This article introduces the paper ['Applications of Magnesium and Its Alloys: A Review'] published by ['Applied Sciences'].

1. Overview:

- Title: Applications of Magnesium and Its Alloys: A Review

- Author: Jovan Tan, Seeram Ramakrishna

- Publication Year: 2021

- Publishing Journal/Academic Society: Applied Sciences (Multidisciplinary Digital Publishing Institute)

- Keywords: materials; engineering materials; biomaterials; magnesium; magnesium alloys; properties; applications

2. Abstracts or Introduction

Magnesium is highlighted as a promising material in this review, owing to its unique combination of mechanical and biomedical properties that render it suitable for a broad spectrum of applications. The abstract of the paper states:

"Magnesium is a promising material. It has a remarkable mix of mechanical and biomedical properties that has made it suitable for a vast range of applications. Moreover, with alloying, many of these inherent properties can be further improved. Today, it is primarily used in the automotive, aerospace, and medical industries. However, magnesium has its own set of drawbacks that the industry and research communities are actively addressing. Magnesium's rapid corrosion is its most significant drawback, and it dramatically impeded magnesium's growth and expansion into other applications. This article reviews both the engineering and biomedical aspects and applications for magnesium and its alloys. It will also elaborate on the challenges that the material faces and how they can be overcome and discuss its outlook."

The introduction elaborates on magnesium's historical significance, from its recognition as an element to its diverse applications ranging from military uses in World War II to contemporary applications in automotive, aerospace, consumer electronics, pharmaceuticals, and general-purpose products. The paper emphasizes the burgeoning interest in magnesium as a biomaterial due to its superior biological properties, particularly its biodegradability in vivo. This review article aims to synthesize and present recent advancements in magnesium and its alloys, focusing on both engineering and biomedical applications, addressing challenges, and discussing future perspectives.

3. Research Background:

Background of the Research Topic:

Magnesium, an alkaline earth metal, is characterized by its shiny, silvery-white appearance and high reactivity. While never found free in nature, its terrestrial and cosmic abundance underscores its significance. Magnesium's unique blend of mechanical and biomedical properties has positioned it as a promising material, particularly in automotive, aerospace, and medical sectors. However, its inherent drawbacks, most notably rapid corrosion, have presented challenges to its wider adoption and expansion across diverse applications.

Status of Existing Research:

The industry and research communities are actively engaged in addressing the limitations of magnesium, with corrosion being a primary focus. Current research explores various strategies to mitigate these drawbacks and enhance magnesium's performance in different applications. The global magnesium market is experiencing growth, driven by its potential as a biomaterial and its established roles in engineering applications. China is a dominant producer, accounting for over 80% of global production.

Necessity of the Research:

Given the sustained interest and ongoing developments in magnesium and its alloys, a comprehensive overview of the current state of knowledge is imperative. This review article serves as a primer for experts and researchers interested in the properties and applications of magnesium, synthesizing recent progress and developments in the field. It addresses the need for a consolidated resource that elucidates both the engineering and biomedical facets of magnesium technology.

4. Research Purpose and Research Questions:

Research Purpose:

This review article aims to synthesize and present the recent progress and developments in the domain of magnesium and its alloys. The primary focus is on elucidating their engineering and biomedical applications. Furthermore, the article intends to elaborate on the challenges inherent in utilizing magnesium and explore potential strategies for overcoming these limitations. Finally, it seeks to discuss the future outlook for magnesium and its alloys in various sectors.

Key Research:

The key research areas explored in this review encompass:

- Production Techniques for magnesium and its alloys, including traditional and emerging methods.

- Engineering applications of magnesium, particularly in aerospace and automotive industries, focusing on material properties and performance.

- Biomedical applications of magnesium, emphasizing biocompatibility, biodegradability, and clinical relevance in musculoskeletal, orthopedic, and cardiovascular fields.

- Challenges associated with magnesium, such as corrosion and flammability, and mitigation strategies involving alloying and surface modification.

- Future outlook and potential advancements in magnesium technology.

Research Hypotheses:

As a review article, this paper does not explicitly test research hypotheses. Instead, it synthesizes existing research to provide a comprehensive overview of the applications, challenges, and future directions of magnesium and its alloys. The review implicitly posits that despite its challenges, magnesium remains a highly promising material due to its unique properties and the ongoing advancements in mitigating its limitations.

5. Research Methodology

Research Design:

This study employs a review paper design, systematically examining and synthesizing existing literature on magnesium and its alloys. It is a descriptive review, aiming to provide a comprehensive overview of the current state of knowledge in the field.

