Mastering ADC-12 Alloy: A Practical Guide to HPDC Defect Analysis and Remedies

This technical summary is based on the academic paper ""Defect analysis and remedies in the High Pressure Diecasting Process with ADC-12 Alloy”. – A Technical review." by R.Govindarao, Dr.K.Eshwara Prasad(Rted), and P Srinivasa Rao, published in American Journal of Multidisciplinary Research & Development (AJMRD) (2022).

Keywords

- Primary Keyword: HPDC Defect Analysis

- Secondary Keywords: ADC-12 Alloy, Casting Defects, Cold Shut, Shrinkage Porosity, Blow Hole, Die Casting Process, High Pressure Die Casting

Executive Summary

- The Challenge: Automotive suppliers using the HPDC process for lightweight ADC-12 aluminum components face significant casting defects, leading to high rejection rates and reduced productivity.

- The Method: The paper provides a systematic technical review, classifying common HPDC defects into surface and internal categories and identifying specific root causes related to the die, process, machine, material, and operator.

- The Key Breakthrough: The research delivers a comprehensive set of actionable remedies for critical defects like cold shut, cracks, and shrinkage porosity by defining precise control parameters for metal temperature, injection velocity, die temperature, and material composition.

- The Bottom Line: By systematically implementing the identified remedies, diecasters can significantly reduce scrap rates from the typical 3-5% range, directly boosting Overall Equipment Effectiveness (OEE) and meeting stringent OEM quality demands.

The Challenge: Why This Research Matters for HPDC Professionals

In today's automotive industry, the drive for lightweighting has made High Pressure Die Casting (HPDC) with aluminum alloys like ADC-12 a vital manufacturing process. However, this shift comes with a significant challenge: a higher incidence of casting defects. As the paper highlights, suppliers are frequently encountering both external and internal abnormalities in their components. These defects, ranging from visible cold shuts to hidden internal porosity, lead to higher rejection rates, production delays, and ultimately, a negative impact on profitability. This research is critical because it moves beyond simply identifying defects and provides a structured framework for diagnosing and resolving the root causes, a problem every HPDC professional faces.

The Approach: Unpacking the Methodology

The authors conducted a thorough technical review to classify and analyze defects inherent to the HPDC process. The methodology is rooted in a systematic, cause-and-effect approach rather than a single experiment.

Method 1: Defect Classification: The study first categorizes all potential issues into two primary groups:

1. Surface (Visual) Defects: Issues that can be identified visually on the casting's surface, such as cold shut, cracks, unfilling, blisters, and soldering.

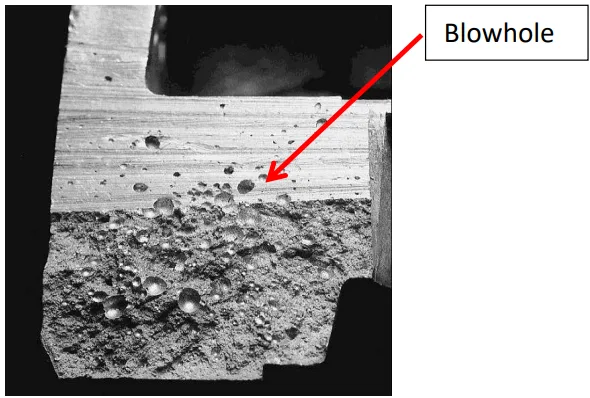

2. Internal Defects: Flaws found after machining or sectioning, including blow holes, shrinkage porosity, and inclusions.

Method 2: Root Cause Analysis by Parameter: For each identified defect, the research attributes the root causes to five distinct operational areas:

* Die: Issues related to the tool itself, like blocked vents, water leaks, or insufficient draft angles.

* Process: Variables within the casting cycle, such as metal temperature, die spray duration, and shot speed.

* Machine: Parameters of the die casting machine, including injection pressure, platen alignment, and accumulator pressure.

* Material: The composition of the ADC-12 alloy, including silicon (Si) and iron (Fe) content, and die coat dilution.

* Man (Operator): Factors related to operator actions, like inconsistent cycle times or improper spray application.

This structured approach allows engineers to methodically troubleshoot problems by isolating the most likely contributing factors.

