Unlocking T6 Heat Treatment: How Vacuum HPDC and Alloy Control Eliminate Defects in Automotive Aluminum Castings

This technical summary is based on the academic paper "Mechanical and Die Soldering Properties of Al-Si-Mg Alloys with Vacuum HPDC Process" by Chang-Yeol Jeong, Yu-Seok Kim, Jun-Hyung Ryu, and Heon-Joo Kim, published in Proceedings of the 12th International Conference on Aluminium Alloys (2010).

Keywords

- Primary Keyword: Vacuum High Pressure Die Casting

- Secondary Keywords: Al-Si-Mg Alloy, Die Soldering, Casting Defects, T6 Heat Treatment, Automotive Aluminum Casting, Mechanical Properties

Executive Summary

- The Challenge: Producing lightweight, high-strength Al-Si-Mg automotive components like cast nodes is hindered by casting defects that prevent effective heat treatment and cause die soldering.

- The Method: The study systematically evaluated the effects of varying Iron (Fe) and Manganese (Mn) content on castability and then applied a vacuum HPDC process (below 100 mbar) to minimize defects.

- The Key Breakthrough: Implementing Vacuum High Pressure Die Casting significantly reduces internal porosity, which allows the Al-Si-Mg alloy to undergo T6 heat treatment without blistering, thereby achieving superior mechanical strength and fatigue life.

- The Bottom Line: A combination of optimized alloy chemistry (Fe < 0.45%, Mn < 0.5%) and a vacuum HPDC process is critical for manufacturing high-integrity, heat-treatable aluminum castings for demanding automotive applications.

The Challenge: Why This Research Matters for HPDC Professionals

In the relentless drive for improved fuel efficiency, the automotive industry is increasingly replacing steel with lightweight aluminum alloys like Al-Si-Mg for chassis and frame components. High Pressure Die Casting (HPDC) is the process of choice for manufacturing complex parts like spaceframe nodes. However, a critical roadblock persists: entrapped air and gas during the high-speed die filling process.

This trapped gas leads to internal porosity and blowholes. While these defects are problematic in any casting, they are catastrophic for parts requiring T6 heat treatment to achieve high strength. During the solution treatment phase, the trapped gas expands, causing surface blisters and rendering the component unusable. Furthermore, die soldering—where the aluminum alloy welds to the steel die—remains a persistent issue that causes production downtime and reduces die life. This research directly addresses these core challenges by investigating how to control both the alloy and the process to produce defect-free, high-performance castings.

The Approach: Unpacking the Methodology

The researchers conducted a two-phase experimental investigation to isolate and solve the key production challenges.

Method 1: Optimizing Alloy Composition for Castability

The study focused on a modified A356 (Al-Si-Mg) alloy. The key variables were the weight percentages of Iron (Fe) and Manganese (Mn), elements known to influence die soldering.

- Fluidity Tests: A metallic mold with long, rectangular channels was used to measure how far the molten alloy could flow before solidifying.

- Shrinkage Tests: The team measured both macro-shrinkage and micro-shrinkage as Fe and Mn content was varied to understand their effect on solidification.

- Die Soldering Tests: SKD61 steel pins (a common die material) were immersed in the molten aluminum alloy at 680°C for 30 minutes. The thickness and composition of the resulting soldered layer were then analyzed using optical microscopy (OM), SEM/EDX, and XRD.

Method 2: Implementing Vacuum HPDC to Eliminate Defects

Based on the castability results, an optimized alloy was used to produce a stair-type test component using both conventional (atmospheric) and vacuum HPDC.

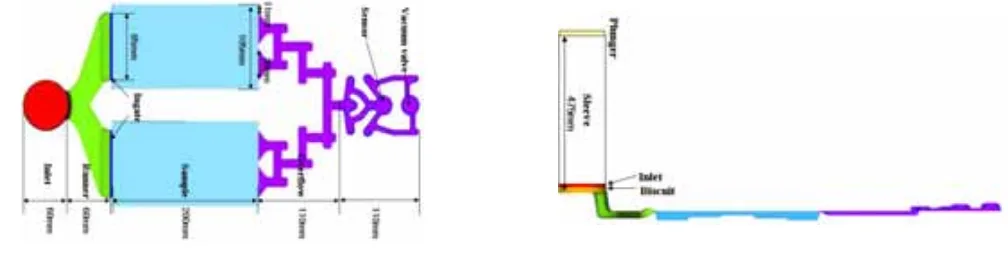

- Casting Simulation: Software was used to model mold filling, turbulence, and air pressure for both atmospheric and vacuum (100 mbar) conditions.

