Unlocking Peak Performance in AlSi7Mg0.3: How Jet Cooling Boosts the Quality Index

This technical summary is based on the academic paper "Quality Index of the AlSi7Mg0.3 Aluminium Casting Alloy Depending on the Heat Treatment Parameters" by E. Czekaj, J. Zych, Z. Kwak, A. Garbacz-Klempka, published in ARCHIVES of FOUNDRY ENGINEERING (2016).

Keywords

- Primary Keyword: AlSi7Mg0.3 Quality Index

- Secondary Keywords: Al-Si alloy, heat treatment, jet cooling, mechanical properties, UTS, YS, elongation

Executive Summary

- The Challenge: Engineers require a reliable metric that combines both strength and ductility to accurately assess the performance of high-demand aluminum components like AlSi7Mg0.3.

- The Method: The study systematically compared the effects of traditional immersion quenching versus an innovative micro-jet cooling method during the heat treatment of AlSi7Mg0.3 alloy.

- The Key Breakthrough: Micro-jet cooling consistently produced a higher Quality Index (QI), a key performance metric, than conventional immersion cooling across various heat treatment conditions.

- The Bottom Line: For critical AlSi7Mg0.3 components, adopting a jet cooling process during heat treatment can yield superior mechanical properties, leading to more durable and reliable end products.

The Challenge: Why This Research Matters for HPDC Professionals

In the world of high-performance castings, particularly for automotive and aerospace applications, simply measuring tensile strength isn't enough. Components must withstand complex operational stresses, requiring a careful balance of strength (the ability to resist load) and plasticity (the ability to deform without fracturing). The AlSi7Mg0.3 alloy is a workhorse in this field, but optimizing its properties through heat treatment remains a critical challenge.

The industry has long needed a unified metric to evaluate this strength-ductility balance. The "Quality Index" (QI) was developed for this exact purpose. It provides a single, quantifiable value that reflects the overall performance potential of a material, making it an invaluable tool for designers and process engineers. This research addresses the crucial question: how can we manipulate heat treatment parameters, specifically the cooling process, to maximize the QI of AlSi7Mg0.3 castings?

The Approach: Unpacking the Methodology

The research team conducted a rigorous experimental study on cast hypoeutectic silumin EN AC-42100 (AlSi7Mg0.3) to isolate the effects of different heat treatment protocols.

- Material: The study used a standard AlSi7Mg0.3 alloy, with its chemical composition verified by spectral analysis (Table 1).

- Heat Treatment Stages: Samples were tested in multiple states: as-cast (F), solutionized and naturally aged (T4), as-cast and artificially aged (T5), and solutionized and artificially aged (T6).

- The Core Innovation: The key variable was the cooling (quenching) method applied during the solution treatment phase.

- Method 1 (P): Traditional immersion cooling, where samples were submerged in water at 20°C.

- Method 2 (M): Innovative micro-jet cooling, where samples were sprayed with micro-jets of water at 20°C.

- Evaluation: After treatment, standard tensile tests were performed to measure Ultimate Tensile Strength (UTS), Yield Strength (YS), and Elongation (A). These values were then used to calculate the Quality Index (QI) using the established formula:

QI = UTS + 150 * log(A).

The Breakthrough: Key Findings & Data

The study revealed a clear performance advantage for the innovative micro-jet cooling method.

Finding 1: Jet Cooling Delivers a Higher Quality Index in the T4 Condition

For solutionized and naturally aged (T4) samples, which represent a baseline for post-solutionizing quality, the jet cooling method produced a measurably higher QI.

- As detailed in Table 2, samples cooled via immersion (P) achieved a QI of 403.4 MPa.

- In contrast, samples cooled with the micro-jet (M) method reached a QI of 412.4 MPa, demonstrating a distinct improvement in the material's combined strength and ductility.

Finding 2: Optimal Performance Achieved with Jet Cooling and T6-S2 Aging

When combining solutionizing with artificial aging (T6 condition), the combination of jet cooling and a specific aging protocol (S2: 175°C for 8h) yielded the highest QI for that stage.

