The Future is Light: Unpacking the Properties and Applications of Lightweight Aluminum Alloy Casting

This technical summary is based on the academic paper "Research on Properties and Applications of New Lightweight Aluminum Alloy Materials" by Yucheng Yong, published in Highlights in Science, Engineering and Technology (2024). It has been analyzed and summarized for technical experts by CASTMAN with the assistance of AI.

Keywords

- Primary Keyword: Lightweight Aluminum Alloy Casting

- Secondary Keywords: Aluminum Alloy Properties, Automotive Lightweighting, High-Strength Aluminum Alloys, Aluminum Casting Methods, 3D Printing Aluminum, Aluminum Alloy Microstructure

Executive Summary

A 30-second overview for busy professionals.

- The Challenge: The growing demand for lighter, more fuel-efficient, and environmentally sustainable vehicles requires advanced materials that can outperform traditional steel without compromising strength or safety.

- The Method: This research provides a comprehensive analysis of the properties, composition, manufacturing processes, and applications of various lightweight aluminum alloys.

- The Key Breakthrough: High-strength aluminum alloys, particularly when fabricated using precision methods like die casting, offer a superior combination of low density, high strength, and processability for modern automotive manufacturing.

- The Bottom Line: The strategic selection of aluminum alloys and advanced fabrication techniques is critical for achieving next-generation performance and sustainability in the automotive industry.

The Challenge: Why This Research Matters for HPDC Professionals

In recent years, the transportation industry has faced immense pressure to reduce vehicle weight, improve energy efficiency, and meet stringent environmental standards. While materials like high-strength steel have been mainstays, the push for even greater performance has opened the door for alternatives. Carbon fiber composites, for instance, offer incredible strength-to-weight ratios but come with a prohibitive price tag for mass-market vehicles.

This creates a critical need for a material that balances performance, cost, and manufacturability. As this paper highlights, lightweight aluminum alloy has emerged as the most suitable candidate for large-scale automobile production. It addresses the core industry challenges by providing a path to significant weight reduction while maintaining the structural integrity, corrosion resistance, and recyclability essential for modern vehicles. Understanding the nuances of these alloys is no longer optional; it's fundamental to competitive automotive design and manufacturing.

The Approach: Unpacking the Methodology

This paper conducts a comprehensive review of lightweight aluminum alloys, synthesizing information from existing academic studies, patents, and industrial applications. The author's methodology involves:

- Compositional Analysis: Examining the role of key alloying elements (such as Si, Mg, Cu, Li, Zn) and their impact on the final material properties, with specific examples from the 6000 and 5000 series alloys.

- Microstructure Evaluation: Describing the macro and microstructural features of aluminum alloys, including grain size, lattice structure, and the segregation of alloying elements. The study also investigates how modern processes like Cold Metal Transition + Pulse (CMT+P) can influence and refine this microstructure.

- Performance Characterization: A detailed evaluation of the comprehensive mechanical, physical, chemical, and process properties of these alloys, providing specific data ranges for tensile strength, density, and thermal conductivity.

- Fabrication Technique Assessment: Comparing various manufacturing methods, including casting (sand vs. die casting), wrought techniques (extrusion, rolling), and advanced methods like powder metallurgy and additive manufacturing (3D printing).

This holistic approach provides a clear and thorough understanding of the material's lifecycle, from initial composition to final application.

The Breakthrough: Key Findings & Data

[Based on the paper's Results section, present the 2-3 most significant findings with concrete data.]

Finding 1: Manufacturing Processes Fundamentally Alter Mechanical Performance

The study emphasizes that the choice of manufacturing process and subsequent treatments has a profound impact on the final properties of an aluminum alloy component. For example, a study by Husaini et al. [6] found a significant performance difference between two types of motorcycle wheel rims:

- Cast wheel rims could withstand a load of 3 tons (30,000 N) and a rim tension of 45.84 MPa before fracture.

