This technical summary is based on the academic paper "Copper in the Rotor for Lighter, Longer Lasting Motors" presented at the ASNE SAN DIEGO SECTION FLEET MAINTENANCE SYMPOSIUM 2005 by C. Stark, J. G. Cowie, D. T. Peters, and E. F. Brush, Jr. It was analyzed and summarized for HPDC experts by CASTMAN experts with the help of LLM AI such as Gemini, ChatGPT, and Grok.

Keywords

- Primary Keyword: Die-Cast Copper Rotor Motors

- Secondary Keywords: High-Pressure Die Casting (HPDC) Copper, Motor Efficiency Improvement, Hot Die Technology, Nickel-Base Alloy Dies, Induction Motor Rotor, Thermal Fatigue (Heat Checking), Aluminum vs. Copper Rotor

Executive Summary

- The Challenge: For decades, the motor industry has sought to use highly conductive copper in motor rotors to boost efficiency, but its high melting point (1083°C) caused rapid thermal fatigue ("heat checking") and failure of standard steel dies, making high-pressure die casting (HPDC) economically unfeasible.

- The Method: Researchers developed and tested a "hot die" system, using durable nickel-base alloy die inserts preheated to over 625°C. This approach minimizes the thermal shock that destroys dies during casting.

- The Key Breakthrough: This new die technology increases die life by 50 to 100 times compared to conventional tool steel, making the mass production of die-cast copper rotors commercially viable. Motors built with these rotors show a 15-20% reduction in total losses, run cooler, and last significantly longer.

- The Bottom Line: HPDC of copper rotors is no longer a manufacturing pipe dream. This technology enables the production of motors that are not only more energy-efficient but can also be designed to be lighter, smaller, and more reliable than their aluminum-rotor counterparts.

The Challenge: Why This Research Matters for HPDC Professionals

For years, induction motors have relied on die-cast aluminum for their rotor squirrel cages. Aluminum is easy to cast, but its electrical conductivity is a limiting factor for motor efficiency. Copper is nearly 60% more conductive, promising a substantial reduction in rotor energy losses (I²R losses). However, a significant manufacturing barrier has stood in the way: copper's high melting point of 1083°C (1982°F).

When molten copper is injected into a conventional tool steel die, the extreme thermal shock causes rapid and severe "heat checking"—a thermal fatigue phenomenon that quickly degrades the die surface. This results in an impractically short die life, making the HPDC process for copper rotors too costly for mass production. Overcoming this long-standing challenge was essential to unlocking the performance benefits of copper in millions of industrial, defense, and aerospace motors sold annually.

The Approach: Unpacking the Methodology

To solve the die life problem, the research team undertook a multi-phase investigation.

The core of the solution was the development of a hot die technology. 3-D thermal modeling showed that by preheating the die and maintaining a high operating temperature, the cyclical thermal strain on the die surface could be reduced to below the material's plastic range. To achieve this, the researchers:

- Tested Advanced Die Materials: They moved beyond standard H-13 tool steel and evaluated high-temperature materials, including molybdenum, tungsten, and various nickel-base alloys (e.g., INCONEL 617, 718, and 754).

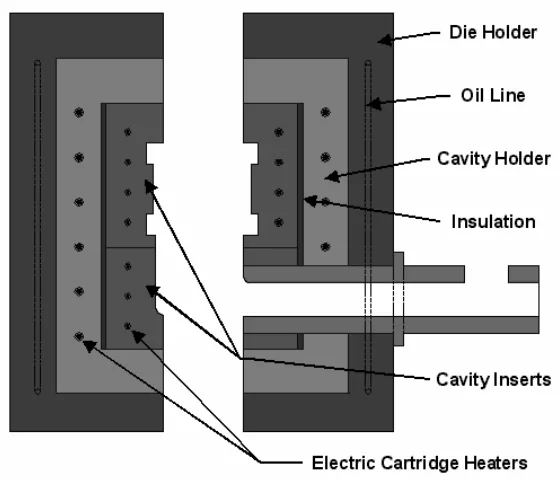

- Engineered a Heated Die System: They designed a practical system incorporating electrical resistance heaters and insulation to maintain the die inserts at an optimal elevated temperature (625°C to 650°C), as shown in Figure 1.

Once the manufacturing process was proven viable, the team die-cast over 140 copper rotors. These were then assembled into motors and subjected to rigorous dynamometer performance testing (per IEEE Specification 112, Test Method B) to quantify the real-world benefits compared to identical motors with standard aluminum rotors.