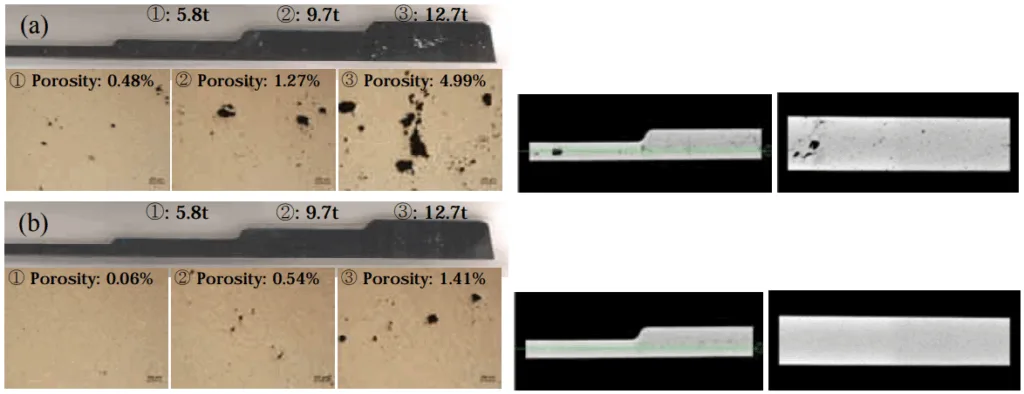

- Defect Analysis: The resulting cast samples were sectioned and analyzed for internal porosity using OM and 3D X-ray CT scanning.

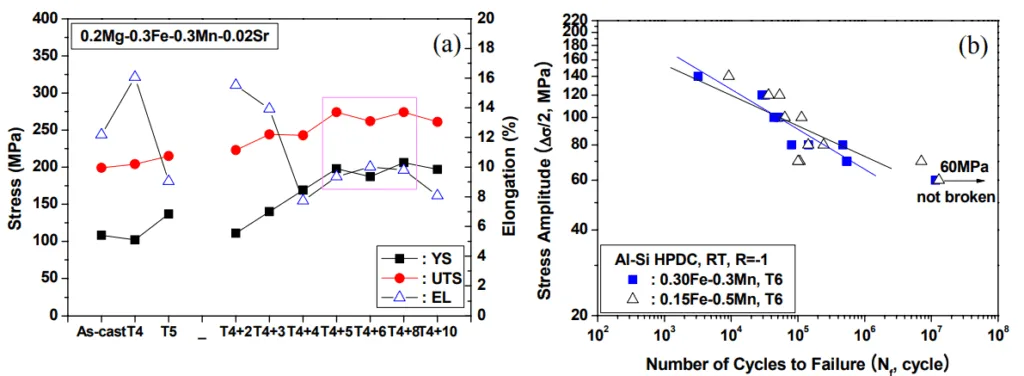

- Mechanical Property Testing: After T6 heat treatment (Solution treatment at 520°C/6hr, water quench; Aging at 180°C/5hr, air cool), cylindrical specimens were machined for tensile tests and high-cycle fatigue (HCF) tests.

The Breakthrough: Key Findings & Data

The study yielded clear, actionable data on how to improve Al-Si-Mg castings.

Finding 1: The Critical Trade-Off Between Fluidity and Die Soldering

The addition of Fe and Mn has a direct and predictable impact on casting behavior. While these elements are beneficial for reducing die soldering, they can negatively affect mold filling.

