Optimizing Anodized Aluminum Components: Why Your Casting Method is the Critical First Step

This technical summary is based on the academic paper "INFLUENCE OF ALUMINIUM ALLOY ANODIZING AND CASTING METHODS ON STRUCTURE AND FUNCTIONAL PROPERTIES" by J. KONIECZNY, K.LABISZ, M. POLOK-RUBINIEC, A. WŁODARCZYK-FLIGIER, published in Arch. Metall. Mater. (2016).

Keywords

- Primary Keyword: Anodized Aluminum Casting

- Secondary Keywords: AlSi9Cu3, HPDC, Wear Resistance, Surface Treatment, Anodizing Process, Casting Method Comparison

Executive Summary

- The Challenge: Achieving consistent and superior functional properties—like hardness and wear resistance—in anodized aluminum components, which are often compromised by the initial casting process.

- The Method: The study compared AlSi9Cu3 alloy components produced by high-pressure casting and sand casting, subjecting both to a controlled anodizing process in a sulphuric acid electrolyte.

- The Key Breakthrough: The initial casting method has a more significant impact on the final surface properties than the anodizing process itself; high-pressure cast parts showed a 46% increase in hardness after anodizing, while sand-cast parts showed negligible change.

- The Bottom Line: For applications requiring high hardness and a smooth surface finish after anodizing, selecting the right Anodized Aluminum Casting method, specifically high-pressure casting, is a critical, non-negotiable first step.

The Challenge: Why This Research Matters for HPDC Professionals

In industries from automotive to aviation, anodizing is a popular surface treatment for enhancing the properties of aluminum alloys. However, engineers often face inconsistencies in the final product. Anodic films can be brittle, and achieving uniform hardness and wear resistance across a component remains a significant challenge. The world economy loses billions of dollars annually due to product damage from surface layer degradation. This research addresses a fundamental question: Does the initial manufacturing process—specifically, the choice between sand casting and high-pressure casting—predetermine the success of the final anodized layer? For any engineer specifying a surface-treated aluminum part, understanding this relationship is crucial for avoiding costly failures and ensuring component reliability.

The Approach: Unpacking the Methodology

The researchers conducted a comparative study to isolate the effects of the casting method on the final properties of anodized AlSi9Cu3 alloy.

Method 1: Casting Process Comparison

- Material: Aluminum alloy AlSi9Cu3(Fe).

- Casting Methods: Two distinct methods were used to produce the initial samples:

1. High-Pressure Casting

2. Sand Casting

- This allowed for a direct comparison of how the initial material structure and surface created by each method would respond to subsequent treatment.

Method 2: Controlled Anodizing Process

- Electrolyte: A sulphuric acid (H₂SO₄) solution with a concentration of 315 g/l.

- Temperature: Maintained between -4°C and 2°C.

- Current: A pulsating current was applied (2 A/dm² for 0.25 s, followed by 1 A/dm² for 0.1 s).

- Analysis: The resulting anodized layers were analyzed for thickness, hardness (HRF), wear resistance (abrasive wear test), and surface morphology using light microscopy, atomic force microscopy (AFM), and a laser profilometer.

The Breakthrough: Key Findings & Data

The study revealed critical differences in how the casting method impacts the final anodized component's performance.

Finding 1: Casting Method Dictates Anodized Layer Thickness and Uniformity

The casting process directly influenced the thickness of the resulting Al₂O₃ layer. While both methods produced functional layers, the results were starkly different.

- High-Pressure Cast Samples: Produced a significantly thicker average anodized layer of 136.25 µm, but with greater variation (ranging from 65 µm to 207.5 µm).

- Sand Cast Samples: Produced a thinner average layer of 65 µm, with a more consistent thickness (ranging from 26.1 µm to 108.3 µm).

This is detailed in Table 3 of the paper, showing that for applications requiring maximum layer thickness, high-pressure casting is superior, though process control is needed to manage variability.

Finding 2: Hardness Improvement is Highly Dependent on the Casting Process

The most significant finding for component design is the dramatic difference in hardness improvement after anodizing.

- High-Pressure Cast Samples: Showed a substantial 46% increase in average hardness, from 9.51 HRF (non-anodized) to 13.96 HRF (anodized).