Data Collection Method:

The data collection method involves a comprehensive literature review of published articles, research papers, industry reports, and relevant academic resources. The authors have compiled information from various sources to present a holistic view of magnesium applications.

Analysis Method:

The analysis method is qualitative, involving the synthesis and summarization of information gathered from the literature review. The authors analyze and categorize the applications, properties, challenges, and advancements related to magnesium and its alloys, presenting a structured and descriptive overview.

Research Subjects and Scope:

The research subjects are magnesium and its alloys. The scope of the review encompasses:

- Magnesium production techniques (electrolytic and thermal processes, including advancements like carbothermic reduction and 3D printing).

- Engineering properties of magnesium and its alloys, including mechanical, thermal, and electrical characteristics.

- Applications in engineering sectors, specifically aerospace and automotive industries.

- Biomedical applications, focusing on musculoskeletal, orthopedic, and cardiovascular uses.

- Challenges related to magnesium, such as corrosion, flammability, and mechanical limitations.

- Mitigation strategies, including alloying, surface modification, and novel processing techniques.

6. Main Research Results:

Key Research Results:

- Production Techniques: The review details electrolytic and thermal methods for magnesium production, highlighting the Pidgeon process as the most widely used thermal route. Emerging techniques like carbothermic reduction and 3D printing are discussed as potential future production methods. Secondary magnesium production through recycling is also addressed.

- Engineering Material Properties: Magnesium is presented as the lightest engineering metal with a high strength-to-weight ratio, good machinability, and damping capacity. Alloying is crucial to enhance its structural properties, with aluminum and zinc being common alloying elements. AZ31 and AZ91 alloys are noted for their widespread use. Magnesium alloy-based nanocomposites are also highlighted for improved strength and ductility.

- Aerospace Applications: Magnesium's low density offers significant weight reduction potential in aircraft, improving fuel efficiency. Despite limitations related to flammability and corrosion, advancements in magnesium research are paving the way for increased aerospace applications, including high-performance alloys like Elektron 21 and Elektron 675.

- Automotive Applications: Magnesium is the third most used metallic material in the automotive industry, primarily in cast forms for powertrain, chassis, and body structure components. Its lightweight nature is increasingly valued for reducing vehicle weight and emissions.

- Biomaterial Applications: Magnesium's biodegradability and biocompatibility make it attractive for temporary implants. It excels in bioabsorbability and is naturally biocompatible. Challenges include managing corrosion rate in vivo. Surface modification and alloying are key strategies to improve corrosion resistance and biocompatibility.

- Musculoskeletal and Orthopedic Applications: Magnesium-based orthopedic implants, such as MAGNEZIX® and K-METTM screws, have shown positive clinical results in fracture fixation and bone healing. They offer advantages over bio-inert materials by eliminating the need for secondary surgeries.

- Cardiovascular Applications: While still largely experimental, magnesium and its alloys are being investigated for cardiovascular applications like stents. Controlling degradation rate is critical for successful cardiovascular implants.

Analysis of presented data:

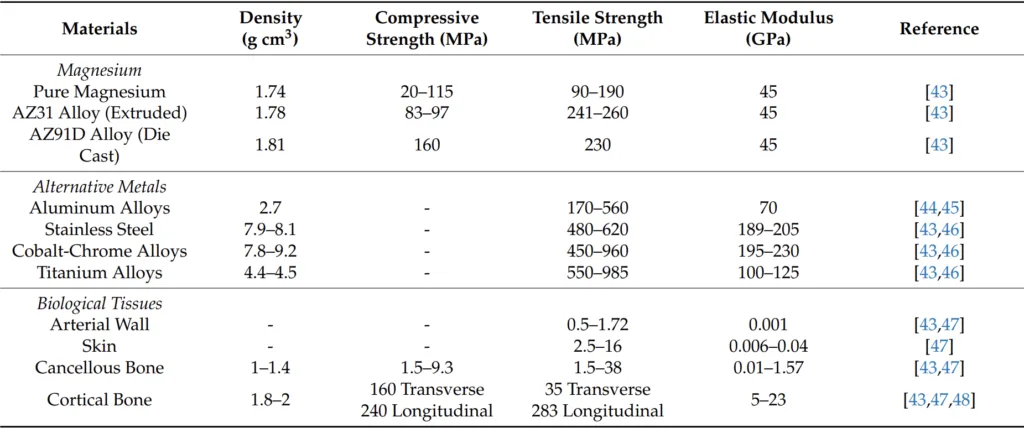

The paper primarily presents a synthesis of existing literature, providing descriptive analyses of magnesium's properties, applications, and challenges. Quantitative data is presented in Table 1. Selected Mechanical Properties, which compares the density, compressive strength, tensile strength, and elastic modulus of magnesium, its alloys, alternative metals, and biological tissues, with references.

