Solving Weldability Issues in Die-Cast Aluminum: A Breakthrough in Electron Beam Welding for Mass Production

This technical summary is based on the academic paper "Mass production welding of die-cast aluminium alloys by electron beam" by Daniel Drimal, Frantisek Kolenic, and Lubos Kovac, published in "E+E" (2018). It has been analyzed and summarized for technical experts by CASTMAN with the assistance of AI.

Keywords

- Primary Keyword: Die-Cast Aluminum Welding

- Secondary Keywords: Electron Beam Welding (EBW), AlSi10Mg(Fe), HPDC Contamination, Welding Porosity, High-Productivity Welding

Executive Summary

A 30-second overview for busy professionals.

- The Challenge: Contamination from the High Pressure Die Casting (HPDC) process, especially piston lubricants, severely reduces the weldability of die-cast aluminum alloys in mass production, causing defects and porosity.

- The Method: Researchers used Electron Beam Welding (EBW) to test intentionally contaminated AlSi10Mg(Fe) T-joints to scientifically identify the root cause of weld defects.

- The Key Breakthrough: Piston lubrication fluid was identified as the primary contaminant causing weld metal eruption and surface defects, proving significantly more detrimental than mould agents or cutting fluids.

- The Bottom Line: A specialized high-production EBW machine, engineered with advanced discharge protection and online monitoring, can successfully overcome contamination issues, enabling stable, high-quality mass production for Die-Cast Aluminum Welding.

The Challenge: Why This Research Matters for HPDC Professionals

Welding die-cast aluminum components is a well-known challenge in high-volume industries like automotive manufacturing. While the base alloy, such as AlSi10Mg(Fe), has a chemical composition and solidification range that is generally favorable for welding, the reality on the production floor is often complicated by defects like porosity and cracking.

This research addresses a critical pain point: the problem often isn't the alloy, but the process. The high-pressure die-casting process itself introduces contaminants that become embedded in the material. These contaminants, combined with aluminum's inherent characteristics—a persistent surface oxide layer, high thermal conductivity, and hydrogen absorption—create a perfect storm for reduced weldability. Specifically, for components like heat exchangers that require gas-tight T-joints, achieving consistent, defect-free welds in a mass production environment has been a significant technological hurdle. This study was necessary to move beyond guesswork and pinpoint the exact source of contamination-induced weld failures.

The Approach: Unpacking the Methodology

To isolate the cause of weld defects, the researchers conducted a systematic investigation using a targeted, practical approach.

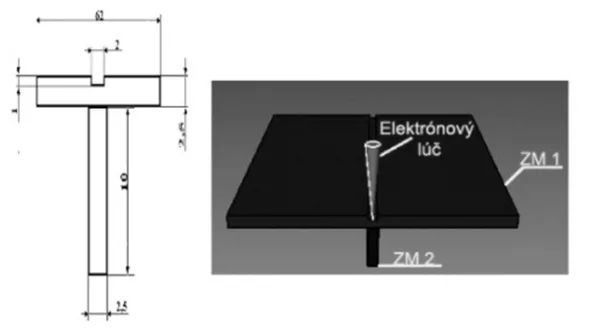

- Material & Component: The study focused on heat exchangers made from high-pressure die-cast AlSi10Mg(Fe) / EN AC-43400. The specific weld was a T-joint connecting the cover to the heat exchanger ribs, a critical connection that must be gas-tight.

- Welding Process: Electron Beam Welding (EBW) was selected for its precision and performance in a high-vacuum environment, which aids in degassing the weld pool.

- Contamination Simulation: The core of the methodology involved identifying potential contamination sources from the entire production chain. The researchers systematically introduced four different fluids, provided by the casting supplier, into the T-joint area before welding:

- High-pressure die casting piston lubrication fluid

- Mould agent (for preventing sticking)

- Mechanical machining cutting fluid

- Cleaning and washing detergent

- Analysis: By subjecting these intentionally contaminated samples to the EBW process, the team could directly observe and compare the effect of each fluid on the final weld quality, both visually and through macrostructure analysis.

