Unlocking A356 Alloy Performance: How Yttrium Addition Refines Microstructure for Superior Castings

This technical summary is based on the academic paper "Effect of Yttrium on the Microstructure of Gravity Die Cast A356 Alloy" by Ying Pio Lim and Wei Hong Yeo, published in Proceedings of the World Congress on Mechanical, Chemical, and Material Engineering (MCM 2015) (2015).

Keywords

- Primary Keyword: A356 Alloy

- Secondary Keywords: Yttrium, gravity die casting, grain refinement, eutectic phase, microstructure, aluminum-silicon alloys

Executive Summary

- The Challenge: The as-cast A356 alloy often suffers from a coarse microstructure and needle-like silicon phases, which lead to poor mechanical properties like low strength and ductility.

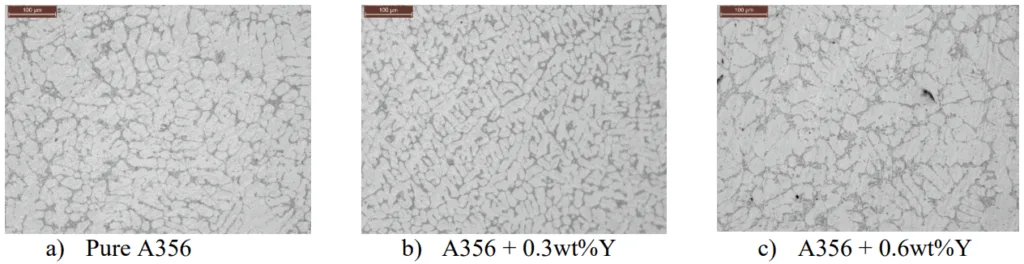

- The Method: Researchers added 0.3 wt% and 0.6 wt% of yttrium to A356 alloy using a gravity die casting process and analyzed the resulting microstructures with optical and scanning electron microscopy.

- The Key Breakthrough: The addition of 0.3 wt% yttrium was identified as the optimal level to significantly refine the primary aluminum grains and transform the coarse eutectic silicon into a finer, more fibrous structure.

- The Bottom Line: Yttrium acts as an effective microstructural modifier for A356 alloy, with a small 0.3 wt% addition creating a more refined and homogenous structure, which is foundational for enhancing mechanical performance.

The Challenge: Why This Research Matters for HPDC Professionals

The A356 aluminum-silicon alloy is a workhorse in the automotive industry, prized for its excellent castability, corrosion resistance, and low cost. However, its performance in demanding applications is often limited by its natural solidification behavior. During casting, A356 tends to form coarse primary aluminum grains and an undesirable network of acicular (needle-like) eutectic silicon.

This coarse and brittle microstructure acts as a stress concentrator, compromising the alloy's mechanical integrity and leading to reduced strength and poor ductility. To unlock the full potential of A356, these microstructural defects must be addressed. This research tackles this fundamental challenge by investigating a promising, yet less common, refining agent: the rare earth element yttrium.

The Approach: Unpacking the Methodology

To ensure credible and repeatable results, the researchers followed a precise experimental protocol. The goal was to isolate the effect of yttrium on the A356 alloy's microstructure under controlled gravity die casting conditions.

Method 1: Material Preparation and Casting: The team began with standard A356 in ingot form and 99.9% pure yttrium. An Al-5Y master alloy was first created in an electrical furnace to ensure accurate and homogenous mixing. This master alloy was then used to produce the final test samples by adding it to pure A356 to achieve target compositions of 0.3 wt% and 0.6 wt% yttrium. An unmodified A356 sample was also cast to serve as a baseline for comparison.