The paper includes four figures:

- Figure 1: "Process flowchart of primary magnesium production via a thermal and electrolytic process. Reproduced with permission from Cherubini, F., et al., LCA of magnesium production; published by Elsevier, 2008 [15]." This figure illustrates the steps involved in both thermal and electrolytic magnesium production.

- Figure 2: "Use of magnesium-based materials in the automotive industry. Reproduced with permission from Sankaranarayanan, S. and M. Gupta (2021). "Emergence of god's favorite metallic element: Magnesium based materials for engineering and biomedical applications."; published by Elsevier, 2021 [54]." This figure pictorially summarizes the various automotive components made from magnesium alloys.

- Figure 3: "A Stiffness-Time inverse relationship between degradable implants and healing bone. Reproduced with permission from Witte, F., et al., Magnesium (Mg) corrosion: a challenging concept for degradable implants; published by Woodhead Publishing, 2011 [60]." This figure graphically represents the ideal degradation profile of a temporary implant in relation to bone healing.

- Figure 4: "Examples of magnesium applications in orthopedics. (A) Use of MAGNEZIX® MgYREZr alloy bioabsorbable compression screw to treat hallux valgus fracture in 13 patients. Reproduced with permission from Wang, J.L., et al. (2020). "Biodegradable Magnesium-Based Implants in Orthopedics-A General Review and Perspectives."; published by Wiley, 2020 [73]; (B) Use of K-METTM MgCaZn alloy bioresorbable bone screw to treat distal radius fracture in 53 patients. Reproduced with permission from Lee, J.-W., et al. (2016). “Long-term clinical study and multiscale analysis of in vivo biodegradation mechanism of Mg alloy."; Copyright 2016, National Academy of Sciences [76]." This figure showcases radiographic images demonstrating the use of magnesium screws in orthopedic applications.

Figure Name List:

![Figure 3. A Stiffness–Time inverse relationship between degradable implants and healing bone. Reproduced with permission from Witte, F., et al., Magnesium (Mg) corrosion: a challenging concept for degradable implants; published by Woodhead Publishing, 2011 [60].](https://castman.co.kr/wp-content/uploads/image-822-png.webp)

![Figure 2. Use of magnesium-based materials in the automotive industry. Reproduced with permission from Sankaranarayanan, S. and M. Gupta (2021). “Emergence of god’s favorite metallic element: Magnesium based materials for engineering and biomedical applications.”; published by Elsevier, 2021 [54].](https://castman.co.kr/wp-content/uploads/image-820-png.webp)

![Figure 4. Examples of magnesium applications in orthopedics. (A) Use of MAGNEZIX® MgYREZr alloy bioabsorbable compression screw to treat hallux valgus fracture in 13 patients. Reproduced with permission from Wang, J.L., et al. (2020). “Biodegradable Magnesium-Based Implants in Orthopedics—A General Review and Perspectives.”; published by Wiley, 2020 [73]; (B) Use of K-MET™ MgCaZn alloy bioresorbable bone screw to treat distal radius fracture in 53 patients. Reproduced with permission from Lee, J.-W., et al. (2016). “Long-term clinical study and multiscale analysis of in vivo biodegradation mechanism of Mg alloy.”; Copyright 2016, National Academy of Sciences [76].](https://castman.co.kr/wp-content/uploads/image-823-1024x849.webp)

- Figure 1. Process flowchart of primary magnesium production via a thermal and electrolytic process.

- Figure 2. Use of magnesium-based materials in the automotive industry.

- Figure 3. A Stiffness-Time inverse relationship between degradable implants and healing bone.

- Figure 4. Examples of magnesium applications in orthopedics.

7. Conclusion:

Summary of Key Findings:

The review concludes that magnesium's unique properties make it highly attractive for both engineering and biomedical applications. Its lightweight nature, high strength-to-weight ratio, and excellent machinability are advantageous for aerospace and automotive industries. In biomedicine, its biocompatibility and biodegradability are particularly valuable, especially for temporary implants. However, rapid biodegradation, primarily corrosion, remains a significant challenge. Mitigation strategies, including alloying and surface modification, are crucial for expanding magnesium's applications. Ongoing research and technological advancements are continuously addressing these limitations.