The Breakthrough: Key Findings & Data

The study produced definitive evidence that die-cast copper rotors are not only manufacturable but also deliver superior performance.

Finding 1: Viable Manufacturing Process: The hot die system using nickel-base alloy inserts proved highly effective. It resisted heat checking for hundreds of shots, demonstrating a potential die life increase of 50 to 100 times over H-13 steel. The resulting copper castings were sound, with minimal defects and an average electrical conductivity of 98% IACS.

Finding 2: Drastic Reduction in Motor Losses: In a 15 Hp motor test, simply substituting copper for aluminum (with no other design changes) yielded a 14% reduction in total motor losses. The key contributors were:

- 40% reduction in Rotor Resistance losses (from 261W to 157W).

- 23% reduction in Stray Load losses, attributed to the superior consistency of the copper casting.

- 37% reduction in Windage & Friction losses, as the cooler-running copper rotor required less aggressive cooling fan designs. These segregated losses are detailed in Table 1.

Finding 3: Improved Efficiency and Longevity: The reduction in losses translated directly to a 1.2 percentage point increase in overall motor efficiency (from 89.5% to 90.7%) for the 15 Hp motor (Table 2). Critically, the motor's operating temperature rise was reduced by nearly 5°C. Based on the industry rule of thumb, this cooler operation could increase motor life by up to 50%.

Finding 4: Lighter and More Cost-Effective Designs: A study by SEW Eurodrive, who designed motors specifically optimized for copper rotors, found that the technology allowed for significant downsizing. Copper rotor motors could be built one frame size smaller than an aluminum motor of equivalent efficiency. This led to weight savings of up to 18% and, surprisingly, cost savings of up to 15%, even with the more expensive copper casting process.

Practical Implications for HPDC Products

This research has profound implications for manufacturers and end-users of HPDC components, particularly in the motor industry.

For Process Engineers: The findings provide a clear blueprint for successfully die-casting high-melting-point alloys like pure copper. The "hot die" concept, detailed in Figure 1, using nickel-base alloy inserts (like Haynes 230 or INCONEL 617/625) and operating at elevated temperatures (above 625°C), is a proven strategy to dramatically extend die life and make challenging projects commercially viable.

For Quality Control: The copper rotors produced in this study were so consistent they did not require the balancing weights typically needed for aluminum rotors. This suggests that the process delivers superior part-to-part consistency and dimensional accuracy, reducing downstream processing steps and improving overall product quality. The reduction in stray load losses (Table 1) further confirms the high integrity of the cast conductor bars.

For Die Design: The study opens the door for designing motors that are fundamentally better. The higher conductivity of copper requires a different approach to rotor bar design to manage torque characteristics. As shown in Figure 6, the optimal bar shape for copper is different from the conventional shape used for aluminum, featuring distinct "starting bar" and "running bar" sections to control performance across the speed range. This allows designers to create motors that are lighter, smaller, and more energy-efficient.

Paper Details

Copper in the Rotor for Lighter, Longer Lasting Motors

1. Overview:

- Title: Copper in the Rotor for Lighter, Longer Lasting Motors

- Author: C. Stark, J. G. Cowie, D. T. Peters, and E. F. Brush, Jr.

- Year of publication: 2005

- Journal/academic society of publication: ASNE SAN DIEGO SECTION FLEET MAINTENANCE SYMPOSIUM 2005

- Keywords: Die-Cast Copper Rotor Motors, High-Pressure Die Casting (HPDC) Copper, Motor Efficiency Improvement, Hot Die Technology, Nickel-Base Alloy Dies, Induction Motor Rotor

2. Abstract:

This paper reviews the advantages of substituting die-cast copper for aluminum in the motor rotor. This advance in motor technology has been long sought by the motor industry but short die life due to the high melting point of copper frustrated attempts to manufacture by pressure die casting. The nickel-base alloy hot die technology developed to solve the manufacturing problem is briefly reviewed. Development work done prior to the present program and commercial motors derived from that work have focused on the increased electrical energy efficiency achievable by using copper with its higher electrical conductivity in the rotor. Performance characteristics of example industrial motors are presented. Modification of the conductor bar shape to control in-rush current and starting torque to accommodate copper in the rotor will be discussed. Modeling by motor manufacturers has shown that by using copper in the rotor, a lighter motor than an aluminum rotor motor at the same efficiency can be built. An example of weight savings calculated for a 15 Hp (11 kW) motor is presented. Data presented here show that motors with copper rotors run cooler. Industry experience shows that cooler operation translates to reduced maintenance costs, improved reliability and longer motor life.