The Breakthrough: Key Findings & Data

The paper provides detailed, actionable remedies for a wide range of defects. Below are two of the most critical findings.

Finding 1: A Clear Strategy to Eliminate Cold Shut

Cold shut, a predominant surface defect, is caused by the premature solidification of two metal fronts before they fuse. The paper provides precise parameters to prevent this. For example, in Table 1, the authors recommend:

* Process Control: Maintain metal temperature between 660°C - 680°C and die temperature between 180°C - 220°C after spray. A fast shot speed of 3.5 m/sec – 4.5 m/sec is critical to ensure the cavity fills before the metal cools.

* Material Control: The silicon (Si) content in the ADC-12 alloy must be verified to be within the 9.0% - 12.0% range to ensure proper fluidity.

* Die Maintenance: Ensure overflows and vents are open and correct any water leakages into the die cavity.

Finding 2: Mitigating Internal Shrinkage Porosity

Shrinkage porosity, an internal defect that weakens the component, forms during solidification due to density changes. The paper outlines specific machine and process settings to combat this. As detailed for Shrinkage Porosity:

* Machine Parameters: Maintain a Specific Injection Pressure of 600 kg/cm² - 850 kg/cm² and an intensification pressure greater than 250 kg/cm². This high pressure feeds molten metal into solidifying areas, compensating for shrinkage.

* Process Design: The runner location should be strategically designed to be parallel to the defect location, ensuring proper metal feed to vulnerable areas. Increasing gate thickness by 30% can also improve metal flow.

* Die Venting: Sufficient die venting is crucial to allow trapped gases to escape, which can otherwise contribute to porosity.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that adjusting key process parameters like metal temperature (660°C-680°C), fast shot speed (3.5-4.5 m/sec), and intensification pressure (>250 kg/cm²) may contribute to significantly reducing defects like cold shut and shrinkage porosity.

- For Quality Control Teams: The data in the paper, such as the definition of a blow hole as porosity with a diameter greater than 0.4mm, can be used to establish or refine internal quality inspection criteria for both visual and post-machining checks.

- For Design Engineers: The findings indicate that die design features like overflow volume (recommendation to increase by 20% for unfilling issues), runner design (parallel to defect areas), and draft angles (1-2 degrees for cracks) directly influence defect formation, making these critical considerations in the early design phase.

Paper Details

"Defect analysis and remedies in the High Pressure Diecasting Process with ADC-12 Alloy”. – A Technical review.

1. Overview:

- Title: "Defect analysis and remedies in the High Pressure Diecasting Process with ADC-12 Alloy”. – A Technical review.

- Author: R.Govindarao, Dr.K.Eshwara Prasad(Rted), P Srinivasa Rao

- Year of publication: 2022

- Journal/academic society of publication: American Journal of Multidisciplinary Research & Development (AJMRD)

- Keywords: HPDC Process, internal defects, external defects

2. Abstract:

In the present automotive supply chain the suppliers are facing the more diecasting defects. Most ofthe automotive manufacturers are changing the products from heavy weight components to lower weight likealuminum. The High pressure diecasting (HPDC) process is the most vital engineering process in which thecomponents are produced with low weight and high productivity. During this process the components foundwith more abnormalities as casting defects in both internal and external .This paper is presenting to avoid suchtype of defects in the HPDC process.