- Spoke wheel rims, which involve welding, could only withstand a smaller compressive load of 2 tons (20,000 N) before breaking at a stress of 66.04 MPa. The local property differences at the weld create a point of failure.

Furthermore, post-processing treatments can yield dramatic improvements. Chakravarty et al. [7] discovered that the cutting force required for a cryogenically treated 7075 aluminum alloy is significantly smaller than for a non-treated alloy. The cutting force for a T6-state alloy was 1.25 times that of a cryogenically treated T6I4-state alloy, a result attributed to a denser and more refined precipitate structure after treatment.

Finding 2: Die Casting is the Superior Method for High-Precision Automotive Parts

When evaluating casting methods, the paper draws a clear distinction between traditional and modern techniques. Sand casting, while capable of quickly producing a large number of parts, suffers from low accuracy and a tendency for defects like shrinkage holes and pores.

In contrast, the paper states, "For the modern automotive industry, lightweight aluminum alloys are more likely to use the die-casting method because it can achieve high precision and surface quality, thereby reducing the time and cost of post-processing and surface treatment processes." This makes die casting the more suitable choice for critical, high-precision components such as engine blocks, cylinder heads, and gearbox housings, where both dimensional accuracy and material integrity are paramount.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that adjusting post-casting treatments, such as solution-quenching-cryogenic cycles, may contribute to achieving superior dimensional stability and mechanical properties in finished parts [8].

- For Quality Control Teams: The data in Section 3.2 (e.g., tensile strength of 200-500 MPa for 6000 series) provides a baseline for mechanical property targets, while the microstructural analysis in Section 2.2.2 illustrates how grain structure directly impacts performance, informing new criteria for metallographic inspection.

- For Design Engineers: The findings indicate that the choice of fabrication technique (e.g., die casting vs. additive manufacturing) fundamentally influences design freedom, production cost, and part performance. The limitations of welding noted in the spoke wheel example [6] suggest that designing single-piece cast components is a valuable consideration for maximizing structural integrity.

Paper Details

Research on Properties and Applications of New Lightweight Aluminum Alloy Materials

1. Overview:

- Title: Research on Properties and Applications of New Lightweight Aluminum Alloy Materials

- Author: Yucheng Yong

- Year of publication: 2024

- Journal/academic society of publication: Highlights in Science, Engineering and Technology, Volume 84 (ACMME 2023)

- Keywords: Aluminum alloy, lightweight materials, modern industry, material properties.

2. Abstract:

The burgeoning demands of contemporary industry have necessitated a huge shift in the selection and utilization of materials, steering focus towards those that embody enhanced properties and environmental sustainability. Lightweight aluminum alloys have emerged as frontrunners in this transition owing to their low density, high strength, ease of processing, and environmental compatibility. These attributes have propelled aluminum alloys to a position of prominence, often superseding steel as the preferred choice in various industrial domains. In the transportation sector, the merits of these alloys are particularly conspicuous. They have become instrumental in automobile manufacturing, facilitating a reduction in vehicle weight, which in turn augments fuel efficiency and bolsters endurance. This trajectory is anticipated to persist, with high-strength aluminum alloys poised to become quintessential structural materials in future automotive manufacturing endeavors. These new materials, characterized by superior strength and enhanced corrosion resistance, are expected to be crafted utilizing emergent technologies such as 3D printing, heralding a transformative era in the automotive industry. This study delineates the escalating significance of lightweight aluminum alloys in modern industry, with a special emphasis on their transformative potential in revolutionizing automotive manufacturing through advancements in material science and technology. It underscores the pivotal role these alloys are set to play in shaping a sustainable and efficient future for the automotive industry.

