Unlocking Performance in Recycled Aluminum: A Deep Dive into Secondary AlZn10Si8Mg Alloy Microstructure

This technical summary is based on the academic paper "CHARACTERIZATION OF PHASES IN SECONDARY AlZn10Si8Mg CAST ALLOY" by Eva Tillová, Emília Ďuriníková, and Mária Chalupová, published in Materials Engineering - Materiálové inžinierstvo (2011).

Keywords

- Primary Keyword: Secondary AlZn10Si8Mg Alloy

- Secondary Keywords: Intermetallic Phases, Aluminum Alloy Microstructure, Recycled Aluminum Casting, Mechanical Properties, Phase Characterization, HPDC Quality Control

Executive Summary

- The Challenge: Effectively using cost-saving, environmentally friendly secondary (recycled) aluminum alloys is complicated by impurities that form complex intermetallic phases, making mechanical properties difficult to predict and control.

- The Method: The study employed a combination of advanced analytical techniques—including light microscopy, scanning electron microscopy (SEM) with deep etching, EDX analysis, and microhardness testing—to comprehensively identify and characterize the phases within the alloy.

- The Key Breakthrough: The research successfully identified and mapped the specific morphologies of detrimental phases, such as brittle, needle-like iron-rich intermetallics, and quantified the extreme hardness of eutectic silicon particles, providing a clear picture of the microstructural elements that impact performance.

- The Bottom Line: A detailed understanding of the microstructure is essential for controlling the mechanical properties of secondary AlZn10Si8Mg alloy, enabling the confident use of recycled materials without compromising component quality.

The Challenge: Why This Research Matters for HPDC Professionals

The push for sustainability and cost reduction has made recycled aluminum a cornerstone of modern manufacturing. Secondary aluminum production requires only 5% of the energy and generates just 5% of the CO₂ emissions compared to primary production. However, this advantage comes with a significant technical challenge.

Recycled aluminum scrap inevitably contains a higher level of impurity elements like iron (Fe), manganese (Mn), and copper (Cu). In alloys like the secondary AlZn10Si8Mg (UNIFONT® - 90), these elements don't just dissolve; they form complex intermetallic phases during solidification. These phases, with their varying shapes, sizes, and distributions, can act as stress concentrators and crack initiation sites, significantly impacting the final component's strength, ductility, and fatigue life. For HPDC professionals, casting with secondary alloys without a deep understanding of these microstructural features is a gamble that can lead to inconsistent quality and unexpected field failures. This research addresses that knowledge gap head-on.

The Approach: Unpacking the Methodology

To achieve a comprehensive characterization of the alloy's complex microstructure, the researchers employed a multi-faceted analytical approach. This ensured that the identification of each phase was cross-validated, building a high degree of confidence in the findings.