The Breakthrough: Key Findings & Data

The study yielded clear, actionable results that directly identified the primary cause of weld defects and proposed a robust engineering solution.

Finding 1: Piston Lubrication Fluid is the Primary Culprit for Weld Defects

The comparative tests revealed a definitive source of contamination. While all fluids had some effect, the piston lubrication fluid was overwhelmingly the most damaging.

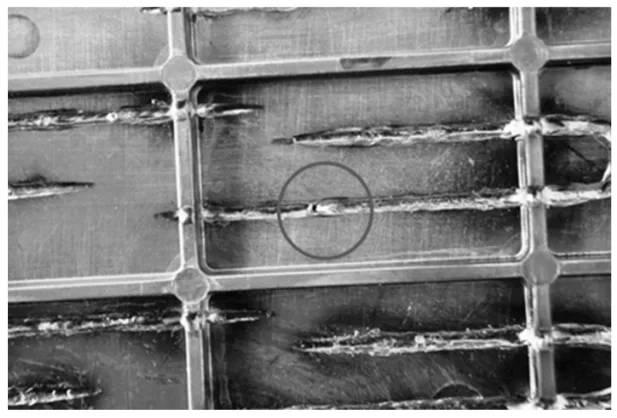

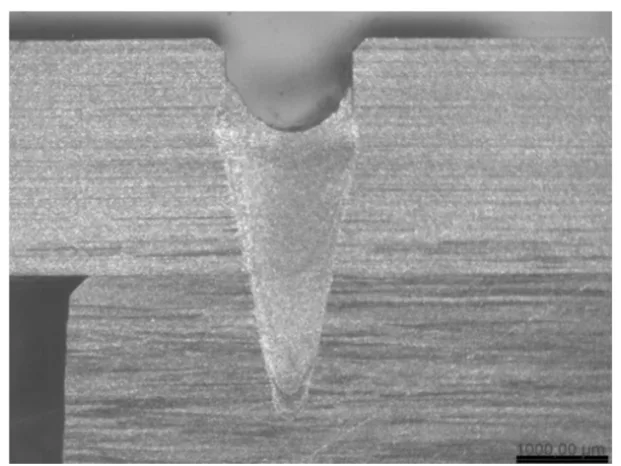

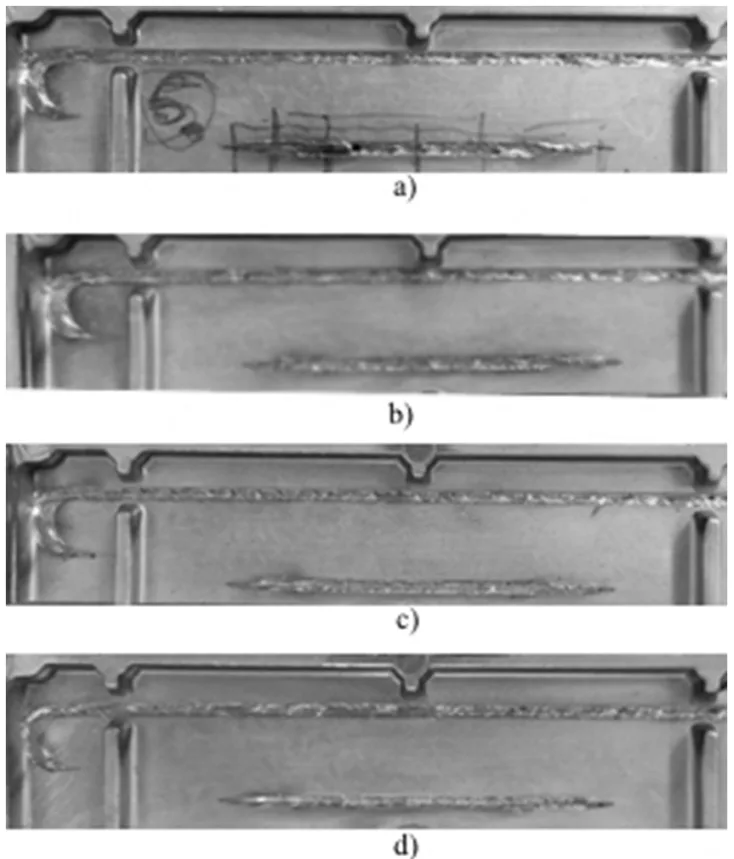

- As shown in Figure 5a and Figure 6b, the deposition of piston lubrication fluid in the weld area caused a violent eruption of the weld metal. This was associated with the formation of carbon scale around the weld and significant colorization of the surface near the defect.

- In contrast, the cutting fluid (Figure 5c, Figure 6a) and detergent (Figure 5d) had only a small influence on weld surface quality. The mould agent (Figure 5b) exhibited a more intensive influence than the cutting fluid but did not cause the severe defects seen with the piston lubricant. This finding proves that controlling contamination from the shot sleeve lubrication during the HPDC process is paramount for achieving high-quality welds.

Finding 2: A High-Productivity EBW Machine Design Overcomes Process Instability

Based on these findings, the paper presents a concept for a mass-production EBW machine designed specifically to handle the challenges of welding die-cast aluminum.

- Continuous Production: The design features one central welding chamber connected to two auxiliary vacuum chambers (Figure 7). This allows one component to be loaded/unloaded in an auxiliary chamber while another is being welded, eliminating downtime for chamber pumping and enabling continuous, non-interrupted production.