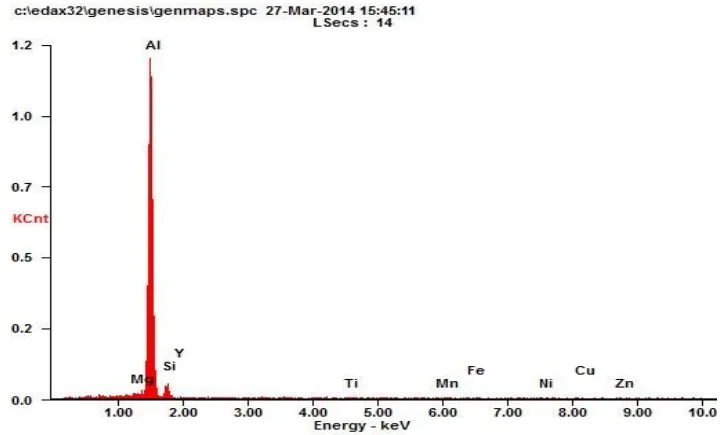

Method 2: Microstructural Analysis: Cylindrical samples were sectioned, mounted, and prepared using standard metallographic grinding and polishing techniques to achieve a fine surface finish. The microstructures were then examined using an optical microscope to observe grain structure and a Scanning Electron Microscope (SEM) for higher-magnification analysis. An Energy-Dispersive X-Ray Spectroscopy (EDX) unit, coupled with the SEM, was used to precisely verify the final chemical composition of each sample.

The Breakthrough: Key Findings & Data

The investigation yielded clear, data-driven evidence of yttrium's effectiveness as a microstructural refiner for A356 alloy.

Finding 1: 0.3 wt% Yttrium Delivers Optimal Grain Refinement

The addition of yttrium had a significant impact on the primary α-Al grain size. The study found that 0.3 wt% yttrium was the most effective concentration.

As measured per ASTM E112-10, the grain size for the unmodified A356 was 62.93 µm. With the addition of 0.3 wt% yttrium, the grain size was reduced by over 32% to just 42.61 µm. Interestingly, increasing the yttrium content to 0.6 wt% was less effective, resulting in a larger grain size of 56.90 µm. This demonstrates that there is an optimal level for refinement and that adding more is not necessarily better.

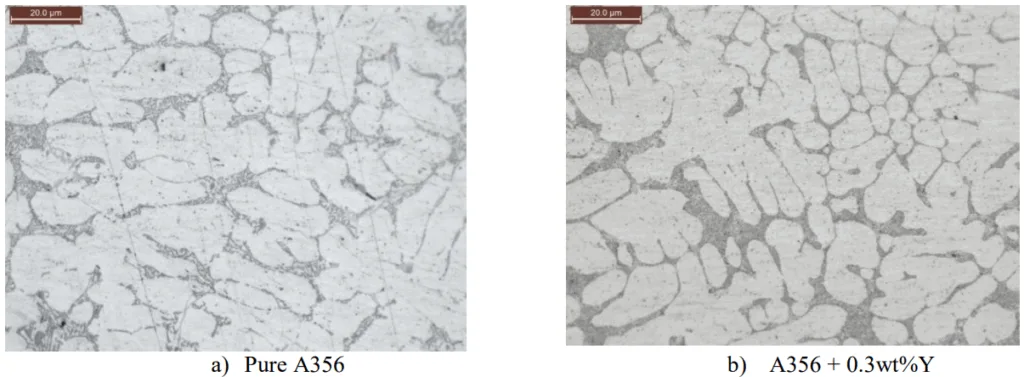

Finding 2: Yttrium Transforms Brittle Eutectic Silicon into a Fibrous Structure

Beyond refining the primary aluminum grains, yttrium effectively modified the morphology of the eutectic silicon phase. In the unmodified A356, the eutectic silicon appeared as coarse, acicular plates (see Figure 4a). This structure is known to be detrimental to mechanical properties.

As shown in Figure 4b, the addition of 0.3 wt% yttrium transformed this coarse structure into a "more fibrous, more globular and well dispersed eutectic phase." This change from sharp, needle-like particles to a fine, fibrous network is critical for improving the alloy's ductility and toughness by reducing internal stress concentration points.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that incorporating a yttrium addition step, specifically targeting a 0.3 wt% concentration, into the melting and holding process for A356 alloy can be a viable strategy to produce a finer, more robust as-cast microstructure.

- For Quality Control Teams: The data in Table 1 (EDX analysis) and the microstructures shown in Figure 2 and Figure 4 provide clear visual and compositional benchmarks. These can be used to develop or refine metallographic inspection criteria to ensure that the desired level of microstructural refinement is being consistently achieved.

- For Materials Engineers: The findings indicate that for components requiring enhanced mechanical performance from A356 alloy, specifying a 0.3 wt% yttrium modification can be an effective path to achieving a superior microstructure, which is a direct precursor to improved ductility and strength.

