Rheocasting AlSi7Mg: A Breakthrough in Porosity Reduction and Microstructure Control

This technical summary is based on the academic paper "Comparison of Microstructure, Density and Shrinkage Porosity for Casting and Rheocasting of AlSi7Mg alloy" by Kawan Abdulrahman et al., posted on Research Square (July 2023). It has been analyzed and summarized for technical experts by CASTMAN.

Keywords

- Primary Keyword: Rheocasting AlSi7Mg

- Secondary Keywords: Shrinkage Porosity, Semi-Solid Forming, Aluminum Casting, Microstructure Control, High-Pressure Die Casting

Executive Summary

- The Challenge: To overcome the critical issue of shrinkage porosity in high-performance AlSi7Mg aluminum castings, which compromises component quality and dependability in automotive and aerospace applications.

- The Method: A direct comparison of AlSi7Mg alloy components produced by conventional pressure casting versus a semi-solid rheocasting process, analyzing microstructure, density, and porosity.

- The Key Breakthrough: Rheocasting dramatically reduces shrinkage porosity from 2.14% in conventional casting to just 0.07%, while creating a significantly more uniform and globular microstructure.

- The Bottom Line: For demanding applications requiring high-integrity AlSi7Mg components, rheocasting offers a superior manufacturing process that yields parts with near-zero porosity and enhanced material consistency.

The Challenge: Why This Research Matters for HPDC Professionals

In the automotive and aerospace industries, the demand for lightweight, high-strength aluminum components is relentless. AlSi7Mg is a popular foundry alloy, but like many aluminum alloys, it is susceptible to defects—chief among them, shrinkage porosity. This porosity, generated during solidification, acts as a critical failure point, degrading mechanical properties and leading to component rejection, especially in parts that must be pressure-tight. As the paper notes, porosity is "one of the most severe issues in aluminum castings." For HPDC professionals, finding a reliable process to minimize or eliminate this defect is essential for improving component quality, reducing scrap rates, and ensuring dependability in the field.

The Approach: Unpacking the Methodology

This study conducted a rigorous comparison between two manufacturing methods for the aluminum alloy AlSi7Mg (EN AB-42000).

- Conventional Pressure Casting: This process involves injecting fully molten metal into a mold, where it solidifies.

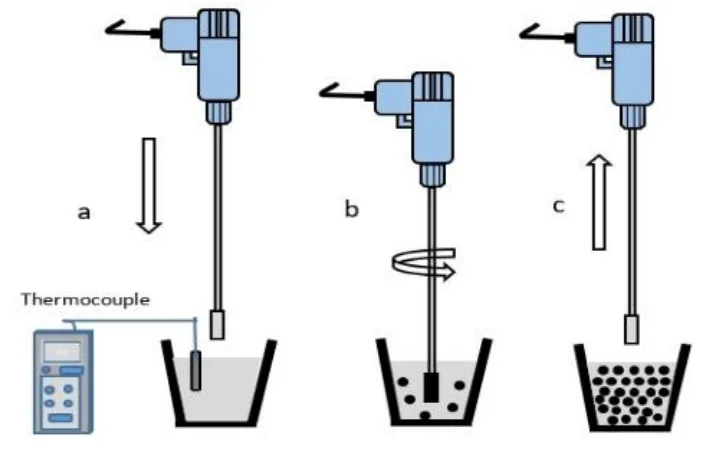

- Semi-Solid Rheocasting: This advanced method prepares a slurry of the alloy in a semi-solid state. A solid block of the alloy is introduced into the melt and stirred, creating a non-dendritic, globular microstructure before the material is formed.

To evaluate the results, the researchers analyzed samples from five distinct locations within the final component for both processes. They employed a multi-faceted approach:

- Theoretical Density: Calculated using JMatPro software based on the alloy's exact chemical composition.

- Practical Density: Measured experimentally using the Archimedes method.

- Microstructure & Grain Size: Examined using optical microscopy and the linear intercept analysis method.

