates the contaminated material, preventing it from compromising the part's integrity.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that adopting a two-piece plunger system, similar to the ACCURAD principle, can be a highly effective strategy for reducing skin-related defects. Additionally, optimizing the biscuit thickness could further limit the amount of skin pushed into the casting at the end of the stroke.

- For Quality Control Teams: The data in Figure 4 and Figure 6 of the paper illustrates the predicted locations of potential skin defects based on the injection process used. This information can be used to develop more targeted and efficient quality inspection protocols for critical areas of the casting.

- For Design Engineers: The findings indicate that the design of the injection system (sleeve, plunger, and oxide traps) is as crucial as the part geometry itself for achieving high internal quality. SPH simulation provides a valuable tool for validating and optimizing these system designs before committing to expensive tooling.

Paper Details

Application of LS-DYNA SPH Formulation to Model Semi-Solid Metal Casting

1. Overview:

- Title: Application of LS-DYNA SPH Formulation to Model Semi-Solid Metal Casting

- Author: F. Pineau, G. D'Amours

- Year of publication: May 2011

- Journal/academic society of publication: 8th European LS-DYNA Users Conference, Strasbourg

- Keywords: Semi-Solid Metal Casting, SPH, LS-DYNA, Skin Inclusion, Die Casting, Simulation

2. Abstract:

Semisolid metal alloys have a special microstructure of globular grains suspended in a liquid metal matrix. This particular physical state of the matter can be exploited to produce near-net-shape parts with improved mechanical properties. Indeed, semi-solid processes take advantage of a much higher apparent viscosity of the die cast materials by limiting the risk of oxide formed on the free surfaces to become incorporated into the casting when the material is injected into the die.

Semi-solid processes that use billets as feedstock material are however tied up with an additional type of surface contamination. During the injection phase, the external-skin on the periphery of the billet, which has been in contact with air and lubricant during the transfer in the shot sleeve may be incorporated into the casting. This can be an important cause of reject for most structural parts in the automotive industry.

In order to predict and control the occurrence of skin inclusion into cast parts during the injection phase of semi-solid processes, Lagrangian methods are appropriate. Indeed, the skin, composed of contaminated or even partially solidified metal, has different mechanical properties compared to the core of semi-solid aluminum. Abitrary-Lagrangian-Eulerian formulations, which can account for the coupling between the “solid” skin and the flow of “semi-solid” aluminum are promising but still necessitate a huge amount of computer power. On the other hand, particle based Smoothed Particle Hydrodynamics (SPH) approaches are particularly well suited to this kind of flows involving complex flow behavior and solidification. These methods are able to track accurately free surface flows with fragmentation and break up as well as to follow the advection of oxides through the flow.

In this paper, a first analysis is performed in order to investigate the potential of the SPH solver of LS-DYNA to deal with the problem of skin inclusion in semi-solid die casting processes. Preliminary results show that the SPH approach is a very promising simulation tool to follow the skins during semi-solid injection casting.

3. Introduction:

Semi-solid metal processing is an attractive technology for producing near-net-shape engineering components. In these processes, aluminum alloys are injected at a temperature between liquidus and solidus, exhibiting shear-thinning behavior. This allows mould cavities to be filled progressively, reducing splashing, gas entrapment, and skin entrapment, leading to parts with low porosity and uniform microstructure suitable for heat treatment. However, the process is not without challenges. The semi-solid billets used as feedstock can form a "skin" on their surface due to contact with air (oxidation) and the container wall during preparation and transfer. When placed in the shot sleeve, this skin, which may be contaminated with lubricants, can be injected into the part, leading to undesired defects. During subsequent heat treatment, trapped lubricants decompose and create "lens shape" porosities, which are detrimental to part integrity. Therefore, a method to predict and control the paths of these skin inclusions is necessary.

4. Summary of the study:

Background of the research topic:

Semi-solid metal casting is prone to a specific defect known as skin inclusion, where the contaminated outer surface of the feedstock billet is incorporated into the final part. This compromises the mechanical integrity of structural components, particularly in the automotive industry.

Status of previous research:

Various numerical methods exist for modeling casting processes. While Eulerian approaches are useful for predicting flow fronts, they are less appropriate for tracking the thin, solid-like skin. Arbitrary Lagrangian-Eulerian (ALE) methods can model the fluid-structure interaction but are computationally very expensive. Smoothed Particle Hydrodynamics (SPH), a meshfree Lagrangian method, has been successfully used to predict oxide generation in other casting processes and is well-suited for tracking free surfaces and material advection.