- Sand Cast Samples: Showed almost no change in hardness, moving from 10.14 HRF (non-anodized) to 11.43 HRF (anodized), a difference within the margin of measurement error.

This data, presented in Table 4, clearly indicates that the fine-grained microstructure typical of high-pressure casting is far more conducive to achieving a hard, functional surface layer through anodization.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that for AlSi9Cu3 components requiring a hard, wear-resistant anodized surface, high-pressure casting should be the preferred manufacturing method. The finer microstructure inherent to HPDC appears essential for the anodizing process to effectively increase surface hardness.

- For Quality Control Teams: The data in Table 3 and Table 4 illustrates that hardness and layer thickness can vary significantly based on the initial casting method. QC teams should establish different inspection criteria for parts originating from sand casting versus high-pressure casting, as their expected performance post-anodizing is fundamentally different.

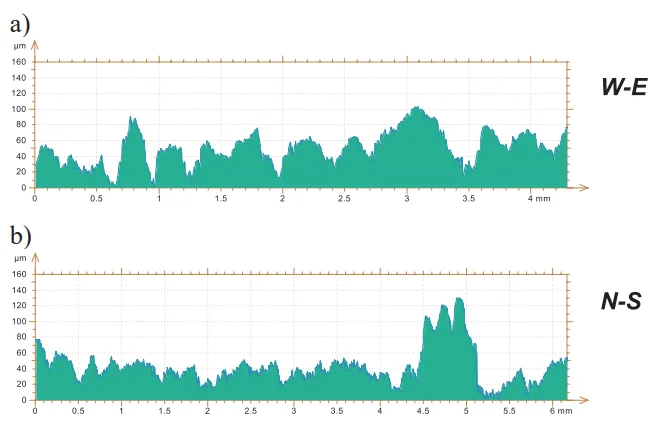

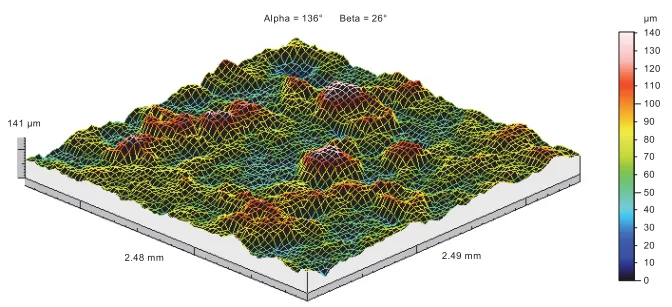

- For Design Engineers: The findings indicate that the initial surface roughness is determined by the casting method and is not significantly altered by the anodizing process (as seen in Figures 5 and 8). If a smooth final surface is required, specifying high-pressure casting is critical in the early design phase, as the anodizing layer will largely conform to the initial surface topography.

Paper Details

INFLUENCE OF ALUMINIUM ALLOY ANODIZING AND CASTING METHODS ON STRUCTURE AND FUNCTIONAL PROPERTIES

1. Overview:

- Title: INFLUENCE OF ALUMINIUM ALLOY ANODIZING AND CASTING METHODS ON STRUCTURE AND FUNCTIONAL PROPERTIES

- Author: J. KONIECZNY, K.LABISZ, M. POLOK-RUBINIEC, A. WŁODARCZYK-FLIGIER

- Year of publication: 2016

- Journal/academic society of publication: Archives of Metallurgy and Materials, Vol. 61, No 3

- Keywords: Anodization, Surface Treatment, Alumina, Al₂O₃ layer, Aluminium alloys, Wear resistance

2. Abstract:

This paper presents the influence of casting method and anodic treatment parameters on thickness and structure of an anodic layer formed on aluminium alloys. As test materials was used the aluminium alloy AlSi9Cu3, which was adopted to the casting process and anodic treatment. In this paper are presented the wear test results and metallographic examination, as well as hardness of non-anodised and anodised alloys subjected to anodising process. The investigations were performed using light and electron microscopy (AFM) for the microstructure determination. The morphology and size of the layer was also possible to determine. The anodising conditions for surface hardening and its influence on properties was analysed. The structure of the surface layer changes in a way, that there is a different thickness of the produced layer. The aluminium samples were examined in terms of metallography using the optical microscope with different image techniques as well as light microscope. Improving the anodization technology with appliance of different anodising conditions. Some other investigation should be performed in the future, but the knowledge found in this research concerning the proper process parameters for each type of alloy shows an interesting investigation direction. The combination of metallographic investigation for cast aluminium alloys – including electron microscope investigation – and anodising parameters makes the investigation very attractive for automobile industry, aviation industry, and others, where aluminium alloys plays an important role.

