Ya’nan Wu1, a, Guojie Huang1, b, Lei Cheng1,c, Daniel Liang2,d, Wei Xiao1,e

1State Key Laboratory of Nonferrous Metals and Processes, General Research Institute for

Nonferrous Metals, Beijing 100088, China

2Motor System,International Copper Association Asia, Tian Zuo International Center,

Beijing 100081, China

aynwu19@163.com, bhuangguojie@grinm.com, cchenglei@grinm.com,

dDaniel.liang@copperalliance.asia, ewxiao@ustb.edu.cn

Keywords: Numerical Simulation, Copper Rotors, FLOW-3D, Die Casting.

Abstract

The parametric optimization of process parameter in cold chamber die casting for an

industrial component (copper motor rotors) was analyzed. The filling process was successfully

simulated based on software FLOW-3D. The distribution of gas entrapment, temperature field and

surface defect during the mold filling process were discussed in details. The numerical results showed

that the pouring velocity had the most significant influence on the filling time, followed by the filling

temperature and the die temperature. As for the filling properties, the effect of the pouring

temperature was dominant. From the simulation results, the places of defect in the copper rotor were

forecasted, and the reasons of the defect were well explained. Thus, the technological parameters

could be improved in numerical simulation, and the simulation results would be further validated in

practice.

Introduction

Induction motors account for approximately 50% of the overall electricity use in industrialized

countries. In the agricultural and commercial areas, power consumption by motors is quite

substantial. On an average, the energy consumed by a motor during its life cycle is 60-100 times the

initial cost of the motor. Therefore efficiency of the motor is of paramount importance both during

selection and operation. Even small increase in efficiency improvement can make a big difference in

energy savings with accompanying decrease in air contamination [1,2].

For electric motors, copper rotors are significantly more efficient than aluminum ones [3].

However, we should balance the properties of high efficiencies, low costs, small sizes and lower

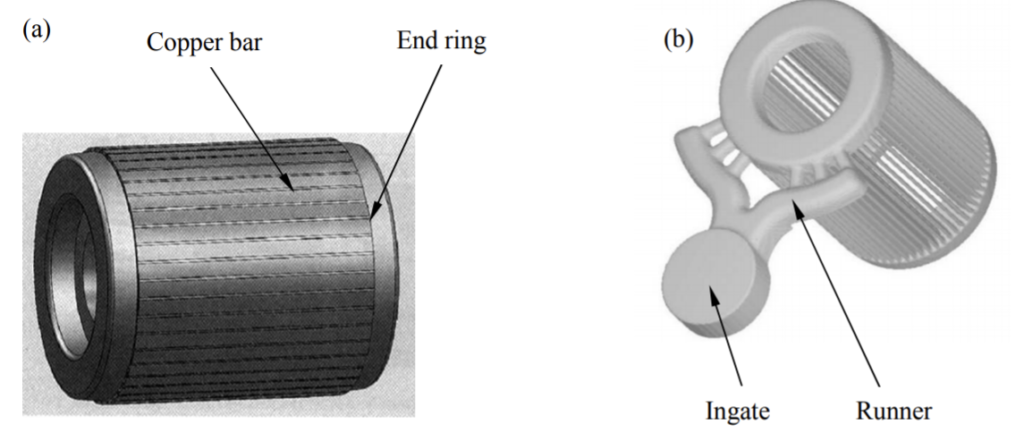

weights of the copper rotors [4,5,6]. Die casting is always used in the manufacture of motor rotors, for

its advantages of high production efficiency, high production quality and high precision [7]. The two

main challenges in copper rotor die-casting are the low tool life and the distribution of porosity.

Numerical simulation is a cost-effective tool to visibly analyze the filling process. Through the study

of numerical simulation, we can design a more reasonable die casting process, which can improve the

casting quality and make the copper rotors a longer life and a higher stability.

A lot of effort has been made by many researchers in the fields of numerical simulations for die

casting of aluminium, magnesium, zinc and pewter alloys [8]. However, simulation work in copper

die casting has rarely been published and the filling pattern of the copper die casting process has not

been well understood. For above mentioned reasons, the objective of this study was to optimize the

filling process of copper rotor based on software FLOW-3D. The behavior of metal flow in the filling

process was investigated. The gas entrapment, temperature field and surface defect of the rotor were

also investigated by the simulation.

Numerical Simulation

Mathematical Modeling. A commercial CAE package (FLOW-3D) was used for numerical

analysis. The software is based on the finite volume method (FVM). Incompressible non-Newtonian

flow with heat transfer is considered, which is described by the continuity equation, the

Navier-Stokes equation and the energy equation. These equations were solved by the FLOW-3D

software for a steady-state solution. As such, it is therefore believed to have a high accuracy by

considering the heat loss during the mould filling stage.

The basic governing equations are presented as follows:

....