3. Introduction:

The Defense community needs are being driven by the need for lighter weight, lower cost, environmentally friendly, and more reliable materials for the Objective Force. Reduced weight is a goal for all weapon systems and logistics support items. The Copper-Based Casting Technology (C-BCT) program supports these goals. The objectives of the C-BCT program are to develop, demonstrate, and deploy applications of copper base alloys to make significantly lighter, more efficient, components for use in defense systems. Specifically, the program will build on new and successfully demonstrated tooling technology to develop and test electrical motors that utilize die-cast copper in the rotor squirrel cage structure. These motors will weigh less, last longer, and operate more efficiently than currently available motors. CBC-T is a four-year funded program comprised of government, industry, and academic team members. The team includes two motor manufactures addressing military, industrial, and aerospace motor applications; an advanced casting and manufacturing facility; a leader in analysis and testing for power electronic and electromechanical systems; a leading research institution in the area of materials characterization; as well as representatives from the Army Research Lab (ARL), and the Defense Logistics Agency (DLA). The program seeks to design, build and test die-cast copper rotor motors having improved electrical energy efficiency or having a substantial weight advantage compared to the aluminum counterpart. Experience has shown that high efficiency motors with copper in the rotor operate at lower operating temperatures compared to the equivalent aluminum rotor. Maintenance costs and the frequency of replacement are directly related to operating temperature. Both 60 Hz motors for ship board and 400 Hz motors for aircraft application having these advantages are included in this project.

4. Summary of the study:

Background of the research topic:

The motor industry has long recognized the performance benefits of using copper in motor rotors due to its superior electrical conductivity compared to aluminum. However, the widespread adoption of copper has been hindered by significant manufacturing challenges related to its high melting point, which makes it difficult to produce rotors economically using the high-volume pressure die casting process.

Status of previous research:

Previous attempts to die-cast copper rotors using conventional tool steel dies were unsuccessful due to extremely short die life. The high temperatures caused rapid thermal fatigue (heat checking), making the process commercially unviable. Consequently, aluminum remained the material of choice for all but the largest or most specialized motors, where slower and more costly fabrication methods could be used.

Purpose of the study:

The primary purpose of this study was to overcome the manufacturing barriers to die-casting copper rotors. The objectives were to:

1. Identify suitable high-temperature die materials and develop a "hot die" technology to achieve commercially acceptable die life.

2. Produce die-cast copper rotors and test them in electric motors to quantify the improvements in efficiency, operating temperature, and overall performance compared to standard aluminum rotors.

3. Explore design optimizations, such as rotor bar geometry, to fully leverage the benefits of copper.

Core study:

The core of the study was a two-part investigation. The first part focused on solving the manufacturing problem by conducting a comprehensive die material study. This involved 3-D thermal modeling and physical casting trials with various materials, leading to the development of a heated nickel-base alloy die system. The second part focused on performance validation. Copper rotors were cast using the new technology and tested in a 15 Hp industrial motor, with their performance (losses, efficiency, temperature, torque) meticulously measured and compared against baseline aluminum rotors. The study also analyzed performance data from commercially available motors that were fully optimized for copper rotors.

5. Research Methodology

Research Design:

The research was designed in two main phases. The first phase addressed the manufacturing challenge through a systematic study of die materials and casting process parameters. This involved 3-D thermal modeling to understand the heat-checking mechanism, followed by experimental die casting of pure copper using various die insert materials (H-13 steel, molybdenum, tungsten, and nickel-base alloys). A key part of the design was a heated and insulated die holder to maintain high, stable die temperatures. The second phase was an empirical performance evaluation. Rotors were die-cast and then tested in motors using a standardized dynamometer setup to compare performance against aluminum counterparts.

Data Collection and Analysis Methods:

Motor performance data was collected using rigorous dynamometer efficiency tests as per IEEE Specification 112, Test Method B. This method segregates energy losses into five categories: Stator Resistance, Iron Core Losses, Rotor Resistance, Windage and Friction, and Stray Load Losses. This detailed loss segregation was crucial for pinpointing exactly where the copper rotor provided benefits. For European motors, the IEC 34-2 test method was used. Performance characteristics such as efficiency, temperature rise, slip, power factor, and torque were measured and compared.

Research Topics and Scope:

The research covered the entire process from die material science to final motor performance. The scope included:

- A die material study to find a solution for casting high-melting-point copper.

- Development of a "hot die" technology with integrated heating and insulation.

- Performance testing of a 15 Hp (11.2 kW) U.S. motor with a direct-substitution copper rotor.