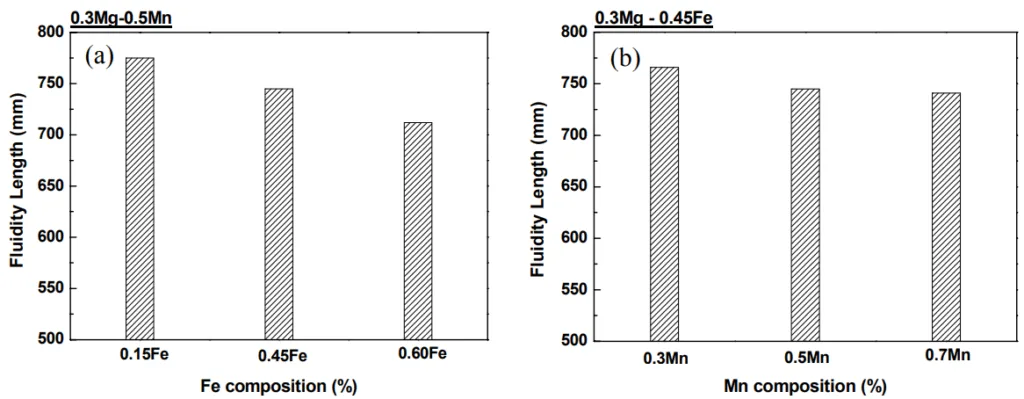

- Fluidity: As shown in Figure 1, fluidity decreased as the content of Fe and Mn increased. The alloy with 0.15% Fe and 0.5% Mn exhibited the highest fluidity at 775 mm, which dropped as Fe content rose to 0.60%. This is attributed to the formation of β-Al₅FeSi and α-Al₁₅(Mn,Fe)₃Si₂ phases that hinder melt flow.

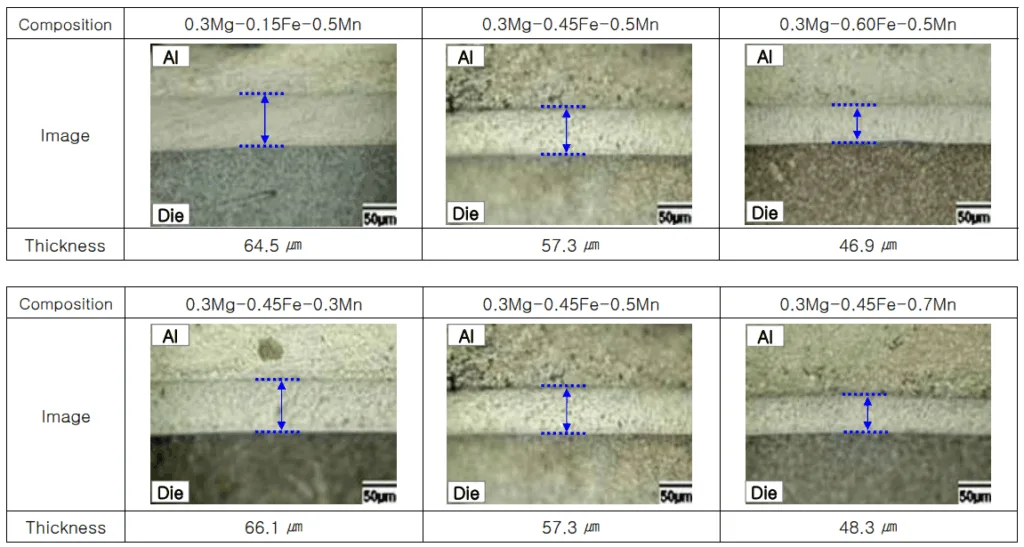

- Die Soldering: Conversely, increasing Fe and Mn content significantly reduced the thickness of the soldered layer on the die material. As detailed in Figure 3, the soldered layer thickness decreased from 64.5 µm at 0.15% Fe to 46.9 µm at 0.60% Fe. A similar trend was observed for Mn. This establishes a clear processing window to balance mold-filling capability with die life.

Finding 2: Vacuum HPDC is Essential for Heat-Treatable Castings

The comparison between atmospheric and vacuum casting demonstrated the transformative impact of removing air from the die cavity before injection.

- Porosity Reduction: The use of a vacuum below 100 mbar drastically reduced internal defects. As quantified in Figure 8, porosity in the thickest section (12.7t) of the casting was reduced from 4.99% under atmospheric conditions to just 1.41% with the vacuum process.

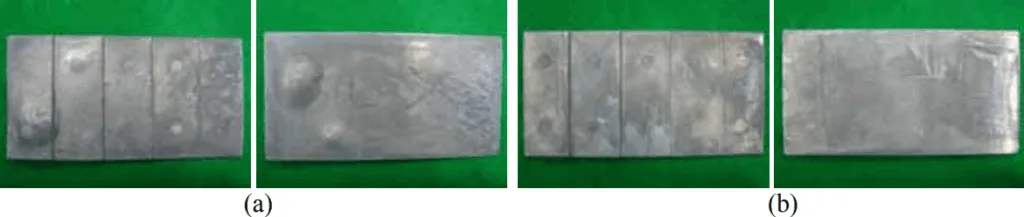

- Enabling T6 Heat Treatment: The reduction in trapped gas directly enabled successful heat treatment. Figure 9 shows the stark difference in surface morphology after T6 treatment. The atmospheric sample is covered in coarse blisters, while the vacuum-cast sample maintains its initial surface features with little to no blistering. This confirms that vacuum HPDC is a prerequisite for achieving the high mechanical properties associated with T6 tempering in these alloys.

