From Scrap to Structure: The Viability of Recycled Aluminum HPDC for E-Mobility

This technical summary is based on the academic paper "LOW CARBON FOOTPRINT ALUMINIUM COMPONENTS FOR E-MOBILITY" by Elisa Fracchia, Claudio Mus, published in ACTA METALLURGICA SLOVACA (2024).

![Fig. 1 RESAL supply format [15].](https://castman.co.kr/wp-content/uploads/image-3103.webp)

![Fig. 2 Production of specimens for alloy characterization. a) casting; b) mould; c) obtained specimen [15].](https://castman.co.kr/wp-content/uploads/image-3104.webp)

Keywords

- Primary Keyword: Recycled Aluminum HPDC

- Secondary Keywords: E-Mobility Components, AlSi9Cu3(Fe), Circular Economy, Low Carbon Footprint, Automotive Die Casting, Aluminum Scrap

Executive Summary

- The Challenge: To produce lightweight, complex aluminum components for the e-mobility sector with a significantly lower carbon footprint, aligning with circular economy principles.

- The Method: Manufacturing an e-mobility battery housing using an optimized High-Pressure Die Casting (HPDC) process with 100% recycled EN AC 46000 (AlSi9Cu3(Fe)) alloy sourced from automotive industry scraps.

- The Key Breakthrough: The final component produced exclusively from recycled scrap exhibited a refined and high-quality microstructure, affirming the viability of this sustainable manufacturing route without compromising material integrity.

- The Bottom Line: Optimized Recycled Aluminum HPDC is a proven, competitive process for producing high-quality, thin-walled e-mobility components, offering a twenty-fold reduction in carbon footprint compared to using primary metals.

The Challenge: Why This Research Matters for HPDC Professionals

In the global shift towards E-mobility, the automotive industry faces immense pressure to reduce its carbon footprint across the entire value chain. While aluminum is a key enabler for lightweighting, its primary production is notoriously energy-intensive, requiring 4 tons of Bauxite and 14,000 kWh of energy per ton. The solution lies in recycling, which saves up to 95% of that energy.

However, using secondary (recycled) alloys, especially for demanding applications like thin-walled battery housings, raises critical questions for engineers about quality, consistency, and mechanical performance. Can components made from 100% scrap meet the stringent microstructural and performance requirements of the e-mobility sector? This study directly addresses this challenge by demonstrating a successful, industrial-scale application of recycled AlSi9Cu3(Fe) alloy, proving that sustainability and high performance are not mutually exclusive.

The Approach: Unpacking the Methodology

The research team evaluated the viability of using exclusively recycled aluminum for a complex e-mobility component.

- Material: The study used EN AC 46000 (AlSi9Cu3(Fe)) alloy, sourced from a wide range of automotive scraps, referred to as RESAL. This was compared against a certified primary ingot of the same alloy.

- Initial Analysis: Before production, the RESAL material was melted and cast into tablet specimens. These, along with the primary ingot tablets, underwent comprehensive analysis including optical emission spectrometry for chemical composition, Brinell hardness testing, and Differential Scanning Calorimetry (DSC) to understand melting and solidification behavior.

- Production Process: The RESAL alloy was loaded into a 5-ton furnace, degassed, and transferred to a 1350-ton HPDC machine. An innovative battery module housing (BM-Basic Module) with thin walls (< 1.5mm) was cast using the following parameters:

- Metal Temperature: 710 °C

- Injection Speed: 2.67 m/s

- Max Pressure: 220 bar

- Component Analysis: The final cast battery housing was then subjected to the same rigorous analysis (hardness, DSC, microstructural observation via optical and scanning electron microscopy) to evaluate its quality against the raw materials.

The Breakthrough: Key Findings & Data

The study confirmed that the HPDC process using 100% recycled scrap produced a high-quality component with a refined microstructure.

