Optimizing Al-Mg-Si-Mn Casting Alloys: The Dual Role of Titanium in Grain Refinement and Microstructure Control

This technical summary is based on the academic paper "Microstructure formation and grain refinement of Al-Mg-Si-Mn casting alloys" by Viktoriya Boyko, Edward Czekaj, Małgorzata Warmuzek, and Kostiantyn Mykhalenkov, published in Transactions of the Foundry Research Institute (2018).

Keywords

- Primary Keyword: Al-Mg-Si-Mn Casting Alloys

- Secondary Keywords: Grain refinement, Titanium addition, AlMg5Si2Mn, Microstructure formation, High Pressure Die Casting (HPDC), Mg2Si, Automotive aluminum alloys

Executive Summary

- The Challenge: The automotive industry requires high-ductility, high-strength aluminum casting alloys, but existing materials often present a trade-off between mechanical properties and castability.

- The Method: Researchers investigated the microstructural effects of adding varying amounts of titanium (Ti) to an AlMg5Si2Mn base alloy cast into a permanent steel mold.

- The Key Breakthrough: Titanium addition has a dual effect, acting as a nucleation substrate for both the primary α-Al solid solution grains and the primary Mg₂Si crystals, significantly refining the microstructure.

- The Bottom Line: Optimizing titanium content (to approximately 0.15 wt.%) is critical for leveraging its grain refining benefits without forming large, undesirable intermetallic particles that can compromise mechanical properties.

The Challenge: Why This Research Matters for HPDC Professionals

In the push for lightweighting and electric vehicles, aluminum alloys are essential for car body structures. While traditional Al-Si-Mg alloys are common, the industry's demand for components with superior ductility and strength has shifted focus to the Al-Mg-Si system. These alloys, like AlMg5Si2Mn, offer an excellent combination of strength, high ductility, corrosion resistance, and good castability.

However, controlling the final microstructure is paramount to achieving these properties consistently. Uncontrolled grain size or the formation of coarse primary phases can lead to inconsistent mechanical performance and reduced ductility. Specifically, understanding how to refine both the aluminum matrix and the strengthening Mg₂Si phase is a key challenge for producing high-performance, reliable structural components. This research directly addresses this challenge by investigating titanium—a well-known grain refiner—to see how it influences the complex solidification behavior of Al-Mg-Si-Mn alloys.

The Approach: Unpacking the Methodology

The study was designed to isolate the effect of titanium on the microstructure of an Al-Mg-Si-Mn alloy. The researchers used a systematic, controlled approach to ensure the reliability of their findings.

Method 1: Alloy Preparation and Composition

Three alloys were prepared in an electric resistance furnace using graphite crucibles. The base alloy (B) was a nominal AlMg5Si2Mn with a residual Ti content of 0.04 wt.%. Two additional alloys were melted with controlled titanium additions, resulting in total Ti contents of 0.09 wt.% (T1) and 0.22 wt.% (T2). High-purity aluminum and master alloys (AlMg50, AlSi25, AlMn26, AlTi6) were used to ensure precise chemical composition, which was verified by X-ray fluorescence analysis.