Academic Significance of the Study:

This review provides a comprehensive and up-to-date handbook-level overview of magnesium and its alloys, consolidating information on production, properties, applications, and challenges. It serves as a valuable resource for experts and researchers in materials science, engineering, and biomedicine, offering a broad understanding of the current state and future directions of magnesium technology.

Practical Implications:

The practical implications of this review are significant for industries utilizing or considering magnesium. It highlights the potential of magnesium alloys in lightweighting applications for automotive and aerospace sectors, contributing to energy efficiency and reduced emissions. In the biomedical field, it underscores the clinical potential of biodegradable magnesium implants, particularly in orthopedics and cardiovascular applications, offering solutions that eliminate the need for secondary surgeries.

Limitations of the Study and Areas for Future Research:

As a review article, the limitations are inherent in the scope of the reviewed literature. The paper points towards several areas for future research implicitly and explicitly mentioned throughout the text:

- Further research into mitigating magnesium's rapid corrosion in both engineering and biomedical applications.

- Development of novel alloying strategies and surface modification techniques to enhance corrosion resistance and biocompatibility.

- Optimization of production techniques, including carbothermic reduction and additive manufacturing, to improve efficiency and reduce environmental impact.

- Continued clinical trials and long-term studies to validate the efficacy and safety of magnesium-based biomedical implants, particularly in cardiovascular applications.

- Exploration of new applications for magnesium and its alloys in emerging fields.

8. References:

- [1] Shand, M.A. History of Magnesia. In The Chemistry and Technology of Magnesia; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2006; pp. 1-4. [CrossRef]

- [2] Dobrzański, L.A. The Importance of Magnesium and Its Alloys in Modern Technology and Methods of Shaping Their Structure and Properties. In Magnesium and Its Alloys; CRC Press: Boca Raton, FL, USA, 2019; pp. 1–28. [CrossRef]

- [3] Song, G.L.; Atrens, A. Corrosion Mechanisms of Magnesium Alloys. Adv. Eng. Mater. 1999, 1, 11-33. [CrossRef]

- [4] Luthringer, B.J.C.; Feyerabend, F.; Willumeit-Römer, R. Magnesium-Based Implants: A Mini-Review. Magnes. Res. 2014, 27, 142-154. [CrossRef]

- [5] U.S. Geological Survey. 01-341, Magnesium, Its Alloys and Compounds. 2001. Available online: https://pubs.usgs.gov/of/2001/of01-341/ (accessed on 25 October 2020).

- [6] Durlach, J. Overview of Magnesium Research: History and Current Trends. In New Perspectives in Magnesium Research; Springer: London, UK, 2006; pp. 3-10. [CrossRef]

- [7] Witte, F. The History of Biodegradable Magnesium Implants: A Review. Acta Biomater. 2010, 6, 1680-1692. [CrossRef] [PubMed]

- [8] Czerwinski, F. Magnesium and Its Alloys. In Magnesium Injection Molding; Springer: New York, NY, USA, 2008; pp. 1–79. [CrossRef]

- [9] Emsley, J. Magnesium. Available online: https://edu.rsc.org/elements/magnesium/2020016.article (accessed on 26 June 2021).

- [10] Powell, B.R.; Krajewski, P.E.; Luo, A.A. Magnesium Alloys for Lightweight Powertrains and Automotive Structures. In Materials, Design and Manufacturing for Lightweight Vehicles; Elsevier: Amsterdam, The Netherlands, 2021; pp. 125–186. [CrossRef]

- [11] Dieringa, H.; Stjohn, D.; Prado, M.T.P.; Kainer, K. Editorial: Latest Developments in the Field of Magnesium Alloys and Their Applications. Front. Mater. 2021. [CrossRef]

- [12] ReportLinker, Global Magnesium Industry, Global Industry Analysis 2020. Available online: https://www.reportbuyer.com/product/5799036/global-magnesium-industry.html (accessed on 10 October 2020).

- [13] U.S. Geological Survey. Mineral Commodity Summaries (Magnesium Metals); Department of the Interior: Washington, DC, USA, 2020.

