Unlocking the Secrets of Die-Casting Die Heat-Checking: New Research Reveals Root Causes and Mitigation Clues

This technical summary is based on the academic paper "MATERIAL PROPERTIES OF DIE-CASTING DIE AROUND HEAT-CHECKING CREATED BY A HIGH-PRESSURE ALUMINUM ALLOY DIE-CASTING OPERATION" by Mitsuhiro Okayasu and Junya Shimazu, published in International Journal of Metalcasting (2025). It has been analyzed and summarized for technical experts by CASTMAN with the assistance of AI.

Keywords

- Primary Keyword: Die-Casting Die Heat-Checking

- Secondary Keywords: Thermal Fatigue, Nitriding, Residual Stress, SKD61, H13 Tool Steel, Microstructure, Hydrogen Embrittlement

Executive Summary

A 30-second overview for busy professionals.

- The Challenge: Heat-checking—surface cracking on die surfaces—is a primary cause of die failure in high-pressure aluminum die-casting, leading to poor part quality and increased tooling costs.

- The Method: Researchers conducted an in-depth analysis of a nitrided SKD61 (H13-equivalent) die after 100,000 casting cycles, examining its microstructure, mechanical properties, and residual stress state around heat-checked areas.

- The Key Breakthrough: The study reveals that heat-checking is not just a result of thermal fatigue; it's driven by a complex interplay of factors including a shift from protective compressive stress to damaging tensile stress, microstructural degradation, and infiltration of molten aluminum into cracks.

- The Bottom Line: Understanding and controlling the evolution of residual stress and microstructural changes on the die surface is critical for extending die life and preventing premature failure from Die-Casting Die Heat-Checking.

The Challenge: Why This Research Matters for HPDC Professionals

In the demanding world of high-pressure die-casting (HPDC), the die is the heart of the operation. However, the extreme conditions—rapid injection of molten aluminum followed by cooling with water-based lubricants—inflict significant damage. The most common failure mode is surface cracking, known as Die-Casting Die Heat-Checking.

This phenomenon is more than a cosmetic issue. It degrades die performance, leading to poor surface finish and dimensional inaccuracies in cast parts, and can ultimately result in catastrophic die failure. While surface treatments like nitriding are used to strengthen the die, the precise mechanisms that lead to cracking, even in treated dies, are not fully understood. This research was necessary to move beyond the general understanding of thermal stress and investigate the detailed material property changes that occur in a production die, providing a clearer picture of why and how these critical cracks form.

The Approach: Unpacking the Methodology

To understand the real-world degradation of a die, the researchers analyzed a die-casting die and core pins made of SKD61 steel (similar to H13). This die had completed approximately 100,000 shots in a 350-ton cold-chamber machine, casting an ADC12 aluminum alloy. The die was heat-treated and nitrided before use.

The investigation employed a suite of advanced analytical techniques to characterize the material properties in and around the heat-checked regions:

- Microstructural Analysis: Electron Backscatter Diffraction (EBSD) and Transmission Electron Microscopy (TEM) were used to examine grain structure and precipitates.

- Compositional Analysis: Energy-Dispersive X-ray Spectroscopy (EDS) identified the elemental composition of the die surface, precipitates, and material that had infiltrated cracks.

- Mechanical Property Testing: Micro-Vickers hardness tests, tensile tests on specimens from the die surface and interior, and Atomic Force Microscopy (AFM) to measure adhesion forces.

- Residual Stress Measurement: An X-ray analyzer was used to measure residual stress on the heat-checked surface, an undamaged surface, and the die interior.

- Hydrogen Content Analysis: Gas chromatography measured hydrogen concentration at various depths from the die surface.

This comprehensive approach allowed for a detailed correlation between the microstructural changes, mechanical property degradation, and the formation of heat-checking cracks.

The Breakthrough: Key Findings & Data

[Based on the paper's Results section, present the 2-3 most significant findings with concrete data.]

Finding 1: The Critical Shift from Compressive to Tensile Residual Stress

Nitriding is intended to create a hard surface layer with high compressive residual stress, which helps resist crack formation. While this was observed on unused portions of the die, the most critical finding was the complete reversal of this stress state in the heat-checked areas.