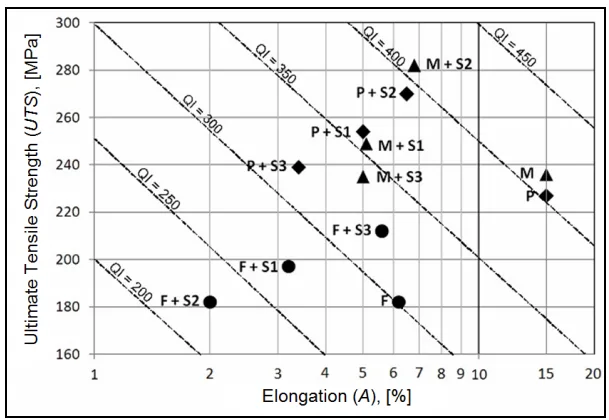

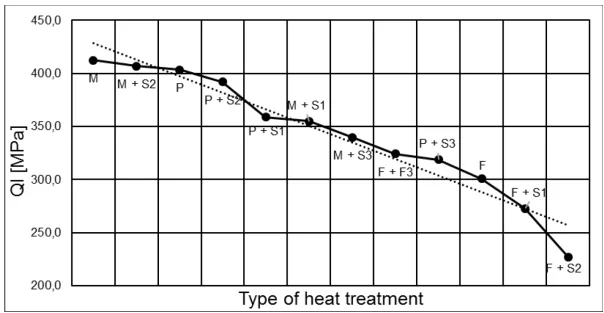

- The ranking in Figure 2 clearly shows that the M + S2 variant (jet cooling + S2 aging) achieved the highest quality level within the T6 group, with a QI of 406.9 MPa.

- This significantly outperformed its immersion-cooled counterpart, P + S2, which had a QI of 391.9 MPa, as well as other aging combinations. This finding highlights a specific, optimized process for maximizing the performance of AlSi7Mg0.3.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that transitioning from traditional immersion tanks to a micro-jet quenching system for AlSi7Mg0.3 can directly contribute to achieving superior and more consistent mechanical properties.

- For Quality Control Teams: The data in Table 2 and Figure 2 provides a valuable benchmark. It illustrates the expected QI values for different heat treatment protocols, enabling teams to set higher, data-driven quality standards.

- For Design Engineers: The findings indicate that components manufactured using a jet-cooled T6 process can offer a better balance of strength and plasticity. This could enable the design of more lightweight parts or components capable of withstanding higher operational stresses without compromising reliability.

Paper Details

Quality Index of the AlSi7Mg0.3 Aluminium Casting Alloy Depending on the Heat Treatment Parameters

1. Overview:

- Title: Quality Index of the AlSi7Mg0.3 Aluminium Casting Alloy Depending on the Heat Treatment Parameters

- Author: E. Czekaj, J. Zych, Z. Kwak, A. Garbacz-Klempka

- Year of publication: 2016

- Journal/academic society of publication: ARCHIVES of FOUNDRY ENGINEERING

- Keywords: Innovative foundry technologies and materials, Al-Si alloy, Quality index, Heat treatment, Jet cooling

2. Abstract:

Issues connected with high quality casting alloys are important for responsible construction elements working in hard conditions. Traditionally, the quality of aluminium casting alloy refers to such microstructure properties as the presence of inclusions and intermetallic phases or porosity. At present, in most cases, Quality index refers to the level of mechanical properties – especially strength parameters, e.g.: UTS, YS, HB, E (Young's Modulus), K₁c (stress intensity factor). Quality indexes are often presented as a function of density. However, generally it is known, that operating durability of construction elements depends both on the strength and plastic of the material. Therefore, for several years now, in specialist literature, the concept of quality index (QI) was present, combines these two important qualities of construction material. The work presents the results of QI research for casting hypoeutectic silumin type EN AC-42100 (EN AC-AlSi7Mg0.3), depending on different variants of heat treatment, including jet cooling during solution treatment.