Paper Details

Effect of Yttrium on the Microstructure of Gravity Die Cast A356 Alloy

1. Overview:

- Title: Effect of Yttrium on the Microstructure of Gravity Die Cast A356 Alloy

- Author: Ying Pio Lim, Wei Hong Yeo

- Year of publication: 2015

- Journal/academic society of publication: Proceedings of the World Congress on Mechanical, Chemical, and Material Engineering (MCM 2015)

- Keywords: Yttrium, gravity die casting, grain refinement, eutectic phase.

2. Abstract:

The efficiency of yttrium on grain refinement of gravity die cast A356 aluminium alloy is investigated in this work. The amount of yttrium added to A356 was specified at 0, 0.3 and 0.6 wt%. A series of melting and casting experiments was carried out to ensure that the intended weight percentage is achieved in the final casting. The composition of yttrium in the as-cast alloy was ensured to be mixed and dispersed equally by Energy-Dispersive X-Ray Spectroscopy (EDX). The master alloy Al-3Y was produced first and used to cast 0.3 and 0.6 wt% samples. The as-cast A356 alloy was then observed under the optical microscope to determine its microstructural characteristic. The specimens were also examined by Scanning Electrons Microscope (SEM). The inoculation of yttrium was found to be able to reduce the primary coarse a-Al and refine the eutectic silicon phase to finer and more fibrous structure. The grain size measured in µm²/grain is 65.2 for pure A356, 51.1 for Al-0.3Y and 57.3 for Al-0.6Y. The addition of 0.3 wt% yttrium to A356 alloy was found to be the most optimal to achieve the finest grain and modify the coarse eutectic phase to be more fibrous. The grain refining efficiency of yttrium is attributed to its ability to reduce the growth of the coarse dendritic grains and smoothen the interface between a-Al and eutectic phase.

3. Introduction:

The A356 alloy belongs to a group of hypoeutectic Al-Si alloys. A conventional cast aluminium-silicon alloy, A356 has been increasingly used in the automotive industry due to its low cost, increased energy efficiency and the concomitant environmental benefits. In addition, aluminium-silicon alloys have castability and good corrosion resistance (Zhao et al., 2011). Besides, A356 also has some benefits in other mechanical properties like good ductility (Hu et al., 2012). The Si content in the alloy has low density and the latent heat is five times higher than Al. Silicone also reduces the weights of the alloy and improves its castability. It can be a very effective wear resistant material due to its high hardness (Kim et al., 2006). However, the formation of Al-Si alloys usually contains undesired acicular-like eutectic silicon and coarse primary silicon phase. The precipitated eutectic silicon has detrimental effects which may result in poor mechanical properties such as low strength and low ductility. Therefore, these precipitations must be modified and refined simultaneously so that the eutectic Si structure is transformed to a finer fibrous structure. Al-Ti-B master alloys are well established for use as grain refiners in aluminium-silicon alloys (Ghadimi et al., 2013). For example, mechanical properties can be improved, susceptibility to hot cracking is reduced and fluidity is improved. Other than Al-Ti-B alloy, the Al-Ti-C alloy is also a typical grain refiner. The quality of casting can be improved by grain refinement where the size of primary a-Al grains nucleated in the as-cast product is reduced. The efficiency of these refiners can be easily undermined by the presence of elements like Zr and V (Li P. et al., 2013).

The rare earth elements in conventional casting aluminium alloys have shown beneficial effects on melting and solidification. These elements reduce the content of impurities and the secondary dendritic arm spacing. Previous study shows that cerium, also plays a role similar to that of yttrium. It was reported that the mechanical properties of Al-Li-Mg alloys was improved and the negative effect of impurity Fe content was controlled by cerium addition (Zhang J. et al., 2011).

4. Summary of the study:

Background of the research topic:

The A356 aluminum alloy, while widely used in the automotive industry for its favorable cost and castability, inherently forms a microstructure with coarse primary α-Al grains and acicular eutectic silicon. These features are detrimental to mechanical properties, particularly strength and ductility, limiting the alloy's performance in high-stress applications.

Status of previous research:

Conventional grain refinement of aluminum-silicon alloys is well-established using Al-Ti-B or Al-Ti-C master alloys. Additionally, rare earth elements have been noted for their beneficial effects on solidification, with elements like cerium showing promise in improving mechanical properties and controlling impurities.