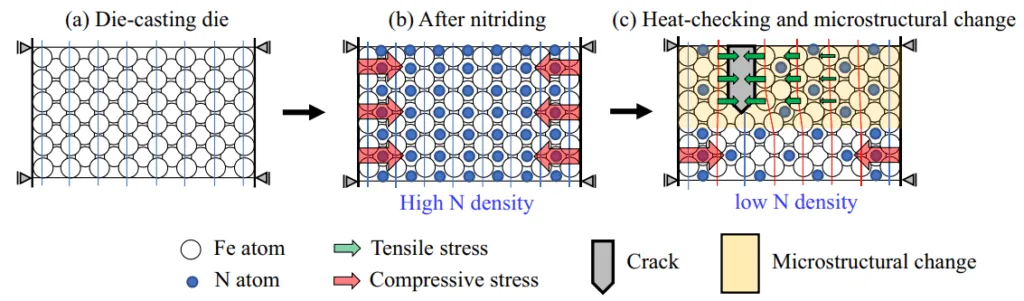

As shown in Figure 11, the die surface outside the cavity (non-heat-checking) exhibited a compressive residual stress of approximately -425 MPa. In stark contrast, the heat-checked surface within the cavity showed a tensile residual stress of around +200 MPa. This tensile stress actively promotes the opening and propagation of cracks, accelerating the progression of Die-Casting Die Heat-Checking. The study hypothesizes this shift is caused by the release of compressive stress due to severe crack formation and a reduction in nitrogen content near the surface.

Finding 2: Microstructural Degradation and Aluminum Infiltration at the Crack Site

The study revealed significant changes to the die's microstructure in the heat-checked region, driven by the intense thermal cycles.

- Microstructure: Figure 9 shows that the original lath martensite structure transformed into fine, equiaxed grains near prior grain boundaries in the heat-checked zone. This recrystallization, along with the formation of numerous Cr-Mo-V-based nitride precipitates, alters the material's mechanical properties and contributes to scattered hardness values.

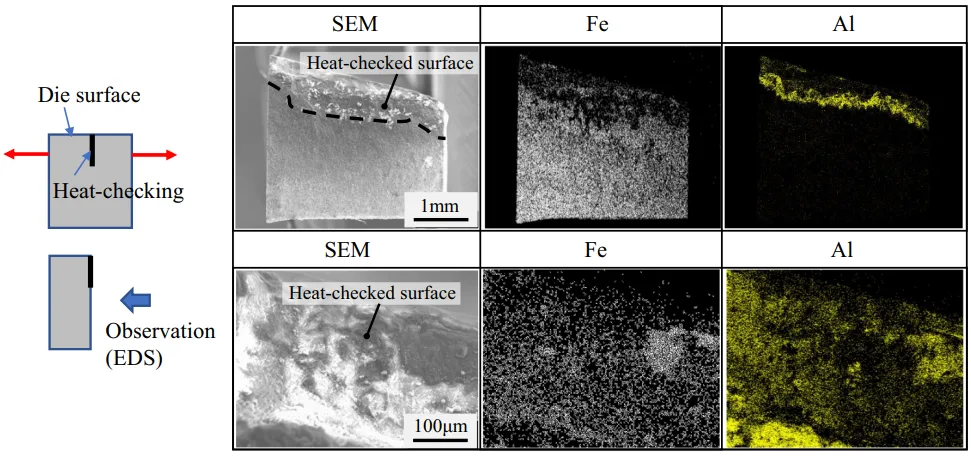

- Aluminum Infiltration: Figure 8 provides clear evidence that molten aluminum alloy penetrates the heat-checking cracks. This infiltration is highly damaging, as the aluminum reacts with the die steel to form hard, brittle intermetallic compounds (e.g., Fe-Al phases). This not only makes the crack tip more brittle but also creates a "wedging" effect that drives further crack propagation under stress.

Practical Implications for R&D and Operations

[Based on the paper's Discussion and Conclusion sections, provide conditional insights for different professional roles.]

- For Process Engineers: This study suggests that managing the die surface environment is crucial. The presence of high hydrogen content near the surface (Figure 3), likely from lubricants, can lead to embrittlement. This may mean that optimizing lubricant application and die cooling strategies could contribute to reducing crack initiation.