- Process Stability via Discharge Protection: Welding contaminated parts releases significant metal vapor and spatter, which can cause breakdowns (discharges) in the electron gun. The machine integrates an Electronic Discharge Protection (EDP) system (Figure 9). This system detects a discharge within 100 microseconds and renews the welding process in 6 to 10 milliseconds, preventing weld defects and dramatically increasing the stability and uptime of the machine.

- Automotive-Grade Quality Control: The system allows for online recording of more than 15 welding parameters, such as welding current, position, and vacuum level (Figure 11). This data can be analyzed off-line to trace the cause of any defects, optimize parameters, and implement the rigorous quality management processes required by the automotive industry.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that adjusting the die-casting process to limit the amount of piston lubrication fluid reaching the component is a critical first step. This may contribute significantly to reducing weld defects and improving overall production efficiency downstream.

- For Quality Control Teams: The data in Figure 5 and Figure 6 of the paper illustrates the distinct visual signatures of different types of contamination on the weld surface. This could inform new visual inspection criteria for incoming cast parts to screen for potential weldability issues before they enter the assembly line.

- For Design Engineers: The findings indicate that the presence of organic impurities can cause explosions in the weld pool. This suggests that joint designs should facilitate easy cleaning and provide sufficient volume to allow for effective degassing during the multipass EBW process, a valuable consideration in the early design phase.

Paper Details

Mass production welding of die-cast aluminium alloys by electron beam

1. Overview:

- Title: Mass production welding of die-cast aluminium alloys by electron beam

- Author: Daniel Drimal, Frantisek Kolenic, Lubos Kovac

- Year of publication: 2018

- Journal/academic society of publication: "E+E", vol. 53, 5-6

- Keywords: electron-beam welding, die-cast aluminium alloys, discharge protection, high-productivity.