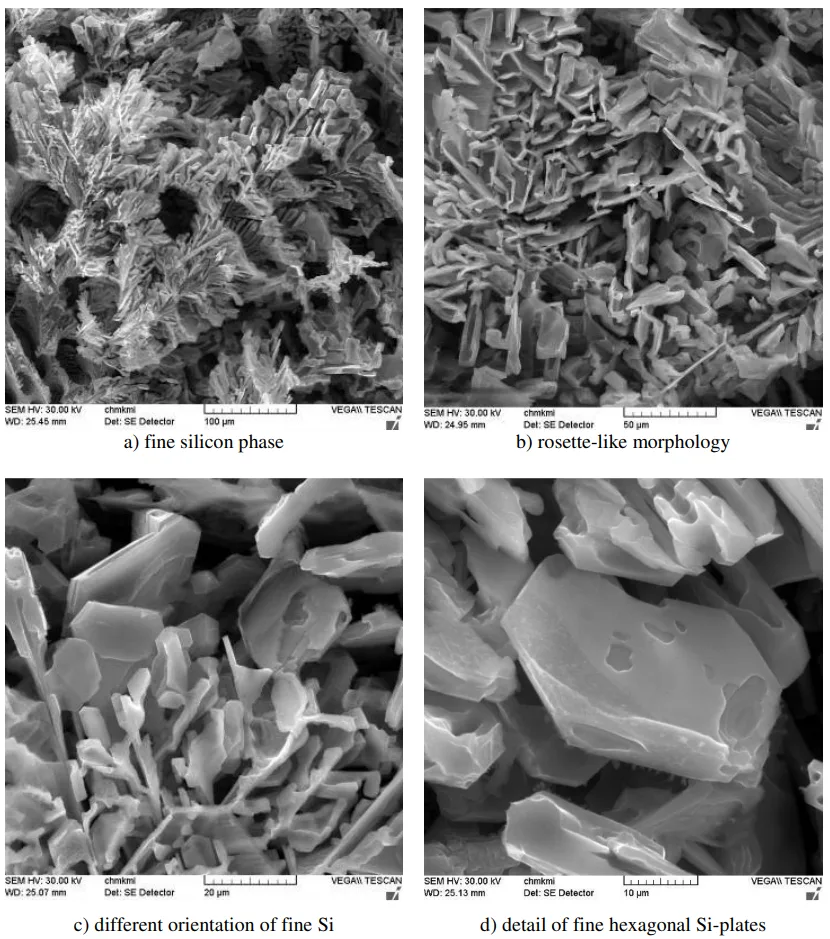

Method 1: Microscopy and Etching: Cast samples were prepared for metallographic observation. Light microscopy was used with a variety of standard and color etchants (Fuss, Dix-Keller, Murakami, etc.) to reveal the general microstructure. For a more detailed view, Scanning Electron Microscopy (SEM) was used, including a deep-etching technique with HCl solution to dissolve the aluminum matrix and reveal the three-dimensional morphology of phases like silicon.

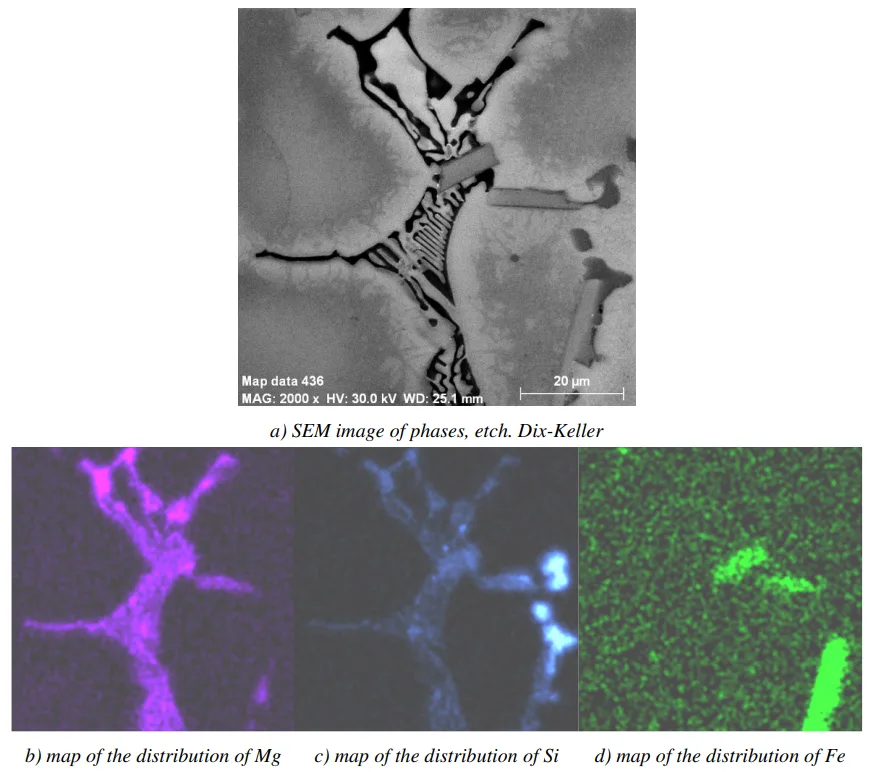

Method 2: Compositional and Hardness Analysis: Energy Dispersive X-ray analysis (EDX) was linked to the SEM to determine the precise chemical composition of each individual phase observed. This was critical for distinguishing between different complex intermetallics. Finally, Vickers microhardness testing (HV 0.01) was performed on each distinct phase to quantify its mechanical properties and understand its contribution to the alloy's overall hardness and brittleness.

The Breakthrough: Key Findings & Data

The combination of these methods yielded a detailed map of the alloy's microstructure and the properties of its constituent phases.