- For Quality Control Teams: The data in Figure 6 (Vickers Hardness) and Figure 7 (Nitrogen Content) illustrates how the protective nitrided layer degrades during service. The nitrogen, initially concentrated within 0.1 mm of the surface, diffuses deeper to 0.2 mm in the cavity area while its surface concentration drops. This suggests that monitoring both hardness and the nitrogen profile could become new criteria for assessing die health and predicting end-of-life.

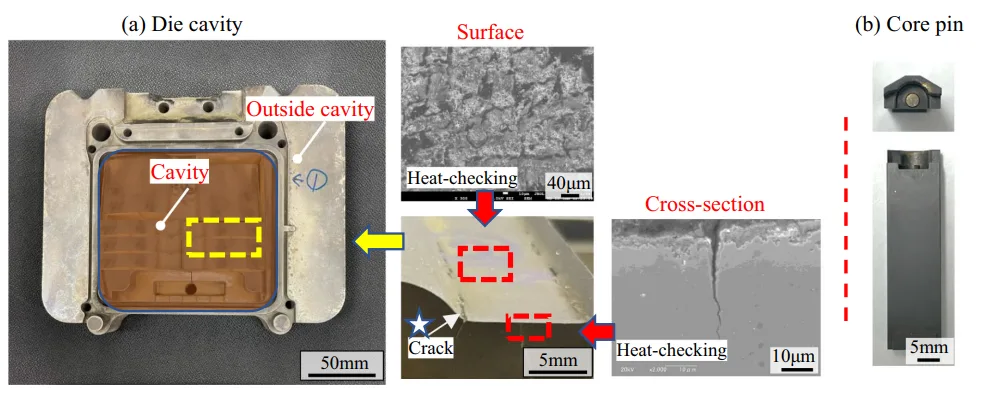

- For Design Engineers: The findings indicate that high stress concentrations are a key factor in initiating the severe cracks that lead to the release of protective compressive stress (as noted in Figure 1 (★) at the die edge). This reinforces the importance of minimizing sharp corners and other stress risers in die design to prevent the initial failure that triggers the cascade of degradation.

Paper Details

MATERIAL PROPERTIES OF DIE-CASTING DIE AROUND HEAT-CHECKING CREATED BY A HIGH-PRESSURE ALUMINUM ALLOY DIE-CASTING OPERATION

1. Overview:

- Title: MATERIAL PROPERTIES OF DIE-CASTING DIE AROUND HEAT-CHECKING CREATED BY A HIGH-PRESSURE ALUMINUM ALLOY DIE-CASTING OPERATION

- Author: Mitsuhiro Okayasu and Junya Shimazu

- Year of publication: 2025 (Published online: 06 April 2025)

- Journal/academic society of publication: International Journal of Metalcasting

- Keywords: die-casting, die, heat-checking, hydrogen embrittlement, mechanical property

2. Abstract:

In this study, the material properties of a nitride die-casting die exhibiting heat-checking after the die-casting process were experimentally investigated using various methods. Based on the obtained results, the authors believe that several possible mechanisms underlying the formation of heat-checking can be identified. The microstructure of the die-casting die near the heat-checking region is characterized by equiaxed grains along the vicinity of the prior y-grain boundaries, resulting from the lath martensitic formation. Additionally, numerous Cr-Mo-V-based nitride particles, approximately 100 nm in diameter, are precipitated. The surface hardness of the die-casting die, enhanced by nitriding, induces compressive residual stresses and increases adhesive forces. As a result of changes in microstructural characteristics and crack formation, the stress state near the die-casting die is altered, where compressive residual stresses, observed in the die-casting die, are released, leading to the tensile residual stresses. This phenomenon could accelerate the formation of a large number of heat-checking cracks.

3. Introduction:

Aluminum alloy die-castings are widely used in industries such as automotive and electronics. The process involves injecting molten aluminum alloys into a die cavity under high speed and pressure. These extreme conditions can cause frequent damage to the die. Surface treatments like nitriding are applied to strengthen the die surface. During the process, the die interacts with molten aluminum, causing erosion, and undergoes rapid heating and cooling cycles, resulting in significant thermal stress and shocks. These thermal cycles weaken the die material, often causing surface cracking known as heat-checking. This stress-induced damage affects die performance, leading to poor surface finish and dimensional inaccuracies. In addition to heat-checking, chemical interactions can form intermetallic compounds, further degrading material properties.