3. Introduction:

The quality index (QI) is a concept used in the design of construction elements to correlate the strength and plastic properties of alloys. First introduced by Drouzy et al. in 1980, the QI is defined as QI = UTS + d·log(A), where UTS is the ultimate tensile strength, A is the elongation, and d is an experimentally determined coefficient (typically 150 for hypoeutectic silumins). This index provides a single metric to evaluate the overall quality of a material, reflecting its ability to serve in responsible applications. Further research has expanded this concept to include other parameters such as yield strength (YS) and strain energy density (W). The quality of Al-Si alloys, which are widely used in casting processes, is significantly influenced by heat treatment methods. This paper investigates the QI of hypoeutectic silumin EN AC-42100 (AlSi7Mg0.3) by focusing on the cooling procedure during solution treatment, comparing traditional immersion cooling with an innovative jet cooling method.

4. Summary of the study:

Background of the research topic:

The operational durability of structural components is dependent on both the strength and plastic properties of the material. For aluminum casting alloys used in demanding applications, quantifying this combined performance is crucial. The Quality Index (QI) serves as a comprehensive metric for this purpose.

Status of previous research:

The concept of the Quality Index was established in 1980 by Drouzy et al. and has since been applied in specialist literature to assess and compare aluminum and magnesium alloys. Studies have recognized the significant influence of heat treatment parameters on the mechanical properties and, consequently, the QI of these alloys. While the QI of hypoeutectic silumins has been previously discussed, this paper introduces a novel perspective by evaluating the effect of the cooling procedure during solution treatment.

Purpose of the study:

The objective of this work was to investigate and present the results of Quality Index (QI) research for the casting hypoeutectic silumin EN AC-42100 (AlSi7Mg0.3). The study specifically aimed to determine how different variants of heat treatment, particularly the comparison between conventional immersion cooling and innovative jet cooling during solution treatment, affect the final QI value.

Core study:

The core of the study involved subjecting cast samples of EN AC-AlSi7Mg0.3 alloy to a series of controlled heat treatments. These treatments included as-cast (F), solutionized and naturally aged (T4), artificially aged (T5), and solutionized and artificially aged (T6) states. The primary experimental variable was the quenching method following solution treatment: one set of samples was cooled by immersion in water (P), while another was cooled using a micro-jet spray station (M). Mechanical properties (UTS, YS, A) were measured for each condition, and the Quality Index (QI) was calculated to compare the outcomes.

5. Research Methodology

Research Design:

The study employed a comparative experimental design. The independent variables were the heat treatment stage (F, T4, T5, T6), the artificial aging parameters (S1, S2, S3), and the cooling method during solution treatment (P for immersion, M for micro-jet). The dependent variables were the mechanical properties (UTS, YS, A) and the calculated Quality Index (QI).

Data Collection and Analysis Methods:

The test material was EN AC-AlSi7Mg0.3, cast in a permanent mould. The chemical composition was confirmed via spectral analysis. Tensile tests were conducted at room temperature on an EU-20 type machine to obtain UTS, YS, and A values. The QI was calculated using the formula QI = UTS + d·log(A) with d=150. The results were tabulated and graphically represented to facilitate comparison and ranking of the different treatment protocols.

Research Topics and Scope:

The research was scoped to the EN AC-42100 (AlSi7Mg0.3) alloy. The solution treatment was standardized at 530°C for 2 hours. The micro-jet cooling was performed at a pressure of 4-6 bars. Three artificial aging variants were investigated: S1 (155°C for 10h), S2 (175°C for 8h), and S3 (205°C for 6h). The study compares the resulting mechanical properties and QI across all combinations.

6. Key Results:

Key Results:

- The highest Quality Index values were observed for the T4 (solutionized and naturally aged) stage. In this stage, jet cooling (M) resulted in a slightly higher QI of 412.4 MPa compared to immersion cooling (P), which yielded 403.4 MPa.

- For the T6 (solutionized and artificially aged) stage, the combination of jet cooling with S2 aging (M + S2) produced the highest QI value for that group, at 406.9 MPa.

- Across comparable aging treatments, the micro-jet cooling method (M) consistently resulted in slightly elevated mechanical properties and QI values relative to the traditional immersion method (P).

- The as-cast (F) and T5 (as-cast and artificially aged) stages produced the lowest overall QI values.