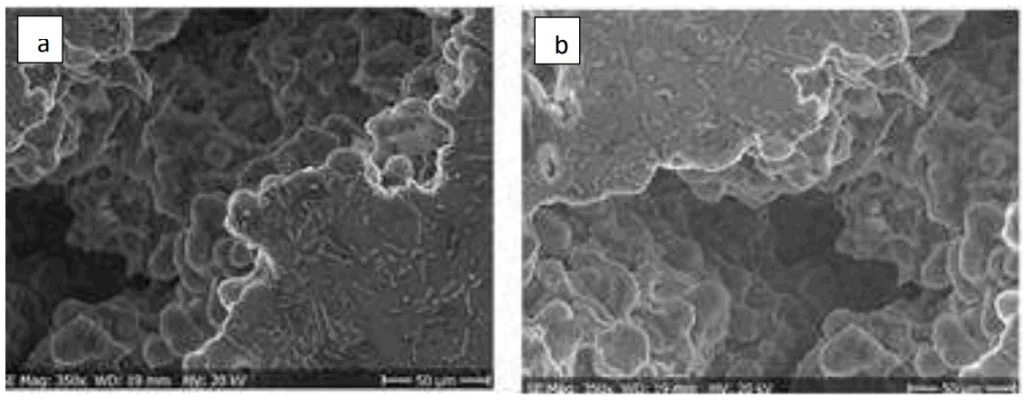

- Porosity: Quantified from density measurements and visually confirmed with Scanning Electron Microscope (SEM) imaging.

The Breakthrough: Key Findings & Data

The research revealed clear and significant advantages of the rheocasting process over conventional pressure casting, with two findings standing out.

Finding 1: Drastic Reduction in Shrinkage Porosity and Higher Density

The most impactful result was the near-elimination of shrinkage porosity. The study found that the conventional casting sample had a shrinkage porosity of 2.14%, a level that can severely compromise mechanical performance. In stark contrast, the rheocasting sample exhibited a shrinkage porosity of only 0.07%. This is visually represented in Figure 13 of the paper. This improvement is directly correlated with density measurements. As shown in Figure 11, the practical density of the rheocasting alloy was 2.69 g/cm³, much closer to the theoretical density of 2.7 g/cm³, while the casting alloy's density was only 2.64 g/cm³.

Finding 2: Superior Microstructure Uniformity and Grain Refinement

The underlying reason for the improved properties is the profound difference in microstructure. Conventional casting produced a typical dendritic (tree-like) structure, which can trap pockets of liquid and lead to porosity. Rheocasting, however, produced a fine, globular (spherical) microstructure. As shown in Figure 8, the rheocast samples (R1-R5) display a uniform, fine spherical phase structure throughout the part. In contrast, the cast samples (C1-C5) show a sizeable dendritic structure. This structural superiority translates to more consistent grain size. For example, at the top of the component (area 5), the primary grain size for rheocasting was 16.67 µm, while for casting it was significantly larger and less uniform at 23.13 µm (Figure 9).

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that adopting a semi-solid rheocasting process for AlSi7Mg can directly contribute to a massive reduction in shrinkage porosity defects, leading to higher yields and more reliable production.

- For Quality Control Teams: The data in Figure 12, showing a consistently higher density across all five measured positions for the rheocast part, illustrates that rheocasting produces a more homogenous and sound component. This consistency simplifies quality inspection and increases confidence in part integrity.

- For Design Engineers: The findings indicate that the uniform, non-dendritic microstructure of rheocast parts could lead to more predictable mechanical properties throughout the component. This allows for designs that are optimized for performance without the need to over-engineer to compensate for potential porosity in critical sections.

Paper Details

Comparison of Microstructure, Density and Shrinkage Porosity for Casting and Rheocasting of AlSi7Mg alloy

1. Overview:

- Title: Comparison of Microstructure, Density and Shrinkage Porosity for Casting and Rheocasting of AlSi7Mg alloy

- Author: Kawan Abdulrahman, Viktor Gonda, Mihály Réger, Péter Varga

- Year of publication: 2023

- Journal/academic society of publication: Research Square (Preprint)

- Keywords: Semi-solid forming, Rheocasting, Aluminum alloy AlSi7Mg, Pressure Casting, Metallography, Porosity, Density, Shape factor.