3. Introduction:

In recent years, the transportation industry has been arguably one of the most active fields of application in materials science. As the demand for transportation continues to grow, so do the property requirements of materials. In terms of strength and stiffness, since vehicles, aircraft, and other kinds of transportation need to have sufficient strength to withstand high-speed motion and vibration, materials must be able to resist these stresses and maintain the structure shape. For example, aluminum alloys and high-strength steel are the most popular automotive materials. In terms of corrosion resistance, vehicles need to be exposed to various environmental conditions for a long time, such as high temperature, low temperature, humidity and salt spray. In order to ensure its stability and safety, it is necessary to choose materials with good corrosion resistance, such as stainless steel, titanium alloys and ceramic materials. In addition, lightweight is becoming a new trend in modern transportation. In order to reduce weight and improve energy efficiency, the transportation industry has been studying lightweight materials. Among lightweight materials, carbon fiber composite is a very popular one, which is lighter than traditional metal materials but at the same time has higher strength and toughness. But due to its higher price, it is not suitable for family cars. At present, the most suitable for automobile production is lightweight aluminum alloy. Moreover, recyclability and environmental protection indicators have always been the basic requirements for modern industry. To meet the performance conditions under the premise of recyclability, it is very important to develop new kinds of environmentally friendly materials. So, developing more advanced and efficient materials to meet changing needs has big potential in modern industry.

In this situation, the development process of vehicles always comes with the replacement of materials. Ford first carried out assembly line production of automobiles, and the independence of each module of the car made material replacement more convenient. If a car wants to increase its speed without the same original power system, the most effective way is to reduce the body mass.

4. Summary of the study:

Background of the research topic:

The transportation industry's continuous demand for materials with higher strength, stiffness, corrosion resistance, and lower weight to improve energy efficiency and meet environmental standards.

Status of previous research:

The paper notes the historical progression of materials in automobiles, from Ford's assembly line production enabling easier material replacement to the large-scale appearance of aluminum alloys in cars since the 1970s. It cites that some German brands have reached aluminum alloy proportions as high as 25% [1] and mentions Audi's first mass production of all-aluminum cars in 1999.

Purpose of the study:

To delineate the escalating significance of lightweight aluminum alloys in modern industry, with a special emphasis on their transformative potential in revolutionizing automotive manufacturing through advancements in material science and technology.

Core study:

The study is a comprehensive review and analysis of the properties (mechanical, physical, chemical), composition, microstructure, fabrication techniques (casting, wrought, additive manufacturing), and applications of new lightweight aluminum alloys, focusing primarily on the automotive sector.

5. Research Methodology

Research Design:

The paper is a comprehensive review and synthesis of existing research, patents, and industrial applications related to lightweight aluminum alloys. It does not present new experimental data but analyzes and consolidates current knowledge.

Data Collection and Analysis Methods:

The author collected information from a range of academic and technical sources, including scientific papers and patents. The analysis involves comparing different alloy series, fabrication methods, and post-processing treatments to evaluate their impact on material properties and suitability for various applications.

Research Topics and Scope:

The research covers the characteristics, performance, fabrication, and application of lightweight aluminum alloys. The scope is primarily focused on their use in the transportation industry, with a significant emphasis on automotive manufacturing for both internal combustion engine and electric vehicles.

6. Key Results:

Key Results:

- Lightweight aluminum alloys offer a superior combination of low density (approx. 1/3 of steel), high strength, corrosion resistance, and recyclability, making them ideal for automotive lightweighting.

- The properties of aluminum alloys are highly dependent on their composition (e.g., 6000 series with Mg/Si) and microstructure, which can be manipulated through heat treatment and advanced processes.

- Manufacturing processes fundamentally determine component performance. Die casting is identified as superior to sand casting for high-precision, complex automotive parts like engine blocks and gearbox housings.

- Post-processing treatments like cryogenic processing can significantly enhance mechanical properties, such as reducing the cutting force required for 7075 alloy by improving the precipitate structure.

- Future trends point towards the increased use of high-strength aluminum alloys, a greater focus on recycling, and the adoption of new technologies like 3D printing, despite its current cost and material limitations.