Figure Name List:

- Fig. 1. Relationship between log A (Elongation) and UTS (Ultimate Tensile Strength) for different variants of heat treatment

- Fig. 2. Ranking of the heat treatment for AlSi7Mg0.3 with use of Quality Index (based on the data of Table 2)

7. Conclusion:

The study concluded that mikro-jet cooling of AlSi7Mg0.3 alloy slightly elevated the mechanical properties and the Quality Index (QI). The results are influenced by both the heat treatment stage (F, T4, T5, T6) and the type of cooling procedure (P or M) used during quenching. The authors suggest that the observed results could be explained by the relatively low water pressure of the jet cooling appliance (approx. 5 bar), which may have led to the formation of a "cushion" of water steam on the sample surface, preventing complete and uniform penetration of the water micro-jets.

8. References:

- [1] Knych, T., Uliasz P., Wiecheć J. & Podeszwa K. (2014). Research on the Selection of Parameters of Solution Heat Treatment of the Commercial Casting Aluminium Alloy AlSi7Mg0.3 Type. Archives of Foundry Engineering. 14(special 4), 59-62.

- [2] Alexopoulos, N.D. & Pantelakis, S.G. (2004). Quality Assessment of Artificially Aged A357 Aluminum Alloys Cast Ingots by Introducing Approximate Expressions of the Quality Index QD. Metallurgical and Materials Transactions A. 35A(10), 3079-3089.

- [3] Drouzy, M., Jacob, S. & Richard, M. (1980). Interpretation of Tensile Results by Means of Quality Index and Probable Yield Strength. AFS Int. Cast Met. J. 5(2), 43-50.

- [4] Din, T., Rashid, A. & Campbell, J. (1996). High Strength Aerospace Casting Alloys: Quality Factor Assessment. Materials Science and Technology. 12, 269-273.

- [5] Alexopoulos, N.D. & Pantelakis, S.G. (2003). Evaluation of the Effects of Variations in Chemical Composition on the Quality of Al-Si-Mg, Al-Cu, and Al-Zn-Mg Cast Aluminum. Journal of Materials Engineering Performance. 12(2), 196-205.

- [6] Alexopoulos, N. D. & Pantelakis, S. G. (2004). Quality evaluation of A357 cast aluminum alloy specimens subjected to different artificial aging treatment. Materials & Design Journal. (25), 419-430.

- [7] Alexopoulos, N. D. & Pantelakis S.G. (2004). Quality assessment of artificially aged A357 aluminum alloy cast ingots by introducing approximate expressions of the quality index Q D. Metallurgical and Materials Transactions A. 35(10), 3079-3089.

- [8] Jacob, S. (1999). Quality Index in the Prediction of Properties of Aluminum Castings. AFS Transactions, Silver Anniversary paper. 107, 811-818.

- [9] Orłowicz, A.W. & Mróz, M. (2004). Indicator of the quality of castings from Al-Si alloy. Archives of Foundry. 4(14), 363-368. (in Polish).

- [10] Mohamed, A., Fawzy S. (2010). Performance of Aluminum-Silicon Cast Alloys. Saabrücken: LAP LAMBERT Academic Publishing GmbH & Co. KG (in Germany).

- [11] Pantelakis, S.G, Alexopoulos, N.D & Chamos, A.N. (2007). Mechanical performance evaluation of cast magnesium alloys for automotive and aeronautical applications. Journal of Engineering Materials and Technology, Transactions of the ASME. 129(3), 422-430.

- [12] Ashby, M., Shercliff, H., Cebon, D. (2011). Material Engineering. Tom 1 i 2. Łódź: Wydawnictwo GALAKTYKA. (in Polish).

- [13] Pysz, S., Czekaj, E., Żuczek, R., Maj, M. & Piekło J. (2016). Low Cycle Mechanical and Fatigue Properties of AlZnMgCu Alloy. Archives of Foundry Engineering. 16(1), 55-60.

- [14] Anon „Advanced Aluminum Precision Casting For Integrally Stiffened Net-Shape Components (ADVACAST). Final Technical Report of the BRITE Project 4084, Brussels, Belgium, 1996.

- [15] ASTM 108/B108M-12: Standard Specification for Alumi-nium-Alloy Permanent Mold Castings.