- Improved Mechanical Properties: The defect-free microstructure achieved through vacuum casting resulted in superior performance. Figure 10(b) shows that the T6 heat-treated, vacuum-cast samples achieved a high-cycle fatigue limit of 60 MPa (at R=-1), a critical performance metric for durable automotive components.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that adjusting the vacuum level to below 100 mbar is a highly effective strategy for reducing turbulence and gas porosity, especially in components with varying wall thicknesses. The simulation results in Figure 6 show a faster, more stable mold fill under vacuum.

- For Quality Control Teams: The data in Figure 8 provides a quantitative benchmark for porosity levels achievable with vacuum HPDC versus atmospheric casting. The absence of blistering after heat treatment (Figure 9) can serve as a simple but effective go/no-go quality check for casting integrity.

- For Design Engineers: The findings indicate that alloy selection, specifically the Fe and Mn content, directly influences both manufacturability (fluidity) and tool life (die soldering). The paper suggests an optimal range of Fe < 0.45%, Mn < 0.5%, and a total sum of Fe+Mn < 0.65% for balancing these characteristics in Al-9Si alloys.

Paper Details

Mechanical and Die Soldering Properties of Al-Si-Mg Alloys with Vacuum HPDC Process

1. Overview:

- Title: Mechanical and Die Soldering Properties of Al-Si-Mg Alloys with Vacuum HPDC Process

- Author: Chang-Yeol Jeong, Yu-Seok Kim, Jun-Hyung Ryu and Heon-Joo Kim

- Year of publication: 2010

- Journal/academic society of publication: Proceedings of the 12th International Conference on Aluminium Alloys, ©2010 The Japan Institute of Light Metals

- Keywords: Al-Si-Mg alloy, Automobile, Vacuum high pressure die-casting, Die-soldering, Fatigue

2. Abstract:

To improve the fuel efficiency and reduce the emissions of automobile, demand for lightweight alloys in application on the transportation equipment has been greatly increased. Especially, researches on aluminum to use in chassis and frame components have drawn great attention. In reduction of weight of engine sub-frame and cross member, it is necessary to develop a cast node component which connects extrusions. This cast node needs to have both sufficient strength and toughness, therefore, high strength alloy design and vacuum high pressure die casing process technology are required to minimize the casting defects. Mechanical properties, microstructure and casting characteristics of Al-Si-Mg alloys were evaluated by varying the ratio of Fe and Mn contents which is important for improving die soldering. To achieve both strength and elongation, optimum heat treatment condition was also established. Casting simulation results showed that the turbulence and air pressure were significantly reduced in vacuum condition compared with air atmosphere, and the experimental results were coincident with the simulation analysis. Moreover, flow of the melt and the internal defects were quantitatively analyzed with and without vacuum during die-casting. Below 100mbar of vacuum condition, the casting defects and blister after T6 heat treatment were greatly reduced and the improved tensile and fatigue properties were resulted.

3. Introduction:

As a result of more stringent requirements for improved fuel economy and emissions, there is a growing trend to substitute aluminum for conventional steel and cast irons in vehicles. Al-Si-Mg casting alloys are widely used in automotive components due to their excellent mechanical properties and castability. The high pressure die casting (HPDC) process is the most common method for manufacturing components such as spaceframe nodes, engine mounts, and chassis parts. A critical requirement for these aluminum castings is the absence of defects that reduce fatigue and impact resistance. Consequently, the solidification microstructure, including dendrite arm spacing, grain size, and eutectic silicon morphology, must be carefully controlled. In addition to alloy chemistry and castability, factors like fluidity and die-soldering must be considered to limit defects. This paper examines the solidification and mechanical properties of aluminum casting alloys made by HPDC and evaluates the effect of alloying elements such as Fe and Mn on cast behavior.