Purpose of the study:

The objective of this work was to investigate the efficiency of yttrium as a grain refiner and microstructural modifier for gravity die cast A356 alloy. The study aimed to determine the effect of varying yttrium concentrations on the primary α-Al grain size and the morphology of the eutectic silicon phase to identify an optimal addition level.

Core study:

The study involved the systematic addition of yttrium at 0, 0.3, and 0.6 weight percentages to A356 alloy. Samples were produced using a gravity die casting process. The resulting as-cast microstructures were then characterized using optical microscopy and Scanning Electron Microscopy (SEM). The chemical composition of the final castings was verified using Energy-Dispersive X-Ray Spectroscopy (EDX). The primary outcome measured was the change in grain size and eutectic phase morphology as a function of yttrium content.

5. Research Methodology

Research Design:

The study employed a comparative experimental design. An unmodified A356 alloy served as the control group, which was compared against two experimental groups: A356 modified with 0.3 wt% yttrium and A356 modified with 0.6 wt% yttrium.

Data Collection and Analysis Methods:

An Al-5Y master alloy was first prepared to facilitate accurate alloying. This master alloy was then added to molten A356 to create the final test compositions, which were cast into cylindrical samples using a gravity die casting mould. Samples were sectioned and prepared for metallographic examination via grinding with 600, 800, and 1000 grit papers, followed by polishing with diamond paste (15, 9, 6, and 3 µm). Microstructural analysis was conducted with an optical microscope and SEM. Compositional analysis was performed using EDX, with five points averaged per sample. Grain size was measured following the ASTM E112-10 standard.

Research Topics and Scope:

The scope of this investigation was confined to the microstructural effects of yttrium additions on A356 alloy produced by gravity die casting. The research focused exclusively on the characterization of the as-cast microstructure (primary α-Al grains and eutectic silicon phase) and did not extend to the evaluation of mechanical properties.

6. Key Results:

Key Results:

- The addition of yttrium was effective in refining the coarse primary α-Al grains and modifying the eutectic silicon phase from an acicular to a more fibrous structure.

- The optimal composition for grain refinement was found to be 0.3 wt% yttrium, which resulted in the finest grain size.

- The average grain size for 0 wt% Y, 0.3 wt% Y, and 0.6 wt% Y was measured to be 62.93 µm, 42.61 µm, and 56.90 µm, respectively.

- The addition of 0.6 wt% yttrium was less effective at grain refinement than the 0.3 wt% addition. The paper suggests the presence of manganese (0.11 wt%) in the 0.6 wt% Y sample could have impeded recrystallization.

- EDX analysis (Table 1) confirmed that the target weight percentages of yttrium were successfully achieved in the final castings.

Figure Name List:

- Fig. 1. Specimen on the Plate

- Fig. 2. Optical microstructures

- Fig. 3. EDX Analysis for A356 + 0.3 wt% Yttrium

- Fig. 4. Eutectic phase of the die cast structure

7. Conclusion:

Based on the microstructure observations done by optical microscope, the unmodified A356 aluminium alloy contains coarse eutectic silicon phase and a-Al grains. Addition of Yttrium was found to be effective to refine a-Al grains and the eutectic silicon phase was refined to be more fibrous. However, the dendritic structure of a-Al phase could not be transformed into globular structure. The optimal composition of 0.3 wt% yttrium in A356 was found to be able to achieve the finest grain size and produce the most fibrous eutectic phase by inhibiting the grain growth of a-Al and transforming the sharp eutectic silicon phase into a more fibrous form.

8. References:

- Ghadimi, H., Hossein, N. S., & Eghbali, B. (2013). Enhanced Grain Refinement Of Cast Aluminum Alloy By Thermal And Mechanical Treatment Of Al-5Ti-B Master Alloy. Transactions of Nonferrous Metals Society of China, 23(6), 1563-1569.

- Hu, X., Jiang, F., Ai, F., & Yan, H. (2012). Effects Of Rare Earth Er Additions On Microstructure Development And Mechanical Properties Of Die-Cast ADC12 Aluminum Alloy. Journal of Alloys and Compounds, 538, 21-27.

- Kim, E.S., Lim, K.M., Kim, Y.H., & Lee, K.H. (2006). A study on the Microstructure Change with Modification and Cast-forging in Hypereutectic Al-Si Alloys. International Forum on Strategic Technology, 407-411.