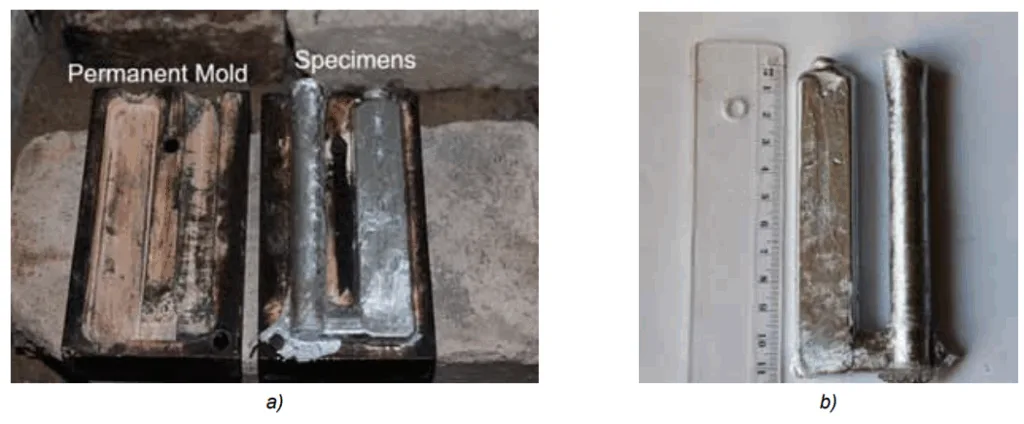

Method 2: Controlled Casting and Solidification

After melting and argon fluxing to remove impurities, the alloys were cast at 700°C into a permanent steel mold held at 25°C. This setup was chosen to produce similar cooling conditions for all alloys, with preliminary tests indicating a cooling rate of 2 K·s⁻¹ prior to solidification. This controlled cooling is crucial for comparing the microstructural evolution between the different alloy compositions.

Method 3: Microstructural Analysis

The solidified ingots were sectioned for detailed metallographic examination. The researchers employed optical microscopy and Scanning Electron Microscopy (SEM) using Zeiss EVO and ULTRA microscopes. These were equipped with Energy Dispersive Spectrometry (EDS) for quantitative chemical microanalysis of the observed phases, allowing for precise identification of the particles acting as nucleation sites.

The Breakthrough: Key Findings & Data

The study revealed a powerful, dual-role mechanism for titanium in Al-Mg-Si-Mn alloys, but also highlighted a critical upper limit for its addition.

Finding 1: Titanium Acts as a Nucleus for α-Al Grains

The investigation of alloy T2 (0.22 wt.% Ti) clearly showed that Ti-rich particles were located at the center of the equiaxed α-Al solid solution grains. As shown in Figure 6, EDS analysis confirmed these particles were primary Al₃Ti, which acted as effective nuclei for the α-Al grains. This confirms titanium's role as a potent grain refiner for the aluminum matrix in this alloy system, which is essential for achieving fine, uniform microstructures and improved mechanical properties.

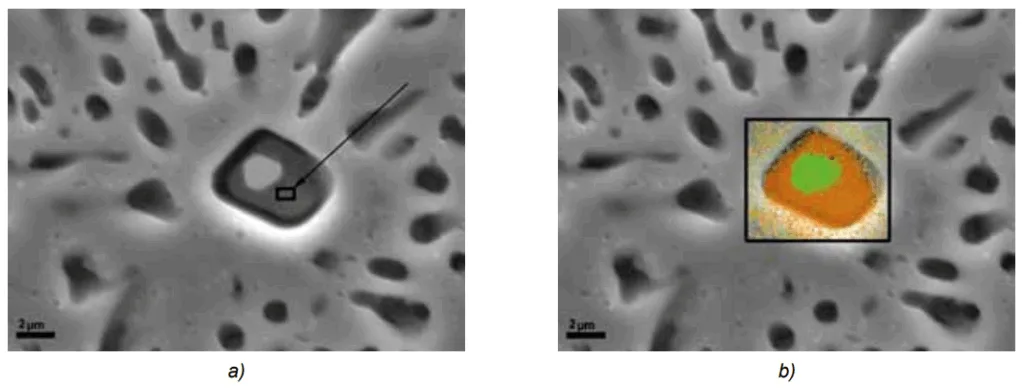

Finding 2: Titanium Also Nucleates Primary Mg₂Si Crystals

More surprisingly, the researchers discovered that Ti-containing particles were also present at the center of primary Mg₂Si crystals (Figure 7). This indicates a multi-step nucleation process: Al₃Ti particles form first in the melt, and subsequently, these particles serve as substrates for the formation of both primary Mg₂Si crystals and α-Al grains. This dual-refining effect is a significant finding, as it offers a pathway to simultaneously control the size and distribution of two critical phases in the microstructure.