Finding 1: Identification of Detrimental Iron-Rich Phases

The study confirmed that iron, a common impurity, is a primary source of performance-degrading phases. These Fe-rich intermetallics appeared in two main forms:

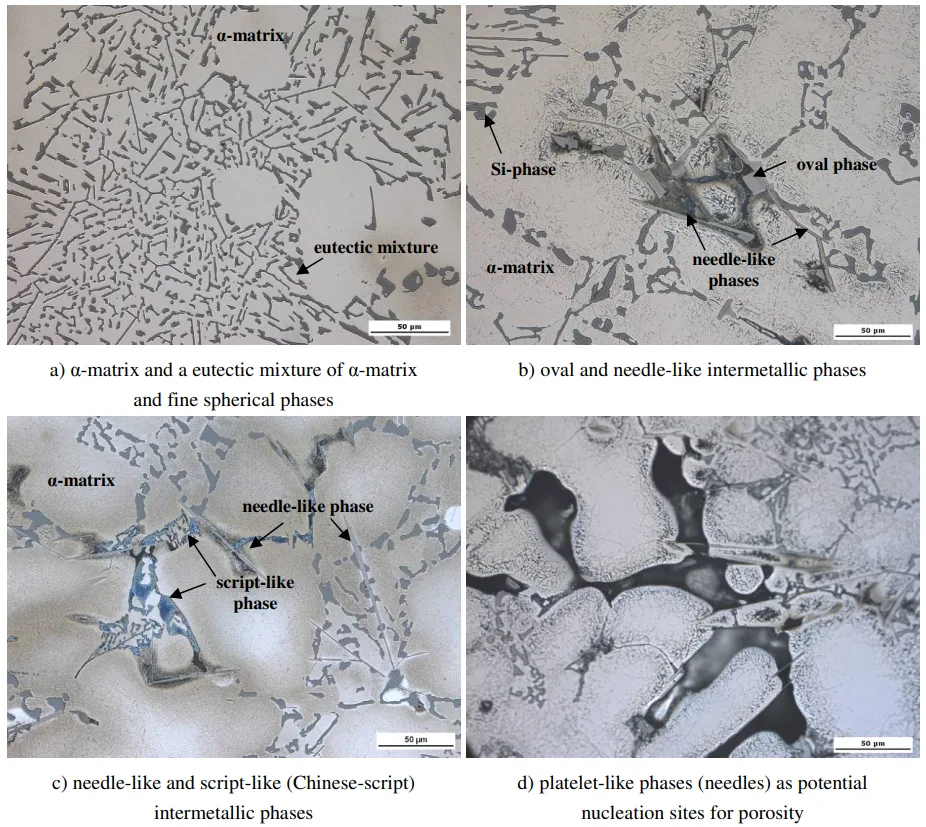

- Platelet or Needle-like Phases (AlFeMn): As shown in Figures 1b and 1c, these phases form as thin, sharp needles. Their morphology is particularly damaging as they act as powerful stress-raisers, reducing ductility and fatigue resistance. The paper notes these "Fe-needles" are also reported to reduce castability and corrosion resistance.

- Sharp-Edged Coarse Particles (AlFeMnSiNi or AlFeNi): These more compact, blocky phases were also observed. While still hard, their less acicular shape is generally considered less detrimental than the needle-like morphology.

Finding 2: Characterization of Silicon and Magnesium Phases and Their Hardness

The analysis provided crucial data on the other major secondary phases:

- Eutectic Silicon (Si): Deep etching revealed that the silicon phase has a fine, rosette-like morphology (Figure 3b) rather than a coarse, plate-like form. Crucially, microhardness testing showed this phase to be extremely hard and brittle. As detailed in Table 2, the Si-particles had a microhardness of 1124 HV 0.01, more than 12 times harder than the surrounding aluminum matrix (92 HV 0.01).

- Magnesium-Silicon (Mg₂Si): This phase was identified by its distinct "Chinese script" or skeleton-like morphology (Figure 1c) and had a significant hardness of 548 HV 0.01.

- Aluminum-Copper-Magnesium (Al₂CuMg): This S-phase was detected as oval, round-like particles with a microhardness of 426 HV 0.01.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that controlling impurity levels, particularly iron, is critical when using secondary AlZn10Si8Mg alloy. Furthermore, managing the solidification rate can influence the morphology of these Fe-rich phases, potentially shifting them from harmful needles to less damaging compact shapes.

- For Quality Control Teams: The data in Table 2 provides a quantitative baseline for phase identification via microhardness. This, combined with the morphological descriptions in Figure 1, can inform new microscopic inspection criteria to quickly assess the quality of incoming secondary alloy melts and final castings.

- For Design Engineers: The findings confirm the alloy's high strength but inherently low ductility (1-2%). The presence of hard, brittle phases like eutectic silicon and Fe-needles means that sharp corners and other stress-concentrating features in a component's design should be carefully evaluated to prevent crack initiation.