- Lloyd, D. J. (1982). Recrystallization Of Unhomogenized Aluminium-Manganese Alloys. Materials Science and Technology, 16(6), 304-308.

- Li, P., Liu, S., Zhang, L., & Liu, X. (2013). Grain Refinement Of A356 Alloy By Al-Ti-B-C Master Alloy And Its Effect On Mechanical Properties. Materials & Design, 47, 522-528.

- Zhang, J., Leng, Z., Zhang, M., Meng, J., & Wu, R. (2011). Effect Of Ce On Microstructure, Mechanical Properties And Corrosion Behavior Of High-Pressure Die-Cast Mg-4Al-Based Alloy. Journal of Alloys and Compounds, 509(3), 1069-1078.

- Zhao, Y., Wu, F., Zhang, J., Cao, G., Guo, E., & Zhang, C. (2011). Effect Of Cerium Addition On Microstructure And Mechanical Properties Of 4004 Aluminium Alloy. International Conference on Electronic & Mechanical Engineering and Information Technology, 928-931.

Expert Q&A: Your Top Questions Answered

Q1: Why was yttrium chosen for this study instead of more common refiners like titanium-boron (TiB)?

A1: The paper notes that while Al-Ti-B master alloys are well-established, rare earth elements have also shown beneficial effects on solidification. This study aimed to specifically investigate the efficiency of yttrium, a rare earth element, to accurately characterize its impact on the A356 microstructure. The goal was to explore an alternative or complementary path to microstructural improvement.

Q2: The results show that 0.6 wt% yttrium was less effective than 0.3 wt%. Why did performance decrease with a higher concentration?

A2: The paper suggests a possible reason for the reduced efficiency at 0.6 wt%. The EDX analysis in Table 1 shows the presence of manganese (0.11 wt%) in the 0.6 wt% sample, which was absent in the others. The authors cite previous research (Lloyd D. J., 1982) indicating that Mn-Al precipitates can impede the recrystallization of α-Al, which could explain the resulting larger grain structure compared to the 0.3 wt% sample.

Q3: How did the researchers confirm that the intended amount of yttrium was present and evenly distributed in the final casting?

A3: They used Energy-Dispersive X-Ray Spectroscopy (EDX) in conjunction with a Scanning Electron Microscope (SEM). As stated in the abstract, EDX was used to ensure the yttrium was "mixed and dispersed equally." The chemical composition data presented in Table 1 shows that the measured yttrium content (0.33 wt% and 0.61 wt%) was very close to the intended targets (0.3 wt% and 0.6 wt%), confirming the accuracy of their alloying process.

Q4: What were the two primary microstructural changes observed with the addition of 0.3 wt% yttrium?

A4: The two main changes were: 1) Grain refinement of the primary α-Al phase, where the average grain size was reduced from 62.93 µm to 42.61 µm. 2) Modification of the eutectic silicon phase, where the structure was transformed from a coarse, acicular (needle-like) form to a much finer and more fibrous morphology, as clearly shown in the comparison in Figure 4.

Q5: The study used gravity die casting. Can these findings be directly applied to High Pressure Die Casting (HPDC)?

A5: The paper exclusively investigates the effects of yttrium in a gravity die casting process. While the fundamental metallurgical principles of grain refinement and eutectic modification would likely apply, HPDC involves significantly faster cooling and solidification rates. These different conditions could alter the efficiency and optimal concentration of yttrium. Therefore, while this study provides a strong foundation, further research would be needed to validate these specific results for HPDC applications.

Conclusion: Paving the Way for Higher Quality and Productivity

This research effectively demonstrates that a small, controlled addition of yttrium is a powerful tool for overcoming the inherent microstructural weaknesses of as-cast A356 Alloy. By adding just 0.3 wt% yttrium, it is possible to achieve significant grain refinement and, crucially, transform the brittle eutectic silicon phase into a more favorable fibrous structure. These improvements create a superior as-cast component that is better prepared to deliver enhanced mechanical performance.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components.

Copyright Information

This content is a summary and analysis based on the paper "Effect of Yttrium on the Microstructure of Gravity Die Cast A356 Alloy" by "Ying Pio Lim, Wei Hong Yeo".

Source: The paper was published in the Proceedings of the World Congress on Mechanical, Chemical, and Material Engineering (MCM 2015), Barcelona, Spain – July 20-21, 2015, Paper No. 123. A direct DOI link is not provided in the document.

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.