Figure Name List:

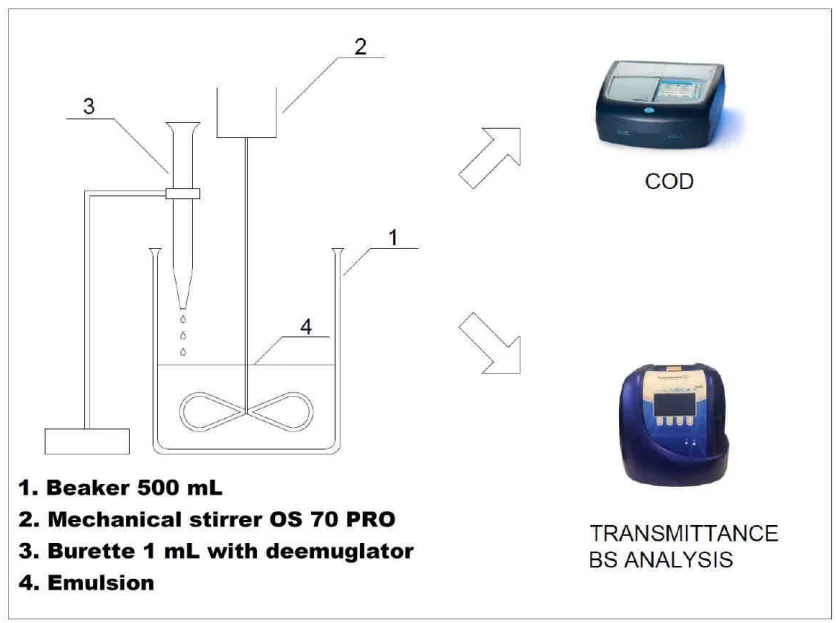

- Fig. 1. Scheme of demulsification set-up

- Fig. 2. TSI value stability ranking [23]

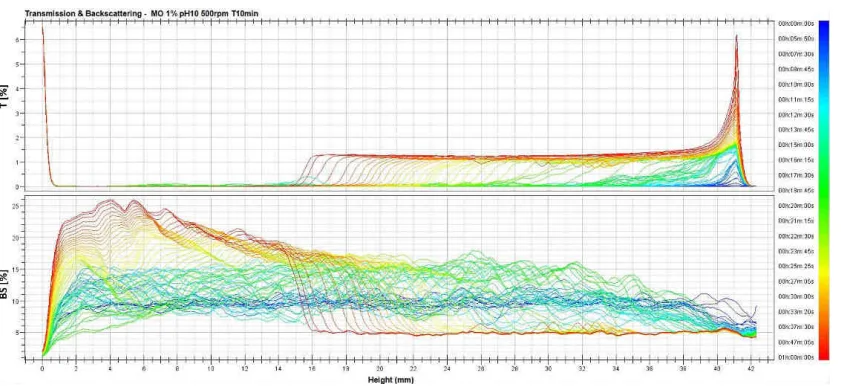

- Fig. 3. Transmittance, T and backscattering BS for raw coolant

- Fig. 4. Transmittance and backscattering for separated coolant (pH = 10.0, demulsifier concentration 1%, stirrer speed 500 rpm, stirring time 10 min)

- Fig. 5. Change in TSI over time as a function of the concentration of the demulsifier (pH = 5.5, stirrer speed 1200 rpm, stirring time 10 min)

- Fig. 6. Change in TSI coefficient over time depending on the pH of the system being separated (demulsifier concentration 1.0%, stirrer speed 500 rpm, stirring time 10 min)

- Fig. 7. Change in TSI coefficient over time depending on the stirrer speed (pH = 10.0 demulsifier concentration 1.0%, stirring time 10 min)

- Fig. 8. Change in TSI coefficient over time depending on the stirring time of the separated emulsion (pH = 10.0, demulsifier concentration 1.0%, stirrer speed 500 rpm)