- [14] Polmear, I.J. Magnesium Alloys and Applications. Mater. Sci. Technol. 1994, 10, 1-16. [CrossRef]

- [15] Cherubini, F.; Raugei, M.; Ulgiati, S. Lca of Magnesium Production. Resour. Conserv. Recycl. 2008, 52, 1093-1100. [CrossRef]

- [16] Holywell, G.C. Magnesium: The First Quarter Millennium. JOM 2005, 57, 26-33. [CrossRef]

- [17] Wu, H.; Zhao, P.; Jing, M.; Li, J.; Chen, T. Magnesium Production by a Coupled Electric and Thermal Field. Vacuum 2021, 183, 109822. [CrossRef]

- [18] Gao, F.; Nie, Z.-R.; Wang, Z.-H.; Gong, X.-Z.; Zuo, T.-Y. Assessing Environmental Impact of Magnesium Production Using Pidgeon Process in China. Trans. Nonferrous Met. Soc. China 2008, 18, 749–754. [CrossRef]

- [19] Ramakrishnan, S.; Koltun, P. Global Warming Impact of the Magnesium Produced in China Using the Pidgeon Process. Resour. Conserv. Recycl. 2004, 42, 49–64. [CrossRef]

- [20] Brooks, G.; Trang, S.; Witt, P.; Khan, M.N.H.; Nagle, M. The Carbothermic Route To Magnesium. JOM 2006, 58, 51-55. [CrossRef]

- [21] Abedini Najafabadi, H.; Ozalp, N.; Epstein, M.; Davis, R. Solar Carbothermic Reduction of Dolime as a Promising Option To Produce Magnesium and Calcium. Ind. Eng. Chem. Res. 2019, 58, 23540–23548. [CrossRef]

- [22] Wang, Y.; Fu, P.; Wang, N.; Peng, L.; Kang, B.; Zeng, H.; Yuan, G.; Ding, W. Challenges and Solutions for the Additive Manufacturing of Biodegradable Magnesium Implants. Engineering 2020. [CrossRef]

- [23] Karunakaran, R.; Ortgies, S.; Tamayol, A.; Bobaru, F.; Sealy, M.P. Additive Manufacturing of Magnesium Alloys. Bioact. Mater. 2020, 5, 44-54. [CrossRef]

- [24] Kurzynowski, T.; Pawlak, A.; Smolina, I. The Potential of Slm Technology for Processing Magnesium Alloys in Aerospace Industry. Arch. Civ. Mech. Eng. 2020, 20. [CrossRef]

- [25] Qin, Y.; Wen, P.; Guo, H.; Xia, D.; Zheng, Y.; Jauer, L.; Poprawe, R.; Voshage, M.; Schleifenbaum, J.H. Additive Manufacturing of Biodegradable Metals: Current Research Status and Future Perspectives. Acta Biomater. 2019, 98, 3-22. [CrossRef]

- [26] Davim, J.P. Additive and Subtractive Manufacturing: Emergent Technologies; De Gruyter: Berlin, Germany, 2020.

- [27] International Magnesium Association. Recycling Magnesium. Available online: https://www.intlmag.org/page/sustain_recycle_ima (accessed on 10 October 2020).

- [28] Ehrenberger, S.; Friedrich, H.E. Life-Cycle Assessment of the Recycling of Magnesium Vehicle Components. JOM 2013, 65, 1303-1309. [CrossRef]

- [29] Mendis, C.L.; Singh, A. Magnesium Recycling: To the Grave and Beyond. JOM 2013, 65, 1283-1284. [CrossRef]

- [30] Yam, B.J.Y.; Le, D.K.; Do, N.H.; Nguyen, P.T.T.; Thai, Q.B.; Phan-Thien, N.; Duong, H.M. Recycling of Magnesium Waste into Magnesium Hydroxide Aerogels. J. Environ. Chem. Eng. 2020, 8, 104101. [CrossRef]

- [31] Moosbrugger, C.; Marquard, L. Engineering Properties of Magnesium Alloys; ASM International: Materials Park, OH, USA, 2017; p. 184.

- [32] Kulekci, M.K. Magnesium and Its Alloys Applications in Automotive Industry. Int. J. Adv. Manuf. Technol. 2008, 39, 851-865. [CrossRef]

- [33] Hornberger, H.; Virtanen, S.; Boccaccini, A.R. Biomedical Coatings on Magnesium Alloys—A Review. Acta Biomater. 2012, 8, 2442-2455. [CrossRef] [PubMed]

- [34] Gray, J.E.; Luan, B. Protective Coatings on Magnesium and Its Alloys—A Critical Review. J. Alloys Compd. 2002, 336, 88–113. [CrossRef]

- [35] Nie, J.-F. Precipitation and Hardening in Magnesium Alloys. Metall. Mater. Trans. A 2012, 43, 3891–3939. [CrossRef]

- [36] Kumar, A.; Kumar, S.; Mukhopadhyay, N.K. Introduction To Magnesium Alloy Processing Technology and Development of Low-Cost Stir Casting Process for Magnesium Alloy and Its Composites. J. Magnes. Alloys 2018, 6, 245-254. [CrossRef]

- [37] Abbott, T. Casting Technologies, Microstructure and Properties. In Magnesium and Its Alloys; CRC Press: Boca Raton, FL, USA, 2019; pp. 29-45.