4. Summary of the study:

Background of the research topic:

The study is driven by the automotive industry's need for lightweight materials to enhance fuel efficiency and reduce emissions. Al-Si-Mg casting alloys are primary candidates for replacing steel and cast iron in components like chassis parts and engine mounts due to their favorable mechanical properties and castability.

Status of previous research:

High pressure die casting (HPDC) is the established manufacturing process for these components. However, a critical challenge is ensuring the castings are free from defects that compromise fatigue and impact resistance. This requires careful control of the solidification microstructure and alloy chemistry. Previous work has identified fluidity and die-soldering as key factors in defect formation and production efficiency.

Purpose of the study:

The purpose of this study was twofold: 1) to evaluate how varying the content of alloying elements Fe and Mn affects the castability (fluidity, shrinkage) and die-soldering behavior of an Al-Si-Mg alloy, and 2) to investigate the effectiveness of a vacuum HPDC process in minimizing casting defects, enabling T6 heat treatment, and ultimately improving the mechanical properties (tensile and fatigue) of the final component.

Core study:

The research systematically analyzed a modified A356 Al-Si-Mg alloy. First, the effects of Fe and Mn content on fluidity, shrinkage, and die-soldering were experimentally determined. Second, based on these findings, casting simulations and physical experiments were conducted using both atmospheric and vacuum (<100 mbar) HPDC processes. The resulting castings were evaluated for internal defects using OM and X-ray CT, surface quality after T6 heat treatment, and mechanical performance through tensile and high-cycle fatigue testing.

5. Research Methodology

Research Design:

The study employed an experimental research design. It first involved a parametric study of alloy composition (varying Fe and Mn content) to assess its impact on castability and die-soldering. This was followed by a comparative study of two casting processes—atmospheric HPDC and vacuum HPDC—to evaluate their effects on casting integrity and mechanical properties.

Data Collection and Analysis Methods:

- Material: A modified A356 Al-Si-Mg alloy with varying Fe (0.15-0.60 wt%) and Mn (0.30-0.70 wt%) content.

- Castability Tests: Fluidity was measured using a metallic mold with channels. Shrinkage was evaluated for both macro and micro effects.

- Die-Soldering Test: SKD61 steel pins were immersed in the melt, and the resulting reaction layer was analyzed using OM and SEM/EDX.

- HPDC Process: A stair-type mold was used for both atmospheric and vacuum (<100 mbar) die casting. Process simulation was also conducted.

- Defect Analysis: Internal porosity was quantified using optical microscopy and 3-dimensional X-ray CT. Surface morphology was inspected visually after T6 heat treatment.

- Mechanical Testing: Axial high-cycle fatigue (HCF) tests were conducted at 60Hz (R=-1), and tensile tests were performed at a strain rate of 2 mm sec⁻¹.

Research Topics and Scope:

The research focused on the interplay between alloy composition and processing conditions for Al-Si-Mg alloys. The scope included the evaluation of fundamental casting characteristics (fluidity, shrinkage, die-soldering) and the analysis of defect formation and mechanical performance in castings produced by vacuum HPDC. The study aimed to establish an optimal composition and process for producing high-integrity, heat-treatable automotive components.

6. Key Results:

Key Results:

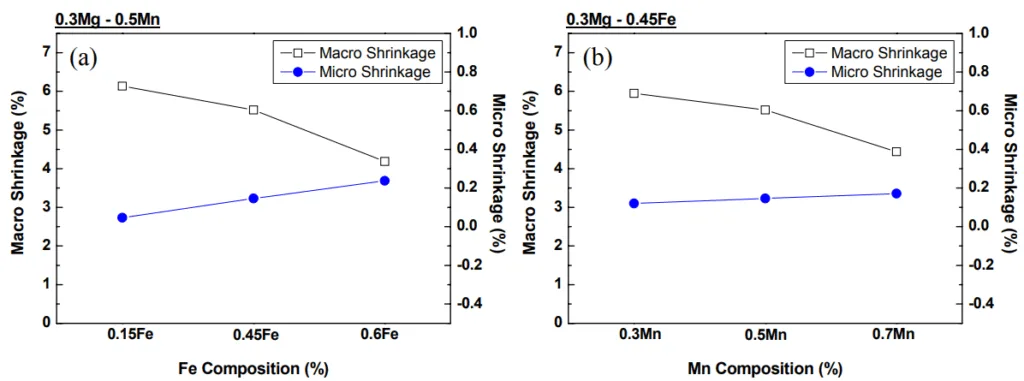

- Increased Fe and Mn content was found to decrease melt fluidity but improve resistance to die soldering by reducing the thickness of the reaction layer.