Purpose of the study:

This paper performs a preliminary investigation into the potential of the SPH solver in LS-DYNA to model and track the problem of skin inclusion during the injection phase of semi-solid die casting processes.

Core study:

The study uses an SPH model to simulate the injection of a semi-solid aluminum billet for an automotive suspension arm. The model specifically tracks particles representing the billet's contaminated outer skin. Two scenarios are compared: a standard injection process with a single-piece plunger and a modified process using a two-piece plunger based on the ACCURAD principle to assess its effectiveness in preventing skin inclusion.

5. Research Methodology

Research Design:

The research employs a numerical simulation approach using the SPH formulation within the LS-DYNA software. It is a comparative study analyzing two different plunger designs to evaluate their impact on skin inclusion.

Data Collection and Analysis Methods:

The model consists of 123,341 SPH particles representing the semi-solid billet. The skin is identified by a subset of these particles (colored yellow). The simulation tracks the position of these skin particles throughout the mould filling process. The analysis is qualitative, based on the final distribution of the skin particles within the cast part for each case. The model is isothermal and uses a constant viscosity.

Research Topics and Scope:

The scope is limited to a preliminary, isothermal analysis of the injection phase of a semi-solid casting process for a single component geometry. The study focuses solely on the advection of the billet skin, assuming the skin has the same mechanical properties as the core material.

6. Key Results:

Key Results:

- The SPH simulation successfully visualized the flow of the semi-solid metal and the trajectory of the billet skin during injection.

- In the standard injection case (Case 1), the simulation showed that the skin is forced into the mould cavity, particularly during the final stage of the plunger stroke.

- The modified injection case using a two-piece plunger (Case 2) demonstrated a significant reduction in skin inclusion, as the design effectively trapped the contaminated skin within the shot sleeve.

Figure Name List:

- Figure 1: Porosity lens defects along a shearing plane

- Figure 2: Suspension arm and associated SPH model

- Figure 3: filling sequence, case 1

- Figure 4: potential “skin defect” locations as predicted by the SPH model, case 1

- Figure 5: "ACCURAD” principle oxide “preventer”

- Figure 6: potential “skin defect” locations as predicted by the SPH model, case 2

7. Conclusion:

This preliminary study demonstrates that the SPH modeling approach is a very promising tool for investigating the flow of semi-solid metal and tracking skin inclusions. The isothermal approach shows that skin inclusions can be mitigated by properly designing the injection sleeve and plunger assembly to strip the skin from the billet before it enters the injection channel. Future work should incorporate a non-Newtonian, temperature-dependent constitutive model to better approximate the complex thixotropic nature of semi-solid flows and assign distinct material properties to the skin particles. These enhanced simulation results should then be validated against real cast parts.

8. References:

- Kirkwood D.H., Suéry M., Kapranos P., Atkinson H.V. and Young K.P., Semi-solid Processing of Alloys, Springer Series in Materials Science 124, 172 р, (2010).

- Doutre D, Hay G, Wales P, Gabathuler J. P. SEED: A new process for semi solid forming. Canadian Metallurgical Quarterly, 43(2): 265-272, (2004)

- Favier V., Solid Approach- Fluid Approach: What differences?, Modelling of Semi-Solid Processing, Chapter 5, H.V. Atkinson ed. Shaker Verlag, Aachen, 105-122, (2008)

- Atkinson H.V., Modelling the semisolid processing of metallic alloys, Progress in Materials Science 50, 341-412, (2005)

- Orgeas L, Gabathuler J-P, Imwinkerlried Th, Paradies Ch, Rappaz M: Modelling of semi-solid processing using a modified temperature-dependent power-law model. Modelling Simul. Mater. Sci. Eng. 11: 553-574, (2003).

- Pineau, F and D'Amours G., Prediction of shear-related defect location in semi-solid casting using numerical flow models. Trans. Nonferrous Met. Soc. China 20: s878-s882, (2010).

- Lucy L.B., Numerical approach to testing the fission hypothesis, Astronomical Journal, 82: 1013-1024, (1977).

- Gingold R.A and Monaghan J.J., Smoothed Particle Hydrodynamics: Theory and Application to Non-spherical stars, Monthly Notices of the Royal Astronomical Society, 181: 375-389, (1977).