- [16] JIS H 5202:2010. Aluminium alloy castings. Japanise Industrial Standarts Committee.

- [17] BS 1490-1988: Specification for aluminium and aluminium alloy ingots and castings for general engineering purposes.

- [18] PN EN-1706:2011 Aluminium and its alloys. Castings. The chemical composition and mechanical properties. (in Polish).

- [19] Ambos, E., Besser, W., Honsel, W., Schulze, M. & Franz P.Ch. (2011). JetCooling Arbeitsweise, Wirkung und Ergebnisse. Giesserei-Rundschau. 58, 57-61.

- [20] Górny, Z., Kluska-Nawarecka, S., Czekaj, E., & Saja, K. (2011). Aplication of microjet in heat treatment of aluminium bronzes. Archives of Foundry Engineering. 11(2), 35-40.

Expert Q&A: Your Top Questions Answered

Q1: What exactly is the Quality Index (QI) and why is it a better metric than just UTS?

A1: The Quality Index (QI) is a composite metric, defined in the paper by the formula QI = UTS + 150*log(A), that combines a material's ultimate tensile strength (UTS) with its elongation (A). It is superior to using UTS alone because it provides a more holistic view of a component's potential performance. A high UTS with very low elongation (a brittle material) might fail unexpectedly in service, whereas the QI rewards a balance of both strength and ductility, which is critical for durable, reliable components in demanding applications.

Q2: Why was the AlSi7Mg0.3 alloy chosen for this study?

A2: The paper identifies AlSi7Mg0.3 (also known as EN AC-42100 or A356) as a hypoeutectic silumin commonly used for "responsible construction elements working in hard conditions." This alloy is prevalent in the automotive and aerospace industries due to its excellent castability and response to heat treatment. Therefore, finding methods to optimize its mechanical properties has direct and significant industrial relevance.

Q3: What is the key difference between the "P" (immersion) and "M" (micro-jet) cooling methods?

A3: The fundamental difference is the mechanism of heat extraction. Method "P" is the traditional quenching process of fully submerging the hot component into a tank of water. Method "M" is an innovative process that uses high-pressure nozzles to spray the component with fine micro-jets of water. The goal of jet cooling is often to achieve a more rapid and uniform cooling rate, which can lead to a finer microstructure and improved mechanical properties.

Q4: According to the data, which specific heat treatment protocol resulted in the highest quality?

A4: The data in Table 2 shows two top performers. The absolute highest QI value of 412.4 MPa was achieved in the T4 condition (solutionized and naturally aged) using micro-jet cooling (M). For the fully heat-treated T6 condition, the optimal combination was micro-jet cooling followed by artificial aging at 175°C for 8 hours (M + S2), which yielded a QI of 406.9 MPa.

Q5: The paper mentions a potential limitation of the jet cooling method used. What was it?

A5: The authors note in the conclusion that the observed improvements, while positive, were slight. They hypothesize this could be due to the "relatively low water pressure" of the jet cooling system (around 5 bars). This pressure may have been insufficient to overcome the Leidenfrost effect, creating a "cushion of water steam" on the sample's surface that insulated it and prevented the micro-jets from making full, efficient contact, thus slowing the effective cooling rate.

Conclusion: Paving the Way for Higher Quality and Productivity

This research provides compelling evidence that the method of cooling during heat treatment is a critical, and often overlooked, factor in determining the final quality of AlSi7Mg0.3 castings. The study demonstrates that innovative micro-jet cooling can elevate the AlSi7Mg0.3 Quality Index beyond what is achievable with traditional immersion quenching. This breakthrough offers a clear path for manufacturers to produce stronger, more ductile, and ultimately more reliable components. By optimizing the quenching process, foundries can unlock the full performance potential of this essential alloy.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components.

Copyright Information

This content is a summary and analysis based on the paper "Quality Index of the AlSi7Mg0.3 Aluminium Casting Alloy Depending on the Heat Treatment Parameters" by "E. Czekaj, J. Zych, Z. Kwak, A. Garbacz-Klempka".

Source: https://doi.org/10.1515/afe-2016-0043

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.