- The study identified an optimal composition for mechanical and casting characteristics in Al-9Si alloys: Fe content less than 0.45%, Mn content less than 0.5%, and the sum of Fe and Mn less than 0.65%.

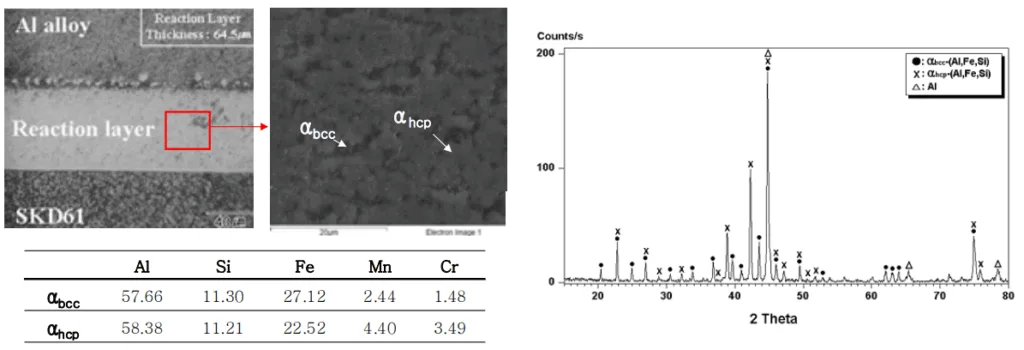

- The soldering layer formed on the SKD61 die material was identified as consisting of αhcp Al₈Fe₂Si and αbcc Al₈Fe₂Si phases.

- Casting simulation and experimental results confirmed that a vacuum HPDC process at a pressure below 100 mbar significantly reduces turbulence, internal air pressure, and the rate of internal blowholes compared to casting in an air atmosphere.

- Porosity in the thickest section (12.7 mm) was reduced from 4.99% in atmospheric HPDC to 1.41% in vacuum HPDC.

- Castings produced under vacuum could undergo T6 heat treatment without the formation of surface blisters, unlike their atmospheric-cast counterparts.

- The vacuum-cast and T6 heat-treated alloy demonstrated improved mechanical properties, including a high-cycle fatigue limit of 60 MPa at R=-1.

Figure Name List:

- Fig. 1. Effects of Fe and Mn contents on melt fluidity of (a) Al-9Si-0.3Mg-0.5Mn alloy, (b) Al-9Si-0.3Mg-0.45Fe alloy.

- Fig. 2. Effects of Fe and Mn contents on shrinkage of (a) Al-9Si-0.3Mg-0.5Mn alloy, (b) Al-9Si-0.3Mg-0.45Fe alloy.

- Fig. 3. Effects of Fe and Mn content on soldering layer.

- Fig. 4. SEM/EDX and XRD results of soldering specimen of Al-9Si-0.3Mg-0.15Fe-0.5Mn alloy.

- Fig. 5. Schematic illustrated modeling for HPDC simulation.

- Fig. 6. Filling behaviors of air and vacuum condition, (a) air, (b) vacuum: 100mbar.

- Fig. 7. Simulation results of air pressure, (a) atmosphere, (b) vacuum condition.

- Fig. 8. Porosity analysis by OM and CT, (a) atmosphere, (b) vacuum condition.

- Fig. 9. Surface analysis of cast node after T6 heat treatment, (a) atmosphere, (b) vacuum condition.

- Fig. 10. Results of mechanical properties, (a) tensile, (b) high cycle fatigue.

7. Conclusion:

(1) The increase of Fe and Mn content lowered the fluidity and shrinkage and improved die soldering. The soldering layers consist of both αhcp Al₈Fe₂Si and αbcc Al₈Fe₂Si phases due to mutual diffusion of Fe and Al between the SKD61 die and the molten aluminum.

(2) A satisfying result for the mechanical and casting characteristics of Al-9Si alloys was obtained when the portion of Fe is less than 0.45%, Mn is less than 0.5%, and the sum of Fe and Mn is less than 0.65%.