Finding 1: Superior Microstructural Refinement in the Final Component

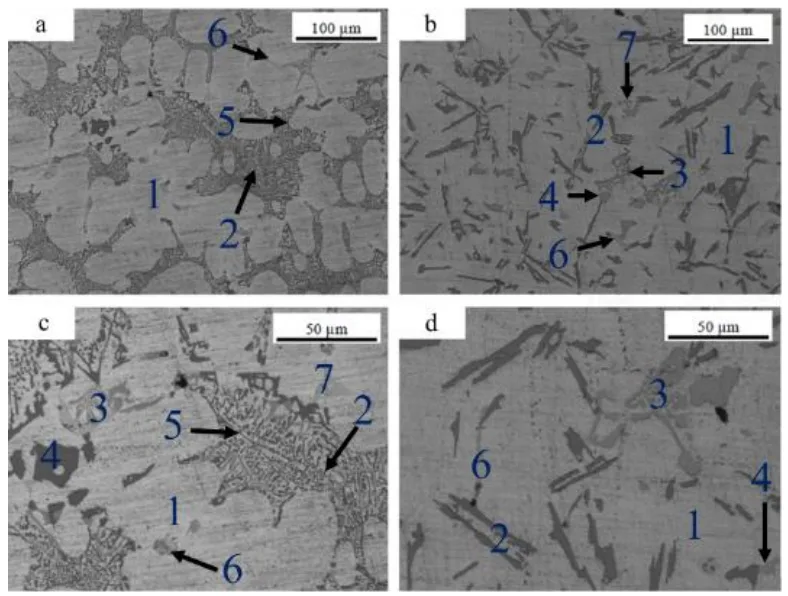

The HPDC process significantly refined the microstructure of the recycled alloy. Microscopic analysis revealed that while the raw RESAL scrap section contained large, plate-like eutectic silicon (Figure 8), the final cast battery housing displayed a "very fine and refined eutectic structure" (Figure 9). This refinement is critical for improving mechanical properties. Furthermore, detrimental β-Al5FeSi phases, which act as stress concentrators, appeared "very thin and shorter" in the final component compared to the raw material, mitigating their negative impact.

Finding 2: Hardness Maintained Through Recycling and Casting Process

The Brinell hardness measurements demonstrated that the recycling and casting process did not degrade the material's fundamental properties. As shown in Figure 6, the final cast battery housing had a hardness of 72 ±1.5 HB. This value was nearly identical to the hardness of the as-supplied RESAL scrap section (73 ±1.6 HB) and comparable to the remelted primary ingot tablets (78.1 ±1.8 HB). This confirms the material's robustness and the process's ability to maintain quality.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that a fast-cooling process, inherent to thin-wall HPDC, is a key factor in achieving a fine, high-quality microstructure even when using 100% recycled alloy. Optimizing injection parameters and thermal management of the die is crucial to mitigating the formation of coarse or detrimental intermetallic phases.

- For Quality Control Teams: The data in Figure 6 (Brinell hardness) and Figures 7-9 (microstructures) of the paper illustrates that while chemical composition of scrap may vary, the final microstructure of the HPDC component can be consistently high-quality. This suggests that microstructural analysis is a vital quality inspection criterion, perhaps even more so than minor fluctuations in elemental composition.

- For Design Engineers: The findings indicate that complex, thin-walled (<1.5mm) components with limited draft angles (<0.2°) can be successfully manufactured using recycled alloys. This provides confidence to design engineers pushing the boundaries of lightweighting for e-mobility applications without being constrained to primary, high-cost materials.

Paper Details

LOW CARBON FOOTPRINT ALUMINIUM COMPONENTS FOR E-MOBILITY

1. Overview:

- Title: LOW CARBON FOOTPRINT ALUMINIUM COMPONENTS FOR E-MOBILITY

- Author: Elisa Fracchia, Claudio Mus

- Year of publication: 2024

- Journal/academic society of publication: ACTA METALLURGICA SLOVACA

- Keywords: Aluminium; High Pressure Die Casting; Aluminium Scrap; AlSi9Cu3(Fe); E-mobility; Recycling