3. Introduction:

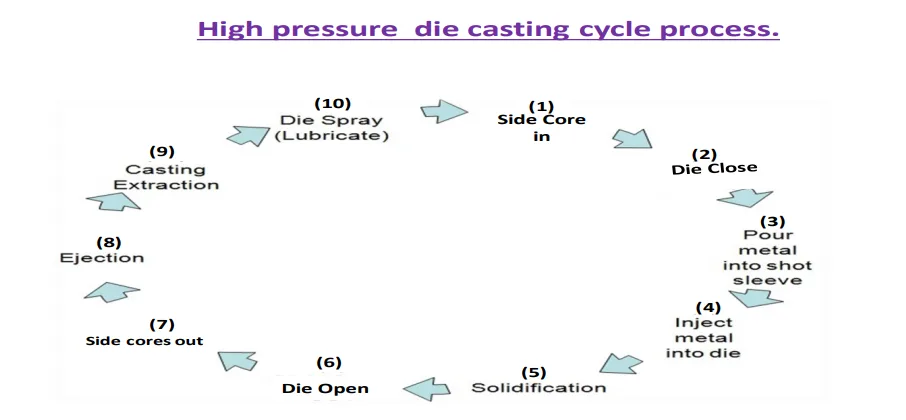

The High Pressure Die Casting (HPDC) process utilizes a horizontal diecasting machine, a mould, and a holding furnace. Molten metal is transferred to a shot sleeve chamber via an autoladle. The injection system propels the metal into the mould at high velocity (2 m/sec – 4.5 m/sec) and high pressure (600kg/cm² to 800600kg/cm²). The metal fills the mould and solidifies for a duration dependent on the casting's wall thickness (4 to 15 seconds). The casting is then ejected. To cool the mould and facilitate the release of subsequent castings, a chemical solution (water mixed with coolant in a 1:200 ratio) is sprayed onto the die halves. This cycle is then repeated.

4. Summary of the study:

Background of the research topic:

The study is set against the backdrop of the automotive industry's shift towards lightweight components, primarily using aluminum. This has elevated the importance of the High Pressure Die Casting (HPDC) process. However, this process is prone to producing components with a variety of casting defects, both internal and external, which negatively impacts productivity and quality for automotive suppliers.

Status of previous research:

The paper does not provide a literature review of previous studies but presents itself as a technical review compiled by an "experienced research scholar." It consolidates established knowledge and practical experience into a structured guide for identifying and remedying common defects, suggesting a focus on practical application over novel theoretical research.

Purpose of the study:

The primary purpose of this paper is to present a systematic analysis of major defects occurring in the HPDC process with ADC-12 alloy. It aims to provide clear, actionable remedies for these defects to help diecasters avoid them, thereby reducing rejection rates and improving the overall quality and efficiency of the manufacturing process.

Core study:

The core of the study is a detailed classification and analysis of diecasting defects. Defects are divided into two main categories: surface defects (e.g., cold shut, crack, unfilling, blister, soldering) and internal defects (e.g., blow hole, shrinkage porosity, inclusion). For each specific defect, the paper identifies a list of potential root causes categorized by their origin: Die, Process, Machine, Material, and Man (operator). Following the root cause analysis, a corresponding list of specific remedies is provided, offering concrete parameter adjustments and procedural changes to resolve the issue.

5. Research Methodology

Research Design:

The research design is a descriptive technical review. It employs a systematic classification framework to organize diecasting defects and uses a root cause analysis methodology to link these defects to specific process parameters and operational factors. The study's structure is that of a practical troubleshooting guide.

Data Collection and Analysis Methods:

The information presented is qualitative and appears to be collected from industry experience and established diecasting principles. The analysis is presented in tabular format, correlating defects with their respective root causes and remedies. The data consists of recommended operational ranges for process parameters (e.g., temperatures, pressures, speeds) and best practices for machine setup, die maintenance, and material control.

Research Topics and Scope:

The scope of the research is focused specifically on the High Pressure Die Casting (HPDC) process using ADC-12 aluminum alloy, which is common in the automotive industry. The research topic covers the identification, root cause analysis, and remediation of common external (surface) and internal casting defects.

6. Key Results:

Key Results:

- The study successfully categorizes HPDC defects into surface and internal types and provides a comprehensive troubleshooting guide.

- For surface defects like Cold Shut, key remedies include maintaining metal temperature between 660°C-680°C, ensuring a fast shot speed of 3.5-4.5 m/sec, and verifying silicon content is 9.0%-12.0%.

- For Cracks, remedies focus on optimizing ejection force, ensuring proper machine platen alignment (<0.3mm), and providing sufficient die coat spray.

- For Unfilling, the paper recommends maintaining specific injection pressure (600-850 kg/cm²), increasing overflow volume by 20%, and ensuring proper runner design.

- For internal defects like Shrinkage Porosity, critical remedies involve maintaining high intensification pressure (>250 kg/cm²), providing spot cooling at problematic areas, and increasing gate thickness.

- For Blow Holes, the study suggests using a degassing process, maintaining a filling ratio between 50%-70%, and ensuring sufficient die venting.