4. Summary of the study:

Background of the research topic:

Heat-checking is a primary failure mechanism for dies used in high-pressure aluminum die-casting. It is generally understood to be caused by repeated thermal stresses, but the detailed failure mechanism and the material property changes in the die after operation are not well understood.

Status of previous research:

Related research has focused on the brittle failure of die materials, especially regarding thermal fatigue. However, detailed information on the material properties of die-casting dies around heat-checking after prolonged operation is insufficient.

Purpose of the study:

To clarify thermal stress-induced die damage in detail by examining the mechanical properties and microstructural characteristics around the heat-checking region of a production die using various experimental techniques.

Core study:

The study performed a comprehensive analysis of a nitrided SKD61 die after 100,000 casting shots. It investigated the microstructure (EBSD, TEM), elemental composition (EDS), mechanical properties (hardness, tensile tests), hydrogen content, and residual stress distribution to identify the factors contributing to heat-checking.

5. Research Methodology

Research Design:

The research was an experimental investigation of a used die-casting die. The properties of regions with heat-checking were compared to regions without heat-checking and to the interior of the die to isolate the effects of the die-casting operation.

Data Collection and Analysis Methods:

- Material: SKD61 die-casting die (Fe-0.36C-0.94Si-5.26Cr-1.2Mo-0.8V mass%) used for ~100,000 shots with ADC12 aluminum alloy.

- Microscopy: SEM, EBSD, and TEM were used for microstructural characterization.

- Spectroscopy: EDS was used for elemental analysis of precipitates and surfaces.

- Mechanical Testing: A micro-Vickers hardness tester and a universal testing machine for tensile tests were used. Adhesion forces were measured with an AFM.

- Stress and Content Analysis: A residual stress analyzer (μ-X360J) and a gas chromatograph were used to measure residual stress and hydrogen content, respectively.

Research Topics and Scope:

The study focused on the material properties of the die in the vicinity of heat-checking cracks. The scope included microstructural changes, hardness and nitrogen profiles, hydrogen absorption, residual stress state, and the effect of aluminum infiltration into cracks.

6. Key Results:

Key Results:

- The heat-checked surface exhibits tensile residual stress (~+200 MPa), while the non-heat-checked surface retains compressive residual stress (~-425 MPa).

- The microstructure near heat-checks shows equiaxed grains and numerous Cr-Mo-V-based nitride precipitates, a change from the original tempered martensite structure.

- The nitrided layer, characterized by high hardness (~900 HV), degrades during operation, with nitrogen diffusing from the surface into a wider region (up to 0.2 mm).

- High hydrogen content (~1.3 wppm) was detected near the die surface, likely from lubricants, which can contribute to embrittlement.

- Molten aluminum infiltrates heat-checking cracks, forming brittle intermetallic compounds and accelerating crack propagation.

Figure Name List:

- Figure 1. Photographs of the die-casting die used for manufacturing mechanical parts after the die-casting operation, showing (a) the die cavity and heat-checking and (b) the core pin.

- Figure 2. (a) EBSD results for the core pin and (b) SEM image and (c) EDS result of the precipitate.

- Figure 3. Hydrogen content of the die-casting die measured from the die surface.

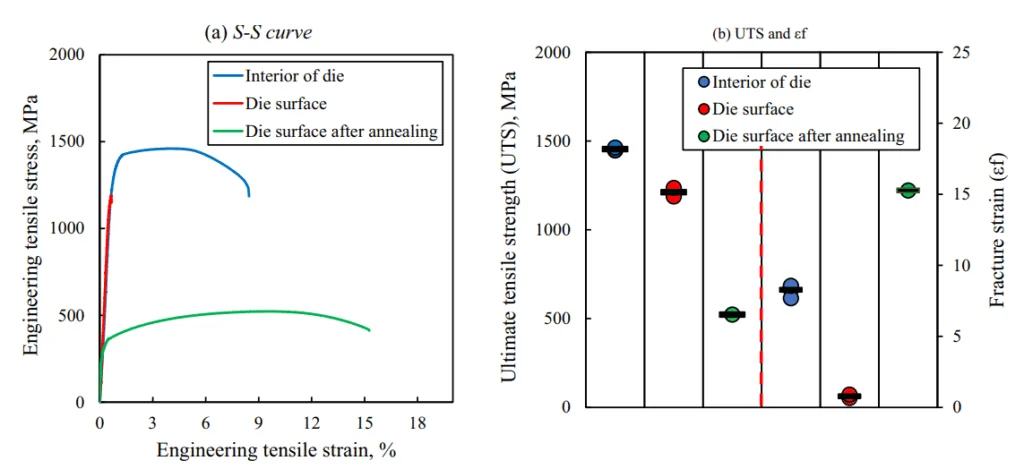

- Figure 4. (a) Representative tensile stress-strain curves for die-casting die samples and (b) comparisons of tensile strength and fracture strain.