2. Abstract:

In the fast-evolving E-mobility transformation, the circular economy is one of the key factors to make Europe carbon neutral by 2050, together with sustainability, achievable only with a synergic approach, from raw material choice to recycling, through product design for re-purposing. Secondary aluminium alloys have a twenty times lower carbon footprint than primary metals, leading to significant CO2 savings. Their properties can satisfy engineering targets through optimized product design. Adopting a smart system layout, in which functions are assigned to assemblies, some of the low-end mechanical properties of secondary alloys can be offset. Design for easy disassembling can then guarantee a selective re-purposing and, finally, an environmentally friendly recycling of components. Innovative products in this field have been developed and successfully produced by means of an optimized high-pressure die casting (HPDC) technology, adopting low carbon footprint raw materials supplied in alternative to ingot format. In this study, a housing component for an e-mobility module battery was manufactured using EN AC 46000 alloy (AlSi9Cu3(Fe)), sourced from automotive industry scraps. The selected scraps were melted and cast to form the battery housing. Consequently, both the initial scraps and the resulting components underwent comprehensive analysis to evaluate the alloy's quality. Chemical analyses, hardness tests, and microstructural observations were performed. The findings confirm a refined and high-quality microstructure in the casting, affirming the viability of producing battery housing through High-Pressure Die Casting (HPDC) using exclusively recycled alloy.

3. Introduction:

Today, the automotive market is moving towards E-mobility, and aluminium and its alloys certainly guide the fast, clean and sustainable way to make the electric transition. In fact, aluminium is renowned as a recyclable material, having excellent specific properties, and, last but not least, is already highly used in the automotive industries [1]. As a matter of fact, aluminium recycling is not an innovation: almost the whole amount of Al in the cast market comes from the recycling of scraps and end-of-life components. Aluminium production from primary sources requires very high energy consumption and a remarkable environmental impact. The production of 1 ton of primary aluminium requires 4 tons of Bauxite and 14.000 kWh of energy consumption [2]; on the other hand, remelting recycled alloys saves up to 95% of energy [3]. Considering this information, the aluminium scraps can only gain more and more consideration. In an era where sustainability and environmental concerns are at the forefront of industrial practices, evaluating the environmental impact of various materials and manufacturing processes has become increasingly important. One area of particular interest is the production of aluminium alloy components in foundries [4]. Moreover, researchers have proven the importance of Aluminium recycling through LCA (Life Cycle Assessment) [5, 6]. Below the vast Al-alloys panorama, the alloy EN AC 46000 (also known as AlSi9Cu3(Fe)) finds extensive application in the automotive sector to cast thin-walled components through HPDC (High-Pressure Die Casting).

4. Summary of the study:

Background of the research topic:

The study is set against the backdrop of the automotive industry's transition to E-mobility and the push for a circular economy to achieve carbon neutrality. It focuses on aluminum, a key material for this transition, highlighting the massive energy savings (up to 95%) and environmental benefits of using recycled aluminum over primary aluminum.

Status of previous research:

Previous research has established the microstructure and properties of the EN AC 46000 (AlSi9Cu3(Fe)) alloy, identifying key phases like dendritic α-Al, eutectic Si, and various intermetallics (α-Fe, θ-Al2Cu, β-Al5FeSi, π-Fe). Studies have also noted the negative impact of certain phases like acicular β-Al5FeSi on mechanical behavior and explored the effects of remelting on alloy properties, with some observing degradation after multiple remelting cycles. While alternative technologies like selective laser melting have been proposed, HPDC remains the primary, competitive process for these components.

Purpose of the study:

The purpose was to demonstrate the feasibility of producing innovative, thin-walled e-mobility components (specifically, a battery housing) via an optimized HPDC process using exclusively recycled AlSi9Cu3(Fe) alloy sourced from automotive scraps. The study aimed to analyze the quality of the final component and affirm that a low-carbon, circular approach can meet engineering requirements without adding fresh ingot alloy.

Core study:

The core of the study involved manufacturing a battery housing from 100% recycled aluminum scrap (RESAL). A comprehensive analysis was conducted on the initial scrap material, a remelted version of the scrap, a primary ingot for comparison, and the final HPDC component. The analysis included chemical composition, hardness testing, DSC, and detailed microstructural characterization to evaluate the quality and integrity of the alloy throughout the recycling and manufacturing process.

5. Research Methodology

Research Design:

The study employed a comparative experimental design. It compared the properties of a final product (HPDC battery housing) made from recycled material (RESAL) against the properties of the raw recycled material itself and a certified primary ingot of the same alloy.

Data Collection and Analysis Methods:

- Chemical Analysis: Optical emission spectrometer (Spectrolab, Ametek) was used to determine the elemental composition of the alloys.

- Hardness Testing: Brinell hardness measurements were performed according to ASTM E10-23 standard (62.5kg load, 2.5mm indenter).