- Analysis of performance data from a series of commercially available, fully optimized copper rotor motors from SEW Eurodrive, ranging from 1.1 kW to 37 kW.

- An investigation into optimizing rotor bar shape for copper's unique electrical properties.

6. Key Results:

Key Results:

- A heated die system using nickel-base alloy inserts (e.g., INCONEL 617) operated at 625-640°C successfully overcame the "heat checking" issue, increasing die life 50 to 100 times compared to H-13 tool steel.

- In a 15 Hp motor, a direct-substitution copper rotor reduced total losses by 14% (from 1306W to 1127W). This was primarily driven by a 40% reduction in rotor resistance losses (Table 1).

- Overall motor efficiency increased by 1.2 percentage points (from 89.5% to 90.7%), and the operating temperature rise was reduced by 4.5°C (Table 2).

- Optimized commercial motors using copper rotors were able to achieve higher efficiency standards while being up to one frame size smaller, 18% lighter, and 15% less costly to manufacture than an equivalent-efficiency aluminum rotor motor.

- The higher conductivity of copper reduces slip and can lower starting torque. This can be compensated for by redesigning the rotor bar shape, for example, using a design with a distinct starting and running bar (Figure 6).

Figure Name List:

- Figure 1. Schematic illustration of the placement of electric resistance heaters and insulation in the die material testing and now being adopted commercially by motor manufacturers

- Figure 2. Loss distributions at 60 Hz for the four SEW motors, copper rotor versions compared to the aluminum rotor lower efficiency standard line.

- Figure 3. Stray load losses per unit input power for the four SEW motors sizes.

- Figure 4. Efficiency dependence on out put power at 60 Hz.

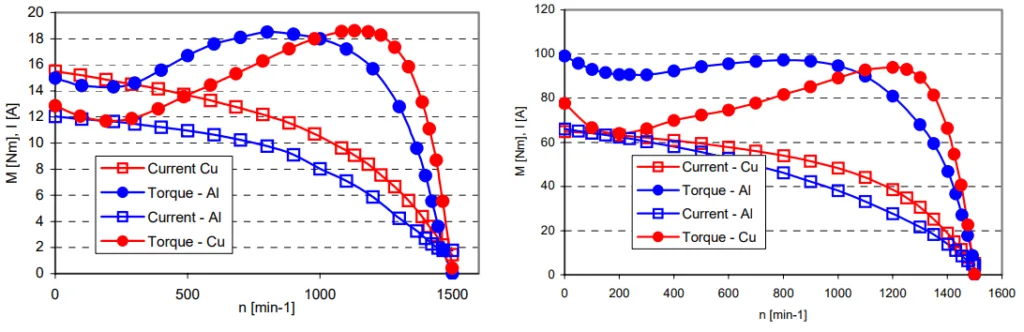

- Figure 5. Torque-speed and current-speed curves for1.1 kW motors (left) and 5.5 kW motors (right). Standard efficiency Al motor (blue); Cu high effficiency motor (red).

- Figure 6. Aluminum conductor bar left and copper bar right

7. Conclusion:

In a cooperative effort of the U. S. and world copper industries and a number of major motor manufacturers world wide, real progress has been made in the long sought goal of improving the induction motor by substituting die-cast copper for aluminum in the rotor. Manufacturing obstacles to production of copper rotors associated with very poor die life in the copper die casting operation have been solved with development of a heated nickel-base alloy die system. This system has demonstrated die life increase of 50 to 100 times compared to tool steel dies and is now in commercial use producing copper rotors. As predicted by motor manufacturer modeling and prototype studies over the years, rotor I²R losses are reduced by about 40% when copper is substituted for aluminum in the rotor squirrel cage structure. This reduction is an important contributor to substantial increases in overall electrical energy efficiency of the motors discussed in this paper. Reductions in stator, iron and stray load losses are seen as well. A very important side benefit of higher efficiency is the resulting reduced temperature of operation. A rule of thumb of motor designers is that motor life doubles with each 10 degree C reduction in operating temperature. It is expected that copper rotor motors replacing large numbers of conventional motors in legacy weapons systems by the Defense Logistics Agency will last at least 50% longer.

8. References:

- Brush, E.F., jr., D.T. Peters, J.G. Cowie, M. Doppelbauer, and R. Kimmich, “Recent Advances in Development of the Die-cast Copper Rotor Motor,” Proceedings of the International Conference on Electric Machines, Crakow, Poland, 2004.