Finding 3: Excessive Titanium Leads to Undesirable Coarse Particles

While beneficial at low levels, the addition of 0.22 wt.% Ti (alloy T2) resulted in the formation of large, unevenly distributed primary Al₃Ti particles (Figure 8). These coarse intermetallics do not contribute to nucleation and can act as stress concentrators, potentially degrading the alloy's ductility and fatigue performance. The study concludes that the optimal Ti addition should be kept close to 0.15 wt.% to achieve the desired nucleating effect while avoiding the formation of these detrimental, large primary intermetallic crystals.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that precise control over titanium addition is crucial. Adding Ti up to ~0.15 wt.% can significantly refine the microstructure, potentially improving melt fluidity and feeding during casting. However, exceeding this level may introduce coarse intermetallics, requiring adjustments to melt treatment or alloy specification.

- For Quality Control Teams: The data in Figures 6, 7, and 8 of the paper illustrate the direct link between titanium content and the presence of both beneficial nuclei and detrimental coarse particles. This could inform new microstructural inspection criteria for incoming materials or cast components, ensuring the Ti level is within the optimal range for peak performance.

- For Design Engineers: The findings indicate that achieving a fine-grained, uniform microstructure through controlled Ti addition can lead to improved and more consistent mechanical properties, particularly ductility. This knowledge allows for greater confidence when designing complex, thin-walled structural components where high performance is critical.

Paper Details

Microstructure formation and grain refinement of Al-Mg-Si-Mn casting alloys

1. Overview:

- Title: Microstructure formation and grain refinement of Al-Mg-Si-Mn casting alloys

- Author: Viktoriya Boyko, Edward Czekaj, Małgorzata Warmuzek, Kostiantyn Mykhalenkov

- Year of publication: 2018

- Journal/academic society of publication: PRACE INSTYTUTU ODLEWNICTWA (TRANSACTIONS OF THE FOUNDRY RESEARCH INSTITUTE), Volume 58, Issue 4

- Keywords: aluminium alloys, Al-Mg-Si system, alloying addition, grain refiners, eutectic modifiers, precipitation, casting

2. Abstract:

Together with development of casting technology for Al-Si-Mg alloys, new groups of casting materials are undergoes its implementation into foundry practice. Al-Mg-Si casting alloys possessed several advantages such as good strength in as-cast state combined with high ductility, good corrosion resistance and castability. In both Al-Si-Mg and Al-Mg-Si systems, the range of the eutectic crystallization occurs: L→αAl + βSi and L→αAl + Mg₂Si, respectively. In the hypoeutectic alloys of both system as a primary phase – dendrites of the solid solution αAl solidify. The transition elements – Ti, Zr, Sc, which provides efficient grain refinement can dissolve in this solid solution αAl causing precipitation strengthening effect. In the article the present state of the researches on the development of Al-Mg-Si casting alloys is considered together with the results of the examinations on the effect of Ti addition on the microstructure of the AlMg5Si2Mn alloy. These researches results were discussed at the annual conference on the casting of non-ferrous metals "Science and Technology" (2018) and initially presented in an shortened form in the article [1].