2. Abstract:

With the increasing application of aluminum foundry alloys for automotive and aerospace components, the aluminum industry must pay close attention to component quality and dependability. This article focuses on the interpretation of the relative density and porosity of Al foundry casting and rheocasting alloys AlSi7Mg. The most popular Al-Si alloy grain refinement utilized in the casting and rheocasting processes is AlSi7Mg. The limitations are using comparable density findings to determine the quality of a component of casting or rheocasting state. Two approaches are employed to attain this goal, first the theoretical analysis using the JMatPro software, which offers density distribution results depending on the chemical composition of the aluminum alloy. Second, the experimental Archimedes method, which provides density data on actual aluminum castings alloy. This study advances substantial research on microstructure, grain sizes, form shape factors, theoretical and practical density, shrinkage porosity, casting and rheocasting application samples alloy, and potential industrial applications of AlSi7Mg. The results show that the average grain size is significantly more uniform in the rheocasting comparing to casting average grain size results. In addition, the results from the metallographic image analysis of casting and rheocasting application shows five different zones from the bottom to the top of the sample. Finally, the study observed that the shrinkage porosity in the casting application sample is higher than those of rheocasting application sample.

3. Introduction:

The casting components have a complete filling at low solid fractions, according to the results. Microstructure size, and solid fraction management for micro shrinkage level are essential. Therefore, this works continues to find further potential commercial applications in gravity die casting [1,20]. Rheocasting alloys used in the telecommunications industry like a hollow filter with a thin wall thickness (about 0.35 mm) [29]. Current aluminum vehicle parts, such as wheels, engines, and transmission components are produced utilizing the tilting rheocasting semi-solid process to decrease gas porosity. By focusing on alloy modification and casting process parameters [25,26], evaluations of slurry quality manufactured utilizing cast procedures, as well as the final microstructure and qualities of rheocasting components [27,29]. They have produced very positive results in both castability and final properties. The casting aluminum alloy AlSi7Mg is to identify the key few processing factors that are critical in the emergence of the shrinkage porosity and to choose remedial actions to reduce the fault so that the components passed a leak test [2,4].

4. Summary of the study:

Background of the research topic:

The study is set against the backdrop of increasing demand for high-quality aluminum alloy components in the automotive and aerospace sectors. A primary challenge in aluminum casting is controlling defects, particularly shrinkage porosity, which negatively impacts mechanical properties and component reliability.

Status of previous research:

Previous research has established semi-solid processing, including rheocasting, as a method to improve microstructure and reduce defects. Studies have shown that managing microstructure size, solid fraction, and process parameters can reduce shrinkage porosity. Rheocasting has been successfully used to produce parts with fine primary Al grains and uniform distribution, leading to superior mechanical properties compared to typical die castings.

Purpose of the study:

The purpose was to conduct a direct, quantitative comparison between conventional pressure casting and semi-solid rheocasting for the AlSi7Mg alloy. The study aimed to interpret and contrast the resulting microstructure, grain size, density, shape factor, and shrinkage porosity to determine which process yields a higher quality component.

Core study:

The core of the study involved producing AlSi7Mg components using both casting and rheocasting methods. Samples were taken from five distinct locations in each component and subjected to a series of analyses. This included theoretical density modeling (JMatPro), experimental density measurement (Archimedes method), and detailed microstructural characterization (optical microscopy, SEM) to quantify differences in grain size, shape factor, and porosity.

5. Research Methodology

Research Design:

The study used a comparative experimental design. Two groups of samples were created from the same AlSi7Mg alloy, with the only variable being the manufacturing process: pressure casting versus semi-solid rheocasting. The properties of the resulting components were then systematically measured and compared.

Data Collection and Analysis Methods:

- Material: Aluminum alloy AlSi7Mg (EN AB-42000).

- Density Analysis: Theoretical density was calculated with JMatPro software. Practical density was measured using the Archimedes method.

- Microstructure Analysis: Samples were prepared (cut, mounted, polished, etched with Keller's solution) and examined using optical microscopy (Neophot 2).

- Grain Size Analysis: The average grain size was determined using the linear intercept analysis approach.

- Porosity Analysis: Shrinkage porosity percentage was calculated from the difference between theoretical and practical densities. Porosity morphology was observed using a Scanning Electron Microscope (JSM 5310).

Research Topics and Scope:

The research focused on the AlSi7Mg alloy and compared the effects of casting vs. rheocasting on several key material properties: microstructure (dendritic vs. globular), average grain size, grain shape factor, practical vs. theoretical density, and the percentage of shrinkage porosity. The analysis was conducted across five different zones of the sample part to assess material homogeneity.

6. Key Results:

Key Results:

- The shrinkage porosity in the casting sample was 2.14%, while in the rheocasting sample it was only 0.07%.