- Thermal Analysis: Differential Scanning Calorimetry (DSC) was conducted using a Setaram Typ. TGA 92 16.18 DSC with a heating rate of 10 K/min up to 650°C to identify phase transformation temperatures.

- Microstructural Analysis: Optical microscopy and Scanning Electron Microscopy (SEM) with EDX probe were used to observe and identify the phases, their morphology, and distribution within the alloy matrix.

Research Topics and Scope:

The research focused on the EN AC 46000 (AlSi9Cu3(Fe)) alloy. The scope included sourcing automotive scrap, characterizing the raw and remelted scrap, producing a thin-walled e-mobility component via HPDC, and conducting a comprehensive evaluation of the final product's quality, specifically its hardness and microstructure.

6. Key Results:

Key Results:

- The HPDC process using 100% recycled scrap (RESAL) successfully produced a thin-walled (<1.5mm) battery housing component.

- The final cast component exhibited a very fine and refined eutectic silicon structure, a significant improvement over the coarser structures seen in the raw scrap and ingot tablets.

- Brinell hardness of the final cast part (72 ±1.5 HB) was comparable to the as-supplied scrap section (73 ±1.6 HB), indicating no significant degradation of this property during the process.

- Detrimental intermetallic phases like β-Al5FeSi were present but appeared thinner and shorter in the final component due to the rapid cooling of HPDC, mitigating their negative effects.

- The study demonstrated the feasibility of recycling Al scraps to create new, high-quality components for the e-mobility sector at low cost using only scrap alloy, without additives like modifiers or grain refiners.

Figure Name List:

- Fig. 1 RESAL supply format [15].

- Fig. 2 Production of specimens for alloy characterization. a) casting; b) mould; c) obtained specimen [15].

- Fig. 3 BM- Basic Module battery housing.

- Fig. 4 DSC analyses - RESAL and Ingot tabs.

- Fig. 5 DSC analyses in the heating and cooling conditions for the Module battery housing alloy.

- Fig. 6 Brinell hardness results.

- Fig. 7 Optical Microscope images. RESAL tablets microstructures (a, c) and ingot microstructures (b, d).

- Fig. 8 Optical Microscope images. RESAL section microstructures. Magnification 20X (left) and 50X (right).

- Fig. 9 Optical Microscope images. Cast microstructures. Magnification 20X (left) and 50X (right).

- Fig. 10 SEM images. Ingot (left) and RESAL (right).

- Fig. 11 SEM image and EDX analysis in cast component (Fig. 3).

7. Conclusion:

In this work, the progress in the European project that involves Endurance Overseas (named IPCEI – BATTERIE 1) has been presented. The work involves the use of end-of-life alloy 46000 castings to produce new castings for use in the e-mobility sector without further treatment of the alloys. From the hardness and microstructural analyses, it is evident that the quality of the alloy appears to be preserved despite the additional re-casting steps, even without the use of casting additives such as modifiers or grain refiners. Furthermore, the microstructure, following the casting process, does not appear to be thickened; on the contrary, an extremely fine and uniformly distributed eutectic silicon phase is observed within the a-aluminium matrix in the casted component. In conclusion, at this state of the project, it was clearly demonstrated the feasibility of recycling Al scraps to realize new components at very low costs and only using scrap alloy. Further characterization improvement will regard the mechanical tests on the Basic Module battery housing to assess the whole quality of such components.

8. References:

네, 바로 마크다운 리스트로 정리해 드릴게요.

- Stojanovic, B.; Bukvic, M.; Epler, I.: Application of aluminum and aluminum alloys in engineering, Applied Engineering Letters, Vol. 3, No. 2, 2018, 52-62, https://doi.org/10.18485/aeletters.2018.3.2.2.

- Nunes, H.; Emadinia, O.; Soares, R.; Vieira, M. F.; Reis, A.: Adding Value to Secondary Aluminum Casting Alloys: A Review on Trends and Achievements, Materials (Basel), 16(3), 2023, 895, https://doi.org/10.3390/ma16030895.

- Kuchariková, L.; Tillová, E.; Bokůvka, O.: Recycling and properties of recycled aluminium alloys used in the transportation industry, Transport Problems, Vol. 11, No. 2, 2016, 117-122, https://doi.org/10.20858/tp.2016.11.2.11.