2. Abstract:

This contribution presents the solution of technological aspects in mass production of die-cast aluminium alloys as well as the design of new modules necessary for successful dealing with production. The welded parts are made of near eutectic aluminium alloy AlSi10Mg(Fe) / EN AC-43400 by high pressure die-casting process. Materials by its chemical composition and narrow solidification range do not represents significant problem from weldability point of view. Major problem is material contamination caused by the die-casting process. Several procedures were proposed to eliminate the problem of reduced weldability. Except for technological problems this contribution presents the concept design of mass production welding machine which is based upon experiences of welding process optimization. Special attention is payed to design of welding machine modules such as discharge protection module and module for online monitoring and recording welding process parameters. Application of discharge protection module increase welding process stability and allow prolongation the electron gun maintenance time. Module for online monitoring and recording allows implementation of Quality Management processes required by automotive industry.

3. Introduction:

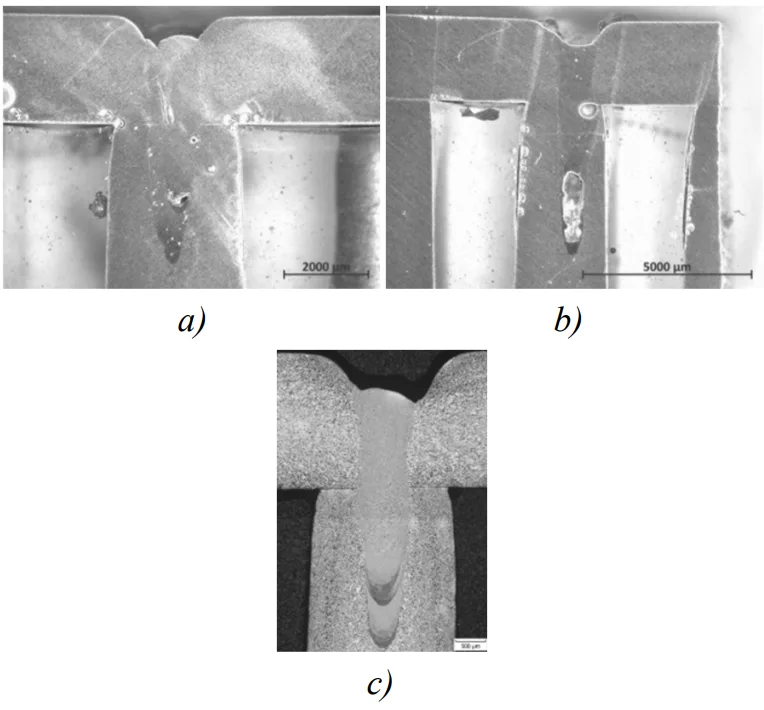

Aluminium and its alloys are widely used in industries like automotive due to their exceptional properties. However, welding these alloys is complicated by several factors: the presence of a surface oxide layer, high thermal conductivity, high thermal expansion, hydrogen content causing porosity, and a wide solidification interval leading to segregation and hot cracking. Porosity is a major issue, often caused by gases from the base metal and humidity in the oxide layer. Increasing the temperature and duration of the molten weld pool can help suppress pore formation.

4. Summary of the study:

Background of the research topic:

The mass production of welded die-cast aluminum components, such as heat exchangers, faces significant technological hurdles. The primary challenge is not the inherent weldability of the aluminum alloy itself, but rather the contamination introduced during the high-pressure die-casting process, which leads to defects and reduced weld quality.

Status of previous research:

While the general challenges of welding aluminum are well-documented, this paper addresses the specific, practical problem of identifying and mitigating process-induced contaminants in a high-volume industrial setting.

Purpose of the study:

The study aimed to (1) identify the specific source of contamination from the die-casting process that causes weld defects in AlSi10Mg(Fe) alloy, and (2) propose a concept design for a high-production Electron Beam Welding (EBW) machine capable of overcoming these challenges to achieve stable, mass production.

Core study:

The core of the study involved systematically contaminating T-joints of die-cast aluminum with four different process fluids (piston lubricant, mould agent, cutting fluid, detergent) and then evaluating the weld quality after EBW. Based on the results, a specialized EBW machine was designed with features for high throughput, process stability, and quality monitoring.