Paper Details

CHARACTERIZATION OF PHASES IN SECONDARY AlZn10Si8Mg CAST ALLOY

1. Overview:

- Title: CHARACTERIZATION OF PHASES IN SECONDARY AlZn10Si8Mg CAST ALLOY

- Author: Eva Tillová, Emília Ďuriníková, Mária Chalupová

- Year of publication: 2011

- Journal/academic society of publication: Materials Engineering - Materiálové inžinierstvo 18 (2011) 1-7

- Keywords: Aluminium alloys, Microstructure, Intermetallic phases, Microhardness

2. Abstract:

Using recycled aluminium cast alloys is profitable in many aspects. Requiring only 5 % of the energy to produce secondary metal as compared to primary metal and generates only 5 % of the green house gas emissions, the recycling of aluminium is therefore beneficial of both environmental and economical point of view. Secondary AlZn10Si8Mg (UNIFONT® - 90) cast alloy are used for engine and vehicle constructions, hydraulic unit and mouldmaking without heat treatment. Properties include good castability, very good mechanical strength and elongation, light weight, good wear resistance, low thermal expansion and very good machining. Improved mechanical properties are strongly dependent upon the morphologies, type and distribution of the secondary phases, which are in turn a function of alloy composition and cooling rate. The presence of additional elements as Mg, Mn, Fe, or Cu allows many complex intermetallic phases to form, which make characterisation non-trivial. These include, for example, Mg₂Si, Al₂CuMg and AlFeMn phases, all of which may have some solubility for additional elements. Phase's identification in aluminium alloys is often non-trivial due to the fact that some of the phases have either similar crystal structures or only subtle changes in their chemistries. A combination different analytical techniques (light microscopy upon black-white and colour etching, scanning electron microscopy (SEM) upon deep etching, energy dispersive X-ray analysis (EDX) and HV 0.01 microhardness measurement) were therefore been used for the identification of the various phase.

3. Introduction:

Aluminium is a significant light metal with excellent properties and a diversified range of applications in sectors like automotive, construction, and aerospace. The increasing demand for aluminium products has led to higher consumption of aluminium scrap for the re-production of alloys. The use of recycled (secondary) aluminium is highly advantageous, as its production requires only about 2.8 kWh/kg compared to 45 kWh/kg for primary aluminium, saving almost 95% of the energy and reducing CO₂ emissions to about 5% of primary production levels. This makes maximizing the use of recycled metal beneficial from both an energy-saving and ecological standpoint.

4. Summary of the study:

Background of the research topic:

Secondary aluminium alloys, particularly Al-Si-Zn systems, are extensively used in the automotive industry and for mechanical components due to their good castability, mechanical properties, and wear resistance. However, a major hurdle in their application is the level of impurities, which can impair the overall properties. The mechanical and microstructural properties are dependent on composition, melt treatment, solidification rate, and thermal treatment.

Status of previous research:

The properties of Al-Si and Al-Zn-Si alloys are known to depend on Si, Zn, Mg, and Fe content, as well as the shape and distribution of silicon particles. The presence of additional elements leads to the formation of complex binary, ternary, and quaternary intermetallic phases such as Mg₂Si, Al₂Cu, Al₂CuMg, Al₅FeSi, and α-Al₁₅(FeMn)₃Si₂, which makes phase identification non-trivial.

Purpose of the study:

The study is part of a larger research project aimed at investigating and providing a better understanding of the morphology and composition of complex microstructures containing intermetallic phases that form in a secondary (recycled) aluminium cast alloy.

Core study:

The research focuses on the characterization of phases in an as-cast, unmodified secondary AlZn10Si8Mg (UNIFONT® - 90) alloy. This alloy was produced via sand casting. The study systematically identifies the various phases present, including the α-matrix, eutectic silicon, and intermetallics formed from impurity elements (Fe, Mn, Cu) and alloying elements (Mg), and characterizes their morphology, composition, and microhardness.

5. Research Methodology

Research Design:

The study employed an observational and analytical research design to characterize the microstructure of a commercially available secondary cast aluminum alloy. Samples were sectioned from test bars (ø 20 mm) produced by sand casting.

Data Collection and Analysis Methods:

A combination of analytical techniques was used for phase identification and characterization:

- Metallography: Samples were prepared using standard procedures (wet grinding, polishing) and examined with an optical microscope (Neophot 32). Various etchants (HF, Fuss, Dix-Keller, H₂SO₄, MA, Weck-Al, Murakami) were used to reveal different phases.