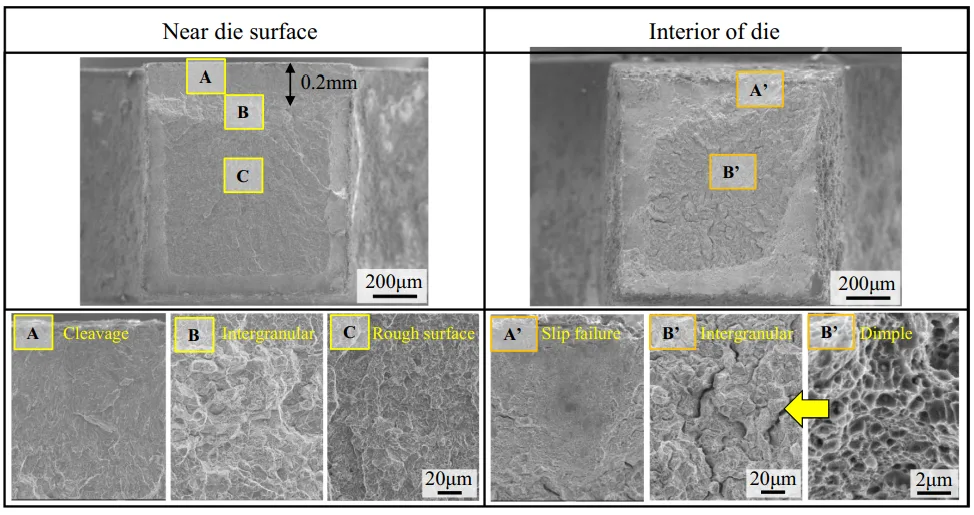

- Figure 5. SEM images of the fracture surfaces for samples obtained from the region near the die surface and the interior of the die after tensile testing.

- Figure 6. Vickers hardness distribution measured from the surface of the die-casting die.

- Figure 7. Variation of nitrogen content of die-casting die examined on the cross section of the cavity and out of cavity samples.

- Figure 8. EDS mappings of the heat-checked surfaces.

- Figure 9. TEM images and TEM-EDS mappings of the cross-sectional area of the die-casting die near the surface with and without heat-checking.

- Figure 10. Adhesion forces measured on the cross section of the die-casting die: near die surface (with N) and interior of die (without N).

- Figure 11. Residual stress of the die-casting die, including on the heat-checked die surface, the die surface outside the cavity, and the interior of the die.

- Figure 12. Models of the die-casting die showing the stress distribution after nitriding treatment and creation of the heat-checking.

7. Conclusion:

The study summarizes several factors contributing to the formation of heat-checking:

1. Microstructural changes near the heat-checked region, including the formation of equiaxed grains and nitride precipitates due to thermal effects.

2. A high-hardness surface layer from nitriding, which also experiences changes in microstructure, nitrogen diffusion, and significant hydrogen absorption.

3. Initial compressive residual stresses from nitriding are converted into tensile residual stresses after cracks form, which serves as a driving force for crack propagation.

4. The penetration of molten aluminum into cracks leads to erosion and high stress concentration at crack tips.

Heat-checking is driven by a complex combination of microstructural changes, tensile residual stress, reduced nitrogen content, and hydrogen penetration, in addition to thermal stress and shock.