- Fig. 9. Comparison of raw emulsion (left) and separated coolant (right) (pH = 10, demulsifier concentration 1%, stirrer speed 500 rpm, stirring time 10 min)

1 %, stirrer speed 500 rpm, stirring time 10 min)

7. Conclusion:

Due to its low density, high strength, easy processing and environmental protection, lightweight aluminum alloy has gradually increased its status in modern industry, surpassing steel in many fields to become the first choice for engineering materials. In the field of transportation, the advantages of lightweight aluminum alloys are very prominent, and they are widely used in automobile manufacturing to reduce vehicle weight and improve fuel efficiency and performance. In the body structure, the low density of aluminum alloy greatly improves transportation efficiency. In the suspension system, aluminum alloy can manufacture high-precision suspension arms and steering knuckles to improve handling performance. In the power system, aluminum alloy can reduce the weight of the engine and does not provide an upper limit for the installation of the battery of the electric vehicle, which greatly strengthens the endurance of the vehicle. In terms of wheels, aluminum alloy wheels have become the first choice of many automakers because of their beauty and corrosion resistance.

In the future, this trend will continue. Because of the increasing demand for lightweight in the automotive industry, high-strength aluminum alloys will become one of the core structural materials for future automobile manufacturing. These high-strength aluminum alloys offer higher strength and better corrosion resistance, allowing them to replace bulky steel components further. Moreover, the new requirements for environmental protection will also greatly affect the development of aluminum alloys. With the extension of the service life of automobiles and the increase in the number of end-of-life cars, aluminum alloy recycling will become an important field. By recycling aluminum alloys, the cost of automobile manufacturing can be reduced while reducing the need for raw materials. Finally, 3D printing technology will gradually be popular in automobile manufacturing, which can bring new opportunities for the manufacture of lightweight aluminum alloys.

Of course, lightweight aluminum alloys also have shortcomings such as high prices, unstable strength of different series, and poor welding performance, which will also become one of the problems that the material industry needs to solve in the future. In short, the application of lightweight aluminum alloys in the automotive industry has achieved remarkable results and will continue to play an important role in the future. With the development of high-strength aluminum alloy, aluminum alloy recycling, 3D printing technology and lightweight design, the application prospect of lightweight aluminum alloy in the automotive industry will be broader.

8. References:

- [1] Varun Sharma, Fatima Zivic, Dragan Adamovic, et al. Multi-criteria decision making methods for selection of lightweight material for railway vehicles. Materials, 2022, 16 (1): 368.

- [2] Yang Yang, Zhao Mingyu and Wang Guanyu. Application of lightweight aluminum alloy in automobile. Heilongjiang Science, 2022, 13 (16): 42-44.

- [3] Patent: US201514708256. Aluminum alloy for vehicle outer panel and production method thereof. Aluminum Processing, 2020, 3: 61.

- [4] Bi Jiawei, Li Zhonghua, Zhang Qifei, et al. Microstructure and mechanical properties of 5356 aluminum alloy based on CMT+P process. Precision Forming Engineering, 2023, 15 (08): 36-44.

- [5] Zhu Liu. Microstructure and mechanical properties of cast aluminum alloy regulated by microcrystals by microcrystals. Jilin University, 2023.

- [6] Husaini Husaini, Nurdin Ali, Abdillah Sofian, et al. Comparison of hardness and microstructure of cast wheel and spoke wheel rims of motorcycles made of aluminum alloy. Key Engineering Materials, 2021, 6229.

- [7] Chakravarty Purnima, Pál Gyula and Sidor Jurij J. Corrigendum to "the dependency of work hardening on dislocation statistics in cold rolled 1050 aluminum alloy" [Materials Characterization Volume 191, September 2022, 112166 volume]. Materials Characterization, 2023, 196: 112564.