3. Introduction:

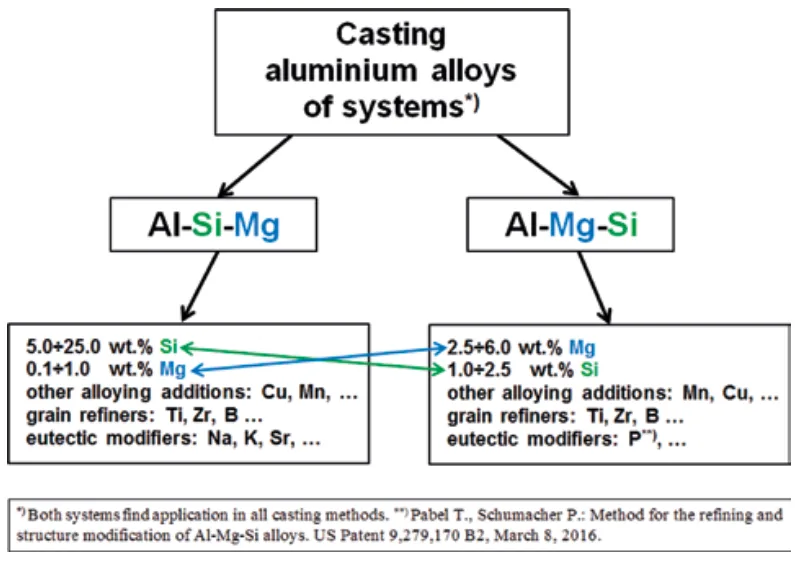

Aluminum alloys are the second most popular casting materials by tonnage after ferrous castings. While Al-Si alloys are dominant, the demand for materials with higher ductility and strength for applications like automotive car bodies has driven the development of Al-Mg-Si alloys. These alloys, particularly in the 6xxx series for wrought products, offer a good combination of strength, corrosion resistance, and castability. To maximize the benefits of aluminum-intensive car bodies, die castings must have mechanical properties comparable to wrought components, which current alloys often fail to provide. Over the last 20 years, new foundry alloys have shifted composition from the Al-Si-Mg system to the Mg-rich part of the Al-Mg-Si phase diagram. This research focuses on these Al-Mg-Si alloys, which are characterized by high Mg (2.5-6.0 wt.%) and lower Si (1.0-2.5 wt.%) content, and investigates methods for microstructural control.

4. Summary of the study:

Background of the research topic:

Al-Mg-Si casting alloys are gaining importance due to their favorable properties for automotive applications, including high strength and ductility. The microstructure of these alloys, consisting of a primary α-Al solid solution and a (αAl + Mg₂Si) eutectic, is highly sensitive to composition and cooling conditions. Transition elements like Titanium (Ti) are known grain refiners in aluminum alloys, but their specific role in the complex solidification of Al-Mg-Si-Mn alloys, particularly their effect on the formation of the primary Mg₂Si phase, is not fully understood.

Status of previous research:

Previous studies have characterized the structure and properties of Al-Mg-Si alloys like Magsimal-59. Research by Fan et al. demonstrated that Ti could significantly increase the elongation of die-cast Al-Mg-Si alloys, with an increase from 11% to 18% elongation when Ti content was raised from 0.015 wt.% to 0.15 wt.%. That work also noted a corresponding 10% increase in strength at 0.2 wt.% Ti. However, detailed structural investigations to explain the mechanism behind these improvements were not performed.

Purpose of the study:

The primary aim of this work was to analyze and discuss the microstructural effect of Titanium (Ti) addition on an Al-Mg-Si alloy. The study sought to understand the role of Ti in the formation of the microstructure, including its influence on both the primary α-Al solid solution and the Mg₂Si intermetallic phase.

Core study:

The study involved melting and casting three Al-Mg-Si-Mn alloys with varying levels of titanium: a base alloy with 0.04 wt.% Ti (B), an alloy with 0.09 wt.% Ti (T1), and an alloy with 0.22 wt.% Ti (T2). The alloys were solidified under controlled cooling conditions in a steel mold. The resulting microstructures were examined using optical and scanning electron microscopy (SEM) with energy dispersive spectrometry (EDS) to identify the phases present and determine the role of Ti-containing particles in the nucleation process.

5. Research Methodology

Research Design:

The research employed an experimental design to compare the microstructures of three alloys of nearly identical base composition but with systematically varied titanium content. This approach allowed for the direct observation of the effect of Ti on phase formation and grain structure during solidification.

Data Collection and Analysis Methods:

Alloys were prepared in an electric resistance furnace. Master alloys AlMg50, AlSi25, AlMn26, and AlTi6 were used with high-purity aluminum. The melt was treated with argon fluxing before being cast at 700°C into a 25°C steel mold to achieve a cooling rate of approximately 2 K·s⁻¹. Specimens were cut from the ingots for metallographic analysis. Microstructure and phase composition were analyzed using a Zeiss Axioskop optical microscope and Zeiss EVO and ULTRA SEMs equipped with EDS for quantitative chemical analysis.

Research Topics and Scope:

The research focused on the AlMg5Si2Mn alloy system. The scope was limited to the as-cast condition to study the effect of Ti addition on the primary solidification microstructure. The investigation centered on identifying the nucleation sites for the α-Al solid solution and primary Mg₂Si crystals and determining the morphological effects of different Ti concentrations.

6. Key Results:

Key Results:

- The microstructure of the base alloy consists of dendritic α-Al grains with an interdendritic lamellar (αAl + Mg₂Si) eutectic.