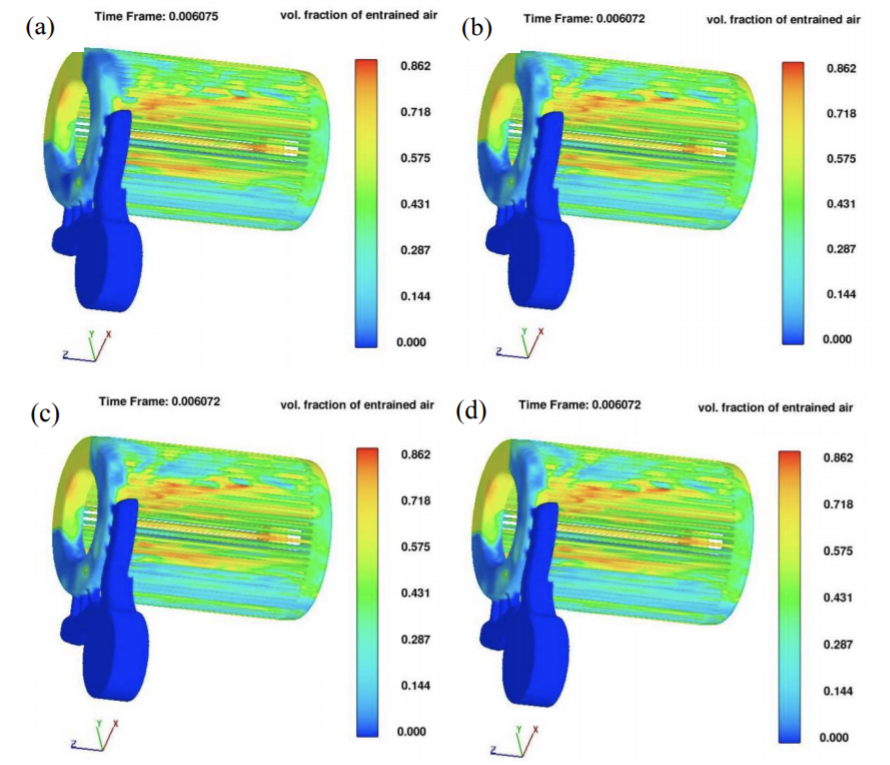

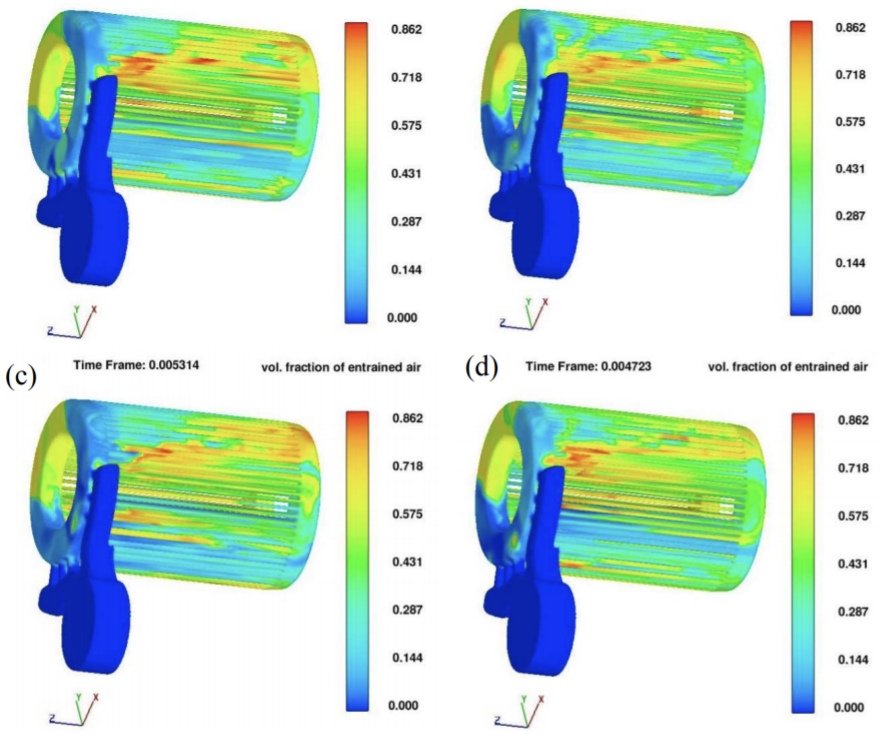

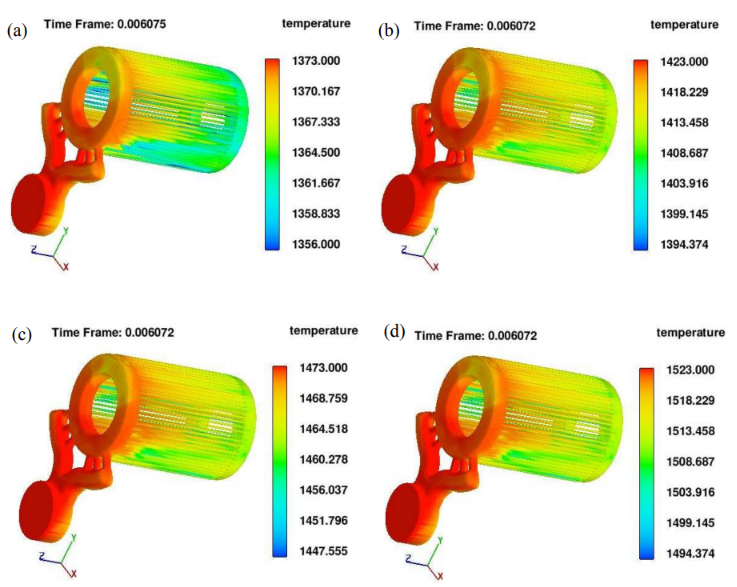

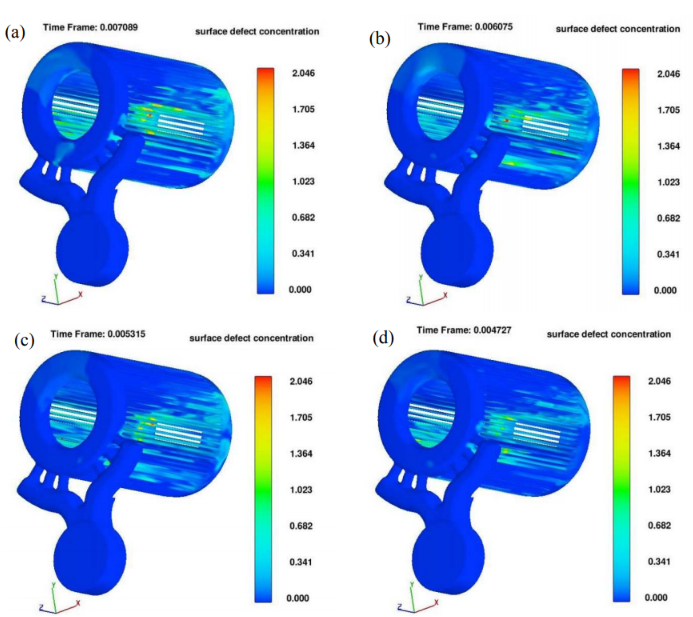

(a) L1; (b) L2; (c) L3; (d) L4

Conclusions

The concluding remarks out of the present study are depicted below.

(1) The best combination of parameters is L2, filling temperatures: 1100℃, pouring velocities:

35 m·s-1, die temperatures: 300℃.

(2)The pouring velocity has the most significant influence on the filling quality.

(3)The last filled regionof the casting has the largest fraction of entrained air, which is in

agreement with the practical product.

(4) As the pouring velocity increases, the flow of melt insidethe die cavity can be more turbulent,

leading to the formation of oxide films and cold shots. At constant filling temperature, a higher

pouring velocity brings lower surface defect concentration. The surface defect concentration is at a

scale of 0-2.046%.

References

[1] Peters D T, Cowie J G, Brush E F, et al. Performance of Motors with Die-cast Copper Rotors in

Industrial and Agricultural Pumping Applications,J. IEEE International Conference on Electric

Machines and Drives, (2005)987-992.