- [38] Somekawa, H. Effect of Alloying Elements on Fracture Toughness and Ductility in Magnesium Binary Alloys; A Review. Mater. Trans. 2020, 61, 1-13. [CrossRef]

- [39] Dziubińska, A.; Gontarz, A.; Horzelska, K.; Pieśko, P. The Microstructure and Mechanical Properties of Az31 Magnesium Alloy Aircraft Brackets Produced by a New Forging Technology. Procedia Manuf. 2015, 2, 337-341. [CrossRef]

- [40] Fujisawa, S.; Yonezu, A. Mechanical Property of Microstructure in Die-Cast Magnesium Alloy Evaluated By Indentation Testing at Elevated Temperature. In Recent Advances in Structural Integrity Analysis—Proceedings of the International Congress (Apcf/Sif-2014); Elsevier: Amsterdam, The Netherlands, 2014; pp. 422-426.

- [41] Gupta, M.; Wong, W.L.E. Magnesium-Based Nanocomposites: Lightweight Materials of the Future. Mater. Charact. 2015, 105, 30-46. [CrossRef]

- [42] Tekumalla, S.; Gupta, M. Processing, Properties and Potential Applications of Magnesium Alloy-Based Nanocomposites: A Review. In The Minerals, Metals & Materials Series; Springer International Publishing: Cham, Switzerland, 2019; pp. 3–18.

- [43] Eddy Jai Poinern, G.; Brundavanam, S.; Fawcett, D. Biomedical Magnesium Alloys: A Review of Material Properties, Surface Modifications and Potential as a Biodegradable Orthopaedic Implant. Am. J. Biomed. Eng. 2013, 2, 218–240. [CrossRef]

- [44] Memsnet®. Material: Aluminum (Al), Bulk. Available online: http://www.memsnet.org/material/aluminumalbulk/ (accessed on 13 May 2021).

- [45] Davis, J.R. Aluminum and Aluminum Alloys; ASM International: Materials Park, OH, USA, 2001; p. 351.

- [46] Chakraborty Banerjee, P.; Al-Saadi, S.; Choudhary, L.; Harandi, S.E.; Singh, R. Magnesium Implants: Prospects and Challenges. Materials 2019, 12, 136. [CrossRef]

- [47] Silver, F.H.; Christiansen, D.L. Mechanical Properties of Tissues. In Biomaterials Science and Biocompatibility; Silver, F.H., Christiansen, D.L., Eds.; Springer: New York, NY, USA, 1999; pp. 187-212.

- [48] Morgan, E.F.; Unnikrisnan, G.U.; Hussein, A.I. Bone Mechanical Properties in Healthy and Diseased States. Annu. Rev. Biomed. Eng. 2018, 20, 119-143. [CrossRef] [PubMed]

- [49] Mordike, B.L.; Ebert, T. Magnesium. Mater. Sci. Eng. A 2001, 302, 37–45. [CrossRef]

- [50] Gupta, M. Utilizing Magnesium Based Materials To Reduce Green House Gas Emissions in Aerospace Sector. Aeronaut. Aerosp. Open Access J. 2017, 1. [CrossRef]

- [51] Gialanella, S.; Malandruccolo, A. Alloys for Aircraft Structures. In Aerospace Alloys; Springer International Publishing: Cham, Switzerland, 2020; pp. 41–127.

- [52] Luo, A.A. Applications: Aerospace, Automotive and Other Structural Applications of Magnesium. In Fundamentals of Magnesium Alloy Metallurgy; Elsevier: Amsterdam, The Netherlands, 2013; pp. 266-316.

- [53] Jeal, N. High-Performance Magnesium. Advanced Materials & Processes. 2005. pp. 65-67. Available online: https://www.asminternational.org/documents/10192/1882931/amp16309p065.pdf/2eea78b4-8417-4e95-bf5b-98041cc3209f (accessed on 1 November 2020).