- The paper concludes that these defects contribute to a rejection rate of 3% to 5% and that addressing them is key to improving Overall Equipment Effectiveness (OEE).

Figure Name List:

- High pressure die casting cycle process.

- Cold shut

- Crack

- Unfilling

- Blister

- Soldering

- Shrinkage

- Blowhole

7. Conclusion:

Diecasters currently face significant challenges with defects such as nonfilling, cold shuts, and internal flaws like blow holes and shrinkage porosity, resulting in rejection rates of 3% to 5%. These defects arise from a combination of tool, machine, and process factors. Internal defects are particularly problematic as they are only discovered after machining, affecting final product quality. The analysis provided is highly useful for diecasters to reduce scrap rates. By reducing defects, the company's profit margin will increase. Furthermore, improving the quality rating directly enhances the Overall Equipment Effectiveness (OEE), a vital metric for achieving world-class manufacturing status, which is a requirement from major OEMs.

8. References:

- [1] Astari Indarsari, Characteristics of Aluminum ADC 12/Sic Composite with the Addition of TiB and Sr Modifier, E3S Web of Conferences 130, 01004 (2019), PP: 1-8

- [2] Abhishek J. Sonawaneet al, Hydraulic DieCasting Using Automation, International Journal of Advanced Research in Electrical, Electronics and Instrumentation Engineering (IJAREEIE) e-ISSN: 2278 – 8875, P-ISSN: 2320 – 3765, Volume 10, Issue 4, April 2021, PP 1227-1229

- [3] Emil Ragan, Marta Kollarova, "Calculation of Transient Haracterostics in Mould cavity, International journal of Engineering”, Tome IX (Year 2011). Fascicule 3. ISSN 1584 – 2673 Page: 1-2

- [4] Rahul T Patilet al, Causes of Casting Defects with Remedies, International Journal of Engineering Research & Technology (IJERT) ISSN: 2278-0181 IJERTV4IS110511 Vol. 4 Issue 11, November-2015,PP:642

- [5] Hassan A. Abdulhadi et al Thermal Fatigue Of Die-Casting Dies: An Overview, MATEC Web of Conferences 74, 00032 (2016) DOI: 10.1051/matecconf/20167400032,PP:1-3

- [6] Prachi K. Tawele, and Laukik P. Raut, Warpage in casting: A Review, ISSN (O):2393-9877, ISSN (P): 2394-2444, Volume 2, Issue 4, April- 2015 PP: 2-3

- [7] Anilchandra and R. Adamane,Influence of Injection Parameters on the Porosity and Tensile Properties of High-Pressure Die Cast Al-Si Alloys: A Review, Article in International Journal of Metal casting, March 2015 PP: 44-47

- [8] Rahul T Patil et al, Causes of Casting Defects with Remedies, International Journal of Engineering Research & Technology (IJERT) ISSN: 2278-0181 IJERTV4IS110511 Vol. 4 Issue 11, November-2015, PP: 642

- [9] Radhika Chavan and P S Kulkarni, Die design and optimization of cooling channel position for cold chamber high pressure die casting machine, IOP Conf. Series: Materials Science and Engineering 810 (2020) 012017 IOP Publishing doi:10.1088/1757-899X/810/1/012017ICEMEM-2019,PP: 2-4

- [10] Radka Podprocká and Dana Bolibruchová Defects in High Pressure Die Casting Process, Article in Manufacturing Technology, September 2015, DOI: 10.21062/ujep/x.2015/a/1213-2489/MT/15/4/674,PP675-676.

- [11] Vaibhav Ingle, Madhukar Sorte, Defects, Root Causes in Casting Process and Their Remedies: Review, Int. Journal of Engineering Research and Application. ISSN: 2248-9622, Vol. 7, Issue 3, (Part -3) March 2017, PP: 47-54.