- The practical density of the rheocast alloy (2.69 g/cm³) was significantly higher than the cast alloy (2.64 g/cm³) and closer to the theoretical density (2.7 g/cm³).

- Rheocasting produced a fine, uniform, globular (spherical) microstructure, whereas casting resulted in a coarse, dendritic structure.

- The average primary grain sizes in the rheocast samples were smaller and more homogenous across the component than in the cast samples.

- The shape factor of the grains in the rheocast samples was significantly higher (closer to the ideal spherical value of 1) than in the cast samples.

Figure Name List:

- Figure 1. Rheocasting process steps: (a) a solid block of the same alloy, fastened to a stainless-steel rod in advance, (b) dissolved in the melt with synchronous stirring action, and (c) the resulting slurry.

- Figure 2. Casting and rheocasting application samples.

- Figure 3. Five area positions of the analyses.

- Figure 4. The solid fraction, liquids, and solidus temperature of ALSI7MGalloy with different Si content.

- Figure 5. Theoretical Density of Aluminum EN AB-42000 alloy by using JMatPro.

- Figure 6. Solid fraction and temperature sensitivity of aluminum ALSI7MGalloy.

- Figure 7. The microstructure of Casting (a) and Rheocasting (b) application samples.

- Figure 8. The microstructures of casting (C) and rheocasting (R) application samples.

- Figure 9. The primary a grain size of the casting and rheocasting application samples.

- Figure 10. The shape factor of casting and rheocasting application samples.

- Figure 11. Density values of the cast, the rheocast alloys, and the theoretical density.

- Figure 12. Density values of five-area positions the cast, the rheocast alloy.

- Figure 13. Shrinkage porosity values of individual casting and rheocasting alloy.

- Figure 14. big and small micro-porosity volume in five areas casting alloy sample.

- Figure 15. The structure of the porous material of AlSi7 alloy: (a) Large Micro Porosity volume; (b) small micro-Porosity volume scanning electron microscope image (JSM 5310, SEM Hv 20.0 kv) in two areas casting alloy sample.

7. Conclusion:

The study concludes that the rheocasting process is significantly superior to conventional casting for producing high-quality AlSi7Mg components. The average grain size and shape factor were found to be significantly more uniform in the rheocast samples. Key conclusions drawn are: micro shrinkage is lower in rheocasting; average primary grain sizes are smaller and more homogenous in rheocasting; and shrinkage porosity is substantially higher in the casting application. The improved shape factor and control over solid fraction are key factors in reducing this porosity.

8. References:

- [1] Pola, Annalisa, Marialaura Tocci, and Plato Kapranos. (2019), Microstructure and properties of semi-solid aluminum alloys: a literature review, Metals 8, no. 3 (2018): 181.

- [2] de Terris, Thibaut, O. Andreau, P. Peyre, F. Adamski, I. Koutiri, C. Gorny, C. Dupuy, Optimization and comparison of porosity rate measurement methods of Selective Laser Melted metallic parts, Additive Manufacturing 28.

- [3] Maskery, Ian, N. T. Aboulkhar, M. R. Corfield, Christopher Tuck, A. T. Clare, Richard K. Leach, Ricky D. Wildman, I. A. Ashcroft, Richard JM Hague, (2016), Quantification and characterisation of porosity in selectively laser melted Al-Si10-Mg using X-ray computed tomography, Materials Characterization 111.

- [4] Gunasegaram, D. R., D. J. Farnsworth, and T. T. Nguyen, Identification of critical factors affecting shrinkage porosity in permanent mold casting using numerical simulations based on design of experiments, Journal of materials processing technology 209, no. 3, (2009)

- [5] Janudom, S., T. Rattanochaikul, R. Burapa, S. Wisutmethangoon, and J. Wannasin. (2010), Feasibility of semi-solid die casting of ADC12 aluminum alloy." Transactions of Nonferrous Metals Society of China 20, no. 9, 1756-1762.

- [6] Arvieu, Corinne, C. Galy, E.Le Guen, E. Lacoste,(2020), Relative density of SLM-produced aluminum alloy parts: Interpretation of results, Journal of Manufacturing and Materials Processing 4, no. 3.

- [7] Pezda, J, (2009), Effect of modifying process on mechanical properties of EN AB-42000 silumin cast into sand moulds, Archives of Foundry Engineering 9, no. 4.