- Cleary P., Prakash M., Sinnott M., Grandfield J., Alguine V. and Oswald K. 3D SPH simulations of the aluminium ingot casting process, Proceedings of the Third International Conference on CFD in the Minerals and Process Industries. CSIRO, Melbourne, Australia, 409-414, December (2003)

- Prakash M., Pereira G.G., Cleary P.W., Rohan P. and Taylor J.A., Validation of SPH predictions of oxides generated during Al melt transfer. Proceedings of the seventh International Conference on CFD in the Minerals and Process Industries. CSIRO, Melbourne, Australia, 1-6, December (2009).

- Prakash M., Cleary P. and Grandfield J., Modelling of metal flow and oxidation during furnace emptying using smoothed particle hydrodynamics. Journal of Materials Processing Technology 209, 3396-3407, (2009)

- Yamashita Y., Okada H., Sakai Y. and Fukui Y., On the flow Analysis of Semi-Solid Forming of Functionally Graded Material by using Smoothed Particle Hydrodynamics Method. Nihon Kikai Gakkai Nenji Taikai Koen Ronbunshu 1, 33-34, (2006).

- Erich Röllin; Hansjörg Huber; Jean-Pierre Gabathuler. Oxide Remover. U.S. Patent 5,730,201, Mar. 24, (1998).

- Harrison P.F., Development of the Cold Chamber Pressure Die Casting Machine, Journal of the Institution of Production Engineers, Vol. 51, (9), 289-297, September (1972).

Expert Q&A: Your Top Questions Answered

Q1: Why was the SPH method chosen for this simulation over other approaches like ALE?

A1: The paper notes that while Arbitrary-Lagrangian-Eulerian (ALE) formulations are promising for this type of problem, they require a huge amount of computer power, making them computationally expensive. SPH, on the other hand, is a meshfree particle method that is particularly well-suited for modeling complex free surface flows with fragmentation and break-up. Crucially, it allows for accurate tracking of the advection of oxides and other contaminants through the flow, which was the primary goal of this study.

Q2: What were the key simplifications made in this SPH model?

A2: This was a preliminary study, so several simplifications were made. The simulation was isothermal, meaning temperature effects were not considered. The viscosity of the semi-solid material was treated as constant, whereas in reality, it is highly dependent on shear rate and temperature (a non-Newtonian, thixotropic fluid). Finally, the particles representing the "skin" were assigned the same material properties as the core aluminum, although the paper acknowledges the skin would have different properties due to contamination and partial solidification.

Q3: What is the "ACCURAD principle" and how was it applied to prevent skin defects?

A3: The ACCURAD principle, as applied here, refers to a two-piece injection plunger. In the simulation, the outer section of the plunger moves with the inner section at the beginning of the stroke. The outer plunger then stops, effectively scraping and trapping the contaminated skin against the shot sleeve wall. The inner plunger continues to move forward, pushing the clean, core material into the die cavity, thus preventing the skin from entering the final part.

Q4: How was the contaminated "skin" represented in the simulation?

A4: The skin of the billet was identified by a set of yellow-colored SPH particles on the periphery of the billet model at the start of the simulation (t=0). This allowed for clear visual tracking of the skin's movement and final location throughout the injection process. However, it is important to note that for this initial analysis, these skin particles were assigned the same material properties as the rest of the semi-solid aluminum.

Q5: What was the function of the "oxide ring" mentioned in the simulation?

A5: The oxide ring is a device located at the entrance to the feeding channel that acts as a constriction. Its purpose is to help trap the oxidized skin and lubricants from the peripheral surface of the billet as the material is pushed forward. As seen in Figure 3, it is effective initially, but can be overwhelmed toward the end of the injection stroke in a standard setup.

Conclusion: Paving the Way for Higher Quality and Productivity

Skin inclusion is a persistent challenge in Semi-Solid Metal Casting, directly impacting the quality and reliability of high-performance components. This research by Pineau and D'Amours demonstrates that Smoothed Particle Hydrodynamics (SPH) simulation is a powerful and practical tool for visualizing, understanding, and ultimately solving this problem. The key breakthrough is clear: a well-designed injection system, such as a two-piece plunger, can mechanically prevent contaminated material from entering the final part.

By leveraging predictive tools like LS-DYNA SPH, manufacturers can optimize tooling and process parameters before production, leading to reduced scrap rates, improved part integrity, and higher overall productivity.

"At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components."

Copyright Information

This content is a summary and analysis based on the paper "Application of LS-DYNA SPH Formulation to Model Semi-Solid Metal Casting" by "F. Pineau, G. D'Amours".

Source: 8th European LS-DYNA Users Conference, Strasbourg - May 2011

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.