5. Research Methodology

Research Design:

The research employed an experimental design to determine cause and effect. By intentionally contaminating weld joints with specific fluids from the manufacturing process, the researchers could isolate the variable responsible for the most severe weld defects. This was followed by a conceptual engineering design phase for a machine to solve the identified problems.

Data Collection and Analysis Methods:

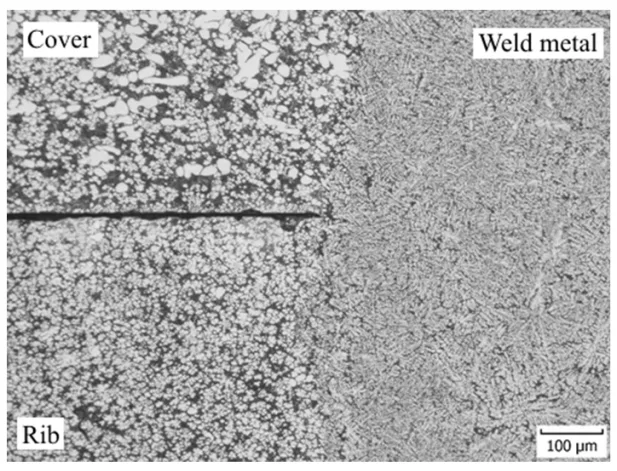

Data was collected through visual inspection of the welded surfaces and metallographic examination of the weld joint macrostructures. The effects of different contaminants were compared qualitatively and documented with photographs and micrographs.

Research Topics and Scope:

The scope was focused on the EBW of T-joints in a specific die-cast aluminum alloy (AlSi10Mg(Fe) / EN AC-43400) used for heat exchangers. The research investigated contamination from the die-casting and machining processes and proposed a complete machine concept for mass production.

6. Key Results:

Key Results:

- The primary source of weld defects, such as metal eruption and carbon scale, was identified as the piston lubrication fluid used in the high-pressure die-casting process.

- Other process fluids like cutting fluid and detergent had a minimal impact, while mould agent had a moderate impact on weld surface quality.

- A high-productivity EBW machine concept was developed, featuring dual auxiliary vacuum chambers for continuous operation.

- An integrated Electronic Discharge Protection (EDP) system was designed to ensure process stability by rapidly recovering from discharges caused by contaminants, allowing for seven-day continuous operation.

- An online monitoring system for recording over 15 process parameters was included to meet the quality management requirements of the automotive industry.

Figure Name List:

- Fig. 1. Weld joint geometry.

- Fig. 2. Structure of T-joint of AlSi10Mg(Fe).

- Fig. 3. Crater in weld of contaminated materials.

- Fig. 4. Structure of T-joint of Al4,5ZnMg1.

- Fig. 5. Surface of the weld joints contaminated by different fluids a) piston lubrication fluid; b) mould agent; cutting fluid; d) detergent.

- Fig. 6. Comparison of weld joint macrostructure a) with cutting fluid; b) piston lubrication fluid; c) without contamination

- Fig. 7. The concept of high production EBW machine.

- Fig. 8. Design of the kinematic part of the high productive welding machine.

- Fig. 9. The function of discharge protection.

- Fig. 10. Replaceable protection of inner parts of the gun by high productive welding.

- Fig. 11. Off-line analyses of four recorded welding parameters.

7. Conclusion:

Electron Beam Welding in a high vacuum is the most suitable method for this type of material. Using multipass welding with appropriate beam oscillations produces solid, tight weld joints with minimal defects. The primary defects observed, transverse deficiencies, arise from the explosion of the welding pool due to localized organic impurities from the casting process. The quality and tightness of the joint can be restored with repair welding. A purpose-built machine, designed for a 3-shift work cycle, can achieve a maximum production of over 100,000 pcs a year, based on an average welding time of 140s and manipulation time of 60s.

8. References:

- [1] Kolenič, F., Ľ. Kováč. Electron and laser beam welding of die-cast aluminium alloy components of heat exchanger for automotive industry. IIW DOC XII-1881-06, Commission XII Intermediate meeting. April 2006.