- [8] Huo Shuhai, Heath Bill and Ryan Dave. Applications of powder metallurgy aluminums for automotive valve-trains. SAE International Journal of Materials and Manufacturing, 2009, 1 (1): 511-515.

- [9] Wei Xiaotian. Research on regulation and control of cold and heat treatment of processing deformation of high-strength aluminum alloy. North China Electric Power University (Beijing), 2022.

- [10] Li Caiwen, Pan Xueshu, Lu Lulu, et al. In-line hardening of 6061, 6005 aluminum alloy profile sets influence of weaving and properties. Metal HT-Treatment, 2010, 6: 59-62.

- [11] Lei Yong. Application research of aluminum alloy in van. Special Purpose Vehicle, 2022, 11: 43-47.

- [12] Ye Zhengting. Development status of aluminum alloy lightweight and connection technology of new energy vehicles. Science and Technology Innovation and Application, 2023, 13 (20): 155-158.

Expert Q&A: Your Top Questions Answered

Q1: Why is die casting specifically preferred over sand casting for modern automotive parts?

A1: According to the paper, die casting is preferred because it achieves high precision and superior surface quality. This significantly reduces the time and cost associated with post-processing and surface treatment steps that are typically required for sand-cast parts. For complex and critical components like engine blocks and gearbox housings, the precision offered by die casting is essential to meet modern engineering tolerances.

Q2: The paper mentions 6000 series alloys. What are their typical mechanical properties?

A2: The paper provides specific data for 6000 series aluminum alloys as an example. Under normal circumstances, their tensile strength is usually between 200-500 MPa, shear strength is between 100-300 MPa, and hardness is between HB 100-300. Their fatigue strength is typically 100-300 MPa.

Q3: How can the performance of aluminum alloys be improved after the initial manufacturing process?

A3: The paper highlights that post-processing treatments can greatly enhance performance. One study [7] found that cryogenic treatment of 7075-T6I4 aluminum alloy resulted in a smaller grain size and denser precipitates compared to non-treated samples, significantly reducing the required cutting force. Another study [8] showed that specific sequences of solution-quenching, cryogenic, and aging treatments could improve the dimensional stability of the final component.

Q4: What are the main trade-offs between using aluminum alloys and carbon fiber composites in cars?

A4: The introduction of the paper clarifies this trade-off. Carbon fiber composite is lighter than traditional metals and possesses higher strength and toughness. However, its primary drawback is its higher price, which makes it unsuitable for mass-produced family cars. Lightweight aluminum alloy provides the most suitable balance of performance (lightweight, strength) and production cost for the current automotive market.

Q5: The paper highlights the future potential of 3D printing. What are its current limitations for aluminum alloys?

A5: Section 4.3 outlines several disadvantages of additive manufacturing (3D printing) for aluminum alloys. The equipment is very expensive, especially for high-volume production. It is difficult to control the accuracy of large-size parts, and the manufactured parts require complex and costly post-processing (cleaning, sintering, heat treatment). Finally, material options are currently limited, especially for high-strength and high-hardness aluminum alloys.

Conclusion: Paving the Way for Higher Quality and Productivity

The shift towards lightweight, high-performance materials is an irreversible trend in modern industry, and this paper confirms that aluminum alloys are at the forefront of this transformation. The key takeaway is that achieving optimal results is not just about selecting the right alloy, but about mastering the manufacturing process. For complex, high-stakes automotive components, Lightweight Aluminum Alloy Casting, specifically high-pressure die casting, offers an unmatched combination of precision, surface quality, and cost-efficiency. As the industry moves towards even higher-strength alloys and more sustainable practices like recycling, expertise in these advanced fabrication techniques will become the defining factor for success.

"At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components."

Copyright Information

- This content is a summary and analysis based on the paper "Research on Properties and Applications of New Lightweight Aluminum Alloy Materials" by "Yucheng Yong".

- Source: https://www.atlantis-press.com/proceedings/acmme-23/125999201

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.