- Luo, A. A.; Sachdev, A. K.; Apelian, D.: Alloy development and process innovations for light metals casting, Journal of Materials Processing Technology, Vol. 306, 2022, 117606, https://doi.org/10.1016/j.jmatprotec.2022.117606.

- Zhang, Y.; Cai, Y.; Liu, S.; Su, Z.; Jiang, T.: Life cycle assessment of aluminum-silicon alloy production from secondary aluminum in China, Journal of Cleaner Production, Vol. 392, 2023, 136214, https://doi.org/10.1016/j.jclepro.2023.136214.

- Hong, J. P.; Wang, J.; Chen, H. Y.; Sun, B. De; Li, J. J.; Chen, C.: Process of aluminum dross recycling and life cycle assessment for Al-Si alloys and brown fused alumina, Transactions of Nonferrous Metals Society of China (English Edition), Vol. 20, No. 11, 2010, 2155-2161, https://doi.org/10.1016/S1003-6326(09)60435-0.

- Puga, H.; Costa, S.; Barbosa, J.; Ribeiro, S.; Prokic, M.: Influence of ultrasonic melt treatment on microstructure and mechanical properties of AlSi9Cu3 alloy, Journal of Materials Processing Technology, Vol. 211, No. 11, 2011, 1729-1735, https://doi.org/10.1016/j.jmatprotec.2011.05.012.

- Cao, X.; Campbell, J.:. Morphology of β-A15FeSi phase in Al-Si cast alloys, Materials Transactions, Vol. 47, No. 5, 2006, 1303-1312, https://doi.org/10.2320/matertrans.47.1303.

- Piekło, J.; Garbacz-Klempka, A.: Use of selective laser melting (SLM) as a replacement for pressure die casting technology for the production of automotive casting, Archives of Foundry Engineering, Vol. 21, No. 2, 2021, 9-16. https://doi.org/10.24425/afe.2021.136092.

- Kasińska, J.; Bolibruchová, D.; Matejka, M.: The influence of remelting on the properties of AlSi9Cu3 alloy with higher iron content, Materials, Vol. 13, No. 3,2020, 575, https://doi.org/10.3390/ma13030575.

- Matejka, M.; Bolibruchova, D.; Kasińska, J.; Kuriš, M.: Study of AlSi9Cu3 alloy crystallization process with increased iron content at different number of remelts, Archives of Foundry Engineering, Vol. 20, No. 1, 2020, 79-83. https://doi.org/10.24425/afe.2020.131287.

- Gottmyers Melwyn, J.; Chandragandhi, B.; Sathiyaseelan, G.; Srinath, P.: Aluminium scrap recycling in a production furnace: Minimizing dross formation for sustainable and efficient recovery, Materials Today: Proceedings, 2023, in press, https://doi.org/10.1016/j.matpr.2023.05.340.

- Djurdjevic, M.; Manasijevic, S.; Mihailović, M.; Stopic, S.: From Bauxite as a Critical Material to the Required Properties of Cast Aluminum Alloys for Use in Electro Automotive Parts, Metals, Vol. 13, No. 11, 2023, 1796. https://doi.org/10.3390/met13111796.

- Ministero delle Imprese e del Made in Italy. (n.d.). IPCEI batterie 1, from https://www.mimit.gov.it/index.php/it/incentivi/ipcei-batterie-1, accessed 26-12-2023

- RMB Spa. (2023). RMB internal report

- Chen, C. L.; West, G. D.; Thomson, R. C.: Characterisation of Intermetallic Phases in Multicomponent Al-Si Casting Alloys for Engineering Applications, Materials Science Forum, Vols 519-521, 2006, 359-364, https://doi.org/10.4028/www.scientific.net/msf.519-521.359.

- Hegde, S.; Prabhu, K. N.: Modification of eutectic silicon in Al-Si alloys, Journal of Materials Science, No. ,2008, 3009-3027, https://doi.org/10.1007/s10853-008-2505-5.

- Que, Z.; Wang, Y.; Fan, Z.: Formation of the Fe-Containing Intermetallic Compounds during Solidification of Al-5Mg-2Si-0.7Mn-1.1Fe Alloy, Metallurgical and Materials Transactions A: Physical Metallurgy and Materials Science, Vol. 49, No. 6, 2018, 2173-2181, https://doi.org/10.1007/s11661-018-4591-6.