- [8] Pezda, J., (2011), Effect of T6 heat treatment on mechanical properties and microstructure of EN AB-42000 alloy modified with strontium, Archives of Foundry Engineering 11.

- [9] Blad, Madeleine, B. Johannesson, P. Nordberg, Johannes Winklhofer, (2016), Manufacturing and fatigue verification of two different components made by semi-solid processing of aluminium TX630 alloy, In Solid State Phenomena, vol. 256, pp. 328-333.

- [10] Pezda, J., (2014), Influence of heat treatment parameters on the mechanical properties of hypoeutectic Al-Si-Mg alloy, Metalurgija 53, no. 2.

- ... [Full list continues as in the paper] ...

- [31] Liu, Zhiyong, Weimin Mao, Tan Wan, Guotao Cui, and Weipan Wang., (2021), Study on semi-solid A380 aluminum alloy slurry prepared by water-cooling serpentine channel and its rheo-diecasting, Metals and Materials International 27, 2067-2077.

Expert Q&A: Your Top Questions Answered

Q1: Why was it necessary to analyze five different zones of the component?

A1: Analyzing five distinct zones from bottom to top (as shown in Figure 3) was crucial for evaluating the homogeneity of the final part. In casting, properties can vary significantly depending on the distance from the sprue and local cooling rates. The results (Figures 9 and 12) showed that rheocasting produced much more uniform grain size and density across all five zones, proving its ability to create a more consistent and reliable component.

Q2: The paper mentions a "shape factor." What is its practical significance for an engineer?

A2: The shape factor is a quantitative measure of how close the primary α-Al grains are to a perfect sphere (a value of 1). A higher shape factor, as seen in the rheocasting samples in Figure 10, indicates a globular, non-dendritic structure. This is practically significant because spherical particles flow more easily in the semi-solid state, allowing for better mold filling and feeding, which directly reduces the formation of shrinkage porosity.

Q3: How does the rheocasting process achieve such a dramatic reduction in porosity (from 2.14% to 0.07%)?

A3: The reduction is primarily due to the nature of the semi-solid slurry. In conventional casting, the liquid metal solidifies by forming dendrites that interlock, trapping isolated pockets of liquid that become shrinkage voids as they cool. The rheocasting process creates a slurry of fine, globular solid particles suspended in liquid. This slurry flows more like a paste, ensuring that liquid metal can continuously feed the solidifying regions, preventing the formation of those isolated, porosity-causing pockets.

Q4: What was the role of the JMatPro software compared to the Archimedes method for measuring density?

A4: They served two different but complementary purposes. The JMatPro software provided a theoretical density (2.7 g/cm³) based purely on the alloy's chemical composition, establishing a perfect, defect-free benchmark. The Archimedes method measured the actual, practical density of the physical samples. By comparing the practical density to the theoretical benchmark, the researchers could accurately calculate the volume percentage of porosity in each sample.

Q5: The grain size in the casting sample increases towards the top of the part (area 5 in Figure 9). Why does this happen, and why is the rheocast part immune to it?

A5: The increase in grain size in the cast sample is likely due to slower cooling rates at the top of the component, which is typically the last area to solidify. This gives the dendrites more time to grow larger. The rheocasting process is less sensitive to these local cooling variations because the initial grain structure is already formed and refined into fine globules during the slurry preparation stage. This pre-conditioning ensures a fine, uniform grain structure throughout the final part, regardless of minor differences in cooling.

Conclusion: Paving the Way for Higher Quality and Productivity

This research provides compelling evidence that the choice of manufacturing process has a profound impact on the final quality of AlSi7Mg components. By moving from a conventional casting process to a semi-solid one, it is possible to virtually eliminate shrinkage porosity and achieve a far superior, homogenous microstructure. For engineers working with Rheocasting AlSi7Mg, this means a direct path to creating stronger, more reliable, and pressure-tight components. The findings underscore that advanced process control is the key to unlocking the full potential of high-performance aluminum alloys.

"At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components."

Copyright Information

- This content is a summary and analysis based on the paper "Comparison of Microstructure, Density and Shrinkage Porosity for Casting and Rheocasting of AlSi7Mg alloy" by "Kawan Abdulrahman, Viktor Gonda, Mihály Réger, Péter Varga".

- Source: https://doi.org/10.21203/rs.3.rs-3143835/v1

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.