- [2] Mathers, G. The welding of aluminium and its alloys. Woodhead Publishing Ltd., Cambridge, England, 2002.

- [3] Bondarev, A. A. Electron beam welding of high-strength aluminium alloys. Paton Welding Journal, 1999, pp.50 -53.

- [4] Kearns, W. H. Welding handbook, Vol. 4, 7. Ed, American Welding Society, Miami, Florida, 1982.

- [5] El-Batahgy, A., M. Kutsuna. Laser beam welding of AA5052, AA5083 and AA6061 aluminium alloys. Advances in Materials Science and Engineering, Hindawi Publishing Corporation, 2009.

Expert Q&A: Your Top Questions Answered

Q1: Why was Electron Beam Welding (EBW) chosen for this application instead of other common methods like laser or arc welding?

A1: The paper implies EBW is most suitable because the process takes place in a high vacuum. This vacuum environment is highly beneficial for welding aluminum as it helps remove gases (like hydrogen) from the molten weld pool, which directly addresses the problem of porosity. This degassing capability is crucial for creating the gas-tight joints required for components like heat exchangers.

Q2: The paper states the AlSi10Mg(Fe) alloy itself doesn't present a significant weldability problem. What exactly is the root cause of the welding issues?

A2: The root cause is material contamination from the high-pressure die-casting process. The study found that while the alloy's metallurgy is manageable, residual fluids from the manufacturing process become trapped in the material. When heated by the electron beam, these contaminants, particularly organic ones, vaporize explosively, causing defects like porosity, craters, and weld metal eruption.

Q3: Of all the potential contaminants from the die-casting process, which one had the most detrimental effect on weld quality?

A3: The piston lubrication fluid had the most severe negative effect. As shown in Figure 5a and Figure 6b, its presence led to the eruption of weld metal, the formation of carbon scale, and discoloration of the surface. This was a far more dramatic defect than those caused by the mould agent, cutting fluid, or detergent.

Q4: How does the proposed machine design address the issue of low productivity, which is often a concern with vacuum-based processes?

A4: The design cleverly uses one central welding chamber flanked by two adjacent auxiliary vacuum chambers. This allows for parallel processing: while one part is being welded in the main chamber under vacuum, a finished part can be unloaded and a new part loaded in the auxiliary chambers. This eliminates the need to vent and pump the main welding chamber for every part, enabling a continuous, non-interrupted production flow suitable for mass production.

Q5: What is the purpose of the Electronic Discharge Protection (EDP) system, and why is it so important for this specific process?

A5: The EDP system is critical for process stability and machine longevity. Welding contaminated die-cast parts releases a lot of spatter and metal vapor, which can cause electrical breakdowns (discharges) in the high-voltage electron gun. The EDP system detects these discharges in under 100 microseconds, temporarily interrupts the beam, and renews the welding process within 6-10 milliseconds. This rapid response prevents the discharge from damaging the gun or causing a weld defect, allowing for stable, continuous three-shift operation.

Conclusion: Paving the Way for Higher Quality and Productivity

This research cuts through the complexity of Die-Cast Aluminum Welding to deliver a clear verdict: process contamination, not material science, is the primary barrier to quality in mass production. By identifying piston lubrication fluid as the main culprit, the study provides a specific target for process control improvements in the casting phase. Furthermore, the proposed high-productivity EBW machine concept, with its intelligent chamber design and robust discharge protection, offers a complete engineering solution to produce high-quality, gas-tight welds reliably and at scale.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components.

Copyright Information

- This content is a summary and analysis based on the paper "Mass production welding of die-cast aluminium alloys by electron beam" by "Daniel Drimal, Frantisek Kolenic, Lubos Kovac".

- Source: "E+E", vol. 53, 5-6, 2018, pp. 119-124. A direct DOI link was not available in the provided document.

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.