- Toschi, S.: Optimization of a A354 Al-Si-Cu-Mg alloy heat treatment: Effect on microstructure, hardness, and tensile properties of peak aged and overaged alloy, Metals, Vol. 8, No. 11, 2018, 961, https://doi.org/10.3390/met8110961.

- Fabrizi, A.; Ferraro, S.; Timelli, G.: The influence of Sr, Mg and Cu addition on the microstructural properties of a secondary AlSi9Cu3(Fe) die casting alloy, Materials Characterization, Vol. 85, 2013, 13-25, https://doi.org/10.1016/j.matchar.2013.08.012.

Expert Q&A: Your Top Questions Answered

Q1: Why was the AlSi9Cu3(Fe) alloy specifically chosen for this e-mobility application?

A1: The paper states that the EN AC 46000 (AlSi9Cu3(Fe)) alloy finds extensive application in the automotive sector, particularly for casting thin-walled components through HPDC. Its established use and known characteristics make it an ideal candidate for demonstrating the viability of a 100% recycled-content approach for new, challenging e-mobility parts like battery housings.

Q2: The paper mentions the detrimental β-Al5FeSi phase. How was its negative effect managed in the final component made from scrap?

A2: The key was the manufacturing process itself. The paper notes that in the final cast component, the β-Al5FeSi phase "appears very thin and shorter than in RESAL microstructures" (Figure 7). This change in morphology is attributed to the fast-cooling nature of the HPDC process for thin-walled parts, which restricts the growth of these acicular, needle-like phases and thus reduces their ability to act as stress concentrators.

Q3: Did the remelting process cause any degradation in the alloy's properties, as some previous studies have suggested?

A3: No, this study found no evidence of degradation. The discussion highlights that "the re-melting of such alloy does not lead to a depletion of the alloy properties or to a coarsening of the Iron-based intermetallics." On the contrary, the final component's microstructure was significantly refined, and its hardness remained comparable to the source material, demonstrating the robustness of the process.

Q4: How did the microstructure of the final component made from recycled material compare to one made from a primary ingot?

A4: The component made from recycled material via HPDC showed a superior eutectic structure. As seen by comparing Figure 9 (cast part) with Figure 7-b,d (ingot tablets), the final component has a "very fine and refined" eutectic silicon structure. In contrast, the slower-cooled ingot tablets exhibit larger, polygonal silicon. This demonstrates the powerful effect of the HPDC process in refining the microstructure, regardless of whether the source is primary or secondary.

Q5: What is the significance of the DSC analysis shown in Figure 5 for the final battery housing?

A5: The DSC analysis in Figure 5 provides crucial insight into the final microstructure. During the heating scan, there are no distinct peaks for Cu-based intermetallic phases, which suggests these phases are very finely dispersed within the matrix due to the "very fast cooling of the casting." However, during the controlled cooling scan, a peak for Cu-based intermetallic nucleation appears at 494°C, confirming their presence in the alloy's chemistry but in a highly refined state in the final product.

Q6: Were any casting additives like grain refiners or modifiers used to achieve the fine microstructure?

A6: No. The conclusion explicitly states that the quality of the alloy was preserved and the fine microstructure was achieved "even without the use of casting additives such as modifiers or grain refiners." This highlights the effectiveness of the optimized HPDC process itself in controlling the final microstructure.

Conclusion: Paving the Way for Higher Quality and Productivity

This research provides compelling evidence that the circular economy is not just a concept but a practical reality for demanding automotive applications. By leveraging an optimized HPDC process, it is entirely feasible to transform 100% automotive aluminum scrap into high-quality, complex e-mobility components. The key breakthrough is that this Recycled Aluminum HPDC process does not compromise quality; in fact, it produces a refined microstructure that is critical for performance, all while drastically cutting the carbon footprint.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components.

Copyright Information

- This content is a summary and analysis based on the paper "LOW CARBON FOOTPRINT ALUMINIUM COMPONENTS FOR E-MOBILITY" by "Elisa Fracchia, Claudio Mus".

- Source: https://doi.org/10.36547/ams.30.1.1997

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.