3. Introduction:

Surface treatment, such as anodising of aluminium, is a popular technique for obtaining porous structures. The utility of anodised aluminium depends on the properties of the oxide layers formed. The significant interest in surface layer technologies is driven by substantial economic losses from product damage due to surface layer degradation. Anodising alters the surface texture and the crystal structure of the metal near the surface. The resulting coatings are typically thick and porous, often requiring a sealing process to enhance corrosion resistance. While anodized surfaces are harder than base aluminium, they have moderate wear resistance. Anodic films are generally stronger and more adherent than paints or metal plating but are also more brittle. Anodic oxidation processes are being developed to increase competitiveness in various industries, competing with technologies like powder spraying. A key advantage of anodization is its resistance to filiform corrosion and the recyclability of products with oxide coatings. The properties of the anodized layer, such as porosity, depend on electrolytic process parameters like current density, electrolyte temperature, and process duration.

4. Summary of the study:

Background of the research topic:

The study addresses the need to improve the functional properties of aluminum alloys through surface treatment, specifically anodizing. It recognizes the economic and industrial importance of creating durable, wear-resistant, and corrosion-resistant surfaces on aluminum components used in automotive, aviation, and other sectors.

Status of previous research:

Previous research has established anodizing as a leading method for finishing aluminum. It is known that process parameters (current, temperature, duration) control the layer's porosity and that impurities in the substrate can cause deviations from an ideal columnar structure. However, the direct comparative influence of the initial casting method (e.g., pressure vs. sand casting) on the final structure and properties of the anodized layer on a specific alloy like AlSi9Cu3 required further investigation.

Purpose of the study:

The aim of this work is to describe the influence of anodising conditions and, crucially, the initial casting method on the obtained layer thickness, uniformity, texture, and functional properties such as hardness and wear resistance for the AlSi9Cu3 alloy.

Core study:

The core of the study involved taking AlSi9Cu3 alloy samples produced by two different methods—high-pressure casting and sand casting—and subjecting them to a standardized anodizing process. The resulting non-anodized and anodized samples were then comprehensively analyzed to compare their microstructure, surface geometry, layer thickness, hardness, and wear resistance.

5. Research Methodology

Research Design:

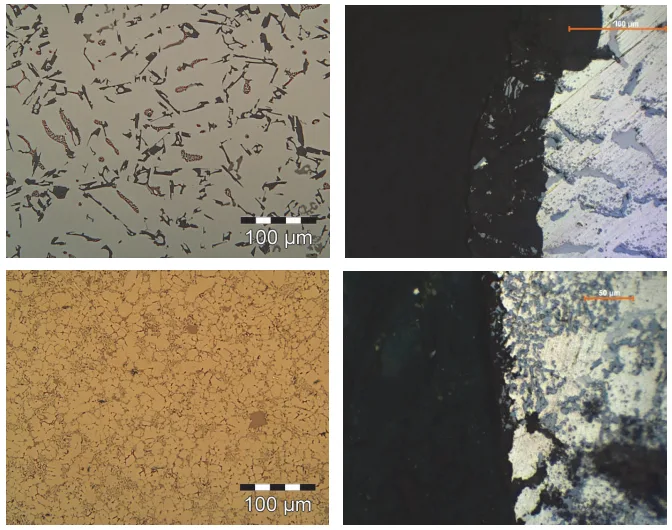

The research was designed as a comparative study. Four groups of materials were analyzed: high-pressure cast (anodized and non-anodized) and sand cast (anodized and non-anodized). This design allowed for the isolation and evaluation of the effects of both the casting method and the anodizing treatment.