- [12] Geoffrey K. Sigworth, Fundamentals of Solidification in Aluminum Castings, Copyright 2013 American Foundry Society, PP: 1-13

- [13] Sebastian Kohlstädtet al, On Determining the Critical Velocity in the Shot Sleeve of a High-Pressure Die Casting Machine Using Open Source CFD, Fluids 2021, MPDI, PP: 2-3

- [14] Vaibhav Ingle and Madhukar Sorte, Defects, Root Causes in Casting Process and Their Remedies: Review, Int. Journal of Engineering Research and Application, ISSN: 2248-9622, Vol. 7, Issue 3, (Part -3) March 2017, PP: 47-54

- [15] Stefan Gaspár et al, Analysis of Causes of Porosity Change of Castings under the Influence of Variable Biscuit Height in the Filling Chamber, Materials 14, no. 22: 6827. https://doi.org/10.3390/ma14226827,MPDI, PP: 1-12

- [17] EWAN LORDANet al, Effective Degassing for Reduced Variability in High-Pressure Die Casting Performance,C@2108 The Minerals, Metals & Materials Society,2018,PP : 1-7

Expert Q&A: Your Top Questions Answered

Q1: The paper mentions both "Constant" and "Variable" parameters. Why is it important for an engineer to focus on the variable ones?

A1: The paper states that Constant parameters belong to the tool/die and machine, which are generally fixed. Variable parameters, however, change due to mechanical, electrical, and frictional losses during production. To reduce defects effectively, the focus must be on controlling these variable parameters (like metal temperature, injection speed, and spray time), as they are the most common source of day-to-day process abnormalities.

Q2: For the "Cold Shut" defect, what is the single most critical process parameter to control according to the paper?

A2: While several factors contribute, the paper strongly emphasizes controlling temperature and speed. Specifically, it recommends maintaining a metal temperature between 660°C - 680°C and a fast shot speed between 3.5 m/sec and 4.5 m/sec. This combination ensures the molten metal flows quickly and fuses properly before it begins to solidify within the die cavity.

Q3: The paper recommends a specific silicon (Si) content of 9.0% - 12.0% for the ADC-12 alloy. Why is this important for preventing defects?

A3: Silicon content is critical for the fluidity of the aluminum alloy. As indicated in the remedies for "Cold Shut," a low Si content (below 9.0%) reduces the metal's ability to flow easily and fill thin sections of the die. Verifying that the Si content is within the correct range is a key material-related remedy to prevent flow-related defects like cold shuts and unfilling.

Q4: How does the paper suggest managing internal defects like "Shrinkage Porosity," which are not visible externally?

A4: The paper stresses the importance of pressure and feed. The key remedies for shrinkage porosity are to maintain a high Specific Injection Pressure (600-850 kg/cm²) and, crucially, a high intensification pressure (over 250 kg/cm²). This final pressure surge compacts the metal during solidification, feeding molten alloy into areas that are shrinking to prevent voids from forming internally.

Q5: What is the recommended filling rate to avoid defects like "Blister"?

A5: To prevent blisters, which are caused by trapped gas expanding under the surface of a hot casting, the paper recommends a very fast filling time. The remedy states the filling rate should be less than 40 milliseconds, depending on the casting geometry. A rapid fill minimizes the time for gas to be generated and trapped during the injection process.

Q6: The paper links Overall Equipment Effectiveness (OEE) to quality. How does reducing defects directly impact OEE?

A6: The paper states that OEE is a multiplication of Availability (A), Performance (P), and Quality (Q). The quality rating (Q) is a direct measure of the number of good parts produced versus the total parts made. By reducing the defect rate from 3-5% to a lower number, the quality rating (Q) increases, which directly multiplies through the OEE calculation (A x P x Q), boosting the overall line efficiency.

Conclusion: Paving the Way for Higher Quality and Productivity

The challenge of minimizing defects in aluminum components is a constant battle in the HPDC industry. This technical review provides a clear and actionable roadmap for HPDC Defect Analysis, demonstrating that a systematic, parameter-driven approach is the key to success. By meticulously controlling variables in the die, process, and machine, manufacturers can overcome common issues like cold shuts and porosity, drastically reducing scrap and rework. These insights are not just theoretical; they are practical steps that can be implemented on the shop floor to boost quality, increase throughput, and improve the bottom line.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components.

Copyright Information

This content is a summary and analysis based on the paper ""Defect analysis and remedies in the High Pressure Diecasting Process with ADC-12 Alloy”. – A Technical review." by "R.Govindarao, Dr.K.Eshwara Prasad(Rted), and P Srinivasa Rao".

Source: https://www.ajmrd.com/wp-content/uploads/2022/07/A470108.pdf

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.