- Addition of titanium leads to the formation of Al₃Ti particles in the melt before the solidification of other phases.

- These Al₃Ti particles were observed to act as nucleation sites for the primary α-Al solid solution grains, resulting in grain refinement.

- Al₃Ti particles also serve as heterogeneous nucleation substrates for primary Mg₂Si crystals, demonstrating a dual-refining capability.

- An excessive addition of titanium (0.22 wt.% in alloy T2) resulted in the formation of large, coarse primary Al₃Ti particles that did not participate in nucleation and are considered structurally undesirable.

- The study suggests an optimal level of Ti addition should be kept close to 0.15 wt.% to maximize the grain refining effect while avoiding the formation of coarse intermetallics.

Figure Name List:

- Fig. 1. General characteristics of chemical composition of casting alloys of Al-Si-Mg and Al-Mg-Si systems

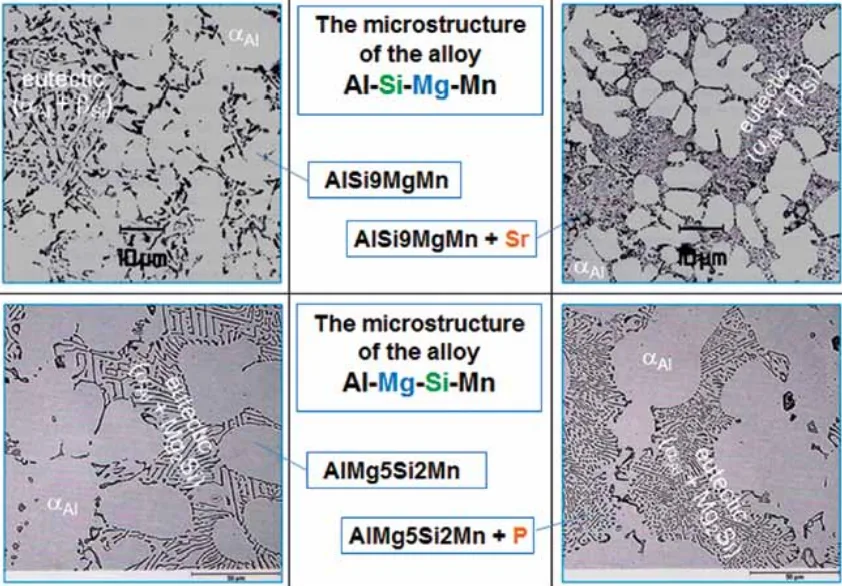

- Fig. 2. Microstructure of Al-Si-Mg-Mn and Al-Mg-Si-Mn alloys in the initial state and after chemical modification of eutectic (developed based on: www.alurheinfelden.com)

- Fig. 3. Microstructures AlMg5.5Si2.3Mn0.6 alloy (Magsimal-59) solidified at a different cooling rate [3]

- Fig. 4. Mold after casting (a) and specimens obtained from alloys subjected to research program (b)

- Fig. 5. Microstructure of alloy B

- Fig. 6. Equiaxed grain of αAl solid solution in alloy T2 (a), particles observed in the grain center (b), enlarged view of the particle in grain center (c) and mapping of Ti, V, Mg and Si concentration (d)

- Fig. 7. Morphology of primary Mg₂Si crystal (a), nucleation particle inside of Mg₂Si, and distribution of Ti concentration (green) inside the crystal Mg₂Si (brown) (b)

- Fig. 8. Distribution and morphology of primary Al₃Ti particles observed in alloy T2

7. Conclusion:

- The addition of Ti to Al-Mg-Si alloys produces a double effect on structure formation. During cooling, Al₃Ti particles are formed in the melt and act as nucleation particles for the formation of solid solution grains, thus acting effectively as a grain refiner. Simultaneously, these particles act as a nucleation substrate for primary Mg₂Si crystals.

- The amount of Ti added to Al-Mg-Si alloys should be optimized to avoid the formation of undesired large Al₃Ti crystals (<0.15 wt.%) and, subsequently, to improve the mechanical properties of alloys.