- Scanning Electron Microscopy (SEM): A VEGA LMU II SEM was used for high-magnification imaging. Some samples were deep-etched for 30s in HCl to reveal the 3D morphology of the silicon phase.

- Energy Dispersive X-ray Spectroscopy (EDX): An EDX analyser (Brucker Quantax) linked to the SEM was used to determine the elemental composition of the observed phases.

- Microhardness Measurement: A MHT-1 microhardness tester was used to measure the Vickers microhardness (HV 0.01) of individual phases under a 1 g load for 10 s.

Research Topics and Scope:

The scope of the research was to identify the types, morphologies, distribution, chemical composition, and microhardness of the various phases present in the as-cast secondary AlZn10Si8Mg alloy.

6. Key Results:

Key Results:

- The microstructure of the as-cast alloy consists of a primary α-solid solution (Al-Zn dendrites), an eutectic mixture of α-matrix and fine spherical phases (silicon), and various intermetallic phases.

- Fe-containing intermetallics, such as AlFeMn phases, form as plate-like needles between the α-dendrites. These are considered deleterious to mechanical properties. Other Fe-rich phases (AlFeMnSiNi or AlFeNi) were observed as sharp-edged coarse particles.

- Mg-containing phases were identified as Mg₂Si, with a "Chinese script" morphology, and S-phase (Al₂CuMg), with an oval, round-like morphology.

- EDX analysis confirmed the spherical phases in the eutectic are silicon. SEM of deep-etched samples showed the eutectic silicon has a fine and rosette-like morphology, not a plate-like form.

- Microhardness measurements (Table 2) showed eutectic silicon to be the hardest phase (1124 HV 0.01), followed by the needle-like AlFeMn phase (950 HV 0.01). The α-matrix was the softest (92 HV 0.01).

Figure Name List:

- Fig. 1. Microstructure of AlZn10Si8Mg cast alloy, etch. Fuss (full colour version available online)

- Fig. 2. EDX phase analysis (full colour version available online)

- Fig. 3. Morphology of Si particles, deep-etch. HCl, SEM

7. Conclusion:

The secondary AlZn10Si8Mg cast alloy possesses a complex as-cast microstructure. Microstructural analysis revealed that all alloying elements studied, except for Zn which is in solid solution, form intermetallic phases. Fe enters intermetallic phases, with Mn and Ni often substituting for Fe. Mg forms phases with Si (Mg₂Si, skeleton-like) or Cu. Cu makes the intermetallic phases more compact. Si is present in a typical fine rosette-like brittle form with the highest microhardness. All Fe-rich phases were found to be very hard and brittle, independent of their morphology.

8. References:

- [1] M. Mahfoud, A.K. Prasada Rao, D. Emadi: J Therm Anal Calorim 100 (2010) 847-851

- [2] K.S. Das: Mater. Sci. Forum 519-521 (2006) 1239-1244

- [3] L. Senčáková, E. Virčíková: Acta Metallurgica Slovaca 13(3) (2007) 412-419

- [4] K.S. Das, J.A.S. Gren: JOM 62(2) (2010) 27-31

- [5] Casting material - www.sag.at

- [6] S. Seifeddine: The influence of Fe on the microstructure and mechanical properties of cast Al-Si alloys. Literature review - Vilmer project. Jönköping University, Sweden (2007).

- [7] E. Tillová, M. Panušková: Mettalurgija 47(3) (2008) 207-210

- [8] E. Tillová, M. Panušková: Materials Engineering - Materiálové inžinierstvo 14(2) (2007) 73-76

- [9] X. Cao, J. Campbell: Metall. Mater. Trans. A35 (2004) 1425-1435

- [10] S.G. Shabestari: Mater. Sci. & Eng. A 383 (2004) 289-298

- [11] www.alurheinfelden.com

- [12] G. Trenda: Druckguss-Praxis 5 (2005) 191-194

- [13] E. Tillová, M. Chalupová: Štruktúrna analýza zliatin Al-Si. EDIS, Žilina 2009 (in Slovak)

- [14] E. Weck, Ε. Leistner: Metallographic Instructions for Colour Etching by Immersion. Part III, Deutscher Verlag für Schweisstechnik-GmbH, Düsseldorf 1986

- [15] Μ. Warmuzek: In: ASM Handbook: Metallography and Microstructures, Vol 9, Ed: G. Vander Voort, ASM International 2004, pp. 711-751

- [16] E. Tillová, M. Chalupová: Acta metallurgica Slovaca (2004) 847-849

- [17] E. Tillová, M. Chalupová, R. Konečná: Materiálové inžinierstvo 7(1) (2000) 61-68 (in Slovak)

- [18] E. Tillová, R. Konečná, M. Chalupová: Materiálové inžinierstvo 10(3) (2003) 331-334 (in Slovak).