Data Collection and Analysis Methods:

- Microstructure and Layer Thickness: Light microscopy (Leica MEF-4A) was used for metallographic investigations and to measure the oxide layer thickness.

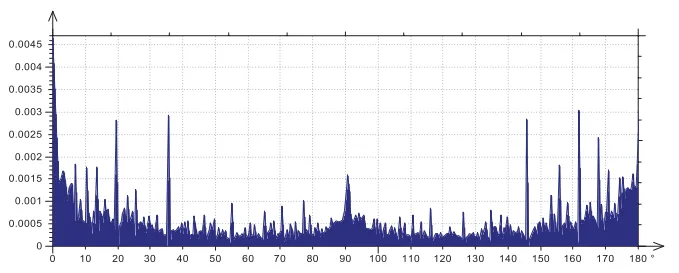

- Surface Geometry & Roughness: A laser profilometer was used to analyze the surface geometry. Atomic Force Microscopy (AFM) was used for high-resolution surface structure analysis.

- Hardness: Hardness measurements were performed on an automatic hardness tester using a 1/16 inch sintered carbide ball penetrator (HRF scale).

- Wear Resistance: Abrasive wear tests were conducted according to ISO 8251, with a load of 4.9 N at a slip velocity of 40 cycles/min.

Research Topics and Scope:

The research focused on the AlSi9Cu3 aluminum alloy. The scope included:

1. Comparing the effects of high-pressure casting and sand casting.

2. Evaluating the change in hardness, wear resistance, and surface structure after anodizing in a sulphuric acid electrolyte.

3. Characterizing the thickness and morphology of the resulting Al₂O₃ layer.

6. Key Results:

Key Results:

- The casting method significantly influences the thickness of the anodized layer; high-pressure casting produced a thicker but more variable layer (average 136.25 µm) compared to sand casting (average 65 µm).

- Anodizing substantially increased the hardness of high-pressure cast samples by 46% (from 9.51 to 13.96 HRF), but had a negligible effect on sand cast samples.

- Anodized samples exhibited improved wear resistance. For high-pressure cast samples, mass loss during wear tests was reduced by approximately half compared to non-anodized samples. For sand cast samples, the reduction in weight loss was 36%.

- The overall surface geometry and roughness are primarily determined by the casting method, not the subsequent anodizing process. The anodized layer conforms to the initial surface texture.

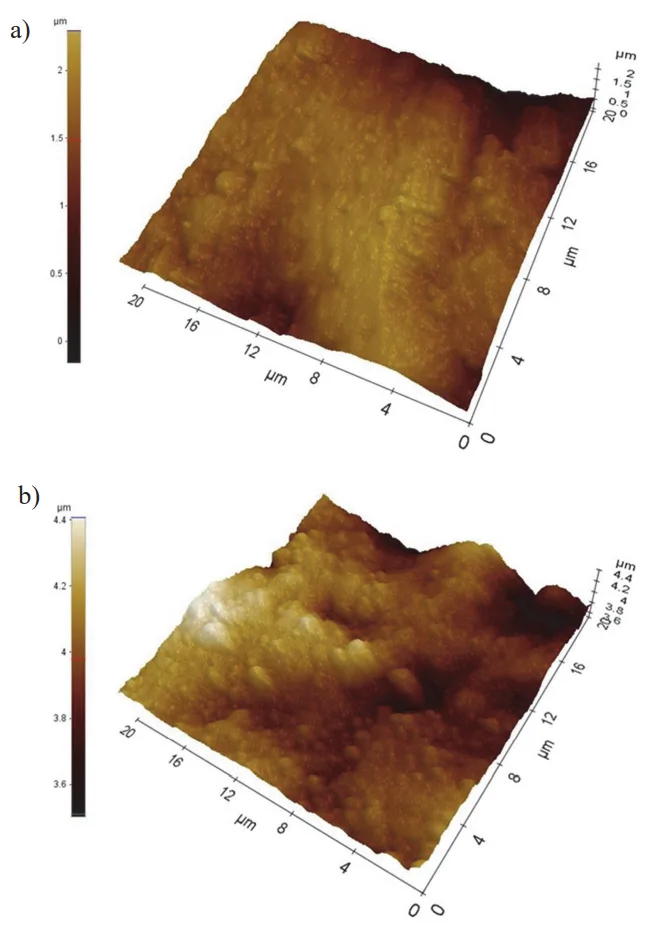

- AFM analysis showed that the anodized alumina surface is smoother (roughness up to 2.3 µm) than the non-anodized surface (roughness up to 4.4 µm).