8. References:

- Boyko V., E. Czekaj, K. Mykhalenkov. 2018. Effect of Ti addition on structure formation of Al-Mg-Si-Mn casting alloy. W Materiały XXI Międzynarodowej Konferencji Naukowo-Technicznej Odlewnictwa Metali Nieżelaznych (Materials of the 21st International Scientific and Technical Conference of Casting of Non-Ferrous Metals), 7–20. Kraków (Poland): Wydawnictwo Naukowe „Akapit”.

- Totten G.E., D.S. MacKenzie (eds.). 2003. Handbook of Aluminium: Vol. 1. Physical Metallurgy and Processes. Valley Forge, PA, USA: Metal Dekker Inc.

- Shimosaka D., S. Kumai, F. Casarotto, S. Watanabe. 2011. „Effect of cooling rates during solidification of Al-5.5%Mg-2.3%Si-0.6%Mn and Al-13%Mg₂Si pseudo-binary alloys on their secondary-particle morphology and tear toughness”. Materials Transactions 52 (5): 920–927.

- Casarotto F., A.J. Franke, R. Franke. 2012. High-pressure die-cast (HPDC) aluminium alloys for automotive applications W Advanced materials in automotive engineering, ed. by Jason Rowe, 109–149. Woodhead Publishing Ltd.

- Ji S., D. Watson, Z. Fan, M. White. 2012. „Development of a super ductile diecast Al-Mg-Si alloy”. Materials Science and Engineering: A 556 (30 October 2012): 824–833.

- Pirš J., A. Zalar. 1990. „Investigations of the distribution of elements in phases present in G-AlMg₅Si cast alloy with EDX/WDX spectrometers and AES. Microchimica Acta 101 (1–6): 295–304.

- Koch H., U. Sternau, H. Sternau, A.J. Franke. 1996. Magsimal-59, an AlMgMnSi-type squeeze-casting alloy designed for temper F. W TMS Annual Meeting, 933–937. Anaheim, LA, February 1996.

- Hartlieb M. 2013. „Aluminium alloys for structural die casting”. Die Casting Engineer (May 2013): 40–43.

- Di Sabatino M., L. Arnberg, S. Brusethaug, D. Apelian. 2006. „Fluidity evaluation methods for Al-Mg-Si alloys”. International Journal of Cast Metals Research 19 (2): 94–97.

- Otarawanna S., C.M. Gourlay, H.I. Laukli, A.K. Dahle. 2009. „Microstructure formation in AlSi4MgMn and AlMg5Si2Mn high-pressure die castings”. Metallurgical and Materials Transactions A 40 (7): 1645–1659.

- Hu Z., L. Wan, S. Lu, P. Zhu, S. Wu. 2014. „Research on the microstructure, fatigue and corrosion behavior of permanent mold and die cast aluminium alloy”. Materials and Design 55 : 353–360.

- Georgatis E., A. Lekatou, A.E. Karantzalis, H. Petropoulos, S. Katsamakis, A. Poulia. 2013. „Development of a cast Al-Mg₂Si-Si in-situ composite: Microstructure, heat treatment, and mechanical properties”. Journal of Materials Engineering and Performance 22 (3): 729–741.

- Boyko V., E. Czekaj, M. Warmuzek, K. Mykhalenkov. 2017. „Effect of additional alloying and heat treatment on phase composition and morphology in Al-Mg-Si-type casting alloy”. Metallurgy and Foundry Engineering 43 (3): 219–239.

- Ji S., D. Watson, Z. Fan, M. White. 2012. „Development of a super ductile diecast Al-Mg-Si alloy”. Materials Science and Engineering: A 556 (30 October 2012): 824–833.

- Мильман Ю.В., Т.Н. Легкая, Н.П. Коржова, В.В. Бойко, И.В. Воскобойник, К.В. Михаленков, Н.М. Мордовец, Ю.Н. Подрезов. 2015. „Structure and mechanical properties of the casting high strength aluminium alloys of Al-Mg-Si ternary system alloyed by Zn and Cu”. Электронная микроскопия и прочность материалов 21: 30–37 (in Russian).