- Cowie, J.G., D.T. Peters and D.T. Brender, “Die-cast Copper rotors for Improved Motor Performance," IEEE Pulp and Paper Conference. Charleston, SC, 2003.

- Kirtley, J.L., Jr., “Designing Squirrel Cage Rotor Slots with High Conductivity,” Proceedings of the International Conference on Electric Machines, Crakow, Poland, 2004.

- Peters, D.T, J.G. Cowie, E.F. Brush, Jr. and S.P. Midson, “Advances in Pressure Die Casting of Electrical Grade Copper," Amer. Foundry Society Congress Paper No. 02-002, Kansas City, Mo., 2002.

- Peters, D.T., J.G. Cowie, E.F. Brush, Jr. and S.P. Midson, "Use of High Temperature Die Materials and Hot Dies for High Pressure Die Casting Pure Copper and Copper Alloys," Trans. of the North Amer. Die Casting Assoc. Die Casting Congress, Rosemont, Il. 2002.

Expert Q&A: Your Top Questions Answered

Q1: What was the primary barrier to die-casting copper rotors, and how did this research solve it?

A1: The primary barrier was the extremely short life of conventional tool steel dies due to "heat checking"—a form of thermal fatigue caused by copper's high melting point (1083°C). This research solved the problem by developing a "hot die" technology using durable nickel-base alloy die inserts (like INCONEL or Haynes alloys) that are preheated and operated at a high temperature of 625°C or more. This minimizes the thermal shock on the die, increasing its life by 50 to 100 times and making the process commercially viable [Source: Copper in the Rotor for Lighter, Longer Lasting Motors, pages 4-5].

Q2: How much more efficient is a motor with a die-cast copper rotor?

A2: A direct substitution of copper for aluminum in a 15 Hp motor resulted in a 14% reduction in total energy losses and a 1.2 percentage point increase in overall efficiency (e.g., from 89.5% to 90.7%). The largest improvement comes from a 40% reduction in rotor resistance (I²R) losses [Source: Table 1 and Table 2, page 7 and 9].

Q3: Besides energy efficiency, what are the other major benefits of using copper rotors?

A3: The key benefits are longer motor life and the potential for lighter, more compact designs. The motors run cooler (a nearly 5°C reduction was measured), which can increase motor life by 50% or more. Furthermore, because of the efficiency gains, manufacturers can design motors that are one full frame size smaller and up to 18% lighter than an aluminum motor with the same efficiency rating [Source: Conclusion, page 14; Industrial Motors Expressly Designed to Use Copper in the Rotor, page 13].

Q4: Does switching to a highly conductive copper rotor negatively affect other performance aspects like torque?

A4: Yes, a simple substitution can lower starting torque because of copper's higher conductivity and the resulting lower slip. In the 15 Hp motor test, starting torque was reduced by 36%. However, the paper makes it clear that this is a solvable design challenge. By optimizing the cross-sectional shape of the rotor bars, designers can maintain the required torque characteristics while still gaining the efficiency benefits [Source: Table 3, page 9; Figure 6, page 14].

Q5: Is this technology just for new motor designs, or can it be used for direct replacement?

A5: The technology is applicable to both. The initial tests were performed on a direct-substitution basis, where a copper rotor replaced an aluminum one in an existing motor design with no other changes, and still showed significant benefits. However, the greatest advantages in weight and cost savings are achieved when a motor is designed from the ground up to optimize the use of copper in the rotor [Source: 15 Hp (11.2 kW) Motor Test Results, page 6; Industrial Motors Expressly Designed to Use Copper in the Rotor, page 10].

Conclusion & Next Steps

This research provides a valuable roadmap for a major advancement in electric motor technology, enabled by a breakthrough in high-pressure die casting. The findings offer a clear, data-driven path toward manufacturing motors that are more reliable, more energy-efficient, and can be made lighter and smaller. The successful development of a commercially viable process for die-casting copper rotors removes a decades-old barrier to innovation.

At CASTMAN, we are dedicated to applying the latest industry research to solve our customers' most challenging die casting problems. If the issues discussed in this paper resonate with your operational goals, contact our engineering team to discuss how we can help you implement these advanced principles in your components.

Copyright

- This material is a paper by "C. Stark, J. G. Cowie, D. T. Peters, and E. F. Brush, Jr.". Based on "Copper in the Rotor for Lighter, Longer Lasting Motors".

- Source of the paper: https://www.researchgate.net/publication/265097366

This material is for informational purposes only. Unauthorized commercial use is prohibited. Copyright © 2025 CASTMAN. All rights reserved.