8. References:

- S. Otarawanna, H.I. Laukli, C.M. Gourlay, A.K. Dahle, Feeding mechanisms in high-pressure die castings. Metall. Mater. Trans. A 41, 1836–1846 (2010). https://doi.org/10.1007/s11661-010-0222-6

- M. Okayasu, S. Yoshifuji, M. Mizuno, M. Hitomi, H. Yamazaki, Comparison of mechanical properties of die cast aluminum alloys: cold v. hot chamber die casting and high v. low speed filling die casting. Int. J. Cast Metal. Res. 22, 374–381 (209). https://doi.org/10.1179/174313309X380413

- R. Shivpuri, M. Yu, K. Venkatesan, Y.-L. Chu, A study of erosion in die casting dies by a multiple pin accelerated erosion test. ASM Int. 4, 145–153 (1995). https://doi.org/10.1007/BF02664107

- D. Klobčar, J. Tušek, Thermal stresses in aluminium alloy die casting dies. Comput. Mater. Sci. 43, 1147–1154 (2008). https://doi.org/10.1016/j.commatsci.2008.03.009

- B. Kosec, Failures of dies for die-casting of aluminium alloys. Murgija 47, 51–55 (2008)

- X. Hu, G. Zhao, B. Wu, Temperature change and stress distribution analysis of die surface in Al-alloy die casting process and experimental study on die heat check. China Foundry 5, 47–53 (2008)

- S.-H. Kang, J.-J. Han, W.-T. Hwang, S.-M. Lee, H.-K. Kim, Failure analysis of die casting pins for an aluminum engine block. Eng. Fail. Anal. 104, 690–703 (2019). https://doi.org/10.1016/j.engfailanal.2019.06.053

- H.A. Abdulhadi, S.N. Aqida, M. Ishak, G.R. Mohammed, Thermal fatigue of die-casting dies: an overview. MATEC Web Conf. 74, 00032 (2016)

- S. Sivertsen, R. Oliver, K. Anantha, G. Maistro, Key properties of die material needed for structural aluminum-high pressure die casting (HPDC). NADCA Trans. T19-111, 1–15 (2019)

- M. Okayasu, K. Shigematsu, Hydrogen embrittlement characteristics of a die-casting die after a high- pressure die-casting operation. Int. J. Metalcast. 18, 810–820 (2023). https://doi.org/10.1007/s40962-023-01081-y

- S.-H. Yeh, L.-H. Chiu, Y.-T. Pan, S.-C. Lin, Relative dimensional change evaluation of vacuum heat-treated JIS SKD61 hot-work tool steels. J. Mater. Eng. Perform. 23, 2075–2082 (2014). https://doi.org/10.1007/s11665-014-0961-4

- M. Kaneko, T. Doshida, K. Takai, Changes in mechanical properties following cyclic prestressing of martensitic steel containing vanadium carbide in presence of nondiffusible hydrogen. Mater. Sci. Eng. A 674, 375–383 (2016). https://doi.org/10.1016/j.msea.2016.08.012

- G.W. Simmons, P.S. Pao, R.P. Wei, Fracture mechanics and surface chemistry studies of subcritical crack growth in AISI 4340 steel. Metall. Trans. A 9A, 1147–1158 (1978). https://doi.org/10.1007/BF02652220

- M. Kohlhepp, P.J. Uggowitzer, M. Hummel, H.W. Höppel, Formation of die soldering and the influence of alloying elements on the intermetallic interface. Materials 14, 1580 (2021). https://doi.org/10.3390/ma14071580

- H.J. Wang, X.P. Su, S.P. Sun, J.H. Wang, Y. Jiang, First-principles calculations to investigate the aniso- tropic elasticity and thermodynamic properties of FeAl3 under pressure effect. Results Phys. 26, 104361 (2021). https://doi.org/10.1016/j.rinp.2021.104361

- Y.C. Chen, K. Nakata, Evaluation of microstructure and mechanical properties in friction stir processed SKD61 tool steel. Mater. Character. 60, 1471–1475 (2009)

- N. Nakada, Y. Arakawa, K.-S. Park, T. Tsuchiyama, S. Takaki, Dual phase structure formed by partial reversion of cold-deformed martensite. Mater. Sci. Eng. A 553, 128–133 (2012). https://doi.org/10.1016/j.msea.2012.06.001

- K. Yatsushiro, M. Hihara, K. Okada, S. Yabuuchi, M. Kuramoto, Effects of thermal cycles on residual stress for nitrided and sulphonitrided hot work die steel, International Centre for Diffraction Data 2000. Adv. X-Ray Anal. 42, 439–450 (2000)

- S. Iwanaga, Y. Sakakibara, T. Konaga, M. Nakamura, T. Kamiya, Initiation and propagation of heat check- ing in aluminum. J. Soc. Mater. Sci. (Japan) 36, 604–609 (1987). https://doi.org/10.2472/JSMS.36.604

- S. Iwanaga, Y. Sakakibara, T. Konaga, M. Nakamura, T. Kamiya, Relationship between heat checking and residual stress in aluminum die casting dies. J. Soc. Mater. Sci. (Japan) 36, 1355–1360 (1987). https://doi.org/10.