(3) Based upon HPDC analysis, at a pressure lower than 100 mbar, turbulence is calmed, internal air pressure is reduced, and the rate of internal blowholes is significantly reduced. Consequently, after T6 heat treatment, surface blisters were not formed, and improved mechanical characteristics were obtained.

8. References:

- [1] P. K. Rohatgi: J. Mater. Sci. 29 (1994) 5975-5984.

- [2] J. U. Ejiofor and R. G. Reddy: JOM 49 (1997) 31-37.

- [3] K. Sato, M. Saito, K. Yasunaga, K. Kiyama and T. Idegomori: J. Jpn. Inst. Light Met. 50 (2000) 121-127.

- [4] H. Koch, U. Hielsher, H. Sternau and A. J. Franke: TMS (1995) 1011-1018

- [5] S. Shankar and D. Apelian: Metall. Trans. 33B (2002) 465-476

- [6] G. B. Winkelman, Z. W. Chen, D. H. John and M. Z. Jahedi: Mater. Sci. Eng. 39 (2004) 519-528

- [7] S. Shankar and D. Apelian: NADCA Trans. 83 (1999) 285-292

Expert Q&A: Your Top Questions Answered

Q1: Why was the focus placed specifically on Iron (Fe) and Manganese (Mn) content?

A1: The paper targets Fe and Mn because they are known to be critical elements for controlling die soldering in aluminum alloys. As explained in the introduction and results, die soldering is a major production issue. The research confirmed that increasing Fe and Mn content forms intermetallic layers (specifically Al₈Fe₂Si phases) at the die-alloy interface, which act as a barrier and reduce the tendency for the aluminum to weld to the steel die.

Q2: What specific vacuum level was identified as effective, and why is it so important?

A2: The study demonstrated that a vacuum level below 100 mbar was highly effective. This is important because removing air from the die cavity before the molten metal is injected prevents gas from being trapped within the casting. As shown in the simulation (Fig. 7) and defect analysis (Fig. 8), this drastically reduces the internal gas porosity that causes blistering during subsequent T6 heat treatment.

Q3: How significant was the reduction in porosity when using the vacuum process?

A3: The reduction was very significant, especially in thicker sections where gas is more likely to be trapped. According to the data in Figure 8, the porosity in the 12.7 mm thick section of the test casting decreased from 4.99% under standard atmospheric conditions to just 1.41% under the 100 mbar vacuum condition. This more than 3.5-fold reduction in porosity is the key reason for the improved mechanical properties and successful heat treatment.

Q4: The paper mentions an optimal Fe and Mn content. What happens if you go above this recommended level?

A4: While higher Fe and Mn levels improve die soldering resistance, the paper shows there is a penalty. According to Figure 1, exceeding the optimal range (Fe < 0.45%, Mn < 0.5%) causes a significant drop in the alloy's fluidity. This can lead to misruns and incomplete filling of the die cavity, particularly in thin-walled or complex components, resulting in a different type of casting defect.

Q5: What was the final fatigue performance achieved, and why is this a critical result for the automotive industry?

A5: The vacuum-cast, T6-treated samples achieved a high-cycle fatigue limit of 60 MPa (at R=-1), as shown in Figure 10(b). This is a critical result because many automotive chassis and suspension components are subjected to millions of stress cycles during their service life. A high and reliable fatigue limit ensures the long-term durability and safety of the component, which is a non-negotiable requirement for the automotive industry.

Conclusion: Paving the Way for Higher Quality and Productivity

This research provides a clear and effective roadmap for overcoming two of the most significant hurdles in producing high-performance aluminum components: casting defects and die soldering. By carefully controlling alloy chemistry and implementing a Vacuum High Pressure Die Casting process, it is possible to manufacture complex, heat-treatable Al-Si-Mg parts that meet the stringent strength and durability requirements of the automotive industry. The key takeaway is that vacuum is not just an incremental improvement; it is an enabling technology that unlocks the full potential of high-strength aluminum alloys.

"At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components."

Copyright Information

This content is a summary and analysis based on the paper "Mechanical and Die Soldering Properties of Al-Si-Mg Alloys with Vacuum HPDC Process" by "Chang-Yeol Jeong, Yu-Seok Kim, Jun-Hyung Ryu and Heon-Joo Kim".

Source: Proceedings of the 12th International Conference on Aluminium Alloys, September 5-9, 2010, Yokohama, Japan, pp. 1768-1773

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.