Figure Name List:

- Fig. 1. Comparison of wear resistance of sand cast alloys and high pressure cast alloys

- Fig. 2. Structure of the sand cast alloy(top left) and anodic layer (top right) and structure of the high pressure cast (bottom left) and anodic layer (bottom right) produced on the composite EN-ACAlSi9Cu3

- Fig. 3. Geometric shape of the test surface, colour intensity map (left), numeric photograph of the sample surface (right), sand cast alloy

- Fig. 4. Selected 2D profiles cut from the test surface: a) in the W-E plane, b) in the N-S plane, sand cast alloy

- Fig. 5. Geometric shape of the selected test surface area (2,5x2,5mm), b) 3D surface topography, sand cast alloy

- Fig. 6. Geometric shape of the test surface, colour intensity map (left), numeric photograph of the sample surface (right), high pressure cast

- Fig. 7. Selected 2D profiles cut from the test surface: a) in the W-E plane, b) in the N-S plane, high pressure cast

- Fig. 8. Geometric shape of the selected test surface area (2,5x2,5mm), b) 3D surface topography, high pressure cast

- Fig. 9 Texture of the Surface (distribution of the characteristic directions) sand cast material

- Fig. 10 Texture of the Surface (distribution of the characteristic directions) high pressure cast material

- Fig.11 Surface structure of the anodised (a), and non-anodised (b) AlSi9Cu3 cast alloy

- Fig. 12 Surface layer thickness measurement results

7. Conclusion:

The investigation demonstrated that the anodized alloy surface shows less weight loss compared to non-anodised material, indicating higher abrasion resistance. The casting method affects abrasion resistance, with sand cast alloys exhibiting less weight loss than high-pressure cast alloys in this study. Based on hardness measurements, samples after the anodization process have higher hardness, increasing to 14 HRF. The results allow for the unequivocal determination that the combination of the manufacturing method and surface treatment influences the final properties, with the sand cast AlSi9Cu3 alloy combination showing favorable results in terms of wear.

8. References:

- [1] P.G. Sheasby, R.Ch. Pinner, The Surface Treatment and Finishing of Aluminum and its Alloys, Materials Park, Ohio & Stevenage, UK: ASM International & Finishing Publications 2001

- [2] H. Adelkhani, H. Forati Rad, Iranian Journal of Surface and Engineering 16, 9-17 (2013)

- [3] J.G. Castaño, F. Echeverría, Ingeniería & Desarrollo. Universidad del Norte. 28 1-14 (2010)

- [4] T. Araújo, Faculdade de Engenharia da Universidade do Porto 2012

- [5] M. Michalska-Domańska, M. Norek, W.J. Stępniowski, B. Budner, Electrochim Acta. 105, 424-432 (2013)

- [6] J. Konieczny, L.A. Dobrzanski, K. Labisz, J. Duszczyk, J Mater Process Tech. SPEC. ISS. 718-723 (2004)

- [7] Y. Goueffon, L. Arurault, C. Mabru, C. Tonon, P. Guigue, J Mater Process Tech. 209, 5145-5151 (2009)

- [8] M.B. Spoelstra, A.J. Bosch, D.H. Van Der Weijde, J.H.W. De Wit, Mater Corros. 51 (3), 155-160 (2000)

- [9] J.M. Montero-Moreno, M. Sarret, C. Müller, Surf Coat Tech. 201, 6352-6357 (2007)

- [10] L. Kwiatkowski, P. Tomassi, Surface Eng. 3, 39-48 (2006)

- [11] P. Tomassi, Steel Construction (in polish), Special ed. 30-31 (1998)

- [12] W. Skoneczny, Surface Eng. 2, 21 – 26 (2000), in polish

- [13] F. Ishigure, S. Inayoshi, J of the Vacuum Soci of Japan. 58 (12), 437-441 (2015)

Expert Q&A: Your Top Questions Answered

Q1: Why was the AlSi9Cu3 alloy chosen for this investigation?