- [54] Sankaranarayanan, S.; Gupta, M. Emergence of God's Favorite Metallic Element: Magnesium Based Materials for Engineering and Biomedical Applications. Mater. Today Proc. 2021, 39, 311–316. [CrossRef]

- [55] Tekumalla, S.; Gupta, M. Introductory Chapter: An Insight Into Fascinating Potential of Magnesium. In Magnesium—The Wonder Element for Engineering/Biomedical Applications; IntechOpen: London, UK, 2020.

- [56] Riaz, U.; Shabib, I.; Haider, W. The Current Trends of Mg Alloys in Biomedical Applications—A Review. J. Biomed. Mater. Res. Part B Appl. Biomater. 2019, 107, 1970–1996. [CrossRef]

- [57] Zhao, D.; Witte, F.; Lu, F.; Wang, J.; Li, J.; Qin, L. Current Status on Clinical Applications of Magnesium-Based Orthopaedic Implants: A Review From Clinical Translational Perspective. Biomaterials 2017, 112, 287–302. [CrossRef]

- [58] Chen, J.; Tan, L.; Yu, X.; Etim, I.P.; Ibrahim, M.; Yang, K. Mechanical Properties of Magnesium Alloys for Medical Application: A Review. J. Mech. Behav. Biomed. Mater. 2018, 87, 68-79. [CrossRef] [PubMed]

- [59] Kamrani, S.; Fleck, C. Biodegradable Magnesium Alloys as Temporary Orthopaedic Implants: A Review. Biometals 2019, 32, 185-193. [CrossRef] [PubMed]

- [60] Witte, F.; Hort, N.; Feyerabend, F.; Vogt, C. Magnesium (Mg) Corrosion: A Challenging Concept for Degradable Implants. In Corrosion of Magnesium Alloys; Elsevier: Amsterdam, The Netherlands, 2011; pp. 403-425.

- [61] Agarwal, S.; Curtin, J.; Duffy, B.; Jaiswal, S. Biodegradable Magnesium Alloys for Orthopaedic Applications: A Review on Corrosion, Biocompatibility and Surface Modifications. Mater. Sci. Eng. C 2016, 68, 948–963. [CrossRef] [PubMed]

- [62] Zeng, R.-C.; Yin, Z.-Z.; Chen, X.-B.; Xu, D.-K. Corrosion Types of Magnesium Alloys. In Magnesium Alloys—Selected Issue; IntechOpen: London, UK, 2018.

- [63] Song, G. Control OF Biodegradation of Biocompatable Magnesium Alloys. Corros. Sci. 2007, 49, 1696–1701. [CrossRef]

- [64] Song, G.; Atrens, A.; Stjohn, D. An Hydrogen Evolution Method for the Estimation of the Corrosion Rate of Magnesium Alloys. In Essential Readings in Magnesium Technology; Springer International Publishing: Cham, Switzerland, 2016; pp. 565-572.

- [65] Tang, Y.; Zhu, L.; Zhang, P.; Zhao, K.; Wu, Z. Enhanced Corrosion Resistance of Bio-Piezoelectric Composite Coatings on Medical Magnesium Alloys. Corros. Sci. 2020, 176, 108939. [CrossRef]

- [66] Mousa, H.M.; Chan, H.P.; Kim, C.S. Surface Modification of Magnesium and its Alloys Using Anodization for Orthopedic Implant Application. In Magnesium Alloys; IntechOpen: London, UK, 2017.

- [67] Narayanan, T.S.N.S.; Park, I.-S.; Lee, M.-H. Surface Modification of Magnesium and its Alloys for Biomedical Applications. In Surface Modification of Magnesium and Its Alloys for Biomedical Applications; Elsevier: Amsterdam, The Netherlands, 2015; pp. 29–87.

- [68] Shao, Y.; Zeng, R.-C.; Li, S.-Q.; Cui, L.-Y.; Zou, Y.-H.; Guan, S.-K.; Zheng, Y.-F. Advance in Antibacterial Magnesium Alloys and Surface Coatings on Magnesium Alloys: A Review. Acta Metall. Sin. (Engl. Lett.) 2020, 33, 615-629. [CrossRef]

- [69] Ahmed, W.; Zhai, Z.; Gao, C. Adaptive Antibacterial Biomaterial Surfaces and Their Applications. Mater. Today Bio 2019, 2, 100017. [CrossRef] [PubMed]

- [70] Feng, H.; Wang, G.; Jin, W.; Zhang, X.; Huang, Y.; Gao, A.; Wu, H.; Wu, G.; Chu, P.K. Systematic Study of Inherent Antibacterial Properties of Magnesium-Based Biomaterials. ACS Appl. Mater. Interfaces 2016, 8, 9662-9673. [CrossRef] [PubMed]