- Eigenfeld K., A. Franke, S. Klan, H. Koch, B. Lenzcowski, B. Pflege. 2004. „New developments in heat resistant aluminium casting materials”. Casting Plant and Technology International (4): 4–9.

- Ji S., D. Watson, Y. Wang, M. White, Z. Fan. 2013. „Effect of Ti addition on mechanical properties of high pressure die cast Al-Mg-Si alloys”. Materials Science Forum 765 : 23–27.

Expert Q&A: Your Top Questions Answered

Q1: Why was a permanent steel mold used for casting instead of a high-pressure die casting setup?

A1: The study used a permanent steel mold to achieve a controlled and relatively slow cooling rate of 2 K·s⁻¹. This allows for clearer observation of the fundamental nucleation and growth stages of the microstructure. While HPDC is the target application, its rapid solidification can obscure these initial events. By understanding the mechanisms at a slower cooling rate, the findings can be extrapolated to inform alloy design for HPDC processes.

Q2: What is the specific mechanism that allows Al₃Ti particles to nucleate Mg₂Si?

A2: The paper proposes a multi-step nucleation hypothesis. The Al₃Ti particles form first at a higher temperature (around 665°C). As the melt cools further to the range where Mg₂Si forms (620-595°C), these existing Al₃Ti particles act as stable, solid substrates in the liquid. This heterogeneous nucleation is energetically more favorable than forming Mg₂Si nuclei directly from the liquid, leading to the refinement of the primary Mg₂Si phase.

Q3: The paper mentions that oxygen was detected during the EDS analysis of Ti-rich particles. What is the significance of this?

A3: The authors note the detection of oxygen but state it is not obvious if this intensity arises from a complex Al-Ti-O compound or from surface oxidation during sample preparation, especially since an oxide polishing suspension was used. While some studies suggest Ti can bind to oxygen, this paper does not draw a firm conclusion, focusing instead on the clear evidence of Al₃Ti acting as the primary nucleant.

Q4: How does the dual-refining effect of titanium translate to improved mechanical properties?

A4: While this paper focuses on microstructure, it builds on previous work (Ref. 17) that linked Ti addition to improved ductility and strength. A finer, more equiaxed α-Al grain structure (grain refinement) generally improves strength and toughness. Simultaneously, refining the primary Mg₂Si crystals prevents the formation of coarse, brittle intermetallics, leading to higher ductility and fracture resistance. The combined effect results in a more robust material.

Q5: Why is 0.15 wt.% Ti suggested as the optimal level?

A5: This level is recommended as a balance. Previous research cited in the paper (Ref. 17) showed that increasing Ti content up to 0.15 wt.% resulted in a significant increase in elongation. This study's microstructural analysis provides the reason: this level is effective for nucleation. However, the analysis of the 0.22 wt.% Ti alloy showed the formation of large, coarse Al₃Ti particles that do not contribute to refinement and can be detrimental. Therefore, ~0.15 wt.% is proposed as the threshold to maximize benefits while avoiding negative effects.

Conclusion: Paving the Way for Higher Quality and Productivity

This research provides critical insights into the role of titanium in advanced Al-Mg-Si-Mn Casting Alloys. The key breakthrough is the discovery of titanium's dual function as a potent nucleant for both the α-Al matrix and the primary Mg₂Si strengthening phase. This offers a powerful tool for microstructural engineering, but it comes with a crucial caveat: the titanium content must be precisely controlled. Exceeding the optimal level of ~0.15 wt.% can introduce coarse, detrimental intermetallics, negating the benefits.

For R&D and operations teams in the HPDC industry, these findings underscore the importance of tight compositional control to unlock the full potential of high-ductility aluminum alloys. By optimizing the use of grain refiners like titanium, manufacturers can produce stronger, more reliable, and higher-quality structural components for the demanding automotive market.

"At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components."

Copyright Information

This content is a summary and analysis based on the paper "Microstructure formation and grain refinement of Al-Mg-Si-Mn casting alloys" by "Viktoriya Boyko, Edward Czekaj, Małgorzata Warmuzek, Kostiantyn Mykhalenkov".

Source: DOI: 10.7356/iod.2018.20

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.