- [19] D. Apelian: Aluminum Cast alloys. NADCA 2009.

- [20] L. Lu, A.K. Dahle: Metall. Mater. Trans A36 (2005) 819-835

- [21] A. Vaško, J. Belan: In: Improvement of Quality Regarding processes and Materials, Warszawa 2007, pp. 53-58

- [22] Μ. Martinkovič: Kvantitatívna analýza štruktúry materiálov. STU, Bratislava 2010 (in Slovak)

- [23] X. Chen, S. Engler: Z. Metallkunde 81(6) (1990) 412-418

Expert Q&A: Your Top Questions Answered

Q1: Why is iron (Fe) such a critical impurity to control in this secondary alloy?

A1: According to the paper, iron has low solubility in aluminum and readily forms various Fe-rich intermetallic phases during solidification. The study identified these phases as having a plate-like or needle-like morphology (Figure 1b), which act as significant stress raisers and are considered "most deleterious to mechanical properties (particularly ductility)." They can also serve as nucleation sites for porosity, further compromising the integrity of the casting.

Q2: What is the significance of the "Chinese script" morphology of the Mg₂Si phase?

A2: The "Chinese script" or skeleton-like morphology is the characteristic form in which the Mg₂Si phase solidifies in this type of alloy. The paper identifies this phase (Figure 1c) as one of the primary ways magnesium, an intentional alloying element, manifests in the microstructure. Its interconnected, script-like shape influences the fracture path and overall mechanical behavior of the material. With a high microhardness of 548 HV 0.01, it contributes significantly to the alloy's strength but also its brittleness.

Q3: How does the microhardness data in Table 2 help in practical quality control?

A3: The microhardness data provides a quantitative "fingerprint" for each phase. For example, the extreme hardness of silicon particles (1124 HV) confirms their brittle nature, while the high hardness of Fe-needles (950 HV) explains why they are so detrimental. A quality control lab could use microhardness testing on a sample casting to quickly verify the presence and identity of these phases, correlating the findings with the overall mechanical properties of the batch to ensure it meets specifications.

Q4: The paper mentions the AlZn10Si8Mg alloy is "self-hardening." What does this mean?

A4: The paper states this is a self-hardening alloy where "mechanical properties are achieved after storage of approximately 7 to 10 days at room temperature." This implies that the alloy undergoes natural aging. After casting, elements like Mg and Zn that are in solid solution in the aluminum matrix begin to precipitate out over time, forming very fine, strengthening precipitates. This process increases the alloy's strength and hardness without the need for a separate, energy-intensive heat treatment.

Q5: Why was it necessary to use a combination of so many different analytical techniques?

A5: The paper explains that phase identification in complex aluminum alloys is "often non-trivial due to the fact that some of the phases have either similar crystal structures or only subtle changes in their chemistries." No single technique is sufficient. Light microscopy with various etchants provided an initial overview, SEM gave high-resolution morphological detail, EDX provided the critical chemical composition to differentiate phases like AlFeMn from Mg₂Si, and microhardness testing confirmed the mechanical identity of each phase. This combined approach was essential for an unambiguous and comprehensive characterization.

Conclusion: Paving the Way for Higher Quality and Productivity

The challenge of using recycled materials is not their availability, but the technical difficulty in ensuring consistent quality. This research provides a clear and actionable roadmap for understanding the complex microstructure of Secondary AlZn10Si8Mg Alloy. By identifying the specific forms of detrimental intermetallic phases and quantifying the properties of each micro-constituent, the study empowers engineers to make more informed decisions about process control, quality assurance, and material selection. Mastering the microstructure is the key to unlocking the full economic and environmental potential of recycled aluminum.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components.

Copyright Information

This content is a summary and analysis based on the paper "CHARACTERIZATION OF PHASES IN SECONDARY AlZn10Si8Mg CAST ALLOY" by "Eva Tillová, Emília Ďuriníková, Mária Chalupová".

Source: http://fstroj.uniza.sk/PDF/2011/01-2011.pdf

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.