- [71] Rodríguez-Sánchez, J.; Pacha-Olivenza, M.Á.; González-Martín, M.L. Bactericidal Effect of Magnesium Ions over Planktonic and Sessile Staphylococcus Epidermidis and Escherichia Coli. Mater. Chem. Phys. 2019, 221, 342–348. [CrossRef]

- [72] Liu, C.; Ren, Z.; Xu, Y.; Pang, S.; Zhao, X.; Zhao, Y. Biodegradable Magnesium Alloys Developed as Bone Repair Materials: A Review. Scanning 2018, 2018, 9216314. [CrossRef] [PubMed]

- [73] Wang, J.L.; Xu, J.K.; Hopkins, C.; Chow, D.H.K.; Qin, L. Biodegradable Magnesium-Based Implants in Orthopedics—A General Review and Perspectives. Adv. Sci. 2020, 7, 1902443. [CrossRef]

- [74] Biber, R.; Pauser, J.; Geßlein, M.; Bail, H.J. Magnesium-Based Absorbable Metal Screws for Intra-Articular Fracture Fixation. Case Rep. Orthop. 2016, 2016, 9673174. [CrossRef]

- [75] European Innovation Partnership on Active and Healthy Ageing. MAGNEZIX®—The Metal Implant that Becomes Bone. 2016. Available online: https://ec.europa.eu/eip/ageing/sites/eipaha/files/innovative_procurement_files/EIPonAHA-2.1-Magnezix-The_metal_implant_that_becomes_bone.pdf (accessed on 30 June 2021).

- [76] Lee, J.-W.; Han, H.-S.; Han, K.-J.; Park, J.; Jeon, H.; Ok, M.-R.; Seok, H.-K.; Ahn, J.-P.; Lee, K.E.; Lee, D.-H.; et al. Long-Term Clinical Study and Multiscale Analysis of In Vivo Biodegradation Mechanism of Mg Alloy. Proc. Natl. Acad. Sci. USA 2016, 113, 716-721. [CrossRef] [PubMed]

- [77] Biospectrum Asia. Singapore Makes Ground-Breaking Innovation in Facial Fracture Fixation. Available online: https://www.biospectrumasia.com/news/54/17376/singapore-makes-ground-breaking-innovation-in-facial-fracture-fixation.html (accessed on 30 June 2021).

- [78] Herber, V.; Okutan, B.; Antonoglou, G.; Sommer, N.G.; Payer, M. Bioresorbable Magnesium-Based Alloys as Novel Biomaterials in Oral Bone Regeneration: General Review and Clinical Perspectives. J. Clin. Med. 2021, 10, 1842. [CrossRef]

- [79] Schilling, T.; Bauer, M.; Lalonde, L.; Maier, H.J.; Haverich, A.; Hassel, T. Cardiovascular Applications of Magnesium Alloys. In Magnesium Alloys; IntechOpen: London, UK, 2017.

- [80] Sangeetha, K.; Jisha Kumari, A.V.; Venkatesan, J.; Sukumaran, A.; Aisverya, S.; Sudha, P.N. Degradable Metallic Biomaterials for Cardiovascular Applications. In Fundamental Biomaterials: Metals; Elsevier: Amsterdam, The Netherlands, 2018; pp. 285-298.

- [81] Fu, J.; Su, Y.; Qin, Y.-X.; Zheng, Y.; Wang, Y.; Zhu, D. Evolution of Metallic Cardiovascular Stent Materials: A Comparative Study Among Stainless Steel, Magnesium and Zinc. Biomaterials 2020, 230, 119641. [CrossRef]

- [82] Zhang, Z.-Q.; Yang, Y.-X.; Li, J.-A.; Zeng, R.-C.; Guan, S.-K. Advances in Coatings on Magnesium Alloys for Cardiovascular Stents—A Review. Bioact. Mater. 2021, 6, 4729-4757. [CrossRef]

- [83] Scafa Udriște, A.; Niculescu, A.-G.; Grumezescu, A.M.; Bădilă, E. Cardiovascular Stents: A Review of Past, Current, and Emerging Devices. Materials 2021, 14, 2498. [CrossRef] [PubMed]

9. Copyright:

- This material is "Jovan Tan, Seeram Ramakrishna"'s paper: Based on "Applications of Magnesium and its Alloys: A Review".

- Paper Source: https://doi.org/10.3390/APP11156861

This material was summarized based on the above paper, and unauthorized use for commercial purposes is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.