A1: The paper specifies AlSi9Cu3 as the test material because it is a common alloy used in industrial applications, particularly in the automotive sector, where both casting and subsequent surface treatments like anodizing are prevalent. Its composition (Table 1) presents a realistic test case for evaluating how casting and anodizing interact to affect functional properties like wear resistance and hardness, which are critical in these applications.

Q2: The paper states that anodizing increases hardness by 46% for pressure-cast parts but has a negligible effect on sand-cast parts. What is the likely metallurgical reason for this?

A2: While the paper doesn't explicitly state the metallurgical reason, it is well-established in materials science that high-pressure casting produces a much finer grain structure and more homogenous distribution of alloying elements compared to the slower cooling rates of sand casting. This finer, more uniform substrate in the HPDC parts likely allows for the formation of a more dense and structurally sound anodic oxide layer, which translates into a significant increase in measured hardness. The coarse, heterogeneous structure of the sand-cast part may lead to a less uniform, more flawed oxide layer that does not contribute significantly to overall hardness.

Q3: According to Table 3, high-pressure casting produces a thicker anodized layer on average (136 µm vs. 65 µm). Why would a faster casting process lead to a thicker subsequent coating?

A3: The paper doesn't provide a direct explanation, but the phenomenon is likely related to the surface chemistry and microstructure created during casting. The rapid solidification in high-pressure casting can lead to a different surface energy and distribution of silicon and copper phases compared to sand casting. These differences can affect the local efficiency and rate of the electrochemical reaction during anodizing, potentially promoting faster oxide growth in certain areas, leading to a thicker average layer, albeit with the higher variability noted in the results.

Q4: The conclusion states that sand-cast alloys exhibit less weight loss (higher abrasion resistance), yet the hardness data shows high-pressure cast parts become much harder after anodizing. How can a softer material be more wear-resistant?

A4: This is an excellent observation of a complex relationship. The paper's conclusion that "sand cast alloys exhibit less weight loss" seems to be a direct interpretation of the wear test results, where improved wear resistance (less mass loss) was noted for both, but perhaps more consistently for sand cast parts. Hardness and wear resistance are not always directly proportional. A very hard but brittle surface (like some ceramic coatings) can fracture or spall under abrasive stress, leading to high mass loss. It's possible the more compliant, though softer, anodized layer on the sand-cast part wore away more uniformly, while the harder layer on the pressure-cast part experienced micro-fracturing, even if its hardness value was higher.

Q5: The study used a pulsating DC current for anodizing. What is the advantage of this method over a standard constant DC current?

A5: The paper specifies the pulsating current parameters in Table 2 (2 A/dm² for 0.25 s, 1 A/dm² for 0.1 s) but does not explain the choice. In industrial anodizing, pulsating currents are often used to achieve denser, harder, and more uniform oxide layers, especially in complex alloys. The high-current pulse promotes rapid oxide formation, while the lower-current or off-period allows for heat dissipation and ion replenishment at the substrate-electrolyte interface, which can prevent burning and lead to a higher quality coating compared to a constant DC process.

Conclusion: Paving the Way for Higher Quality and Productivity

This research provides a critical insight for any manufacturer of high-performance aluminum components: the initial casting method is a decisive factor in the final quality of an anodized surface. The study clearly demonstrates that for AlSi9Cu3 alloy, high-pressure casting is the superior route for achieving a significant increase in surface hardness after anodizing. By understanding this fundamental relationship, engineers can make more informed decisions at the design stage, preventing downstream quality issues and ensuring components meet demanding performance specifications. This knowledge is essential for optimizing Anodized Aluminum Casting processes for better wear resistance and durability.

"At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components."

Copyright Information

This content is a summary and analysis based on the paper "INFLUENCE OF ALUMINIUM ALLOY ANODIZING AND CASTING METHODS ON STRUCTURE AND FUNCTIONAL PROPERTIES" by "J. KONIECZNY, K.LABISZ, M. POLOK-RUBINIEC, A. WŁODARCZYK-FLIGIER".

Source: DOI: 10.1515/amm-2016-0220

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.