Expert Q&A: Your Top Questions Answered

Q1: Why was a die that underwent 100,000 shots specifically chosen for this study?

A1: The researchers selected a die after approximately 100,000 shots to study the material in a realistic, service-aged condition where heat-checking is well-developed. This allows for a direct investigation of the failure mechanisms as they occur in an actual production environment, rather than relying solely on laboratory simulations. This approach provides invaluable insights into the cumulative damage that leads to end-of-life failure.

Q2: Figure 11 shows tensile stress on the heat-checked surface. How is this possible when nitriding is known to create compressive stress?

A2: This is a key finding of the paper. The initial state of the die surface after nitriding is indeed high compressive stress. However, the paper hypothesizes that during the die-casting process, severe cracks form at points of high stress concentration (like die edges). The formation of these cracks physically relieves the built-in compressive stress. This relaxation, combined with a reduction of nitrogen content in the surface layer as shown in Figure 7, causes the stress state to flip from protective compression to damaging tension.

Q3: What is the significance of the equiaxed grains found near the heat-checked surface in Figure 9?

A3: The presence of equiaxed grains indicates that the die material has undergone recrystallization in that specific area. The original hardened and tempered microstructure is lath martensite. The intense, repeated thermal cycles from the molten aluminum cause localized heating sufficient to transform this structure into new, strain-free equiaxed grains. This change fundamentally alters the mechanical properties, contributing to the scattered hardness values and overall degradation of the die material.

Q4: The paper mentions high hydrogen content near the surface (Figure 3). How does this contribute to heat-checking?

A4: The paper attributes the high hydrogen content (up to 1.3 wppm) to the water-based lubricants used in the process. This hydrogen can lead to hydrogen embrittlement. The study notes that this is likely non-diffusible hydrogen trapped at sites like the Cr-Mo-V-based precipitates. Citing previous work, the authors suggest that during cyclic stressing, this trapped hydrogen can be released and interact with vacancies, severely exacerbating embrittlement and making the material more susceptible to cracking.

Q5: How does the infiltration of aluminum shown in Figure 8 accelerate die failure?

A5: The infiltration of molten aluminum into existing heat-checking cracks accelerates failure in two primary ways. First, the aluminum reacts with the iron in the die steel to form a layer of hard and brittle intermetallic compounds, such as η-Fe2Al5 and θ-FeAl3. This makes the material at the crack tip more prone to fracture. Second, the solidified aluminum acts as a physical wedge within the crack, leading to high stress concentrations at the crack tip during thermal cycles, which actively drives the crack deeper into the die with each cycle.

Conclusion: Paving the Way for Higher Quality and Productivity

This research provides a critical update to our understanding of Die-Casting Die Heat-Checking. It demonstrates that this common failure mode is not simply a matter of thermal fatigue but a complex degradation process involving a detrimental shift from compressive to tensile residual stress, significant microstructural changes, and chemical attack from both hydrogen and molten aluminum.

For HPDC professionals, these findings highlight that extending die life requires a multi-faceted approach. It's about more than just selecting the right steel; it involves optimizing nitriding processes, managing lubricant and cooling strategies to minimize hydrogen uptake, and designing dies to reduce stress concentrations. By understanding these root causes, we can develop more robust processes and predictive maintenance strategies to maximize the productivity and longevity of critical tooling.

"At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components."

Copyright Information

- This content is a summary and analysis based on the paper "MATERIAL PROPERTIES OF DIE-CASTING DIE AROUND HEAT-CHECKING CREATED BY A HIGH-PRESSURE ALUMINUM ALLOY DIE-CASTING OPERATION" by "Mitsuhiro Okayasu and Junya Shimazu".

- Source: https://doi.org/10.1007/s40962-025-01573-z

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.