[2] Brush E F, Peters D T, Cowie J G, et al. Recent Advances in Development of the Copper Motor

Rotor J. 2003.

[3] Brush E F, Cowie J G, Peters D T, et al. Die-Cast Copper Motor Rotors: Motor Test Results,

Copper Compared to Aluminum, J. Energy Efficiency in Motor Driven Systems. Springer Berlin

Heidelberg,(2003)128-135.

[4] Cowie J G, Peters D T, Jr E F B, et al. Materials & modifications to die cast the copper

conductors of the induction motor rotor, J. Die Casting Engineer, 45(2001)38-47.

[5] Stark C, Cowie J G, Peters D T, et al. Copper in the Rotor for Lighter, Longer Lasting

Motors,2010.

[6] Liang D, Yang X, Yu J, et al. Experience in China on the die-casting of copper rotors for induction

motors,J. Electrical Machines (ICEM), (2012)256-260.

[7] Cleary P W, Savage G, Ha J, et al. Flow analysis and validation of numerical modelling for a thin

walled high pressure die casting using SPH, J. Computational Particle Mechanics, 1(2014)229-243.

[8] ZHAO Hai-dong, BAI Yan-fei, OUYANG Xiao-xian, et al. Simulation of mold filling and

prediction of gas entrapment on practical high pressure die castings, J. Transactions of Nonferrous

Metals Society of China, 20(2010)2064-2070.